Low light transmittance energy-saving privacy glass and preparation method thereof

A privacy and glass technology, applied in chemical instruments and methods, inorganic chemistry, iron compounds, etc., can solve the problems of low visible light transmittance, reducing effect, expensive price, etc., achieve the best energy-saving effect, low cost, and simple components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

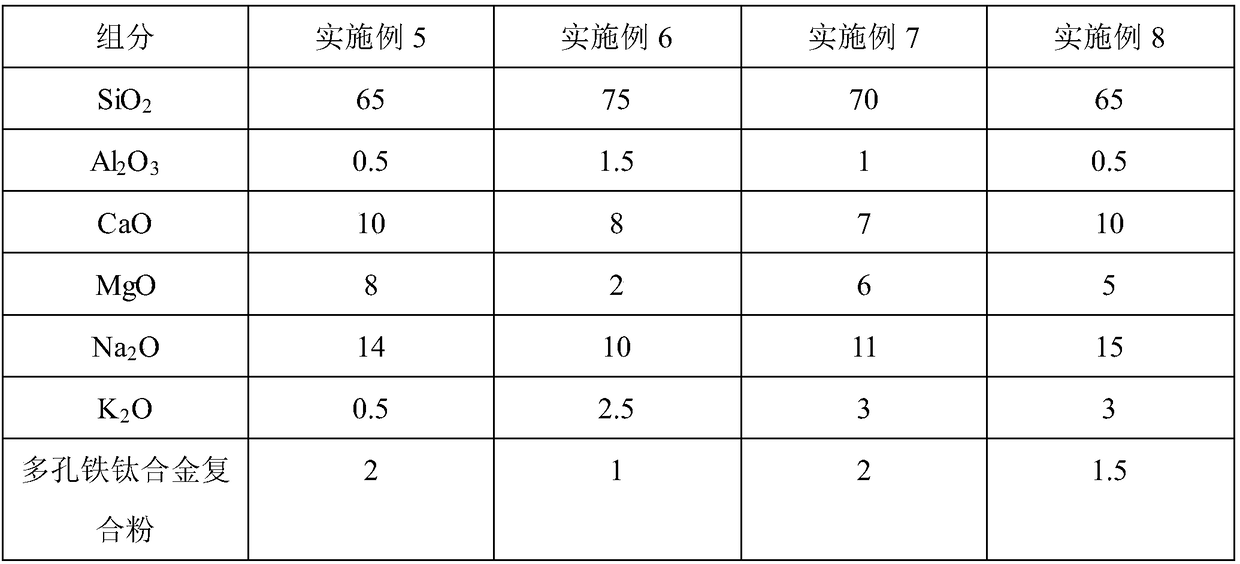

Examples

Embodiment 1

[0031] Example 1 Preparation of Iron-Titanium Composite Metal Oxide Porous Matrix

[0032] (1) Mix ferric nitrate and titanium tetranitrate at a molar ratio of 2:1, add deionized water, and stir until completely dissolved to obtain solution A; mix citric acid and polyethylene glycol 4000, add deionized water, and stir Until it is completely dissolved, solution B is obtained. The molar ratio of citric acid to ferric nitrate is 1:1; the amount of polyethylene glycol 4000 added is 3% of the total weight of ferric nitrate and titanium tetranitrate.

[0033] (2) Slowly add solution B to solution A, and stir while adding dropwise to obtain a mixed solution. Put the mixed solution in a water bath at 55°C and stir for 60 minutes, then raise the temperature to 72°C, and continue to stir for 7 hours until the water evaporates completely. Viscous foaming state, that is, gel.

[0034] (3) Dry the gel at 110°C for 12 hours, take it out, grind it into powder, and put the powder in a muffle...

Embodiment 2

[0036] Example 2 Preparation of Iron-Titanium Composite Metal Oxide Porous Matrix

[0037] (1) Mix ferric nitrate and titanium tetranitrate at a molar ratio of 3:1, add deionized water, and stir until completely dissolved to obtain solution A; mix citric acid and polyethylene glycol 4000, add deionized water, and stir Until it is completely dissolved, solution B is obtained. The molar ratio of citric acid to ferric nitrate is 2:1; the amount of polyethylene glycol 4000 added is 4% of the total weight of ferric nitrate and titanium tetranitrate.

[0038] (2) Slowly add solution B to solution A, and stir while adding dropwise to obtain a mixed solution. Put the mixed solution in a water bath at 60°C and stir for 30 minutes, then raise the temperature to 85°C, and continue stirring for 5 hours until the water evaporates completely, showing Viscous foaming state, that is, gel.

[0039] (3) Dry the gel at 110°C for 8 hours, take it out, grind it into powder, and put the powder in ...

Embodiment 3

[0041] Preparation of Example 3 Porous Iron-Titanium Alloy Composite Powder

[0042] Disperse nano-silicon carbide with a diameter of 10-100 nm in N,N-dimethylformamide to obtain a nano-silicon carbide dispersion with a mass volume concentration of 4%, and then add the iron-aluminum composite metal oxide prepared in Example 1 The weight ratio of the iron-aluminum composite metal oxide to nano-silicon carbide is 1:0.05, impregnated at room temperature for 24 hours, and vacuum-dried to remove the solvent, that is, the porous iron-titanium alloy composite powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com