Antibacterial and environment-friendly coating and preparation method thereof

A technology of environmentally friendly coatings and raw materials, applied in the field of coatings, can solve the problems of endless emergence of environmentally friendly coatings, prone to mildew spots, and mildew on interior walls, to prevent the occurrence and spread of diseases, excellent antibacterial sterilization and mildew resistance, and resist foreign The effect of microbial erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

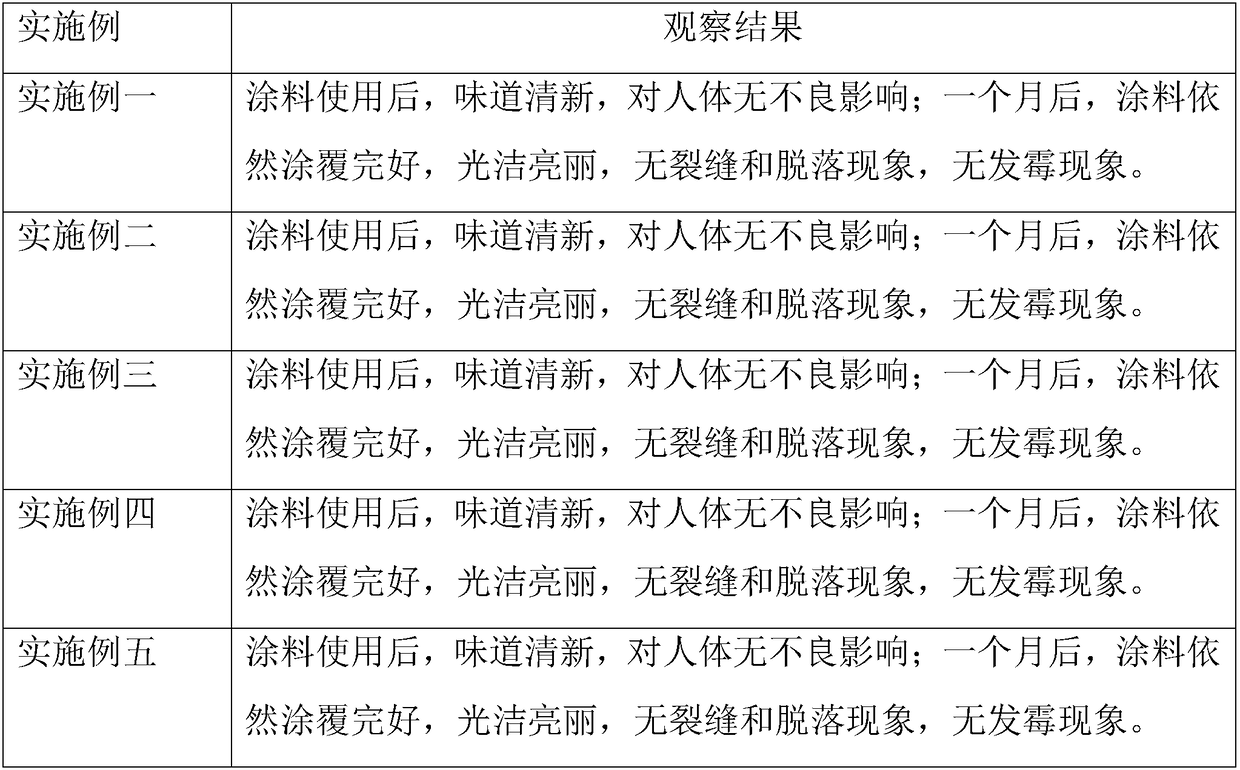

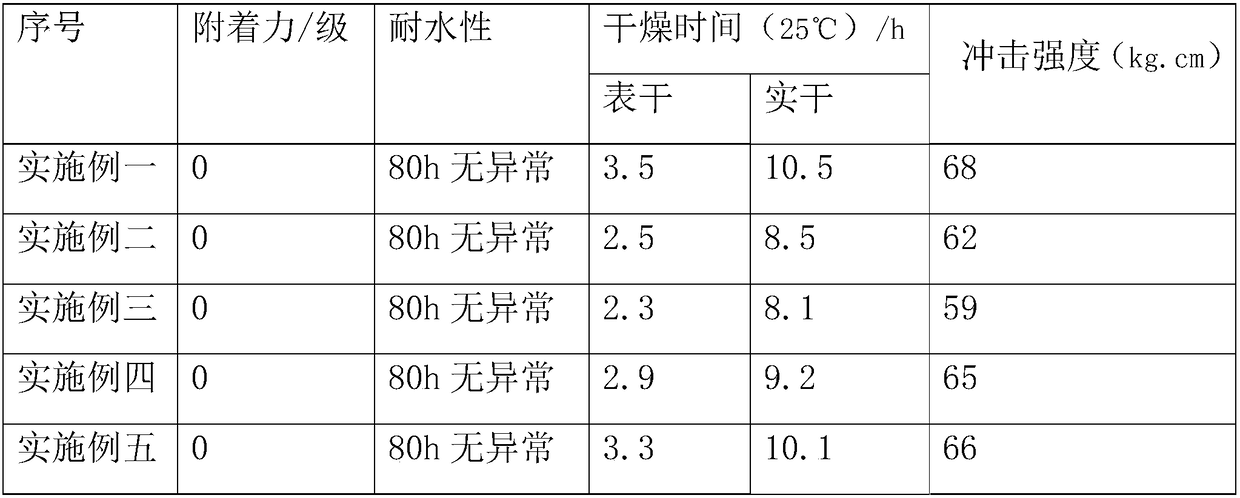

Examples

Embodiment 1

[0027] The antibacterial and environment-friendly paint provided by the present embodiment comprises the following raw material components in parts by weight: 32 parts of polyvinyl alcohol, 19 parts of polyacrylate emulsion, 10 parts of nano-attapulgite, 13 parts of nano-kaolin, diatomaceous earth 15 parts, 12 parts of shell powder, 8 parts of sepiolite powder, 3 parts of hokutolite powder, 1 part of nano-titanium oxide, 1.5 parts of polyacrylamide, 8 parts of epoxy resin, 1 part of mineral oil defoamer, ammonium polyacrylate 0.3 parts of powder, 0.2 parts of carboxymethyl cellulose, 5 parts of coconut oil, 4 parts of pine needle powder, 3.5 parts of naringenin, 2 parts of thyme, 2 parts of tamarind shell, 5.5 parts of naked flower purple pearl, 4.5 parts of wintergreen leaf, Nepeta 2 parts, deionized water 65 parts.

[0028] Present embodiment also provides the method for preparing this antibacterial environmental protection paint, comprises the steps:

[0029] a. Take dried...

Embodiment 2

[0033] The antibacterial and environment-friendly paint provided by the present embodiment comprises the following raw material components in parts by weight: 25 parts of polyvinyl alcohol, 19 parts of polyacrylate emulsion, 8 parts of nano-attapulgite, 13 parts of nano-kaolin, diatomaceous earth 12 parts, 12 parts of shell powder, 5 parts of sepiolite powder, 3 parts of hokutolite powder, 0.5 parts of nano-titanium oxide, 1.5 parts of polyacrylamide, 6 parts of epoxy resin, 1 part of mineral oil defoamer, ammonium polyacrylate 0.2 parts of powder, 0.2 parts of carboxymethyl cellulose, 3 parts of coconut oil, 4 parts of pine needle powder, 2.5 parts of naringenin, 2 parts of thyme, 1 part of tamarind shell, 5.5 parts of naked flower purple pearl, 3 parts of wintergreen leaves, Nepeta 2 parts, deionized water 55 parts.

[0034] Present embodiment also provides the method for preparing this antibacterial environmental protection paint, comprises the steps:

[0035] a. Take drie...

Embodiment 3

[0039] The antibacterial and environment-friendly coating provided in this embodiment comprises the following raw material components in parts by weight: 25 parts of polyvinyl alcohol, 17 parts of polyacrylate emulsion, 8 parts of nano-attapulgite, 11 parts of nano-kaolin, diatomaceous earth 12 parts, 10 parts of shell powder, 5 parts of sepiolite powder, 2.5 parts of hokutolite powder, 0.5 parts of nano-titanium oxide, 1 part of polyacrylamide, 6 parts of epoxy resin, 0.5 parts of mineral oil defoamer, ammonium polyacrylate 0.2 parts of powder, 0.1 parts of carboxymethyl cellulose, 3 parts of coconut oil, 3.5 parts of pine needle powder, 2.5 parts of naringenin, 1.5 parts of thyme, 1 part of tamarind shell, 4.5 parts of naked flower purple pearl, 3 parts of wintergreen leaf, Nepeta 1 part, deionized water 55 parts.

[0040] Present embodiment also provides the method for preparing this antibacterial environmental protection paint, comprises the steps:

[0041] a. Take dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com