Double-reinforced mulching film and manufacturing method thereof

A production method and technology of double fascia, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of inability to realize the recovery of ultraviolet absorption, reduce the service life of ultraviolet rays, etc., and achieve the nutritional space of a single plant Coordinated and standardized planting is good and the effect of reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In the present embodiment, adopt each component of following percentage by weight:

[0022] Linear low density polyethylene: 30%;

[0023] LDPE: 40%;

[0024] Metallocene: 10%;

[0025] Vinyl acetate: 15%;

[0026] Auxiliary: 5%

[0027] Create a double fascia by following these steps:

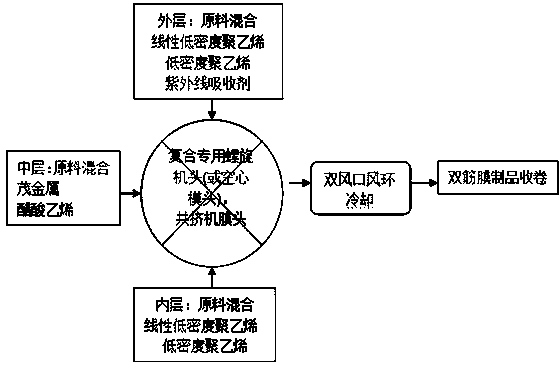

[0028] Firstly, the linear low density polyethylene, low density polyethylene, metallocene and vinyl acetate are pretreated. The pretreatment process is to stir the corresponding linear low density polyethylene, low density polyethylene, metallocene and vinyl acetate, and then the The pretreated linear low-density polyethylene, low-density polyethylene, metallocene, vinyl acetate and additives are packaged according to the components and content ratios of each layer of the double fascia;

[0029] The double fascia has three layers, namely the outer layer, the middle layer and the inner layer. The components included in each layer and the content of the components are as follows...

Embodiment 2

[0033] In the present embodiment, adopt each component of following percentage by weight:

[0034] Linear low density polyethylene: 33%;

[0035] LDPE: 40%;

[0036] Metallocene: 14%;

[0037] Vinyl acetate: 12%;

[0038] Additives: 1%.

[0039] Create a double fascia by following these steps:

[0040] Firstly, the linear low density polyethylene, low density polyethylene, metallocene and vinyl acetate are pretreated. The pretreatment process is to stir the corresponding linear low density polyethylene, low density polyethylene, metallocene and vinyl acetate, and then the The pretreated linear low-density polyethylene, low-density polyethylene, metallocene, vinyl acetate and additives are packaged according to the components and content ratios of each layer of the double fascia;

[0041] The double fascia has three layers, namely the outer layer, the middle layer and the inner layer. The components included in each layer and the content of the components a...

Embodiment 3

[0045] In the present embodiment, adopt each component of following percentage by weight:

[0046] Linear low density polyethylene: 35%;

[0047] Low-density polyethylene: 38%;

[0048] Metallocene: 15%;

[0049] Vinyl acetate: 10%;

[0050] Additives: 2%.

[0051] Create a double fascia by following these steps:

[0052] Firstly, the linear low density polyethylene, low density polyethylene, metallocene and vinyl acetate are pretreated. The pretreatment process is to stir the corresponding linear low density polyethylene, low density polyethylene, metallocene and vinyl acetate, and then the The pretreated linear low-density polyethylene, low-density polyethylene, metallocene, vinyl acetate and additives are packaged according to the components and content ratios of each layer of the double fascia;

[0053] The double fascia has three layers, namely the outer layer, the middle layer and the inner layer. The components included in each layer and the content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com