Equipment for crushing and reusing concrete blocks at a building construction site

A technology for concrete blocks and building construction, which is applied in the direction of grain processing, etc., to achieve high strength, ensure sand making efficiency, and not easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is further described in detail through specific implementation methods:

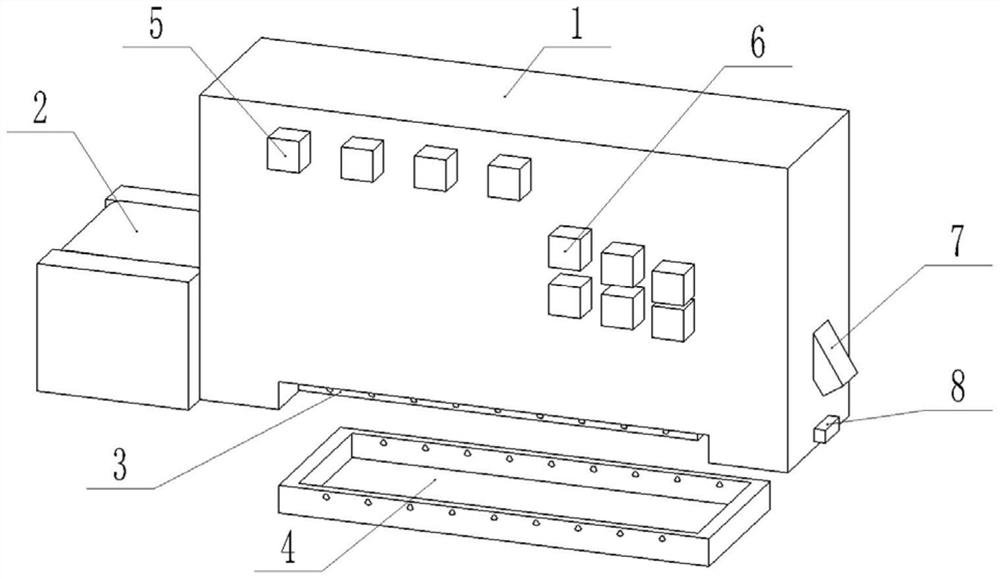

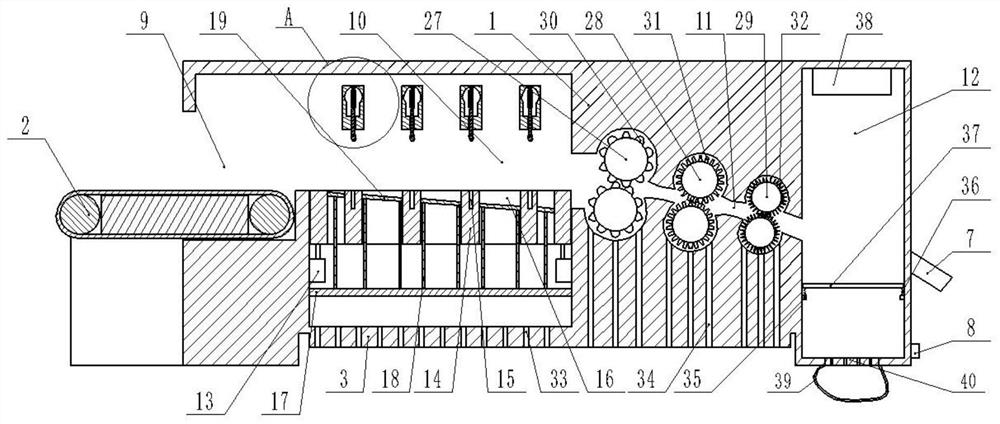

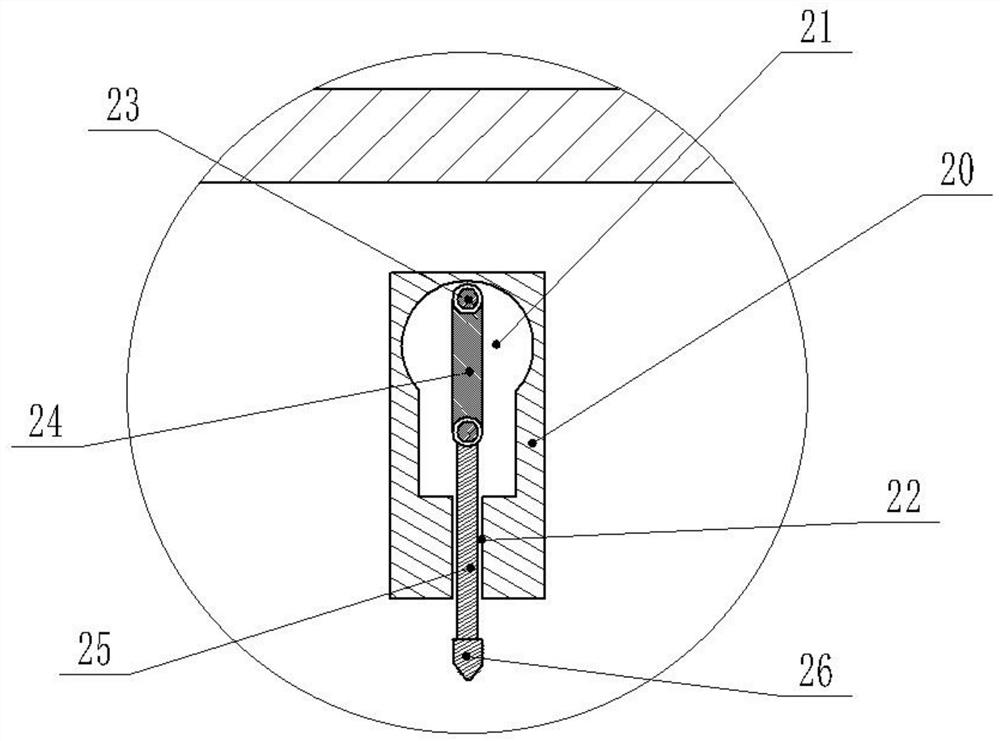

[0029] The reference signs in the accompanying drawings of the specification include: casing 1, conveyor belt mechanism 2, boss 3, slag box 4, first storage box 5, second storage box 6, discharge port 7, slag discharge port 8, transmission space 9. Resonance space 10, sand making space 11, storage space 12, hydraulic cylinder 13, jacking seat 14, first tank body 15, second tank body 16, bottom plate 17, guide frame 18, guide rod 19, piston cylinder 20 , the first shaft chamber 21, the second shaft chamber 22, the eccentric shaft 23, the connecting rod 24, the piston shaft 25, the resonance hammer 26, the first sand making roller 27, the second sand making roller 28, the third sand making roller 29, The first sand-making cone head 30, the second sand-making cone head 31, the third sand-making cone head 32, the first leak hole 33, the second leak hole 34, the support 35, the spring 36,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com