Wet-type fine polishing wheel and preparation method thereof

A fine polishing and wet technology, applied in the direction of grinding/polishing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of operator injury, weak self-sharpening, low elasticity, etc., and achieve super sharpness and wear resistance High degree, high elasticity and flexibility, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

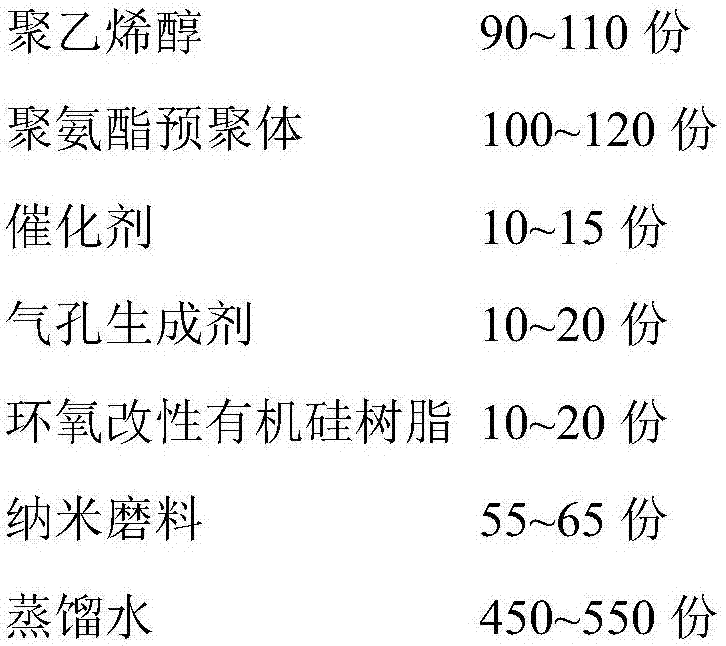

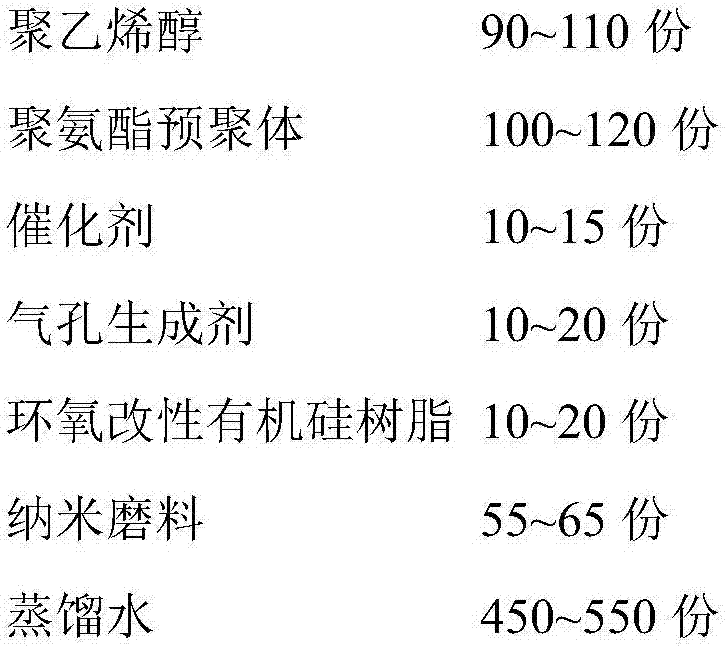

[0029] A preparation method of a wet fine polishing wheel of the present invention comprises the following steps:

[0030] S1: mixing polyvinyl alcohol and distilled water in a mass ratio of 1:5, and dissolving in a water bath for 20 to 30 minutes to obtain an aqueous polyvinyl alcohol solution;

[0031] S2: Add abrasive to the polyvinyl alcohol aqueous solution, and stir evenly;

[0032] S3: add polyurethane prepolymer, epoxy modified silicone resin, catalyst and pore-forming agent to the mixed solution obtained in S2, stir evenly, and leave it to react in the mold for 10-15 minutes;

[0033] S4: curing at 50~90℃ for 2~4h;

[0034] S5: Take out the sponge-like solid obtained by curing, and perform drilling, cutting, grinding and fine grinding on it as required to obtain a finished wet polishing wheel.

[0035]Specifically, the abrasive is nano-diamond with a particle size of 0.5-10 nm. 所述的聚氨酯预聚体为TDI或者MDI的聚氨酯预聚体,可选用Bayhydur305、Bayhydur2655、Bayhydur401-7、BayhydurT0607、Bayhydu...

Embodiment 1

[0041] A kind of preparation method of wet fine polishing wheel of the present embodiment, comprises the steps:

[0042] S1: Mix 90g of polyvinyl alcohol with 450g of distilled water, dissolve in a water bath at 70°C for 20 minutes, and use a stirrer to obtain an aqueous solution of polyvinyl alcohol at a speed of 400r / min;

[0043] S2: Add 55g of nano-diamonds to the polyvinyl alcohol aqueous solution, and use a disperser to stir evenly in a 30°C water bath at a speed of 400r / min;

[0044] S3: Add 100g polyurethane prepolymer (Bayhydur305), 10g epoxy-modified silicone resin, 8g stannous octoate, 2g dibutyltin dilaurate, 5g n-pentane and 5g silicone oil to the mixed solution obtained in S2, at 30 Mix evenly in a water bath at ℃, and react for 10 minutes under stirring with a mixer at a speed of 400r / min;

[0045] S4: curing the gel solution obtained in S3 at 70°C for 2 hours;

[0046] S5: Take out the solidified spongy solid, and perform drilling, cutting, grinding, and fine...

Embodiment 2

[0049] A kind of preparation method of wet fine polishing wheel of the present embodiment, comprises the steps:

[0050] S1: Mix 110g of polyvinyl alcohol with 550g of distilled water, dissolve in a water bath at 90°C for 30 minutes, and use a stirrer to obtain an aqueous solution of polyvinyl alcohol at a speed of 600r / min;

[0051] S2: Add 65g of nano-diamonds to the polyvinyl alcohol aqueous solution, and use a disperser to stir evenly in a 60°C water bath at a speed of 600r / min;

[0052] S3: Add 120g polyurethane prepolymer (Bayhydur401-7), 15g epoxy-modified silicone resin, 12g stannous octoate, 3g dibutyltin dilaurate, 6g n-pentane, 4g silicone oil and Mix 5g of starch evenly in a water bath at 60°C, and react for 15min while stirring with a mixer at a speed of 500r / min;

[0053] S4: curing the gel solution obtained in S3 at 50°C for 4 hours;

[0054] S5: Take out the solidified spongy solid, and perform drilling, cutting, grinding, and fine grinding on it as required ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com