A kind of preparation method of antibacterial ultraviolet light contact lens

A contact lens and anti-ultraviolet light technology, which is applied in the direction of optical components, other household appliances, household appliances, etc., can solve problems such as the growth of bacteria on the surface of the eyeball, allergic reactions, corneal neovascularization reactions, etc., to improve antibacterial and optical properties, reduce The effect of ultraviolet light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

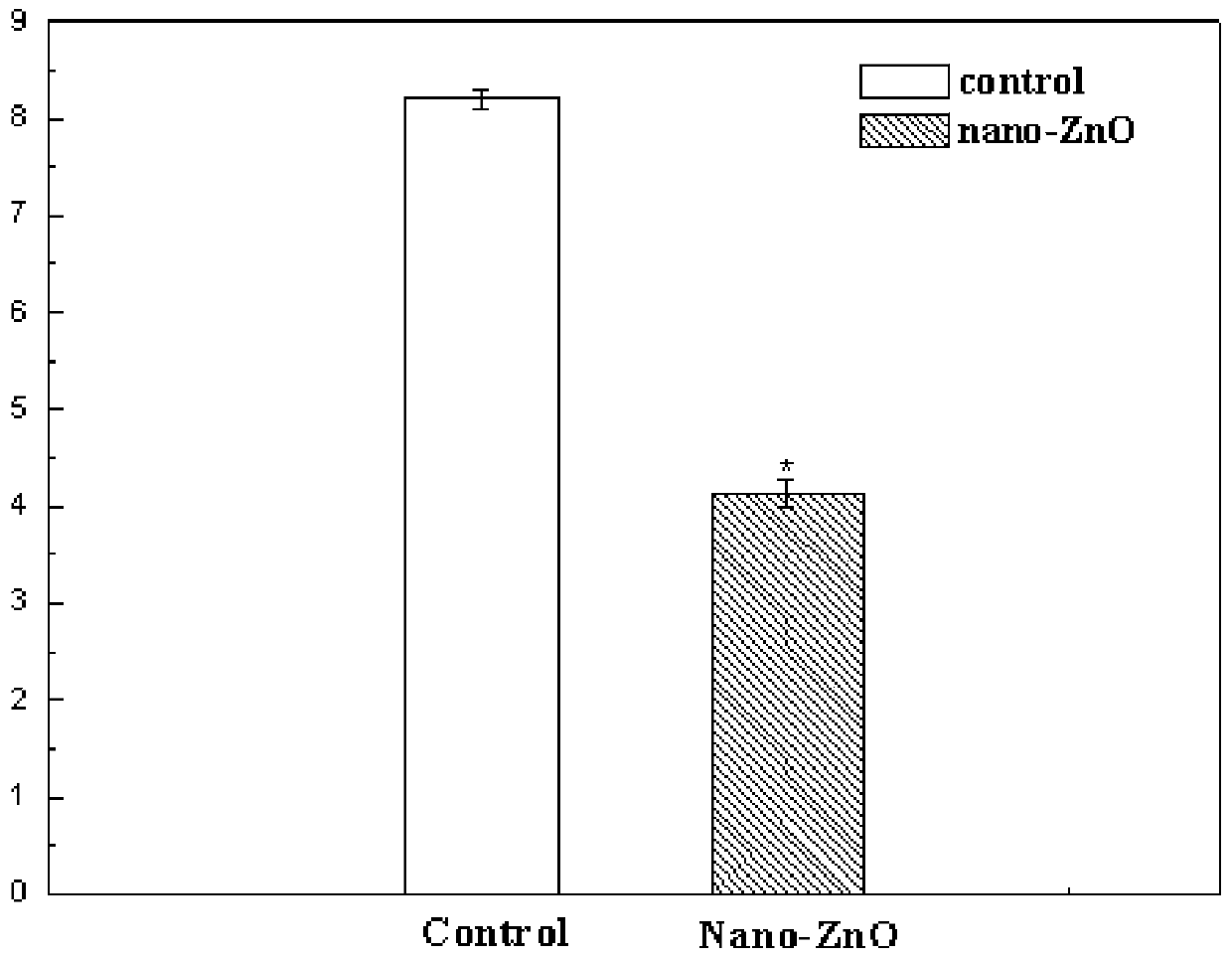

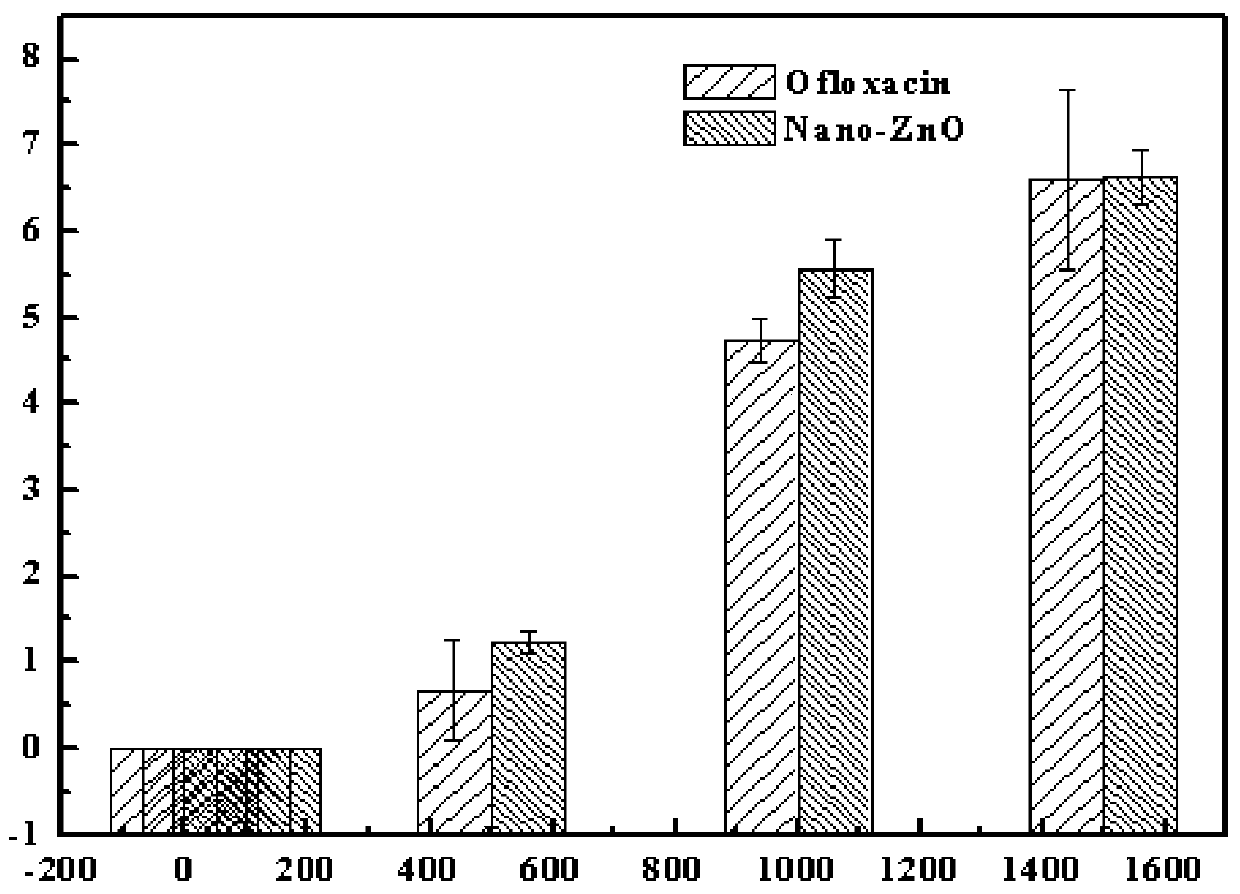

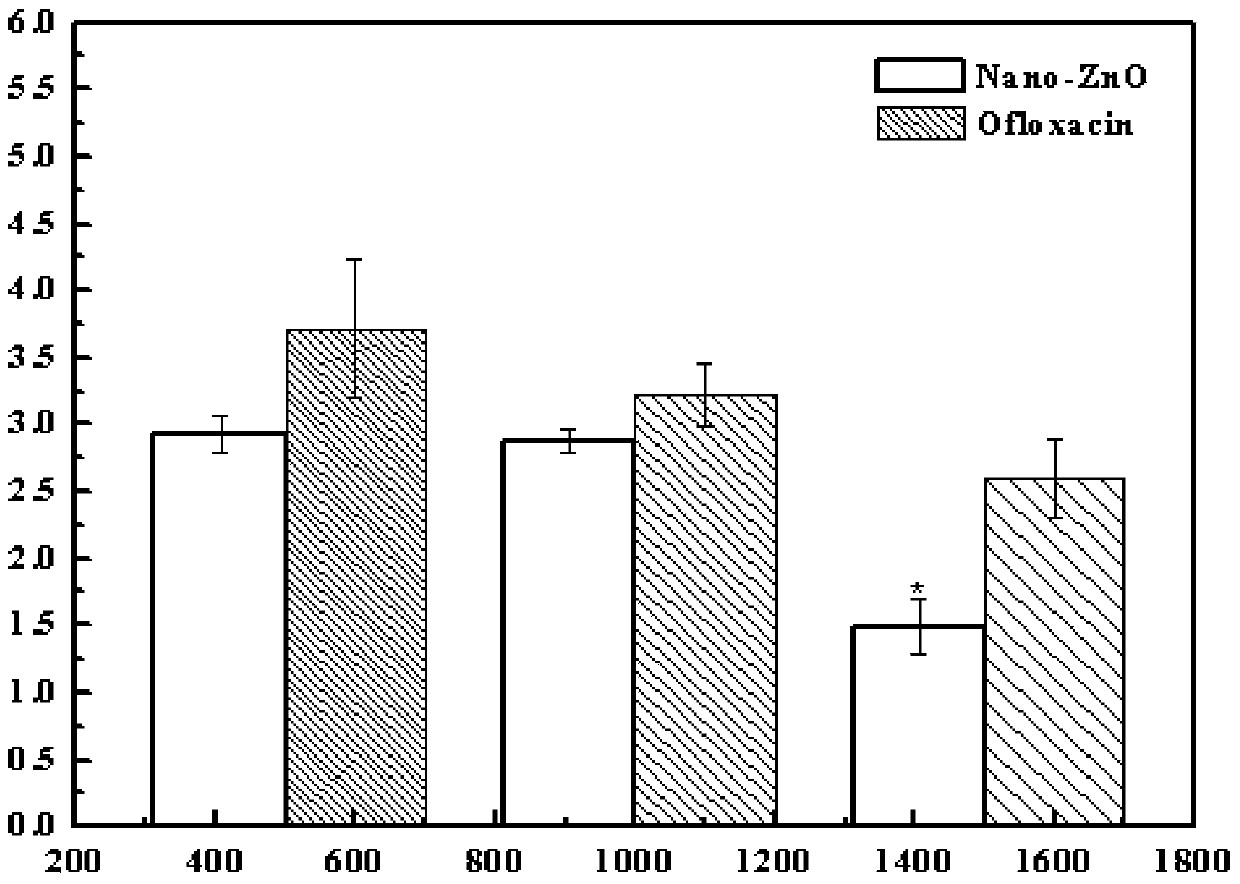

[0035] Specific embodiment one: the preparation method of a kind of antibacterial anti-ultraviolet light contact lens described in this embodiment, described method is realized according to the following steps:

[0036] Step 1: Prepare materials: directly prepare zinc oxide nanoparticle materials by chemical synthesis, the particle size of each zinc oxide nanoparticle is 3 nanometers-1000 nanometers, prepare hydrogel materials, the weight of zinc oxide nanoparticles is the same as that of zinc oxide The total weight ratio of nanoparticles and hydrogel is 1%-15%;

[0037] Step 2: mixing materials: mixing and stirring the proportioned zinc oxide nanoparticles and hydrogel, and stirring the zinc oxide nanoparticles and hydrogel evenly;

[0038] Step 3: Ultraviolet light irradiation: inject the uniformly stirred zinc oxide nanoparticles and hydrogel into the rotating contact lens preparation mold, and irradiate with ultraviolet light to harden and shape the mixed solution in the m...

specific Embodiment approach 2

[0041] Specific embodiment two: the preparation method of a kind of antibacterial anti-ultraviolet light contact lens described in this embodiment, described method is realized according to the following steps:

[0042] Step 1: Prepare materials: directly prepare zinc oxide nanoparticle materials by chemical synthesis, the particle size of each zinc oxide nanoparticle is 3 nanometers to 1000 nanometers, prepare hydrogel materials, and the weight of zinc oxide nanoparticles accounts for 1%-15% of the total weight of nanoparticles and hydrogel is mixed;

[0043] Step 2: Heat treatment: Mix the proportioned zinc oxide nanoparticles and hydrogel into a long glass tube, stir the zinc oxide nanoparticles and hydrogel evenly, and heat the long glass tube to a temperature of When the temperature is 50°C-300°C, the mixture in the long glass tube becomes hard;

[0044] Step 3: shape processing: separate the blank in the long glass tube from the long glass tube in step 2, and process th...

specific Embodiment approach 3

[0047] Specific embodiment three: the preparation method of a kind of antibacterial anti-ultraviolet light contact lens described in this embodiment, described method is realized according to the following steps:

[0048] Step 1: Prepare materials: directly prepare zinc oxide nanoparticle materials by chemical synthesis, the particle size of each zinc oxide nanoparticle is 3 nanometers-1000 nanometers, prepare hydrogel materials, the weight of zinc oxide nanoparticles is the same as that of zinc oxide The total weight ratio of nanoparticles and hydrogel is 1%-15%;

[0049] Step 2: mixing materials: mixing and stirring the proportioned zinc oxide nanoparticles and hydrogel, and stirring the zinc oxide nanoparticles and hydrogel evenly;

[0050] Step 3: Ultraviolet light irradiation: inject the uniformly stirred zinc oxide nanoparticles and hydrogel into the rotating contact lens preparation mold, and irradiate with ultraviolet light to harden and shape the mixed solution in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com