A high-current pole assembly with error-proof function for a battery pack

A battery pack, error prevention technology, applied to battery pack components, small-sized batteries/battery packs, electrical components, etc., can solve problems such as large temperature rise and voltage drop, short circuit, large current supply contact resistance, etc. Achieve the effect of small contact resistance and low temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

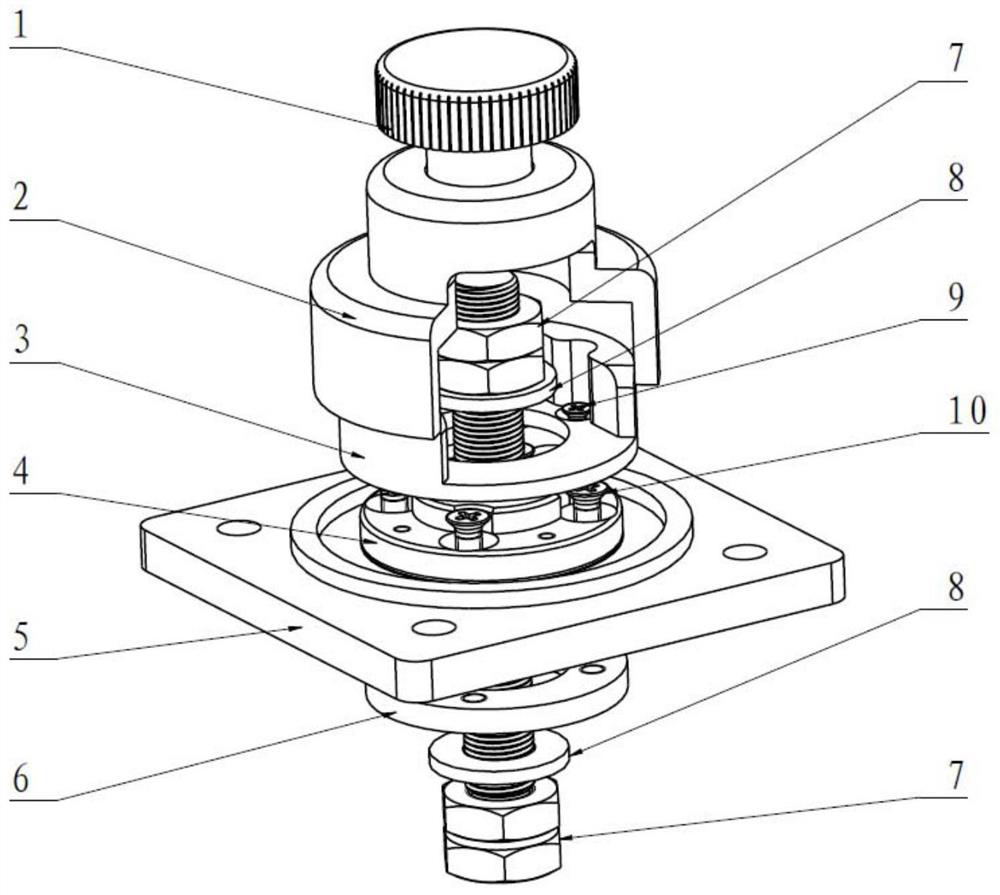

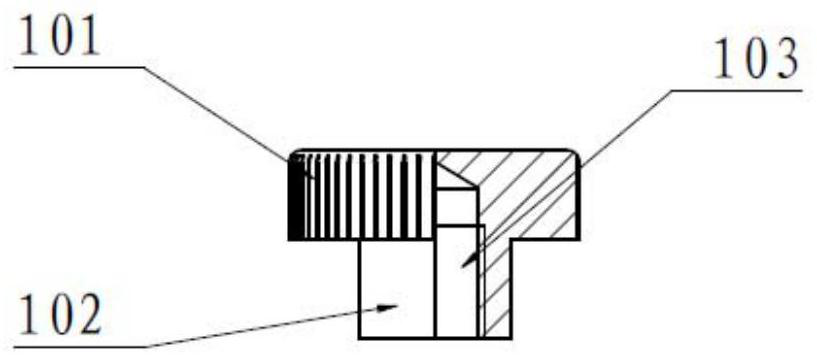

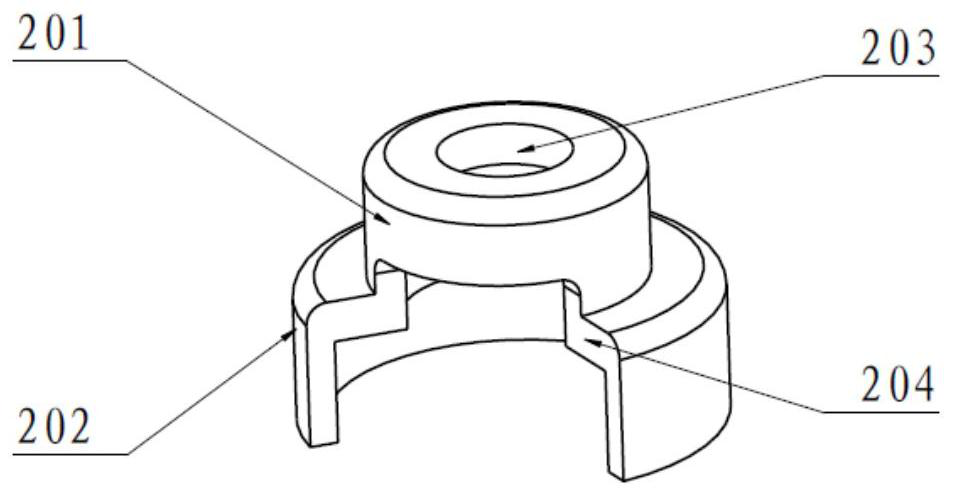

[0019] Such as figure 1 As shown, a battery pack of the present invention has a high-current pole assembly with an error-proof function, and the battery pack has a high-current pole assembly with an error-proof function, including a fastening cap 1, a protective cover 2, Limiting piece 3, pole 4, flange seat 5, mounting ring 6, conductive nut 7, conductive washer 8, countersunk head screw one 9, countersunk head screw two 10. One end of the pole assembly with a fastening cap 1 is installed outside the battery pack, and the other end is installed inside the battery pack. The pole 4 is embedded in the second counterbore in the middle of the flange seat 5, and is connected with the four threaded holes of the mounting ring 6 at the bottom after passing through the pole 4 and the flange seat 5 through four countersunk screws 2 10 , the limit piece 3 above the pole 4 is installed on the two threads of the pole assembly through two countersunk screws 9 through the limit piece 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com