Screw cover assembly and washing machine

A screw cover and washing machine technology, which is applied to other washing machines, threaded fasteners, bolts, etc., can solve the problems of low versatility, poor production efficiency, and high cost, and achieve the effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

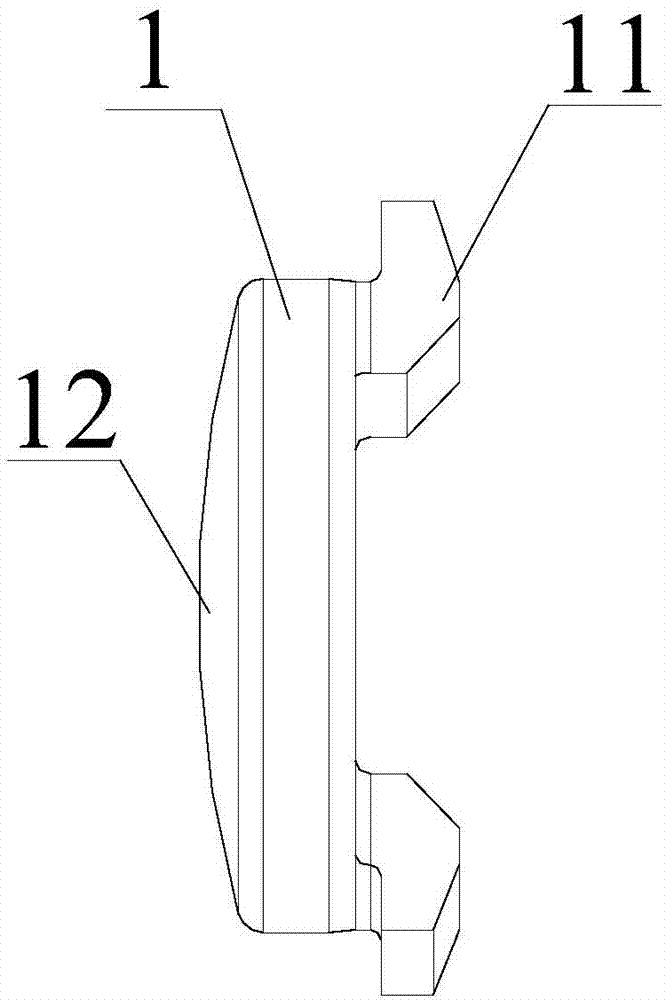

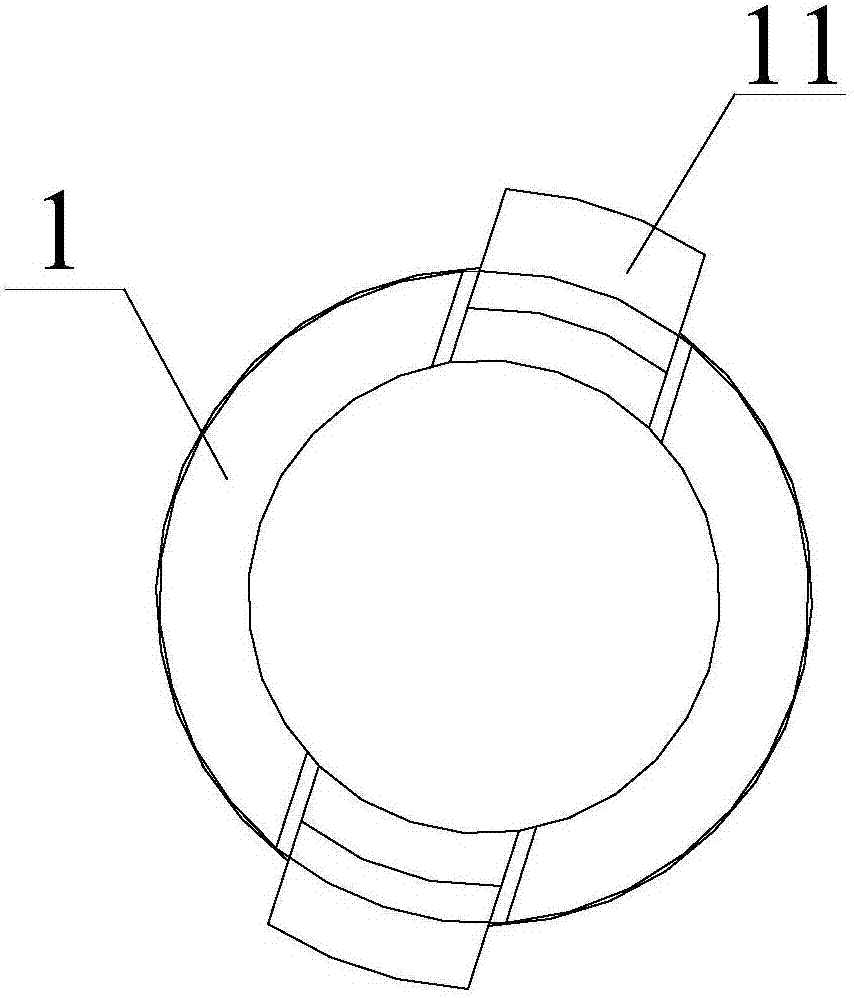

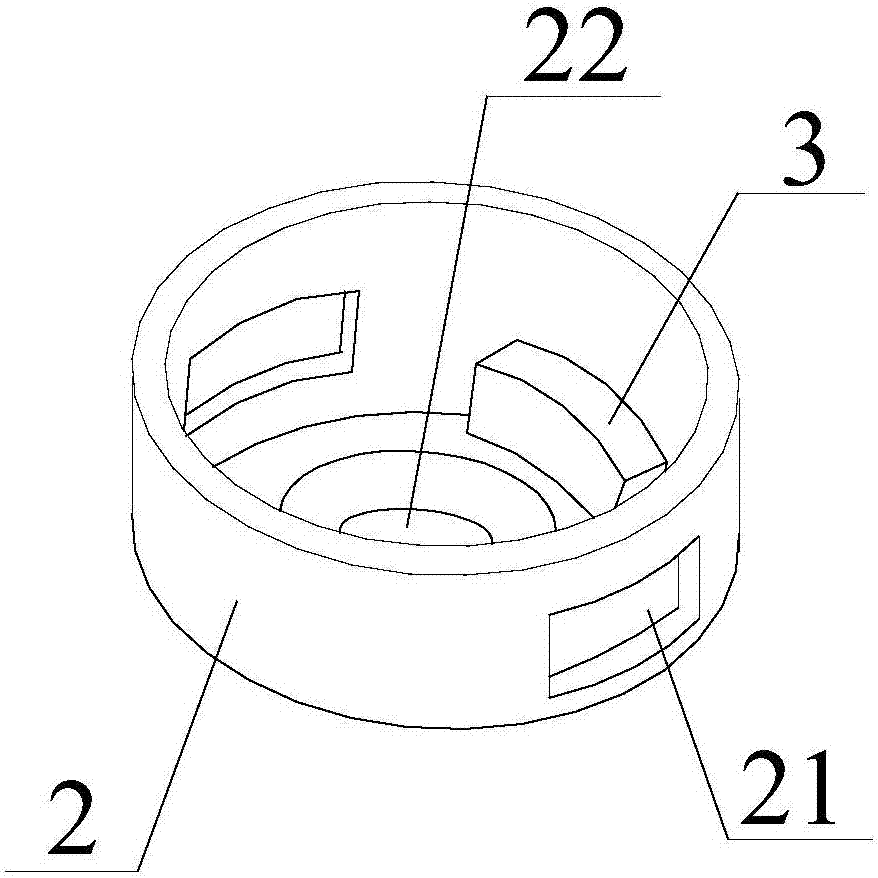

[0029] Such as Figure 1-3 As shown, a screw cover assembly includes a cover body 1 and a tank body 2 connected with the cover body 1. The bottom of the cover body 1 is provided with claws 11 extending horizontally outward, and the side wall of the tank body 2 is provided with a The claw 11 is connected to the bayonet 21;

[0030] A raised platform 3 for supporting the bottom of the cover body 1 is provided between the cover body 1 and the tank body 2 , and the raised platform 3 is arranged at the bottom of the tank body 2 .

[0031] The screw cover assembly has high versatility and can be used for different types of tank bodies 2 (with the same diameter and different depths), and the required cover body 1 can adopt a uniform type of cover body 1 . Specifically, under normal circumstances, the tank body 2 is not set alone, but is used in conjunction with related products. When producing corresponding products, the tank body 2 and the raised platform 3 in the tank body 2 are s...

Embodiment 2

[0039] Such as Figure 4 and Figure 5 Shown, a kind of washing machine comprises a fuselage, and the top of the fuselage is provided with loam cake 4, and loam cake 4 comprises loam cake upper part 41 and loam cake lower part 42, and loam cake upper part 41 is provided with screw thread near loam cake lower part 42. Hole 43, upper cover lower part 42 is provided with screw cover assembly;

[0040] The upper cover lower part 42 is provided with a through hole, and the tank body 2 is located in the through hole. The bottom of the tank body is opposite to the threaded hole 43, and the bottom of the tank body 2 is provided with a connecting hole 22 communicating with the threaded hole 43.

[0041] During use, the upper cover 4 needs to be lifted, at this time, the lower part 42 of the upper cover is exposed, and the through hole is arranged on the lower part 42 of the upper cover, and the cover body 1 is connected with the tank body 2, the threaded hole 43 and the screws connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com