Thrust bearing shoe sharpening machine and repair method

A technology for thrust bearings and repair methods, which is applied to machine tools, grinding machines, grinding/polishing equipment, etc., which are suitable for grinding workpiece planes, and can solve the problems of high bearing temperature, low utilization rate of pads, and babbitt alloy surfaces of pads. Adhering to flake grease and other problems, achieving consistent flatness, ensuring performance, smooth surface and consistent smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

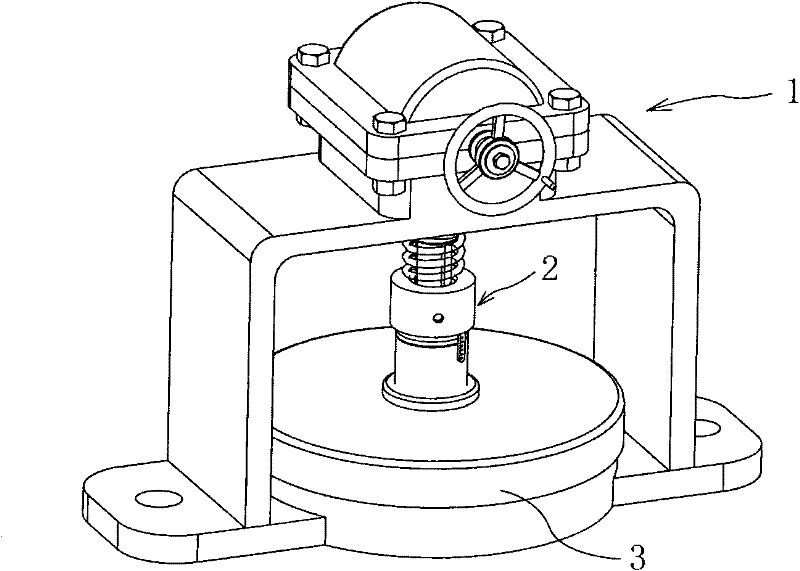

[0070] ①. Install the thrust bearing pad grinding machine rotating mechanism 1 and pressing mechanism 2 in place;

[0071] ②. Check the condition of the Babbitt alloy surface of the tile to be ground;

[0072] ③. According to the condition of the babbitt alloy surface of the tile to be ground, select one side of the grinding plate 401 and the industrial scouring pad 4012 or spunlace non-woven fabric 4013 of the grinding plate as the grinding surface;

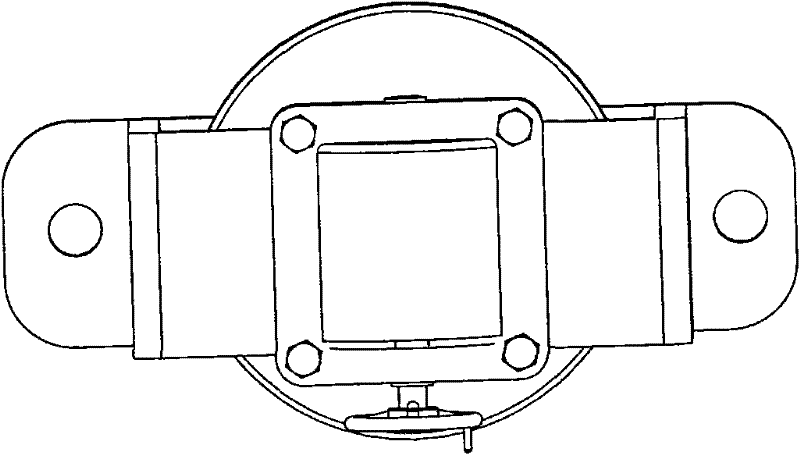

[0073] ④. Fix the selected grinding disc and the grinding disc facing up on the disc base 104 with the anti-rotation bolt assembly 402;

[0074]⑤. Insert the entire group of tiles to be ground into the tile holes 32 of the turntable 3 (note: the surface of the tiles to be ground babbitt faces downward);

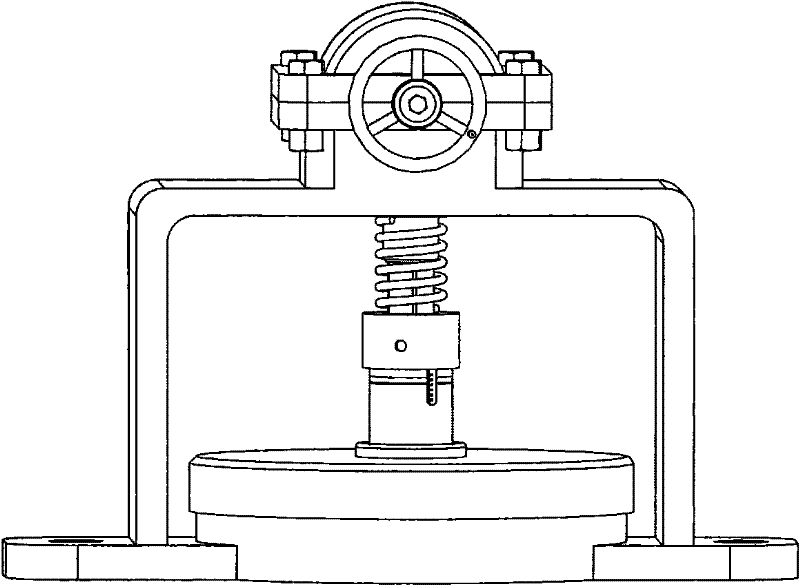

[0075] ⑥. Lift up the transition sleeve 204 in the direction of arrow A in the figure;

[0076] ⑦. Put the turntable 3 in place on the disc base 104 according to the direction of the arrow B in the figure, put down the transi...

Embodiment 2

[0080] ①. Install the thrust bearing pad grinding machine rotating mechanism 1 and pressing mechanism 2 in place;

[0081] ②. In this embodiment, the scratches on the surface of the babbitt alloy to be ground are relatively deep (not exceeding 1 / 3 (0.4mm) of the babbitt alloy coating or the sintered hard spot bump is obvious;

[0082] ③. Select 180# industrial scouring pad with the abrasive side facing up and fix it on the disc base 104 with the anti-rotation bolt assembly 402 for physical repair;

[0083] ④. Insert the entire group of tiles to be ground into the tile hole 32 of the turntable 3 (note: the babbitt alloy face of the tiles faces downward);

[0084] ⑤. Lift up the transition sleeve 204 (according to the direction of arrow A in the figure);

[0085] ⑥. Put the turntable in place on the disc base 104, put down the transition sleeve 204, and put it on the turntable square insert 31;

[0086] ⑦. Increase the pressing force of the adjustment dial 3, and adjust the ad...

Embodiment 3

[0090] ①. Install the thrust bearing pad grinding machine rotating mechanism 1 and pressing mechanism 2 in place;

[0091] ②. In this embodiment, the scratches on the surface of the Babbitt alloy to be ground are relatively shallow or the sintered hard spots are not obvious;

[0092] ③. You can choose 320# or 600# industrial scouring pads with the abrasive surface facing up and fix them on the disc base 104 with the anti-rotation bolt assembly 402 for physical repair;

[0093] ④. Insert the entire group of tiles to be ground into the tile hole 32 of the turntable 3 (note: the babbitt alloy face of the tiles faces downward);

[0094] ⑤. Lift up the transition sleeve 204;

[0095] ⑥. Put the turntable 3 in place on the disc base 104, put down the transition sleeve 204, and insert it into the turntable square insert 31;

[0096] ⑦. Increase the pressing force of the adjustment dial 3, and adjust the adjustment cap 203 to the upper 3 to 4 grids;

[0097] ⑧. Turn the hand wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com