Method for preparing anti-bacterial plastic filament

An antibacterial plastic and filament technology, applied in the direction of single-component polyolefin rayon, single-component polyamide rayon, etc., can solve the problems of easy to darken color, poor chemical stability, low antibacterial performance, etc. High application value, simple preparation process, and the effect of eliminating bacteria and fungi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

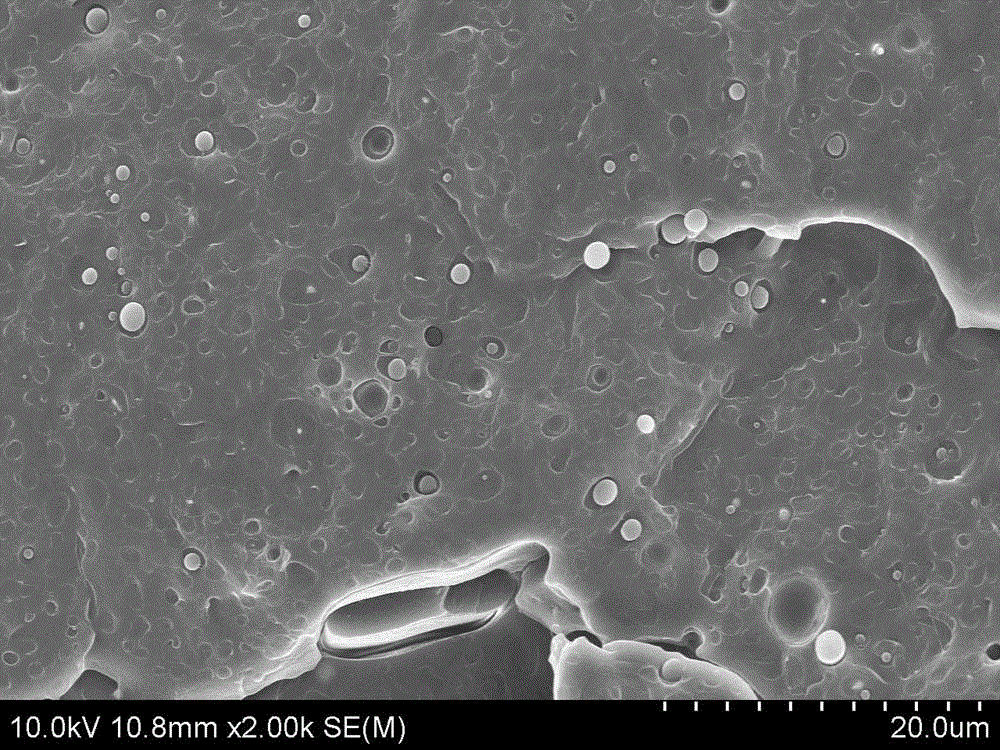

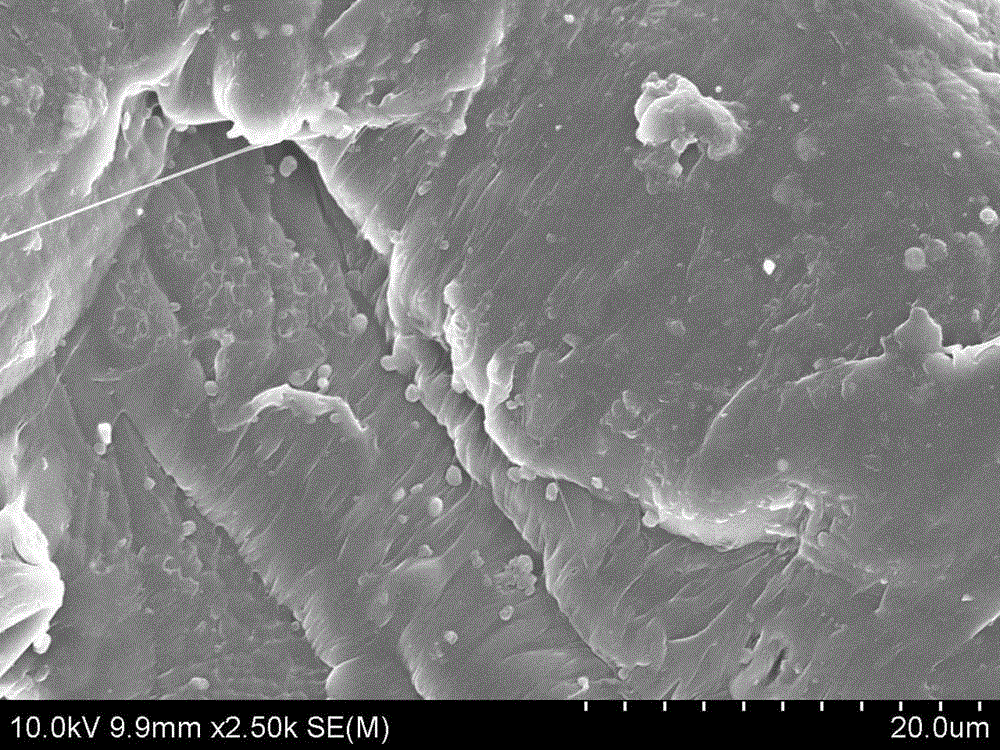

Image

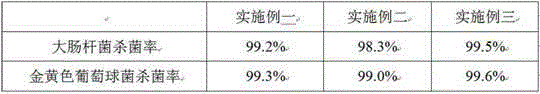

Examples

Embodiment 1

[0020] Weigh 100 g of copper powder, add it to 400 g of ethanol, stir with a high-speed shear disperser for 10 min, adjust the pH value with HCl and NaOH, then add 3 g of silane coupling agent (KH550), and shear at high speed for 60 min , After drying at 110°C for 3 h, the modified nano-copper powder was obtained. Weigh 100 parts of polyethylene resin, 1 part of liquid paraffin, 0.1 part of antioxidant, 2 parts of modified nano-copper antibacterial agent, then fully mix it evenly, process it with a twin-screw extruder, and each district of the twin-screw extruder The temperature is: Zone 1 70°C, Zone 2 80°C, Zone 3 100°C, Zone 4 140°C, Zone 5 155°C, Zone 6 155°C, Zone 7 160°C, Zone 8 160°C, Zone 9 160°C, Zone 10 zone 160°C, zone 11 160°C, zone 12 160°C, head 155°C, feeding speed: 12, extruder speed: 180 rpm, after granulation, slices were dried at 80°C for 3 hours, and the slices were drawn to prepare into copper / polyethylene antibacterial wire.

Embodiment 2

[0022] Weigh 100 g of copper powder, add it to 500 g of ethanol, stir it with a high-speed shear disperser for 5 minutes, then add 2 g of titanate coupling agent (NDZ-311), after high-speed shearing for 80 minutes, at 100 ° C After drying for 3 h, the modified nano-copper powder was obtained. Weigh 100 parts of nylon 6 resin, 1 part of zinc stearate, 0.1 part of antioxidant, and 1.5 parts of modified nano-copper antibacterial agent. The water adsorbed on the surface, then fully mix the weighed nylon 6, modified copper powder, antioxidant and lubricant, and process it with a twin-screw extruder. The temperature of each zone of the twin-screw extruder is: Zone 1 180°C, 200°C in zone 2, 200°C in zone 3, 220°C in zone 4, 255°C in zone 5, 258°C in zone 6, 258°C in zone 7, 258°C in zone 8, 258°C in zone 9, 258°C in zone 10, 11 zone 258°C, zone 12 255°C, head 250°C, feeding speed: 10, extruder speed: 160 rpm, after granulation, dry at 80°C, and draw the slices to prepare antibacteri...

Embodiment 3

[0024] Weigh 150 g of copper powder, add it to a mixture of 800 g of ethanol and water, stir for 15 min with a high-speed shear disperser, adjust the pH value with HCl and NaOH, and add 2.5 g of silane coupling agent (KH570) after stabilization , high-speed shearing for 90 min, and drying at 100 °C for 8 h to obtain modified nano-copper powder. Weigh 100 parts of nylon 6 resin, 1.8 parts of calcium stearate, 0.3 parts of antioxidant, and 3 parts of nano-copper antibacterial agent. Firstly, put the nylon 6 raw material in a dehumidification dryer, and dry it at 100°C for 8 hours to remove the water adsorbed on the surface, then fully mix the weighed nylon 6, copper powder, antioxidant and lubricant, and use a twin-screw Extruder for processing, the temperature of each zone of the twin-screw extruder is: zone 1 150°C, zone 2 180°C, zone 3 200°C, zone 4 225°C, zone 5 250°C, zone 6 255°C, zone 7 258°C , eighth zone 258°C, ninth zone 260°C, tenth zone 258°C, eleventh zone 255°C, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com