A kind of composite porous sponge material and preparation method thereof

A porous and sponge technology, applied in medical science, prosthesis, tissue regeneration, etc., can solve the problems of easy deformation, weak strength, and difficulty, and achieve the effect of easy absorption and contraction, promotion of cell reproduction, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

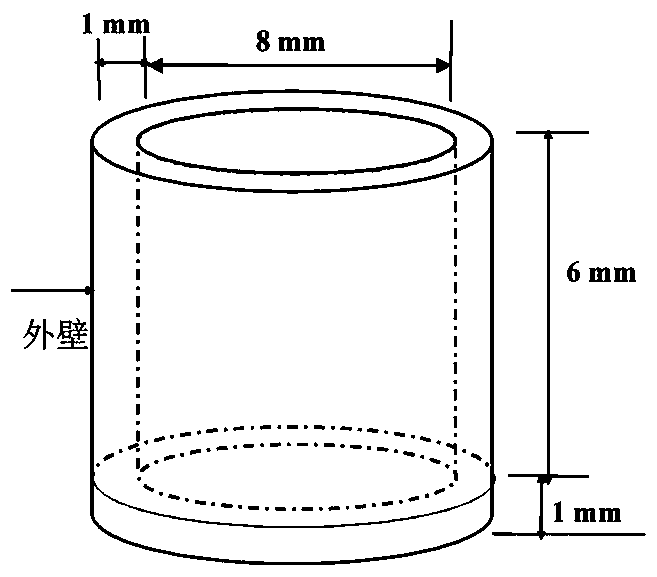

Embodiment 1

[0045] The sodium chloride crystalline particles are separated by sieving with a 170-mesh sieve and a 100-mesh sieve to obtain particles with a diameter of about 90 μm to 150 μm. On the other hand, 1 g of PLLA was dissolved in 5 mL of chloroform to prepare a synthetic polymer solution. Put the chloroform solution in which PLLA is dissolved into a glass test tube, add 9 g of sodium chloride crystal particles (9 times the amount of PLLA) of 90 μm to 150 μm and mix evenly. Then, the uniformly mixed PLLA-NaCl-chloroform was filled into a mold (made of polytetrachloroethylene). Use this mold to make a hollow porous sponge structure composed of bioabsorbable synthetic polymers. The mixture is tightly filled into the mold gap, dried in the atmosphere for 3-4 days, and then vacuum dried for another day. After drying, remove the solid PLLA-sodium chloride from the casting mold, and soak in distilled water to wash out the sodium chloride. Distilled water was exchanged every 2 hours f...

Embodiment 2

[0048] The sodium chloride crystalline particles are separated by sieving with a 100-mesh sieve and a 60-mesh sieve to obtain particles with a diameter of about 150 μm to 250 μm. On the other hand, 1 g of PLLA was dissolved in 5 mL of chloroform to prepare a synthetic polymer solution. Put the chloroform solution in which PLLA was dissolved into a glass test tube, add 9 g of sodium chloride crystal particles (9 times the amount of PLLA) with a particle size of 150 μm to 250 μm, and mix evenly. Then, the uniformly mixed PLLA-NaCl-chloroform was filled into a mold (made of polytetrachloroethylene). Use this mold to make a hollow porous sponge structure composed of bioabsorbable synthetic polymers. The mixture is tightly filled into the mold gap, dried in the atmosphere for 3-4 days, and then vacuum dried for another day. After drying, remove the solid PLLA-sodium chloride from the casting mold, and soak in distilled water to wash out the sodium chloride. Distilled water was e...

Embodiment 3

[0051] Bone morphogenetic protein BMP can induce mesenchymal cells to differentiate into bone, cartilage, ligament, tendon and nerve tissue to promote cartilage joint repair. Regulate calcium and phosphorus metabolism to deposit bone calcium, stimulate osteoblast proliferation, inhibit inflammatory infiltration of joint inflammation and postoperative swelling and pain after fracture. This example tries to add BMP-2 to make a composite material, and the growth factor is not limited to BMP.

[0052] The sodium chloride crystalline particles are separated by sieving with a 170-mesh sieve and a 100-mesh sieve to obtain particles with a diameter of about 90 μm to 150 μm. On the other hand, 1 g of PLLA was dissolved in 5 mL of chloroform to prepare a synthetic polymer solution. Put the chloroform solution in which PLLA is dissolved into a glass test tube, add 9 g of sodium chloride crystal particles (9 times the amount of PLLA) of 90 μm to 150 μm and mix evenly. Then, the uniforml...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com