Release film special for MLCC and preparation method

A technology of release film and silicone oil, which is applied in the direction of coating, etc., can solve the problems affecting the normal production of MLCC, poor aging resistance of release film, low light transmittance, etc., and achieve better practical effect, stable release force, Highly functional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

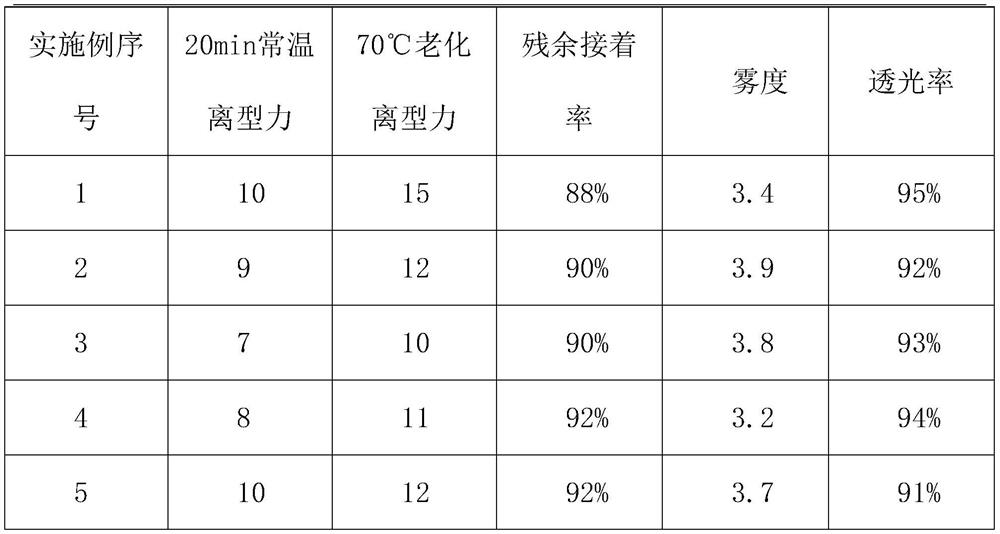

Examples

Embodiment 1

[0024] A special release film for MLCC,

[0025] Specifically, it consists of the following components: 100 parts of vinyl-terminated silicone resin, 1-10 parts of methyl hydrogen-containing silicone oil, 0.3-3 parts of fluorine-containing polysiloxane, 1-5 parts of anchoring agent, 1-5 parts of catalyst, 500-1000 parts of solvent.

[0026] A kind of preparation method of release film special for MLCC,

[0027] Made with the following steps:

[0028] S1. Mix and stir 500 parts by weight of solvent D120 and 100 parts by weight of toluene for 10 minutes, first put in 100 parts by weight of silicone oil SB-01, mix and stir for 10 minutes at 1000 r / min, then put in 5 parts by weight of silicone oil SB-04 and continue stirring for 10 minutes Minutes, then add 2 parts by weight of DB-08, then drop in 2 parts of anchoring agent, continue to stir and drop in 2 parts by weight of platinum catalyst and stir for 10 minutes to prepare a coating solution;

[0029] S2, coating the above-...

Embodiment 2

[0034] A special release film for MLCC,

[0035] Specifically, it consists of the following components: 100 parts of vinyl-terminated silicone resin, 1-10 parts of methyl hydrogen-containing silicone oil, 0.3-3 parts of fluorine-containing polysiloxane, 1-5 parts of anchoring agent, 1-5 parts of catalyst, 500-1000 parts of solvent.

[0036] A kind of preparation method of release film special for MLCC,

[0037] Made with the following steps:

[0038] S1. Mix and stir 500 parts by weight of solvent D120 and 100 parts by weight of toluene for 10 minutes, first put in 100 parts by weight of silicone oil SB-01, mix and stir for 10 minutes at 1000 r / min, then put in 1 part by weight of silicone oil SB-04 and continue stirring for 10 minutes Minutes, then add 0.3 parts by weight of DB-08, then drop in 2 parts of anchoring agent, continue to stir and drop in 2 parts by weight of platinum catalyst and stir for 10 minutes to prepare a coating solution;

[0039] S2, coating the above...

Embodiment 3

[0044] A special release film for MLCC,

[0045] Specifically, it consists of the following components: 100 parts of vinyl-terminated silicone resin, 1-10 parts of methyl hydrogen-containing silicone oil, 0.3-3 parts of fluorine-containing polysiloxane, 1-5 parts of anchoring agent, 1-5 parts of catalyst, 500-1000 parts of solvent.

[0046] A kind of preparation method of release film special for MLCC,

[0047] Made with the following steps:

[0048] S1. Mix and stir 500 parts by weight of solvent D120 and 100 parts by weight of toluene for 10 minutes, first put in 100 parts by weight of silicone oil SB-01, mix and stir for 10 minutes at 1000 r / min, then put in 5 parts by weight of silicone oil SB-04 and continue stirring for 10 minutes Minutes, then add 0.3 parts by weight of DB-08, then drop in 2 parts of anchoring agent, continue to stir and drop in 2 parts by weight of platinum catalyst and stir for 10 minutes to prepare a coating solution;

[0049] S2, coating the abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com