Formula of environment friendly water-based ink for transfer printing and preparation method thereof

A water-based ink and transfer printing technology, applied in transfer printing, ink, printing, etc., can solve the problems of high price and cost, performance characteristics not suitable for textile transfer printing process, etc., achieve low cost, and is conducive to safe production and environmental protection , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

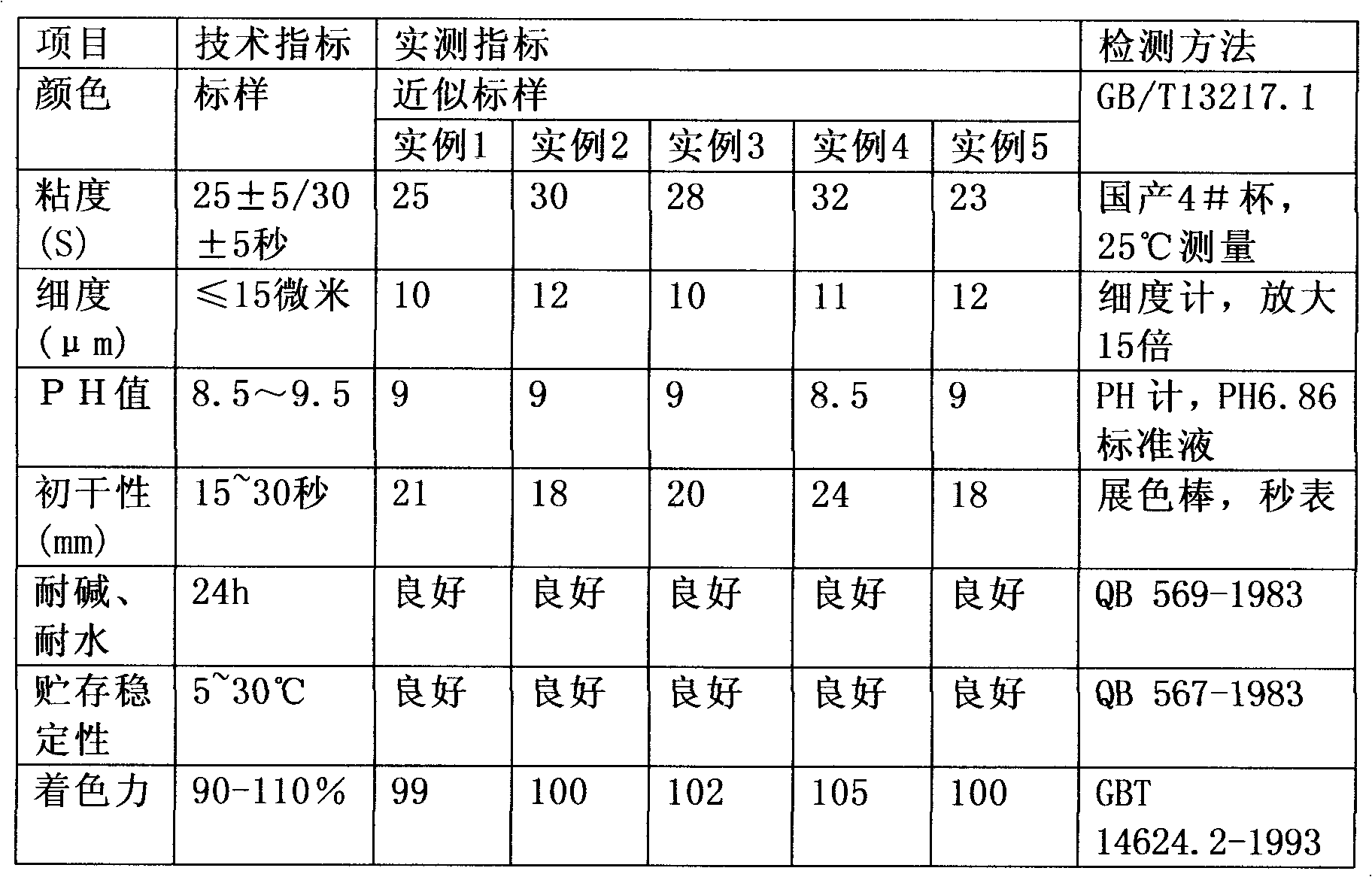

Embodiment 1

[0017] A kind of environmentally friendly water-based ink formula for transfer printing of the present embodiment includes the following raw materials in weight percentage: 35% of R-27 water-soluble acrylic resin, 15% of disperse dye, 8% of triethanolamine, 1.5% of butyl ether, and 2.5% of auxiliary agent %, water 38%. Among them, 0.5% butyl phosphate defoamer, 0.2% ammonia water stabilizer, 0.5% FS-29 dispersant, 0.2% Yunqing brand preservative, 0.8% SR3088 leveling agent, 0.1% ink slip agent and 0.2 % ink crosslinking agent. First, weigh the above-mentioned raw materials according to the formula, and then put the disperse dye in a ball mill to make the fineness of the color paste less than or equal to 12 microns; put the ground color paste in a stirrer and stir at a high speed, and neutralize it until the pH value is 8.5~9.5; then add water-soluble acrylic resin, triethanolamine, butyl ether, additives and water into the color paste in sequence, stir and mix evenly to make ...

Embodiment 2

[0019] A kind of environment-friendly water-based ink formulation for transfer printing of the present embodiment comprises the following raw materials in weight percentage: 40% of R-31 water-soluble acrylic resin, 15% of disperse dye, 2.2% of butyl ether, 1.8% of auxiliary agent, and 41% of water . The additives are 0.4% butyl phosphate defoamer, 1.2% SR3088 leveling agent, 0.1% ink slip agent and 0.1% ink crosslinking agent. First, weigh the above-mentioned raw materials according to the formula, and then put the disperse dye in a ball mill to make the fineness of the color paste less than or equal to 12 microns; put the ground color paste in a stirrer and stir at a high speed, and neutralize it until the pH value is 8.5~9.5; then add water-soluble acrylic resin, triethanolamine, butyl ether, additives and water into the color paste in sequence, stir and mix evenly to make it have sufficient fineness and tinting strength; adjust the viscosity to 20-35 seconds with water Aft...

Embodiment 3

[0022] A kind of environment-friendly water-based ink formulation for transfer printing of the present embodiment includes the following raw materials in weight percentage: 50% of R-27 water-soluble acrylic resin, 10% of disperse dye, 3% of auxiliary agent, and 37% of water. Among them, 0.5% butyl phosphate defoamer, 0.5% F001 dispersant, 0.2% Yunqing preservative, 1.5% SR3088 leveling agent and 0.3% ink crosslinking agent are used as auxiliary agents. First, weigh the above-mentioned raw materials according to the formula, and then put the disperse dye in a ball mill to make the fineness of the color paste less than or equal to 12 microns; put the ground color paste in a stirrer and stir at a high speed, and neutralize it until the pH value is 8.5~9.5; then add water-soluble acrylic resin, triethanolamine, butyl ether, additives and water into the color paste in sequence, stir and mix evenly to make it have sufficient fineness and tinting strength; adjust the viscosity to 20-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com