High ridge plastic film mulching machine

A mulching and mechanical technology, applied in the direction of plant protection cover, etc., can solve the problems of difficult operation, smooth operation, increased buried pressure, complex geometry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

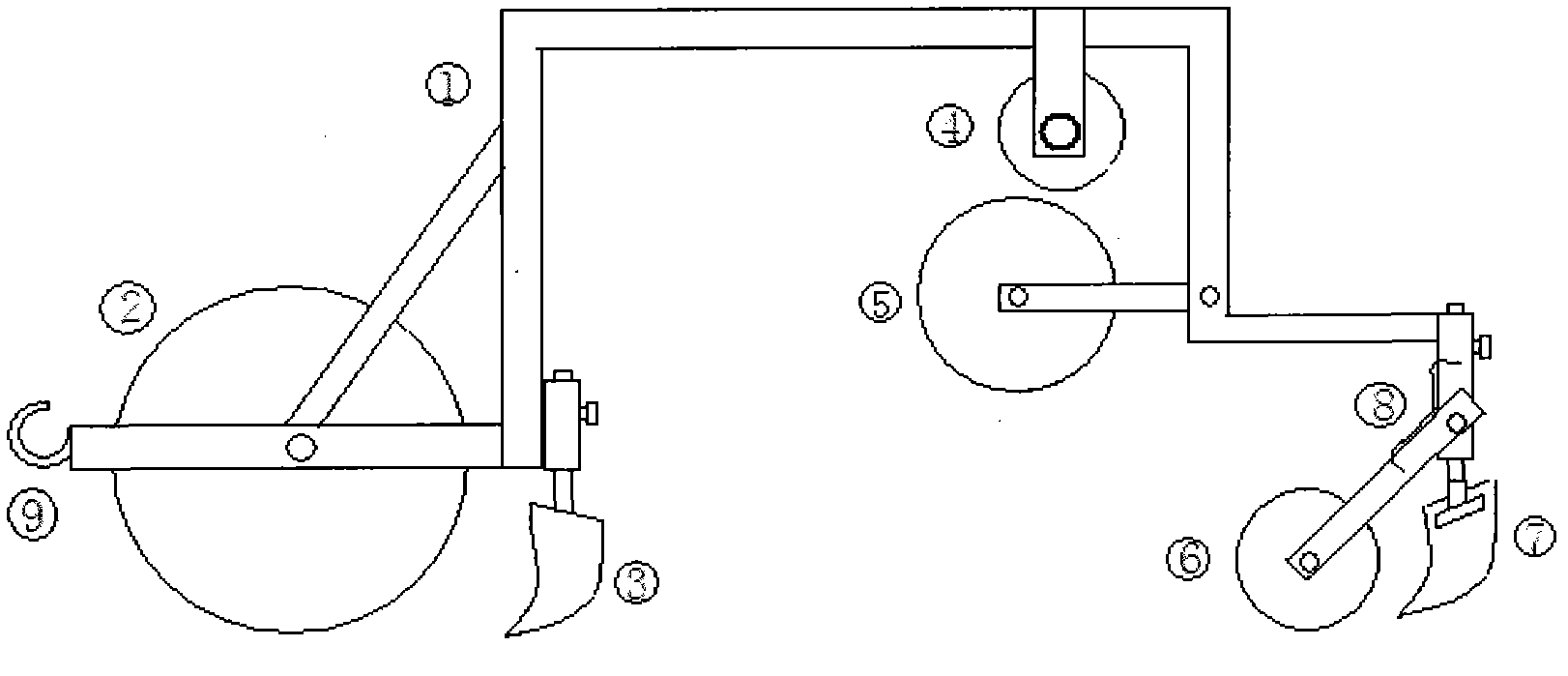

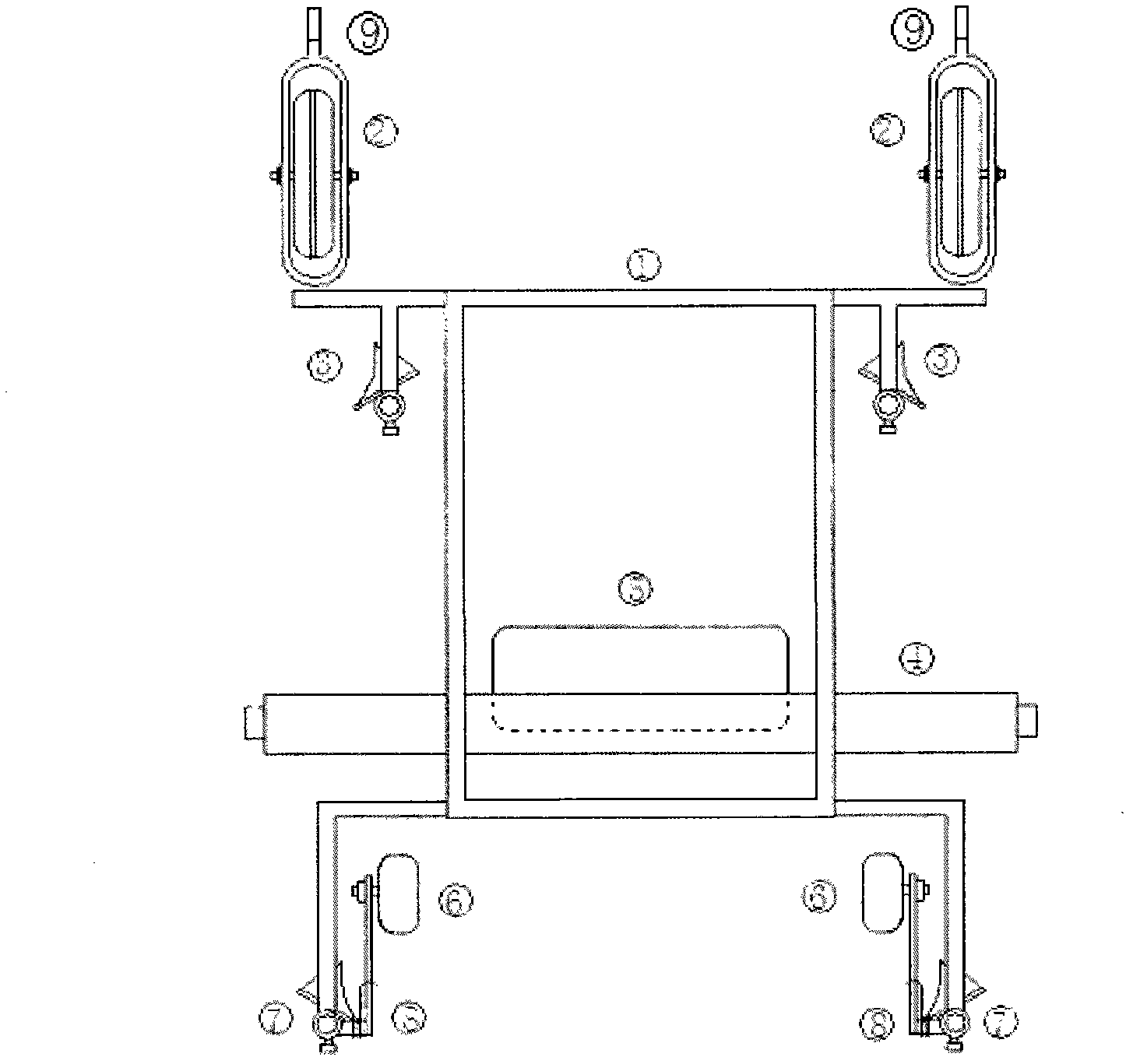

[0014] figure 1 with figure 2 Shown in is the structural form of the present invention and the positional relationship of each component.

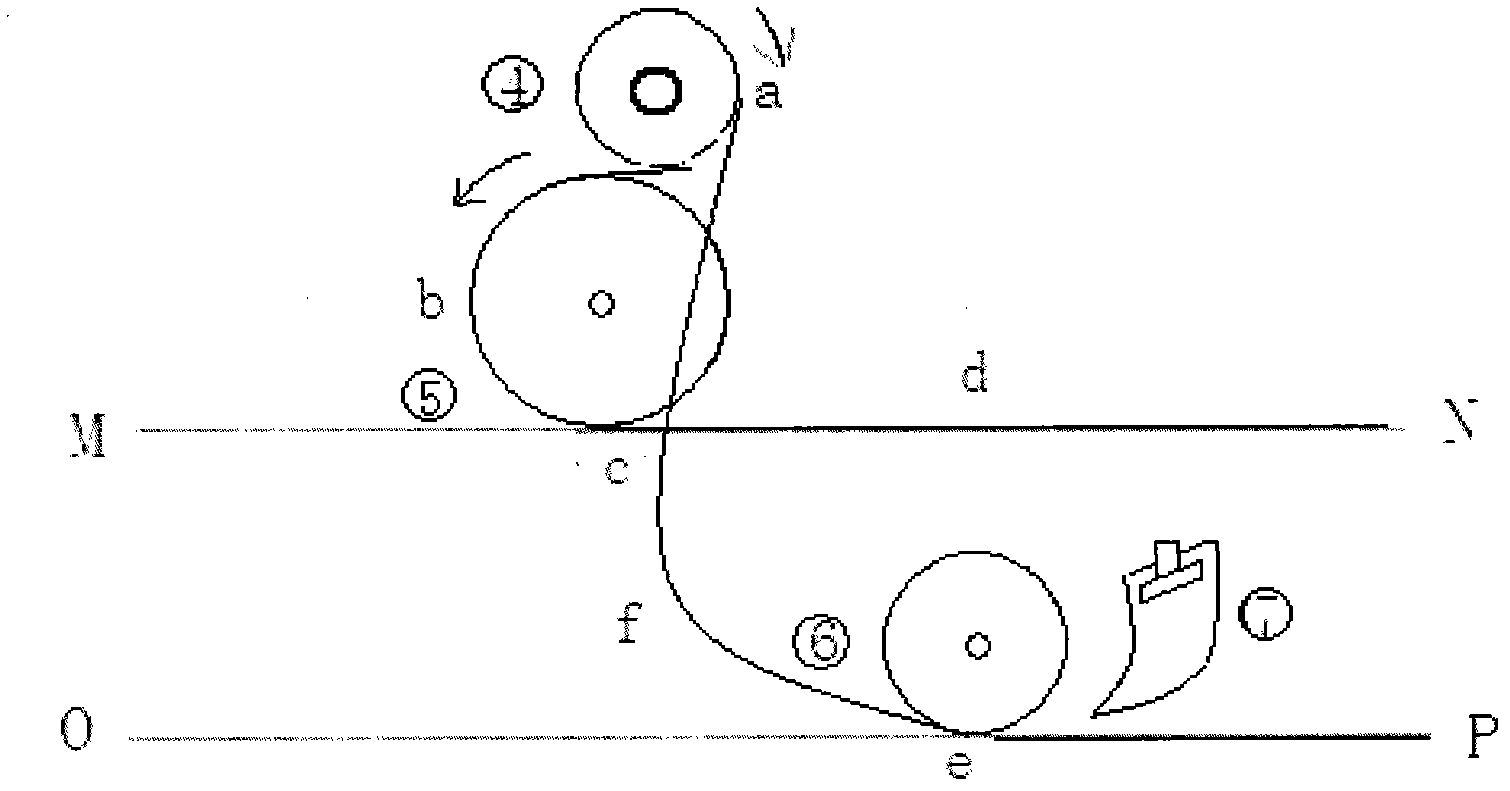

[0015] Hang the mulch film roll on the film support ④, with the end of the mulch film facing down and facing forward (see image 3 ), pull out the end, go from top to front and then down through point a, b, c, bypass the stretching roller ⑤ and pull it back to point d, extend to both sides in the middle, press the two sides along the sides of the ridge body, The two edges are attached to the furrows, and the film pressing wheel ⑥ is lifted to tuck in the two corners of the end of the mulch film, and the end of the mulching film is pressed firmly when the film pressing wheel is put down. Apply forward pulling force to the traction hook ⑨, and the traction main frame ① will drive all the mechanisms forward. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com