Anti-down-draft exhaust fume collecting hood for water heater

A technology for fume collecting hoods and water heaters, which is applied in the direction of fluid heaters, lighting and heating equipment, etc., which can solve the problems of easy jamming of valve plates, limited turning space of pipes, and air entering into water heaters, so as to avoid backflow of air flow, save energy and reduce energy consumption. Good consumption, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

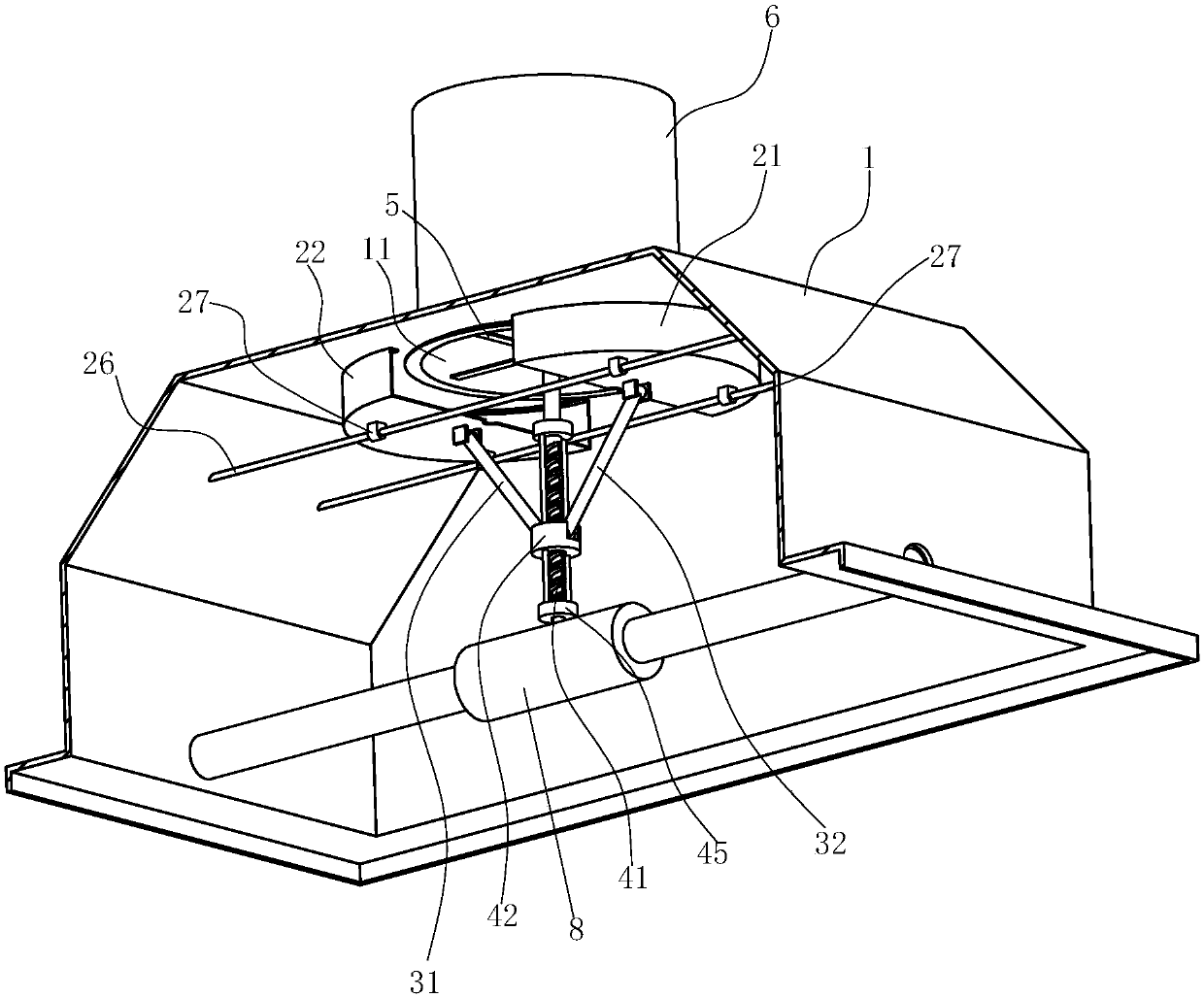

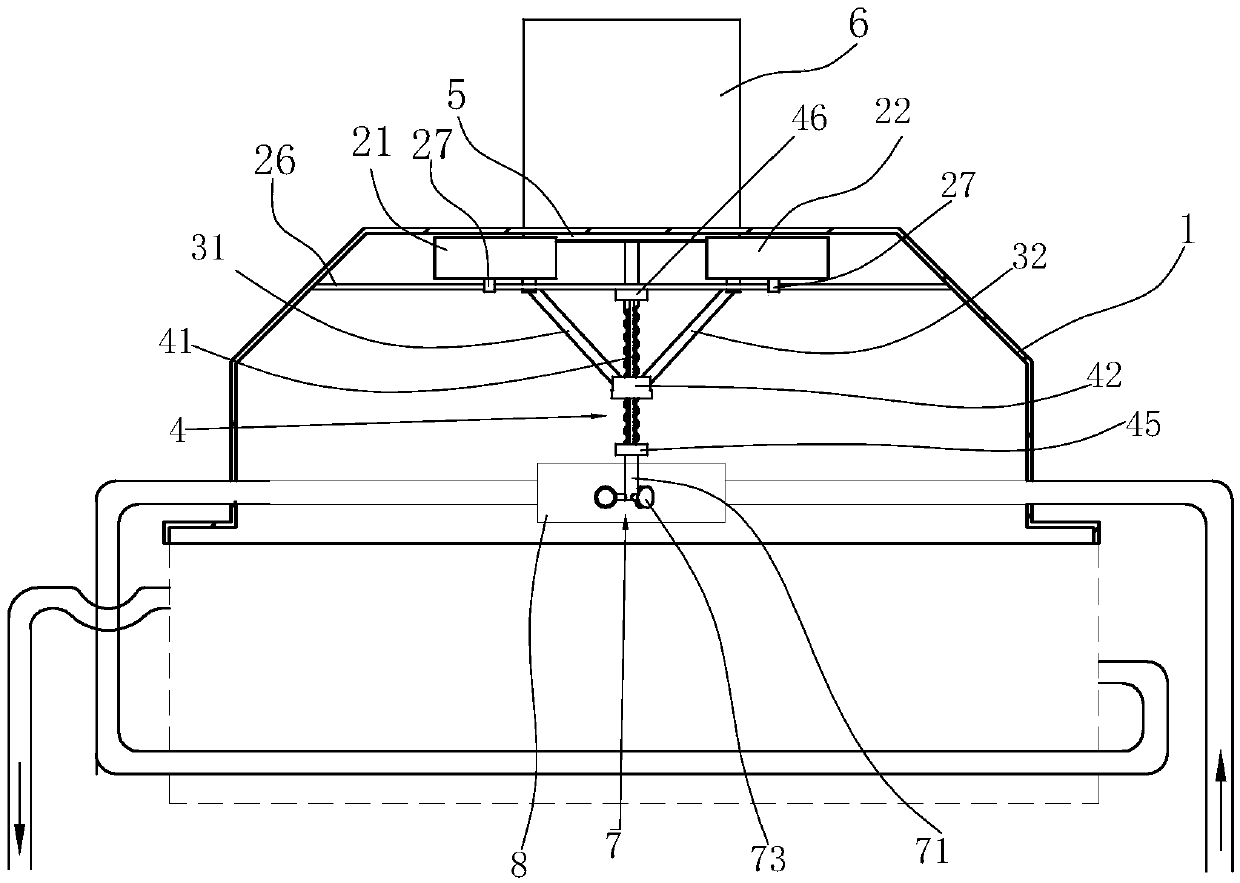

[0035] like figure 1 To such as Figure 5 As shown, the backdraft hood for the water heater includes:

[0036] The smoke collecting hood 1 is installed above the heat exchanger of the water heater, and is a collection and buffer space for the smoke to be discharged. The smoke collecting hood 1 is provided with an air outlet 11 for connecting the smoke exhaust pipe 6 .

[0037] The smoke exhaust pipe 6 is connected to the air outlet 11, and is a passage for the smoke discharged from the air outlet to be discharged outdoors. In this embodiment, the periphery of the inner port of the smoke exhaust pipe 6 connected to the air outlet 11 is provided with an outwardly folded flange 61, and the flange 61 is accommodated in the smoke collection hood 1 and between the inner wall of the smoke collection hood with gaps (not shown).

[0038] The bracket 5 is connected to the inner wall of the fume collecting hood along the periphery of the air outlet 11, and is the connection base of ot...

Embodiment 2

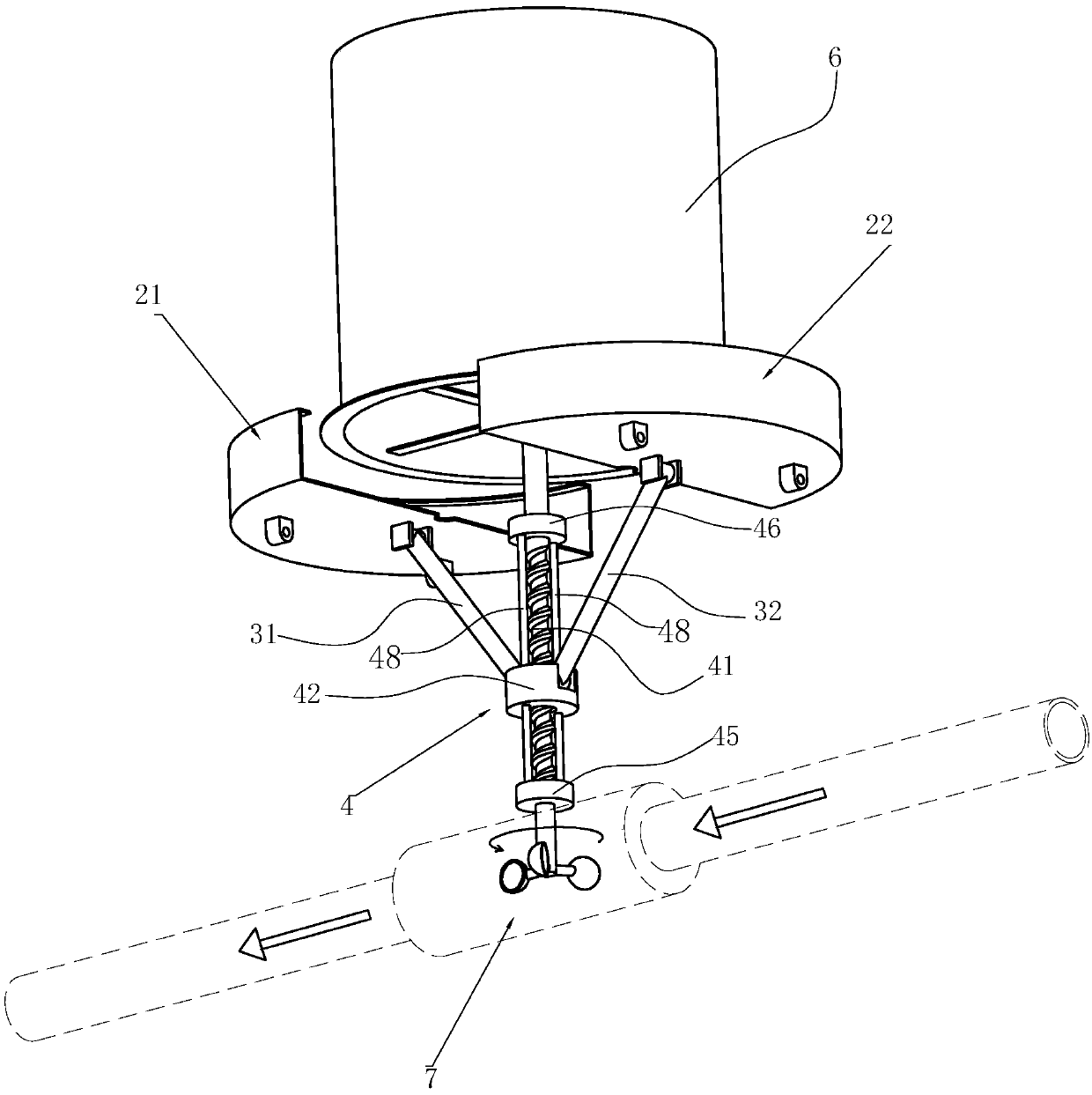

[0048] like Image 6 As shown, the rotating part in this embodiment is the turbine 7, which is arranged in the water pipe 8.

[0049] The rotating member is coaxially connected with the first bevel gear 43 , the first bevel gear 43 meshes with the second bevel gear 44 , and the second bevel gear 44 is connected with the rotating shaft 47 .

[0050] The upper end of the rotating shaft 47 is sealed and connected to the ball screw 41 through the water pipe 8 .

[0051] When the water heater is working, the water flow impacts the turbine to rotate, and the turbine transmits the kinetic energy to the first bevel gear, the second bevel gear and the ball screw in sequence.

[0052] All the other contents are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com