Permanent magnet speed governing water pump electromagnetic clutch

An electromagnetic clutch and permanent magnet speed regulation technology, which is applied in the direction of magnetic drive clutches, clutches, non-mechanical drive clutches, etc., can solve the problem of incompatibility between the pump and the engine, save materials and man-hours, save energy, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

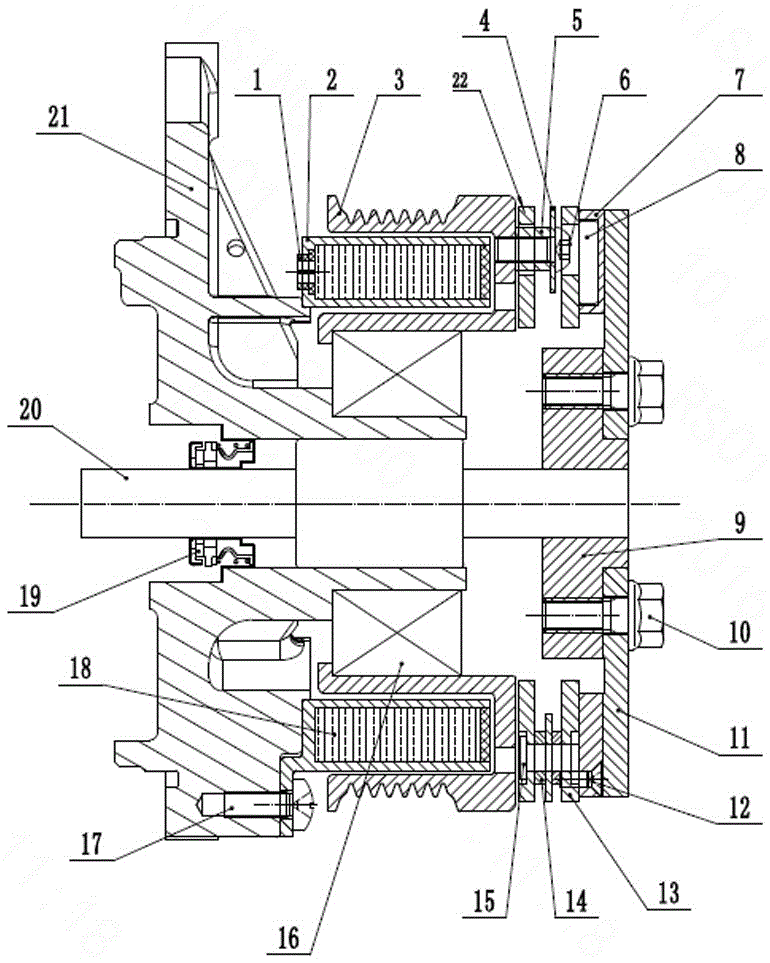

Image

Examples

Embodiment 1

[0024] When the engine is just started, due to the low water temperature, the temperature control sensor in the engine water tank sends a signal to the ECU, and the ECU sends a signal to the electromagnetic coil 18, the electromagnetic coil 18 is energized, the friction disc 11 is separated from the driving disc 13, and the water pump operates at a low speed. running, the engine warms up quickly; when the engine water temperature rises to 93°C, the temperature control sensor in the water tank sends a signal to the ECU, and the ECU controls the electromagnetic coil 18 to cut off the power, the friction disc 11 and the driving disc 13 are attached through the magnetic poles, and the water pump starts Direct transmission speed operation; when the engine water temperature is lower than 83°C, the temperature control sensor in the water tank sends a signal to the ECU, and the ECU controls the electromagnetic coil 18 to energize, the friction disc 11 and the driving disc 13 fit togethe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com