PET release film applied to OCA glue and production process thereof

A production process and release film technology, applied in adhesives, film/sheet adhesives, coatings, etc. Poor flatness and other problems, to achieve the effect of improving leveling, enhancing adhesion, and reducing floating dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

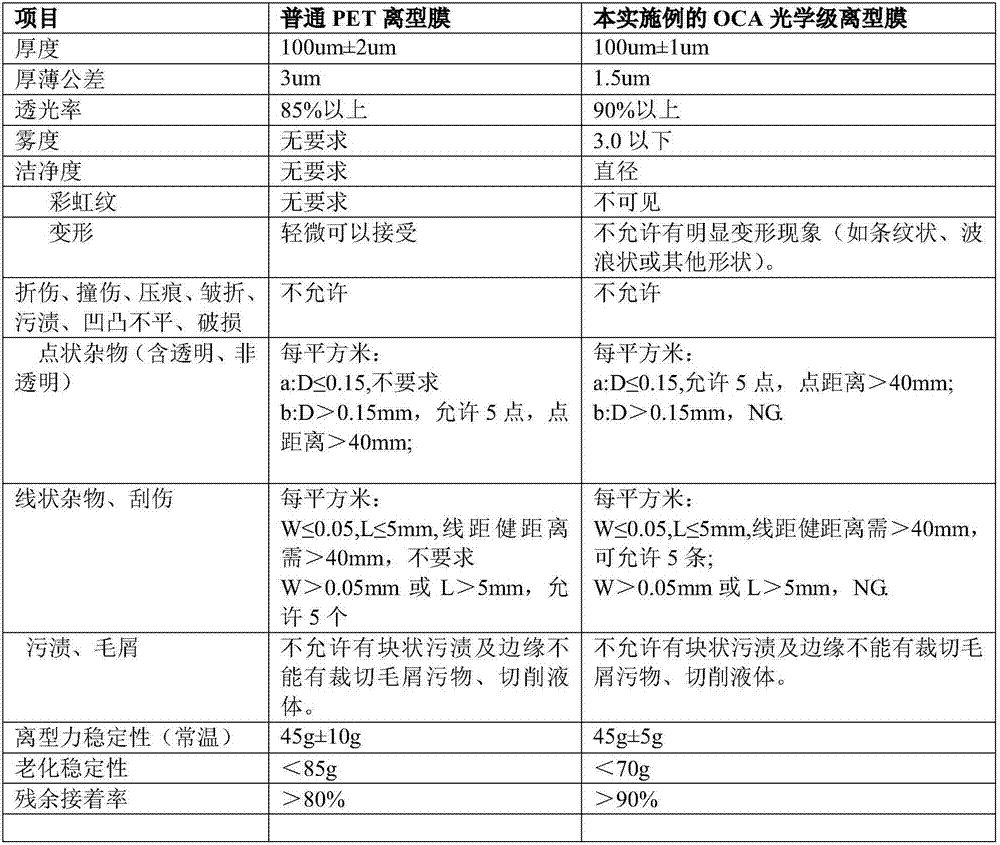

Image

Examples

Embodiment 1

[0020] A PET release film applied to OCA glue, comprising the following components in parts by mass: 3 parts of D120 solvent naphtha, 8 parts of D30 solvent naphtha, 4 parts of butanone, 2 parts of isopropanol, 0.5 parts of silicone oil main agent, 0.6 parts of heavy stripping additive, 0.05 parts of crosslinking agent, 0.01 part of anchoring agent, and 0.02 parts of catalyst.

[0021] The production process of the above-mentioned PET release film applied to OCA glue comprises the following steps:

[0022] 1) Coating configuration Mix D120 solvent oil, D30 solvent oil, methyl ethyl ketone and isopropanol, stir at 1200 rpm for 30 minutes, filter with a 200-mesh filter, and use within 3 hours;

[0023] 2), the original film treatment includes corona treatment and dust removal treatment; the corona value is greater than 50 during the corona treatment, and the gap between any two points is guaranteed to be no more than 5; thereby enhancing the adhesion of the film surface; the Th...

Embodiment 2

[0029] A PET release film applied to OCA glue, comprising the following components in parts by mass: 8 parts of D120 solvent naphtha, 3 parts of D30 solvent naphtha, 8 parts of butanone, 0.5 parts of isopropanol, 2 parts of silicone oil main agent, 0.2 parts of heavy stripping additive, 0.09 parts of crosslinking agent, 0.01 part of anchoring agent, and 0.02 parts of catalyst.

[0030] The production process of the above-mentioned PET release film applied to OCA glue comprises the following steps:

[0031] 1) Coating configuration Mix D120 solvent oil, D30 solvent oil, methyl ethyl ketone and isopropanol, stir at 1200 rpm for 30 minutes, filter with a 200-mesh filter, and use within 3 hours;

[0032] 2), the original film treatment includes corona treatment and dust removal treatment; the corona value is greater than 50 during the corona treatment, and the gap between any two points is guaranteed to be no more than 5; thereby enhancing the adhesion of the film surface; the Th...

Embodiment 3

[0038] A PET release film applied to OCA glue, comprising the following components in parts by mass: 5 parts of D120 solvent naphtha, 5 parts of D30 solvent naphtha, 6 parts of butanone, 1 part of isopropanol, 1 part of silicone oil main agent, 0.4 parts of heavy stripping additive, 0.07 parts of crosslinking agent, 0.01 part of anchoring agent, and 0.02 parts of catalyst.

[0039] The production process of the above-mentioned PET release film applied to OCA glue comprises the following steps:

[0040] 1) Coating configuration Mix D120 solvent oil, D30 solvent oil, methyl ethyl ketone and isopropanol, stir at 1200 rpm for 30 minutes, filter with a 200-mesh filter, and use within 3 hours;

[0041] 2), the original film treatment includes corona treatment and dust removal treatment; the corona value is greater than 50 during the corona treatment, and the gap between any two points is guaranteed to be no more than 5; thereby enhancing the adhesion of the film surface; the The du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com