Conductive bracket for motor

A technology of conductive brackets and conductive pins, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as easy loosening of connecting rods and conductive connecting pieces, deformation of PCBA boards, and unreasonable positioning and support, so as to avoid poor contact , improve efficiency, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below through specific embodiments.

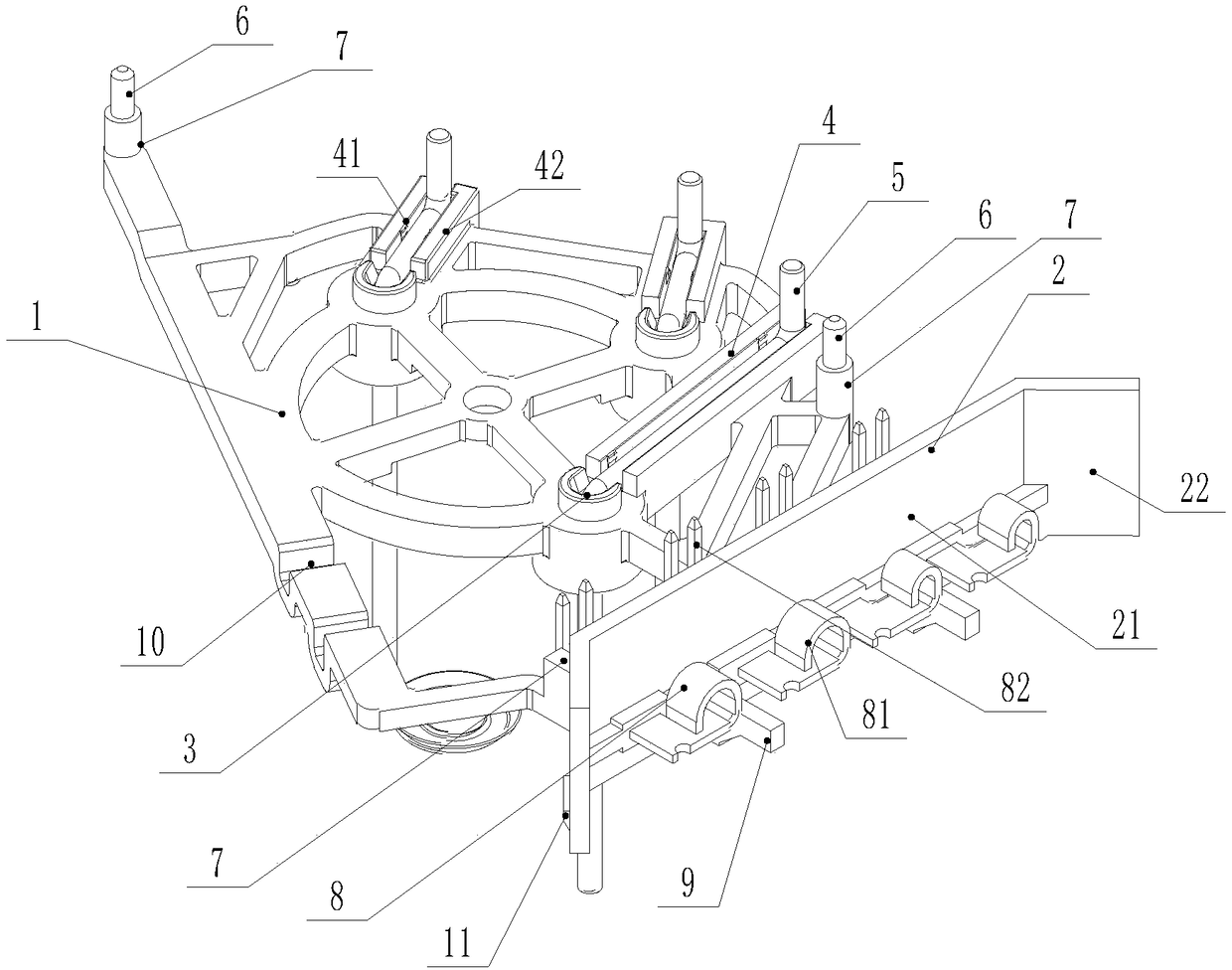

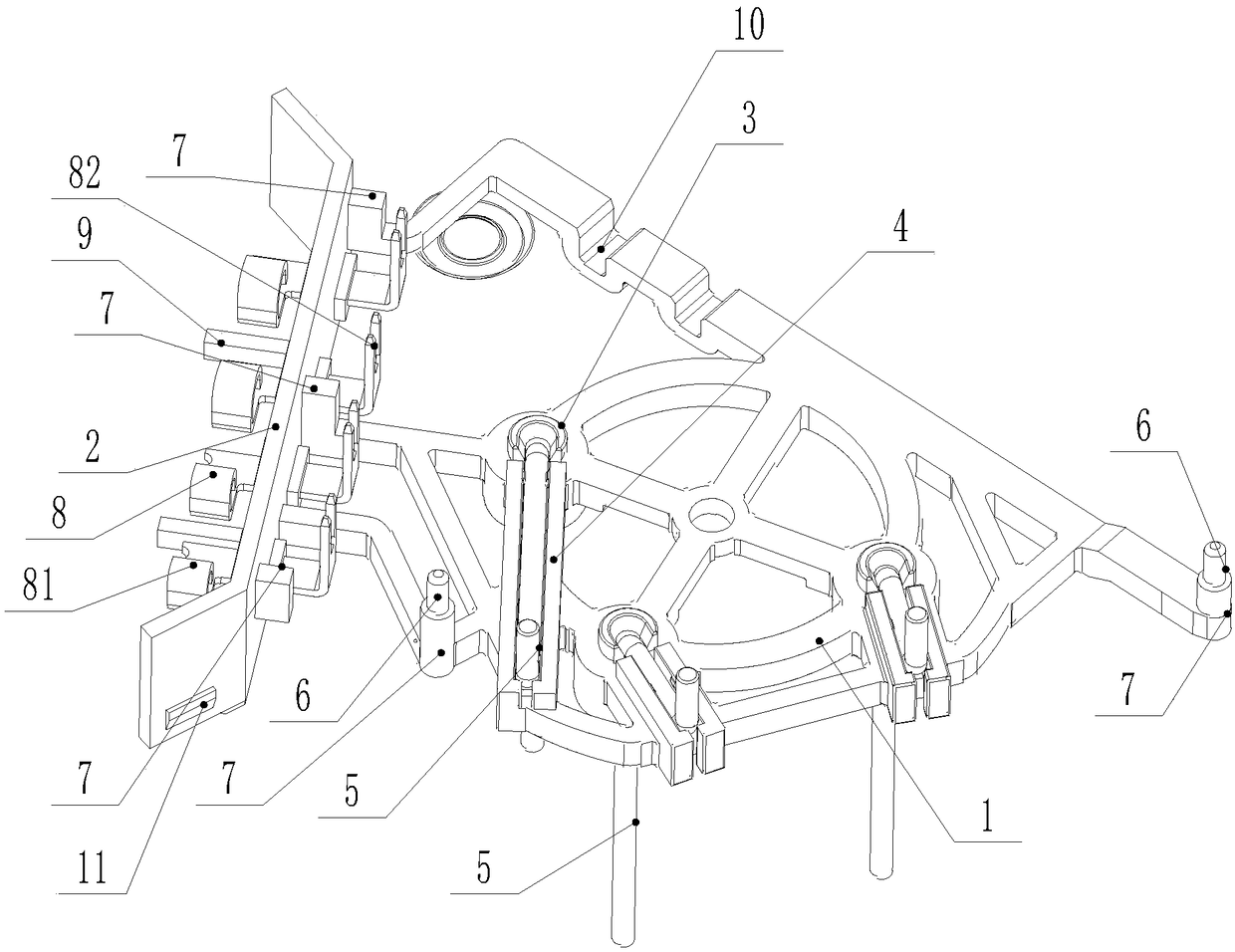

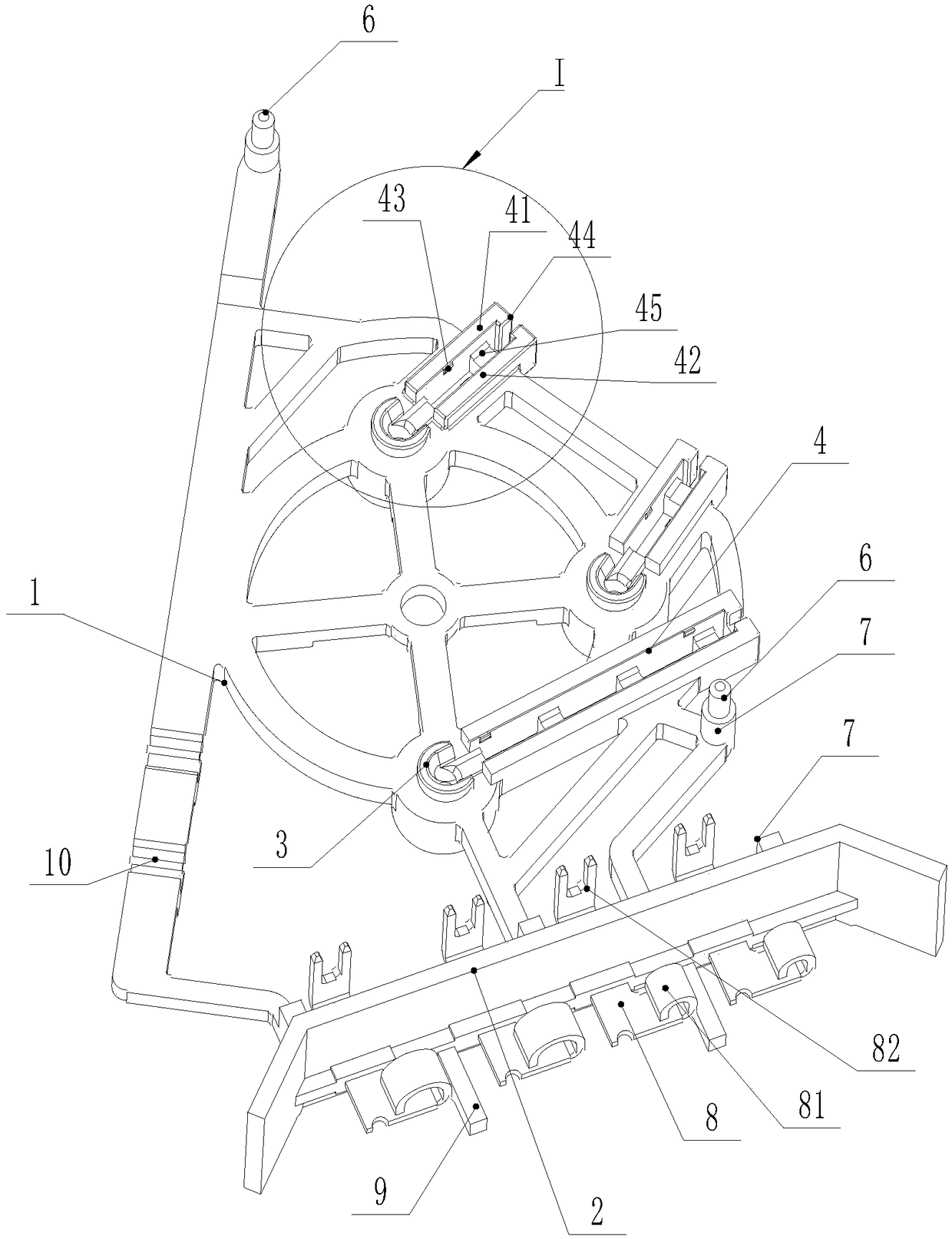

[0030] Such as Figure 1 to Figure 6 As shown, a conductive support for a motor is shown, and the conductive support is a hollow conductive support. It includes a plastic bracket body 1, three mounting holes 3 penetrating through the front and back are provided on the bracket body, and the back side of the bracket body 1 is provided with a positioning slot 4 that communicates with the three mounting holes 3 and extends along the back. In the example, the front side is the side close to the stator, and the reverse side is the side close to the PCBA board 12.

[0031] Each mounting hole 3 is filled with a conductive connecting rod 5. The tail section of the conductive connecting rod 5 is bent and embedded in the positioning slot 4, and the tail end of each conductive connecting rod 5 is bent from the positioning slot 4 The inwardly extending back side is used for electrical welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com