Low-energy UV-curing automotive refinishing paint as well as application and usage method thereof

An automotive refinishing paint, low-energy technology, applied in vehicle maintenance/repair, vehicle maintenance, transportation and packaging, etc., can solve problems such as allergies, skin redness, acute conjunctivitis, etc., to achieve the effect of repairing scratches and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

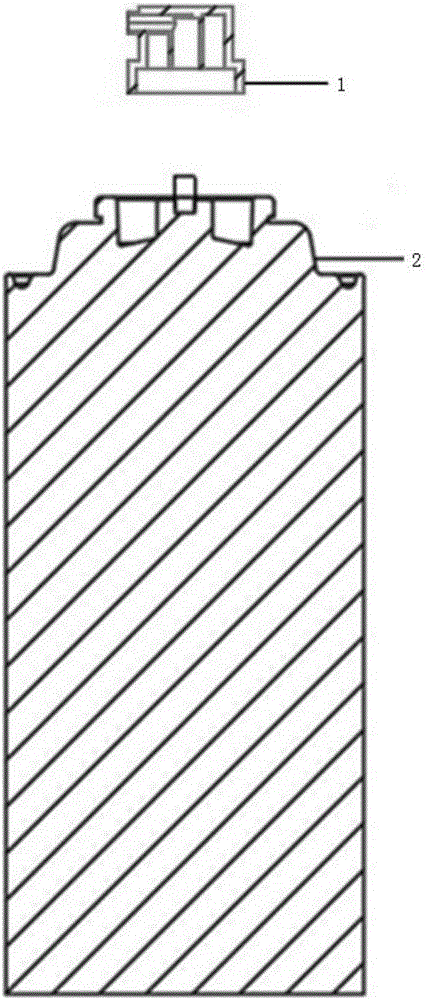

Image

Examples

Embodiment 1

[0092] Application of a low-energy UV automotive refinish paint in the process of auto body paint repair

[0093] 1. Supplementing putty:

[0094] If the car body is sunken and damaged, use dry sandpaper 240# to polish the damaged part of the car paint, and fill it with putty. Use dry sandpaper 400# to polish the surface of the interface between the putty surface and the car paint until it is smooth and even.

[0095] 2. Make up trachoma:

[0096] Putty to fill trachoma, sandpaper marks. After drying, sand it with 600# dry sandpaper. Remove surface dust, oil stains. And wipe off moisture.

[0097] 3. Covering:

[0098] Wear protective equipment, remove the dust and oil stains on the surface being sprayed, and wipe off the water. Use a masking film to cover the area to be sprayed to prevent over-spraying.

[0099] 4. Spray primer:

[0100] Spray 1 layer of primer at a distance of 15-20 cm. (Room temperature 25 degrees Celsius, 10 minutes to dry.) After drying, polish i...

Embodiment 2

[0119] A method for using low-energy UV automotive refinish paint in the automotive lamp repair process, characterized in that: comprising the steps:

[0120] (1) Grinding

[0121] Use 320#~600#~1000# water sandpaper to polish the car lights with severe scratches, abrasions and oxidized cracks until the water flowing down is milky white, or use dry sandpaper 240#~400#~600 in sequence #~800# dry grinder to grind until frosted white, and then use 2000# water sandpaper to add water to grind until the surface is smooth and flat;

[0122] (2) cleaning

[0123] Use detergent and water to clean the dust and oil stains on the surface to be sprayed, and wipe off the water, and use a masking film to cover the parts to be sprayed to prevent over-spraying;

[0124] (3) Spraying

[0125] Wipe the surface of the car light with a dust-removing cloth, and spray one or two coats of UV car light repair paint back and forth. The spraying distance is 15-20 cm, and the interval between layers i...

Embodiment 3

[0133] A method for using an aerosol low-energy UV automotive refinishing paint in the automotive body paint repairing process, is characterized in that: comprises the steps:

[0134] 1. Supplementing putty:

[0135] If the car body is sunken and damaged, use dry sandpaper 240# to polish the damaged part of the car paint, and fill it with putty. Use dry sandpaper 400# to polish the surface of the interface between the putty surface and the car paint until it is smooth and even.

[0136] 2. Make up trachoma:

[0137] Putty to fill trachoma, sandpaper marks. After drying, sand it with 600# dry sandpaper. Remove surface dust, oil stains. And wipe off moisture.

[0138]3. Covering:

[0139] Wear protective equipment, remove the dust and oil stains on the surface being sprayed, and wipe off the water. Use a masking film to cover the area to be sprayed to prevent over-spraying.

[0140] 4. Spray primer:

[0141] Spray 1 layer of primer at a distance of 15-20 cm. (Room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com