Amorphous PET release film as silica gel roll protective film and production technology of amorphous PET release film

A production process and protective film technology, applied in the field of non-silicon PET release film production process, can solve the problems of immature process, monopoly of non-silicon PET release film, damage to the physical and chemical properties of silicone rollers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

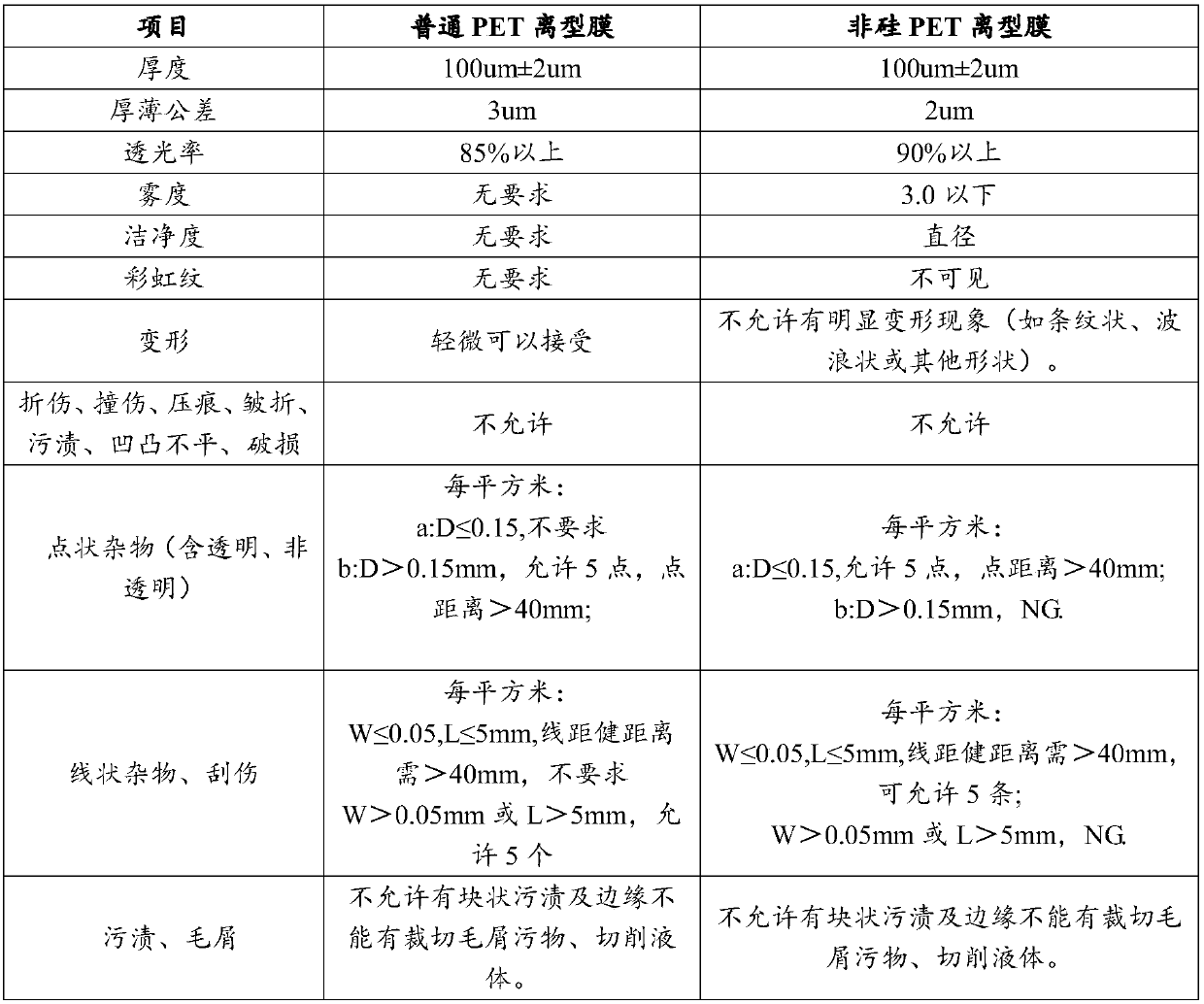

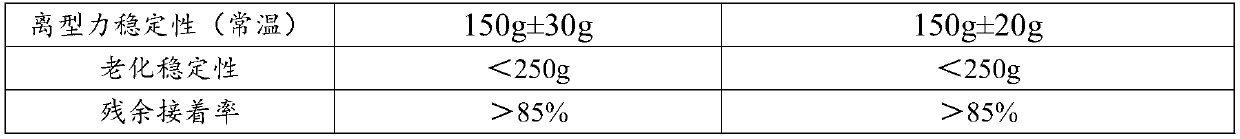

Image

Examples

Embodiment 1

[0025] A non-silicon PET release film used as a protective film for a silica gel roller, comprising a PET base film, one surface of the PET base film is provided with a functional coating layer.

[0026] The functional coating layer includes in parts by weight: 3 parts of D120 solvent naphtha, 8 parts of D30 solvent naphtha, 4 parts of butanone, 2 parts of isopropanol, 0.5 parts of non-silicon release agent, 0.45 parts of toluene, 0.6 parts of heavy release additive, 0.05 part of crosslinking agent, 0.01 part of anchoring agent, and 0.02 part of catalyst.

Embodiment 2

[0028] A non-silicon PET release film used as a protective film for a silica gel roller, comprising a PET base film, one surface of the PET base film is provided with a functional coating layer.

[0029] The functional coating layer includes in parts by weight: 3 parts of D120 solvent naphtha, 8 parts of D30 solvent naphtha, 4 parts of butanone, 2 parts of isopropanol, 0.5 parts of non-silicon release agent, 0.45 parts of toluene, 0.6 parts of heavy release additive, 0.05 part of crosslinking agent, 0.01 part of anchoring agent, and 0.02 part of catalyst.

Embodiment 3

[0031] A non-silicon PET release film used as a protective film for a silica gel roller, comprising a PET base film, one surface of the PET base film is provided with a functional coating layer.

[0032] The functional coating layer includes in parts by weight: 5 parts of D120 solvent naphtha, 5 parts of D30 solvent naphtha, 6 parts of butanone, 1 part of isopropanol, 1 part of silicone oil main agent, 0.4 part of heavy stripping additive, 0.07 part of crosslinking agent, Anchoring agent 0.01 part, catalyst 0.02 part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com