A Treatment Method for Improving the Abrasion Resistance and Toughness of Rotary Knife

A processing method and technology of rotary tiller, which are applied in the direction of manufacturing tools, plasma welding equipment, welding equipment, etc., can solve the problems of right-angle rotary tiller being unsuitable for paddy field farming, increase labor intensity, and increase operation cost, and achieve shortened time. The effect of process interval, high preheating and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

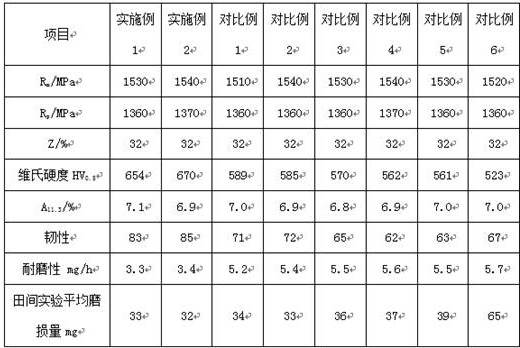

Examples

Embodiment 1

[0021] A treatment method for improving the abrasion resistance and toughness of a rotary tiller, the specific method is as follows:

[0022] (1) Grind the rotary cultivator with a sand mill for 27s, the speed is 2500r / min, the sanding is rotating forward, the sharpening frequency is 60 times / min, the mass fraction is 4% water-based coolant to aid grinding, the grinding pressure 150N, then cross-polished with water sandpaper with a particle size of 600 mesh at a 45° angle for 2 minutes, washed with deionized water for 4 times, and then put in ethyl diaminopropyl trimethoxy methacrylate with a weight ratio of 1.43:3.25 and The cleaning agent made of 8% acetic acid solution was ultrasonically treated for 60s, the treatment temperature was 34°C, the ultrasonic power was 200W, the frequency was 50kHz, the insulation was kept for 600s, and deionized water was used to clean twice, and then put into the Soak in an alkaline detergent made of sodium hydroxide and sodium tripolyphosphat...

Embodiment 2

[0032] A treatment method for improving the abrasion resistance and toughness of a rotary tiller, the specific method is as follows:

[0033] (1) Grind the rotary cultivator with a sand mill for 25s, the speed is 2300r / min, the sanding is rotating forward, the sharpening frequency is selected to be 50 times / min, the mass fraction is 3% water-based coolant to aid grinding, and the grinding pressure 140N, then use water sandpaper with a particle size of 400 mesh at a 45° angle to dip in water and cross-polish for 1min, then wash it with deionized water for 3 times, and then put in ethyl diaminopropyl trimethoxysilane methacrylate with a weight ratio of 1.3:3.25 and The cleaning agent made of 8% acetic acid solution was ultrasonically treated for 40s, the treatment temperature was 33°C, the ultrasonic power was 200W, the frequency was 50kHz, the insulation was kept for 580s, and deionized water was used to clean once, and then put into the Soak in an alkaline detergent made of so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com