Antibacterial and mould-proof shoe material and preparation method of shoe sole

An antibacterial, antifungal, and shoe material technology, applied in footwear, applications, clothing, etc., can solve the problems of small particle size, large surface energy, and particle agglomeration of inorganic antibacterial agents, so as to achieve difficult agglomeration, improved dispersion performance, and improved anti-skid sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

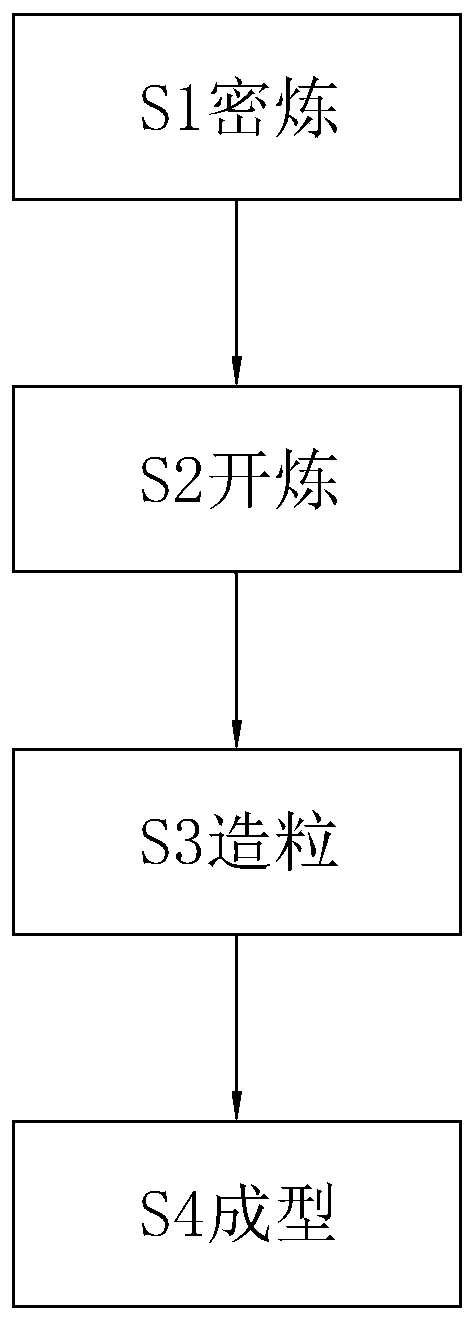

Method used

Image

Examples

Embodiment 1

[0055] An antibacterial and mildew-proof shoe material, comprising the following components by weight:

[0056] 23 copies of EVA;

[0057] 17 parts of POE, including 40% POE with 28% VA content and 60% POE with 33% VA content;

[0058] 6 copies of OBC;

[0059] 4 copies of EDPM;

[0060] 7 parts of natural rubber;

[0061] 4 parts of talcum powder;

[0062] 0.3 parts of tasteless DCP;

[0063] AC blowing agent 1.2 parts;

[0064] 0.8 parts of zinc oxide;

[0065] 0.4 parts of stearic acid;

[0066] Zinc stearate 0.2 parts;

[0067] 0.4 part of nano antibacterial agent;

[0068] Plant antibacterial agent 0.2 part.

[0069] The preparation process of nanometer antibacterial agent is as follows:

[0070] 1. In parts by weight, add 5 parts of silver-loaded zeolite to 18 parts of absolute ethanol / water mixed solution with a volume ratio of 6:1, then add 1.2 parts of isobutyltriethoxysilane, and then heat to 70°C, keep stirring for 20 minutes, and finally filter, dry, an...

Embodiment 2

[0081] An antibacterial and mildew-proof shoe material, comprising the following components by weight:

[0082] EVA 27 copies;

[0083] 21 parts of POE, including 50% POE with 28% VA content and 50% POE with 33% VA content;

[0084] 9 copies of OBC;

[0085] 6 copies of EDPM;

[0086] 10 parts of natural rubber;

[0087] 6 parts of talcum powder;

[0088] 0.6 parts of odorless DCP;

[0089] AC blowing agent 2 parts;

[0090] 1.2 parts of zinc oxide;

[0091] 0.6 parts of stearic acid;

[0092] Zinc stearate 0.4 parts;

[0093] 0.5 part of nano antibacterial agent;

[0094] Plant antibacterial agent 0.3 part.

[0095] The preparation process of nanometer antibacterial agent is as follows:

[0096] 1. In parts by weight, add 7 parts of silver-loaded zeolite to 20 parts of absolute ethanol / water mixed solution with a volume ratio of 8:1, then add 1.5 parts of isobutyltriethoxysilane, and then heat to 75°C, keep stirring for 25 minutes, and finally filter, dry, and gri...

Embodiment 3

[0107] An antibacterial and mildew-proof shoe material, comprising the following components by weight:

[0108] 25 copies of EVA;

[0109] 19 parts of POE, including 45% POE with 28% VA content and 55% POE with 33% VA content;

[0110] 8 copies of OBC;

[0111] 5 copies of EDPM;

[0112] 8 parts of natural rubber;

[0113] 5 parts of talcum powder;

[0114] 0.45 copies of odorless DCP;

[0115] 1.6 parts of AC blowing agent;

[0117] 0.5 parts of stearic acid;

[0118] Zinc stearate 0.3 parts;

[0119] 0.45 parts of nano antibacterial agent;

[0120] Plant antibacterial agent 0.25 parts.

[0121] The preparation process of nanometer antibacterial agent is as follows:

[0122] 1. In parts by weight, 6 parts of silver-loaded zeolite is added to 19 parts of dehydrated alcohol / water mixed solution with a volume ratio of 7:1, and then 1.3 parts of isobutyltriethoxysilane is added, and then heated to At 72°C, keep stirring for 23 minutes, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com