Patents

Literature

30results about How to "Uniform covering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

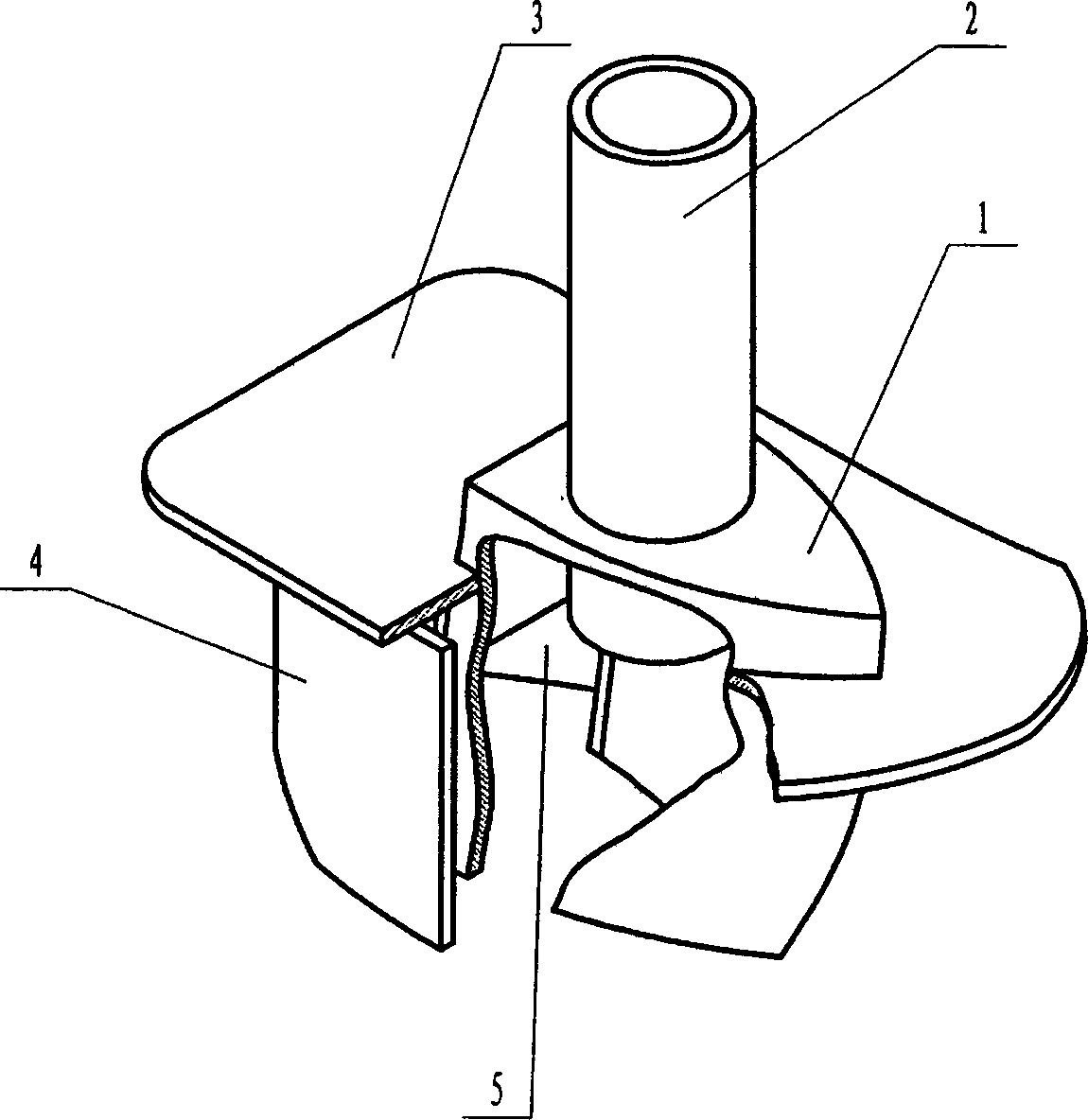

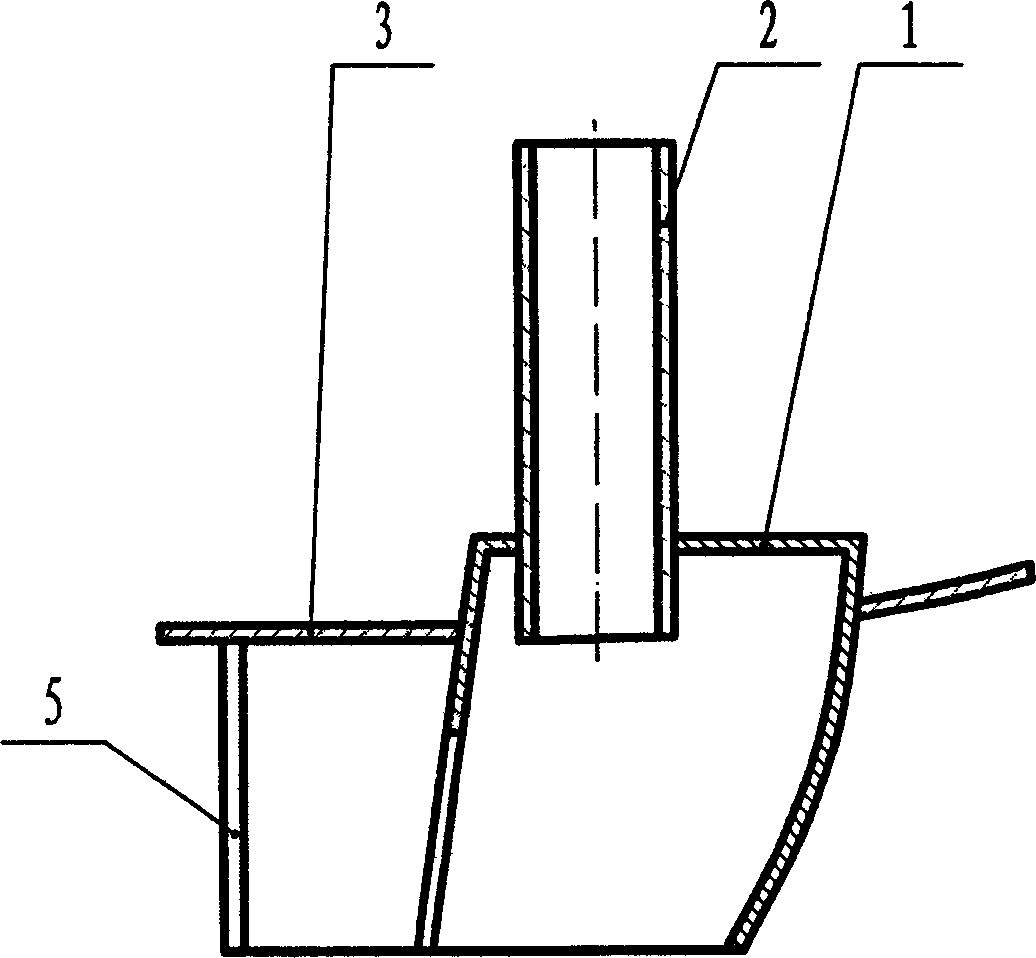

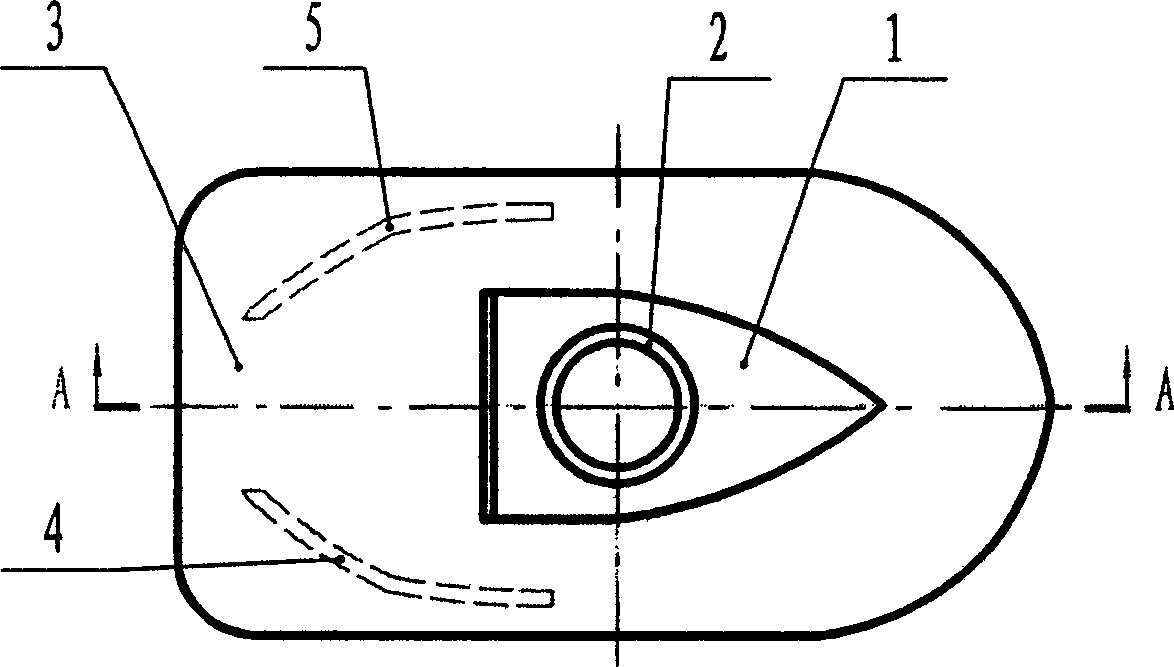

Ship-type deep-fertilizing furrow opener

InactiveCN1742532AReduce Waterlogging ProblemsUniform coveringPlantingFurrow making/coveringEngineeringPaddy field

The present invention discloses a boat type furrow opener. The upper portion of furrow opener body is closed, front breast form of furrow opener body along furrow-opening direction is front portion of said boat body, left and right two sides are symmetrically crossed in the intermediate blade edge, said blade edge is inclined backward from top to bottom, the upper portion of the furrow opener body is equipped with a spacing plate. Besides, said furrow opener also is equipped with soil-covering plate, fertilizer and fertilizer-discharging tube, etc. Said boat-type furrow opener mainly is used for deep fertilizer application in paddy field.

Owner:ZHEJIANG SCI-TECH UNIV

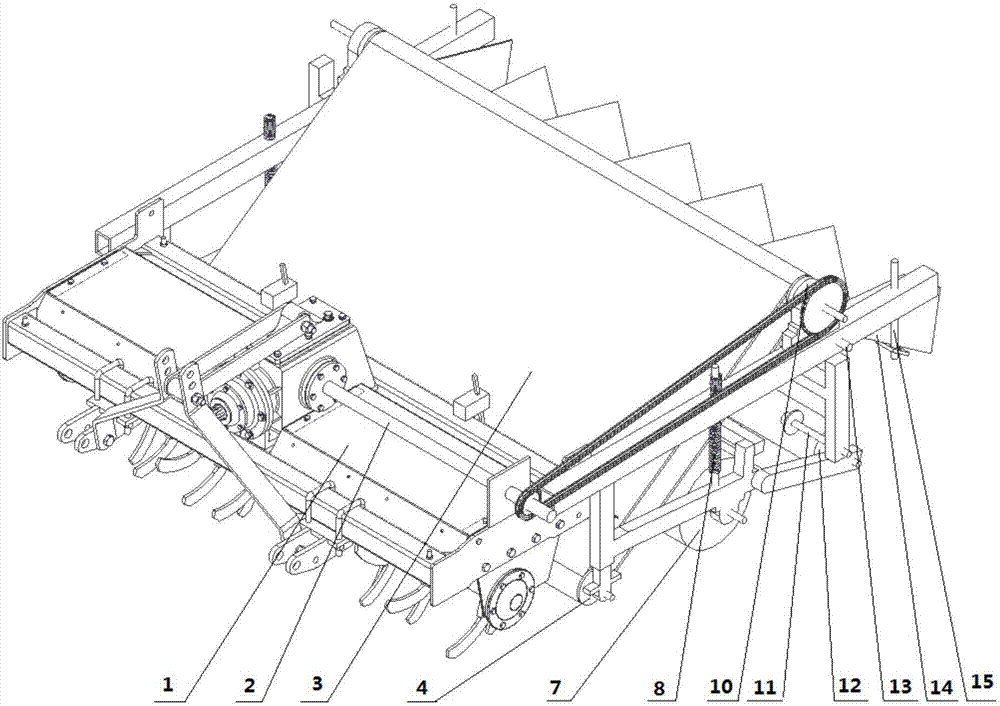

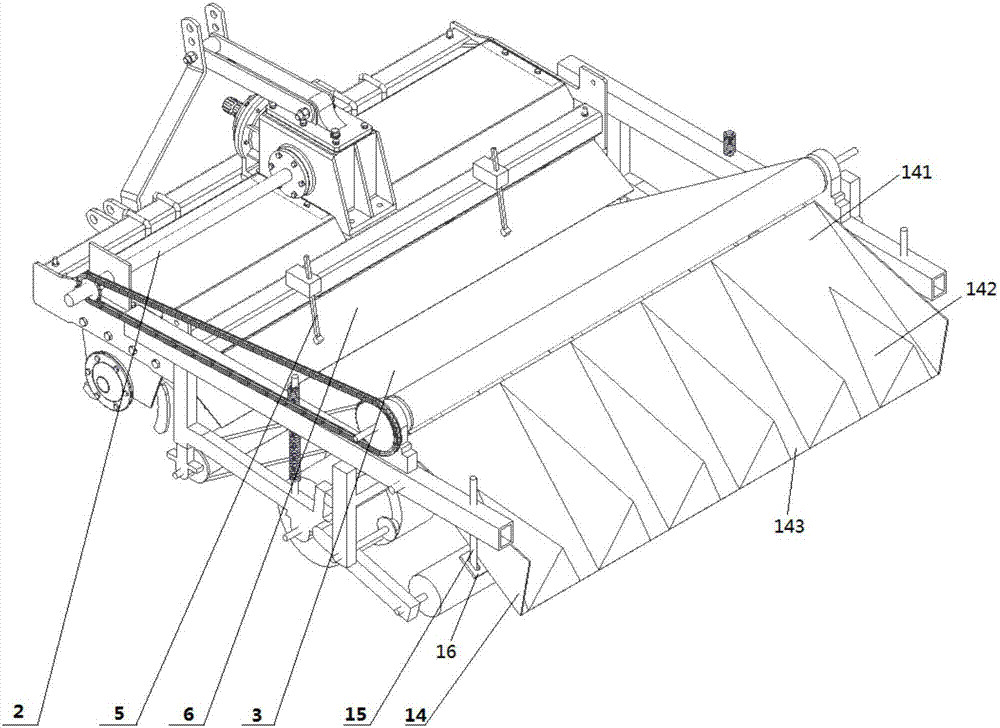

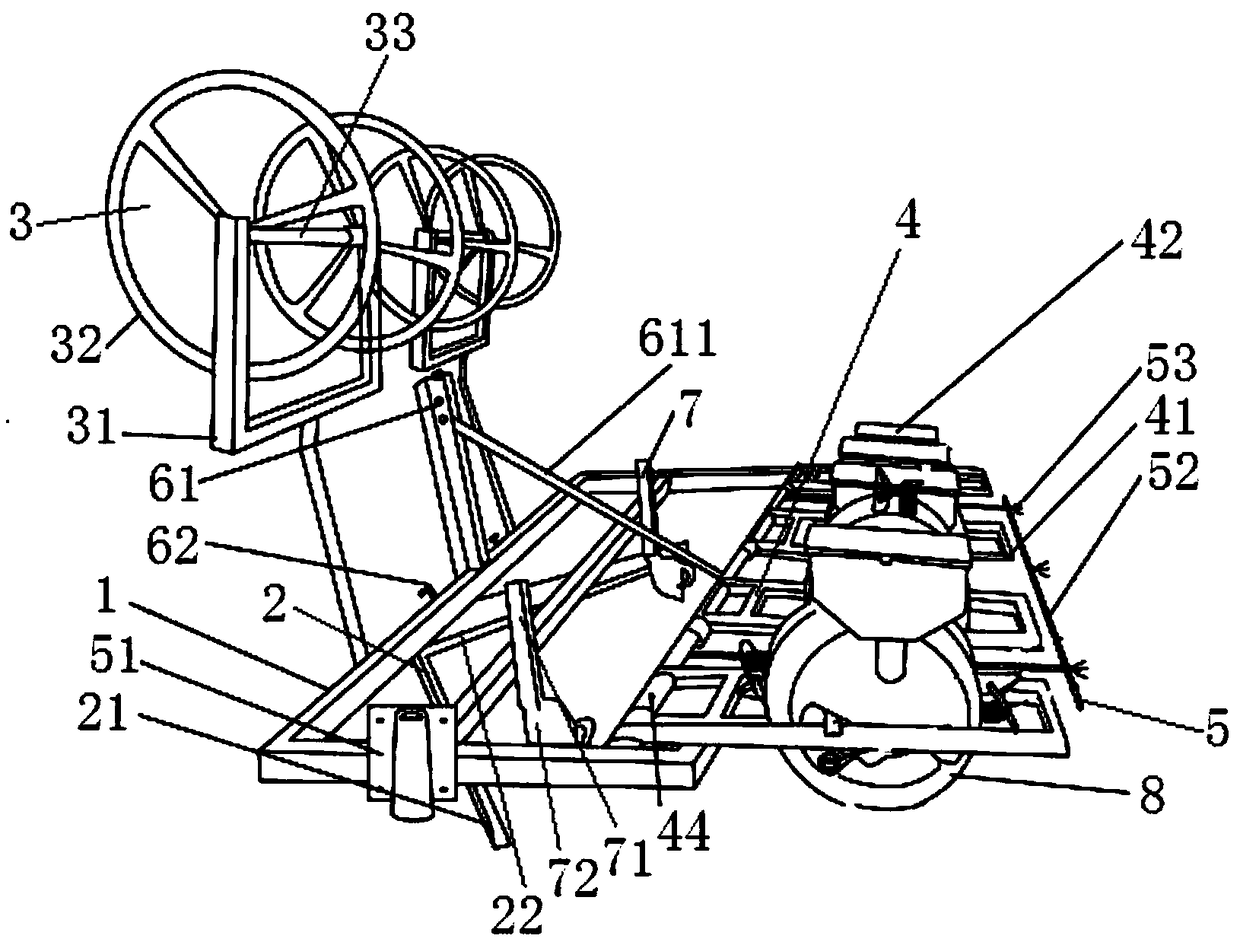

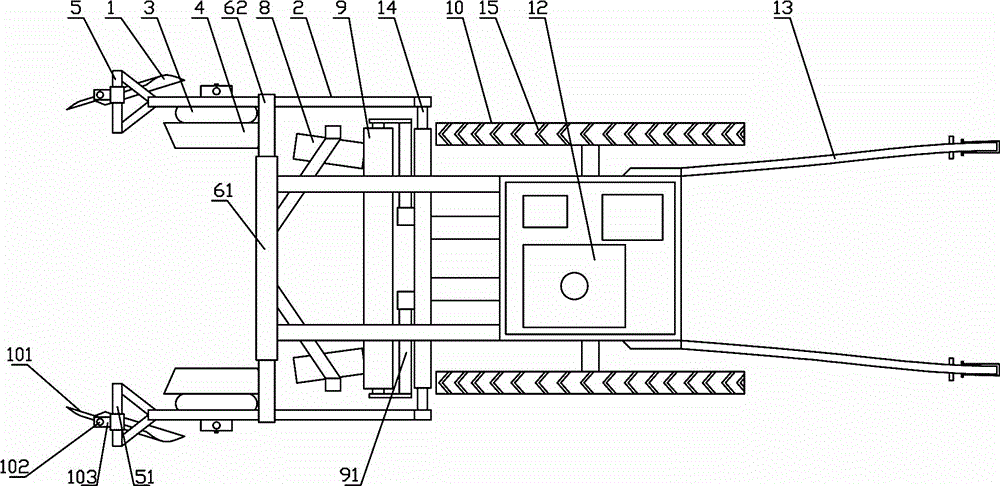

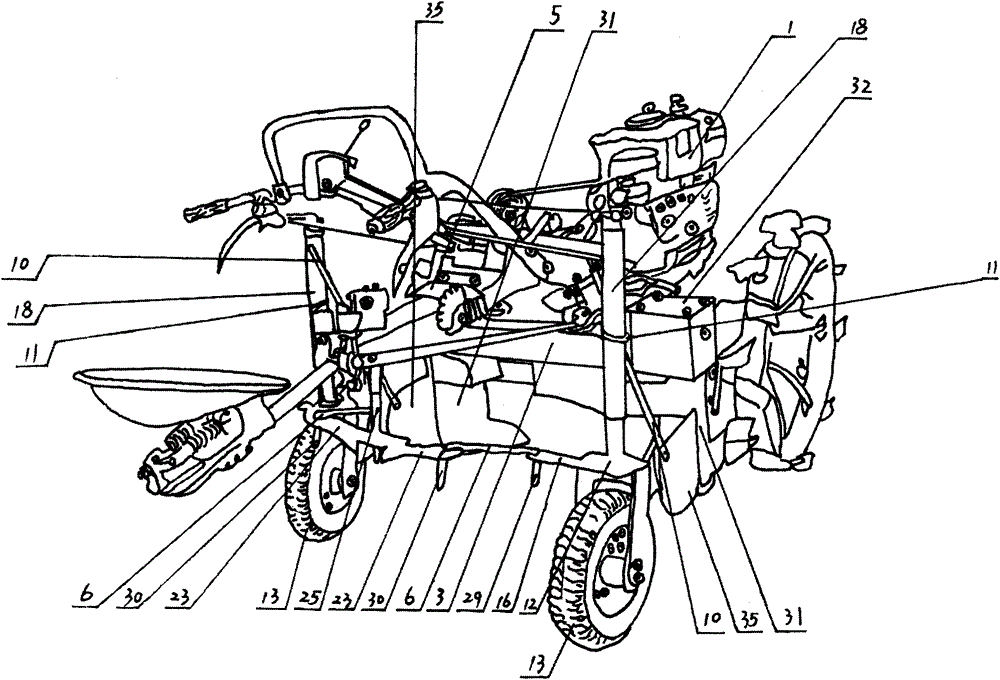

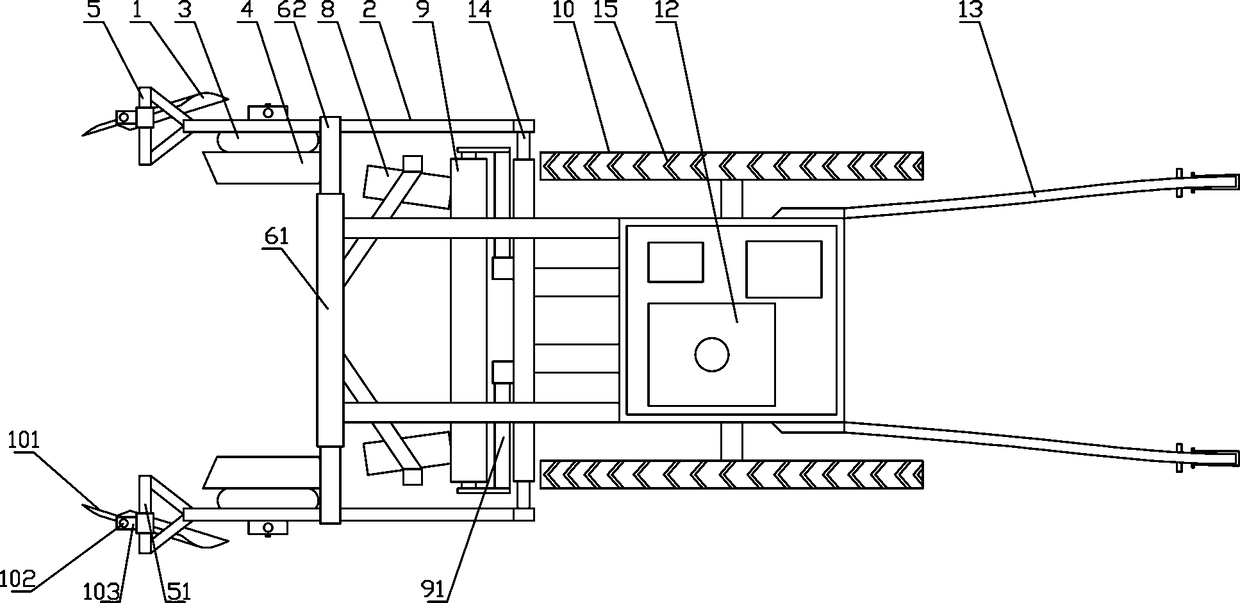

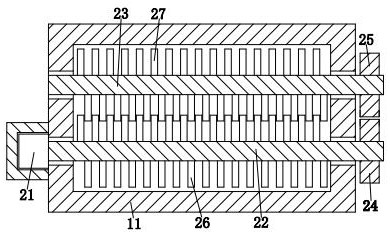

Rice-seed-film-mulching and direct-sowing machine

InactiveCN107027357AEliminate dangling phenomenonGuaranteed outputSpadesPloughsAgricultural engineeringAdemetionine

The invention provides a rice-seed-film-mulching and direct-sowing machine and belongs to the technical field of agricultural machines. The machine includes a machine frame, a rotary tillage soil crushing device, a press roller, a covering soil transmission device, a shunt guiding device and a seed film mulching device; the rotary tillage soil crushing device, the press roller and the seed film mulching device are arranged below the machine frame in sequence, and the rotary tillage soil crushing device is arranged below the working front end of the machine frame and used for rotary tillage of soil; the seed film mulching device is arranged below the working rear end of the machine frame, the shunt guiding device is arranged above the machine frame, the covering soil transmission device is obliquely arranged on the portion, located between the rotary tillage soil crushing device and the seed film mulching device, of the machine frame, and after rotary tillage is conducted by the rotary tillage soil crushing device, the soil is thrown to the covering soil transmission device and falls off from a mulching film through the covering soil shunt guiding device; the press roller is located below the covering soil transmission device; when the machine is in work, a film press roller of the seed film mulching device presses against the seed film, and the soil falling off through the covering soil shunt guiding device covers a seed belt of the seed film. The machine eliminates the phenomenon of seed film hanging, soil covering is centralizedly and evenly conducted, and the seedling emergence rate and the grain yield are guaranteed.

Owner:灯塔市大河南镇新光农机专业合作社 +1

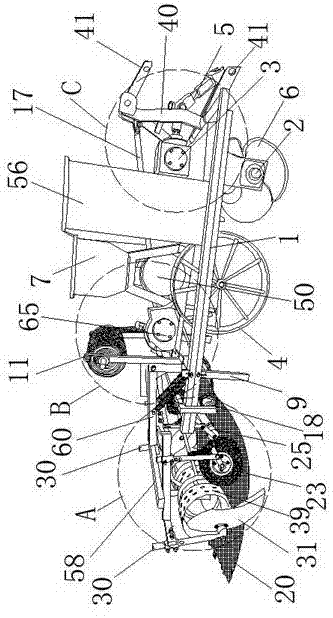

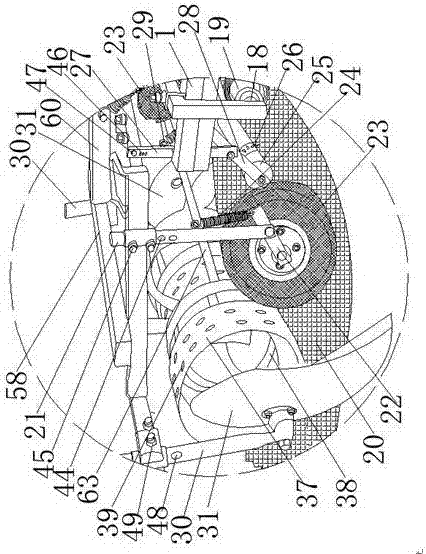

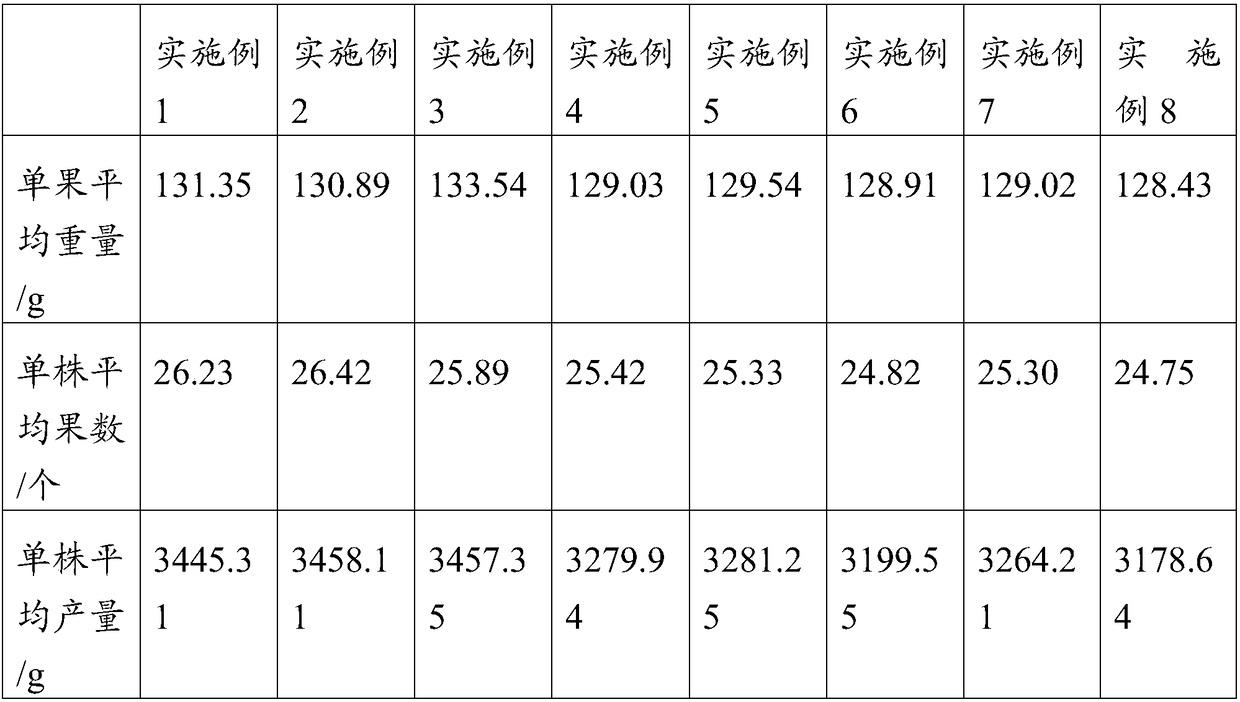

Multi-functional peanut seeder and summer-peanut disaster reducing and efficiency improving cultivation method using multi-functional peanut seeder

ActiveCN107182318AEasy to adjustImprove soil loosening efficiencySpadesWatering devicesSeederPunching

The invention discloses a multi-functional peanut seeder and a summer-peanut disaster reducing and efficiency improving cultivation method using the multi-functional peanut seeder. The multi-functional peanut seeder includes a tractor and a rack which is mounted at the rear end of the tractor, wherein a soil loosening device, a fertilizer laying device, a ridging device, a seeding apparatus, a seed coating agent spraying device, a seed burying device, a water hose laying device, a herbicide spraying device, a film mulching device, a perforating device and an earthing device are successively arranged on the rack from front to rear. The summer-peanut disaster reducing and efficiency improving cultivation method includes the steps of cleaning stubble in a race against time, loosening the soil, laying fertilizer, conducting ridging, conducting seeding, spraying seed coating agents, burying seeds, laying water hoses, spraying herbicide, conducting film mulching, punching and earthing, and conducting drip irrigation under mulch. The multi-functional peanut seeder and the summer-peanut disaster reducing and efficiency improving cultivation method using the multi-functional peanut seeder have the advantages of auto slotting, reducing the input of the human body, and reducing the labor intensity.

Owner:高唐县润丰粮食种植专业合作社 +1

Soil covering device for strawberry planting

ActiveCN112616368AEasy to cover with soilReduce utilizationPlantingSoil-working equipmentsFragariaAgricultural engineering

The invention provides a soil covering device for strawberry planting. The soil covering device comprises a machine frame, a smashing unit and a paving and filling unit, and is characterized in that a feeding port is formed in the upper end of the machine frame, the smashing unit is installed on the inner wall of the machine frame, and the paving and filling unit is arranged on the outer wall of the right end of the machine frame. The soil covering device can solve the problems that soil paving and filling is carried out on most of existing strawberry seedlings in a manual soil covering mode in the planting process, but soil blocks inside soil cannot be completely smashed through manual soil covering, so that a better covering effect cannot be achieved, consequently the utilization rate of the soil is decreased, in addition, the strawberry seedlings are easily smashed by the soil blocks in the paving and filling process, then the cost is wasted, in addition, the uniformity of the paved and filled soil cannot be effectively controlled by manual operation, so that the survival rate of the strawberry seedlings is easily decreased, in addition, the seedlings need to be supplemented, the workload is increased, in addition, the labor cost is wasted, and the like.

Owner:FUYANG HONGFU AGRI SCI & TECH CO LTD

Precision seeder

The invention provides a precision seeder which comprises a stand and a seeding mechanism arranged on the stand, wherein the seeding mechanism comprises a seeding bracket, a seed box and a seeding wheel; the seeding wheel comprises an outer wheel body and an inner machine body; seed discharging ports are uniformly formed in the outer side circumferential surface of the outer wheel body; a seed catching slot is formed in the inner side circumference; one side of the seed catching slot is provided with a spiral-shaped seed storage box communicated with the seed discharging ports; a plurality ofcams are arranged in the center of the outer wheel body; driving wheels matched with the cams are arranged on the inner machine body; a plurality of seed vortexes are arranged on the circumference ofa seed discharging wheel on the inner machine body; each seed vortex only accommodates one seed. According to the precision seeder, the seed discharging wheel provided with the seed vortexes and a brush are arranged on the inner machine body, and the spiral-shaped seed storage box is arranged on the outer wheel body, so that when the cams and the driving wheels are matched, one seed is precisely seeded via the spiral-shaped seed storage box through the seed discharging ports; the phenomenon of ridge breakage during seeding of the existing seeder is avoided; waste of seeds is reduced; the unnecessary economical loss is reduced.

Owner:杨秀国

Cultivating method of ornamental bamboo seedlings

The invention discloses a cultivating method of ornamental bamboo seedlings. The cultivating method comprises the following steps: (A) pretreating seeds; (B) preparing a medium; (C) leveling a seedling bed; (D) carrying out seeding and soil covering; (E) carrying out nursery management; (F) transplanting bamboo seedlings; and (G) nourishing, managing and protecting the bamboo seedlings. Through the adoption of the method, the bamboo seedlings can be cultivated on a large scale by using bamboo seeds, and the germination rate and the transplanting survival rate are both high.

Owner:XINYANG AGRI & FORESTRY UNIV

Film mulching and soil covering dry farming method for rice in cold region

InactiveCN108142232ASave seedlingsOmit transplantingPlant protective coveringsRice cultivationWater savingPlant disease

The invention provides a film mulching and soil covering dry farming method for rice in a cold region. The method comprises the following steps: (1) soil preparation stage before seed sowing: carryingout autumn soil preparation on the to-be-sowed ground and carrying out one-turning-two-rotating or deep-loosening-two-rotating so that the to-be-sowed ground is flat, soil blocks are fine and brokenand the ground is in a to-be-sowed state; (2) film mulching: adhering rice seeds to fertilizers by using environmentally friendly glue on a biodegradable film and then storing the film for mulching; (3) film mulching and soil covering: applying a seed fertilizer and a base fertilizer into soil of the to-be-sowed ground, laying the biodegradable film adhered with the rice seeds in step (2) on the ground, covering the film with soil and then pressing to ensure soil moisture content of the soil and early emergence; and (4) after management: carrying out leaf fertilizer application management, disease management, insect management and water replenishing management after sowing the seeds and before harvesting, and then harvesting the rice. The method is water-saving, labor-saving, environmentally friendly, economical and simple, meanwhile, complicated and difficult links of seedling culture, rice transplanting, weeding and the like are omitted, and a planting procedure is simplified reasonably.

Owner:佳木斯高坤农业科技发展有限公司

Slow-release, anti-drought and salt-tolerant lawn paper and preparation method thereof

InactiveCN101871188ADegradable water absorptionImprove moisture conditionsPlant growth regulatorsBiocideFertilizerNutrient

The invention discloses slow-release, anti-drought and salt-tolerant lawn paper and a preparation method thereof. The method is characterized by comprising the following steps: using plant straws as main materials, processing the plant straws into gel through modification and ultrasonic treatment; adding nutrient solution into the gel for soaking to prepare nutrient absorbent resin, spraying the nutrient absorbent resin to paper, covering a layer of cotton pulp soft paper and drying, thereby obtaining the slow-release, anti-drought and salt-tolerant lawn paper. The lawn paper is suitable for any kind of soil, and can reduce the grass planting workload and also the conventional cumbersome process with soil fertilizers. The operation is simple, and the lawn paper is breathable and water-permeable and can not be bonded with the foundation. When the lawn paper is used, the grass planting environment is acidic with good ventilation, nutrients needed in each growth stage of the grass can be released slowly, and the grass with thick and strong roots can be obtained. Therefore, the lawn paper is suitable for growth of roof greening plants, lawn greening plants, greening plants for the saline-alkali soil and the like.

Owner:刘利军

Method for planting photinia fraseri dress

InactiveCN108476846AEfficient preparationEasy to observe workSeed and root treatmentGrowth substratesPhotinia fraseriSurvival rate

The invention discloses a method for planting photinia fraseri dress. The method comprises the following steps of (A) seed pretreatment; (B) substrate preparation; (C) seedbed leveling; (D) sowing andearthing; (E) nursery management; (F) sapling transplanting; (G) sampling raising, management and protection. According to the method for cultivating and planting the photinia fraseri dress, the germination rate of seeds is 97.8%, the germinative force is 96.5%, 30 days after germination, the survival rate reaches up to 98.9%, three months after sowing, the number of the photinia fraseri dress seedlings with 90%-110% of average seedling height accounts for 90.3% of the total number of the photinia fraseri dress, and the number of the photinia fraseri dress seedlings with 90%-110% of average ground diameter accounts for 96.3% of the total number of the photinia fraseri dress.

Owner:XINYANG AGRI & FORESTRY UNIV

Genetic breeding method of oil-tea camellia

InactiveCN108377902AEfficient preparationEasy to observe workCultivating equipmentsPlant genotype modificationCamellia oleiferaLoment

The invention discloses a genetic breeding method of oil-tea camellia. The genetic breeding method comprises the following steps: (A) collecting oil-tea camellia pollen of the oil-tea camellia in theXinyang prefecture at a full-bloom stage; after naturally drying, preserving at 4 DEG C; standing for 1 to 2h under a room-temperature condition before pollination; preparing the oil-tea camellia pollen and ultrapure water according to the mass ratio of 1 to (500 to 1000) to obtain oil-tea camellia pollen liquid; then spraying the oil-tea camellia pollen liquid on female plants of the oil-tea camellia in the south of Hunan for 2 to 4 times, wherein the time interval of each time of spraying is 3 to 5 days; fertilizing according to fertilization conditions of a land of the pollinated female plants; after fruits become ripe, collecting fruits to obtain hybridized oil-tea camellia seeds and pre-treating the hybridized seeds; (B) preparing a base material; (C) flattening a seedling bed; (D) sowing the seeds and coverings oil; (E) managing a nursery garden; (F) transplanting tree seedlings; (G) fostering, managing and protecting the tree seedlings. By adopting the genetic breeding method ofthe oil-tea camellia, an oil-tea camellia variety applicable to the regions in the south of Hunan can resist accidental low-temperature weathers and the survival rate of oil-tea camellia seedlings isimproved.

Owner:XINYANG AGRI & FORESTRY UNIV

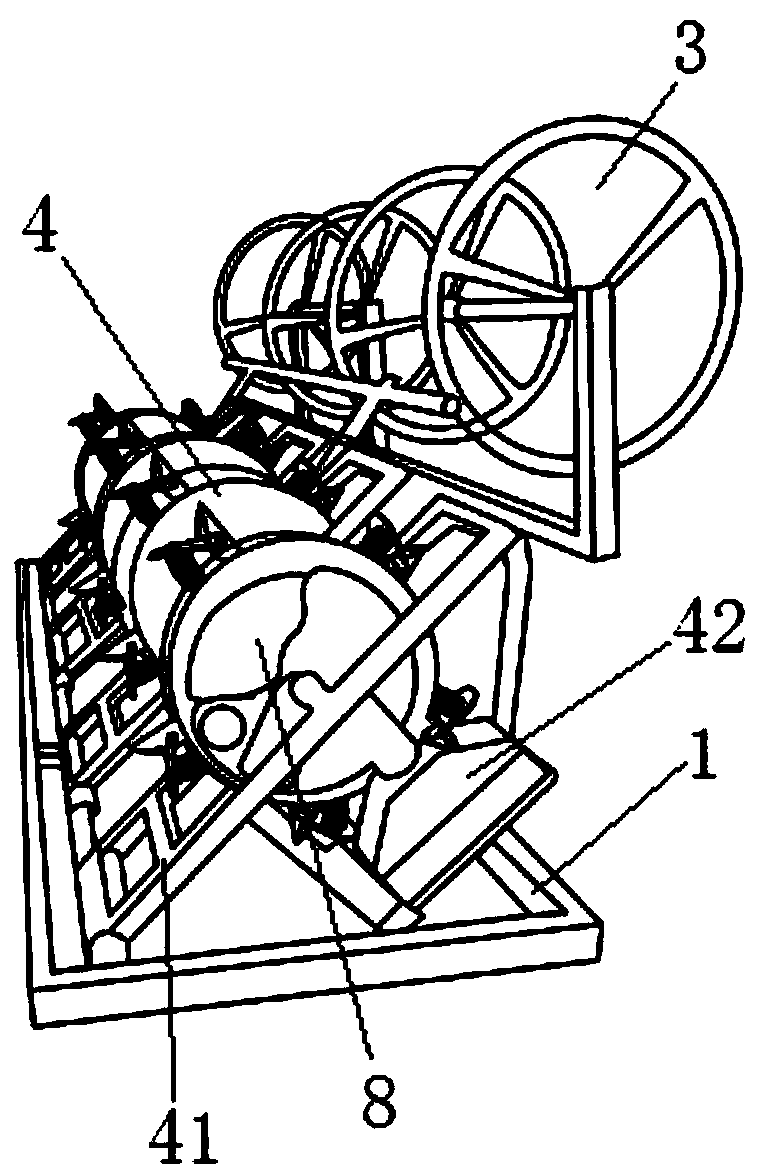

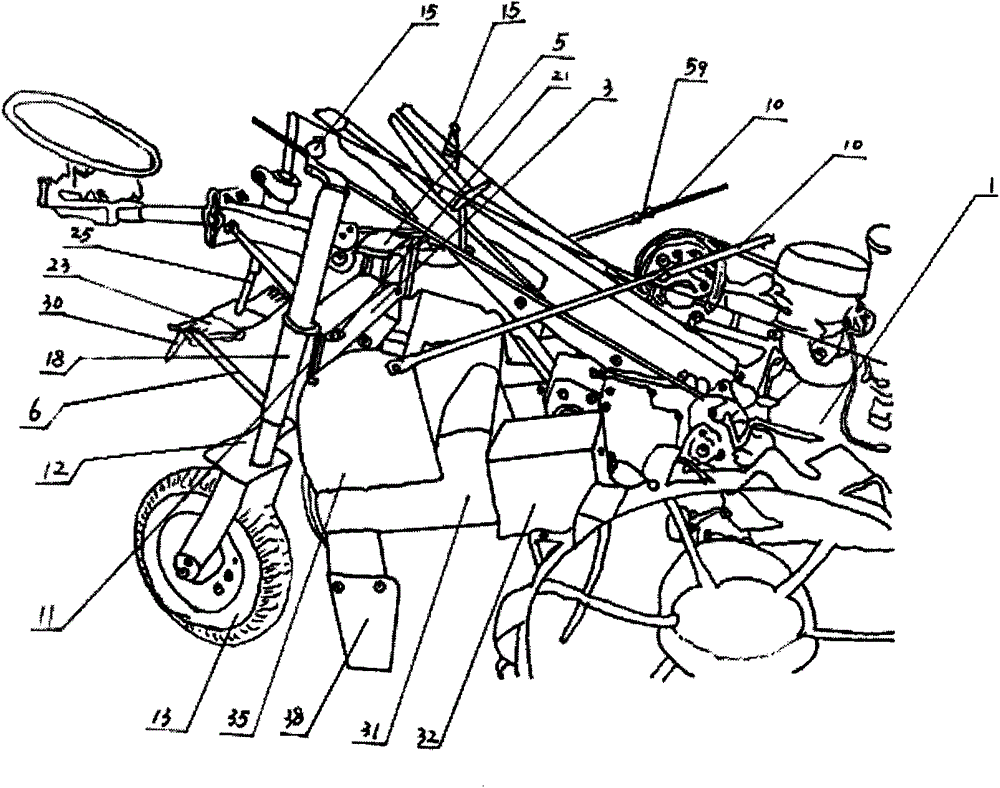

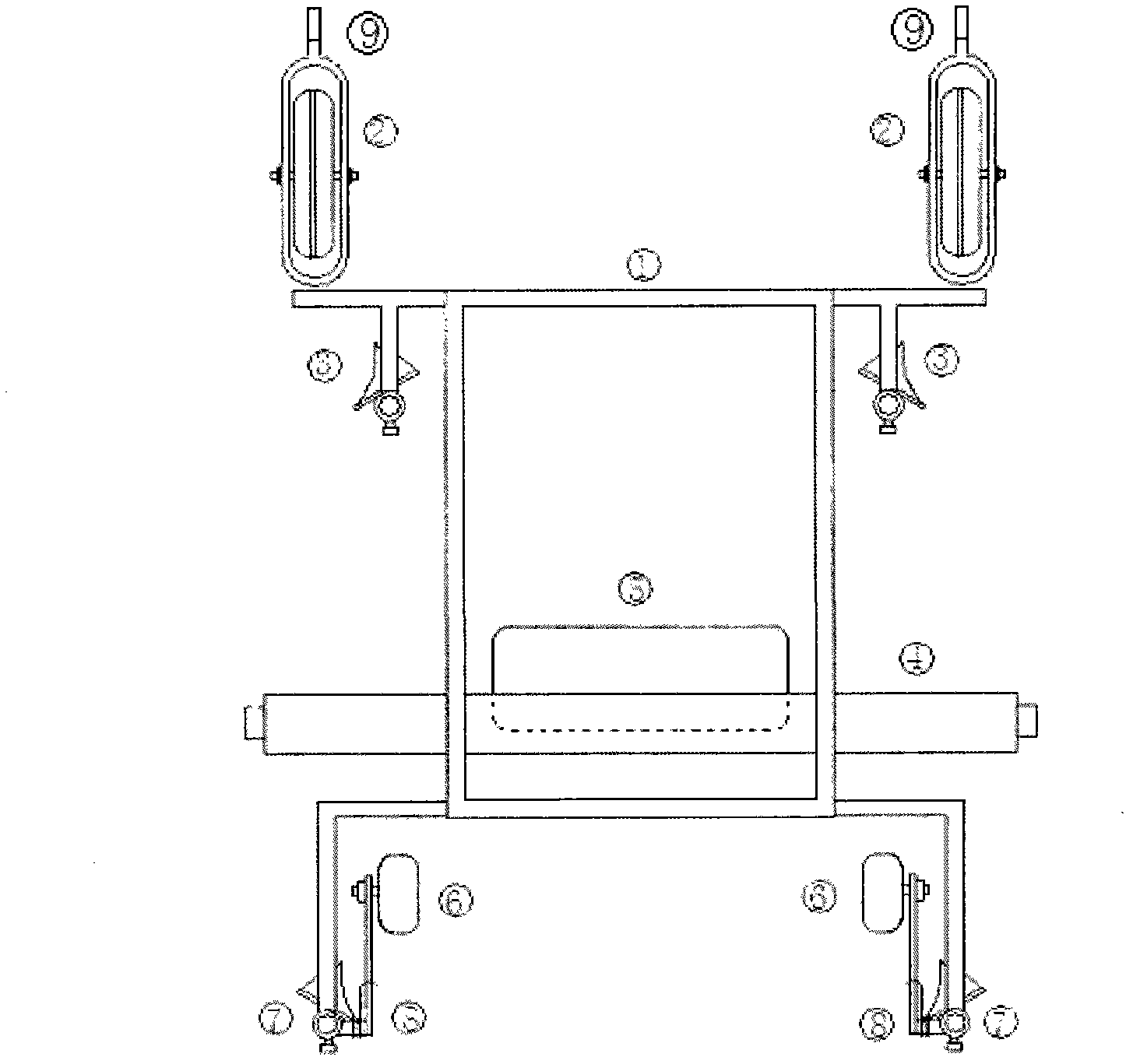

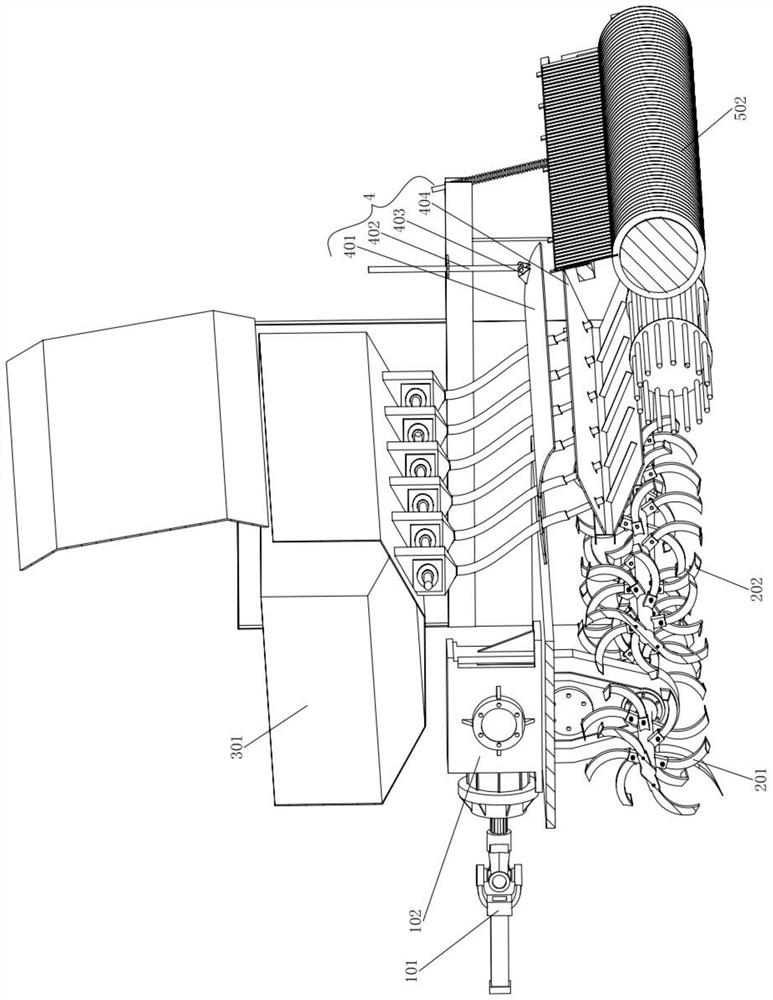

Micro-ridge full film-mulching and banking machine

InactiveCN105766103AFacilitate large-scale cultivationHigh degree of mechanizationSpadesPlantingAgricultural scienceAgricultural engineering

The present invention relates to the field of agricultural machinery, in particular to a micro-ridge full film-mulching and banking machine which is high in mechanization degree and sets rotary tillage-performing, micro-ridge-performing, film-mulching, banking and film-pricking functions in one machine. The micro-ridge full film-mulching and banking machine includes a body frame, a suspension bracket, a differential case, a rotary tillage mechanism, a film-mulching mechanism and a banking mechanism; a left chain wheel and a right chain wheel are arranged on the differential case, the rotary tillage mechanism is arranged at the front bottom of the body frame, the rotary tillage mechanism includes a rotary cultivator and rotary cultivator chain wheels, the banking mechanism is arranged at the middle upper part of the body frame, the film-mulching mechanism is arranged at the rear of the body frame; and the micro-ridge full film-mulching and banking machine also includes a film-pricking mechanism and ditching plows, the film-pricking mechanism is arranged at the rear of the film-mulching machine, and the ditching plows are fixed at the middle lower part of the body frame through a plow frame. The micro-ridge full film-mulching and banking machine is high in mechanization degree, simple in operation, capable of reducing labor intensity, high in work efficiency, standard in ridging, capable of preserving temperature and moisture in the soil, even in banking and capable of harvesting rain and saving water, and micro-ridge planting is convenient for large-scale water-saving cultivation for close planting crops.

Owner:陈万雄

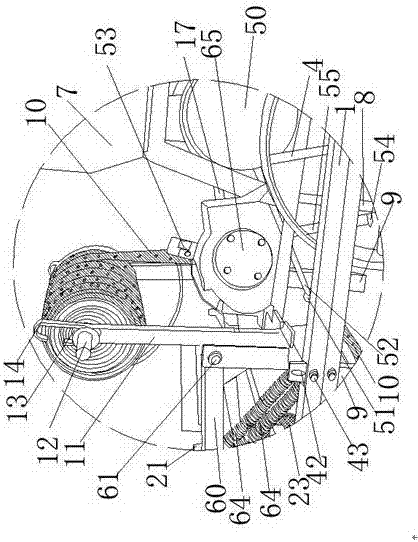

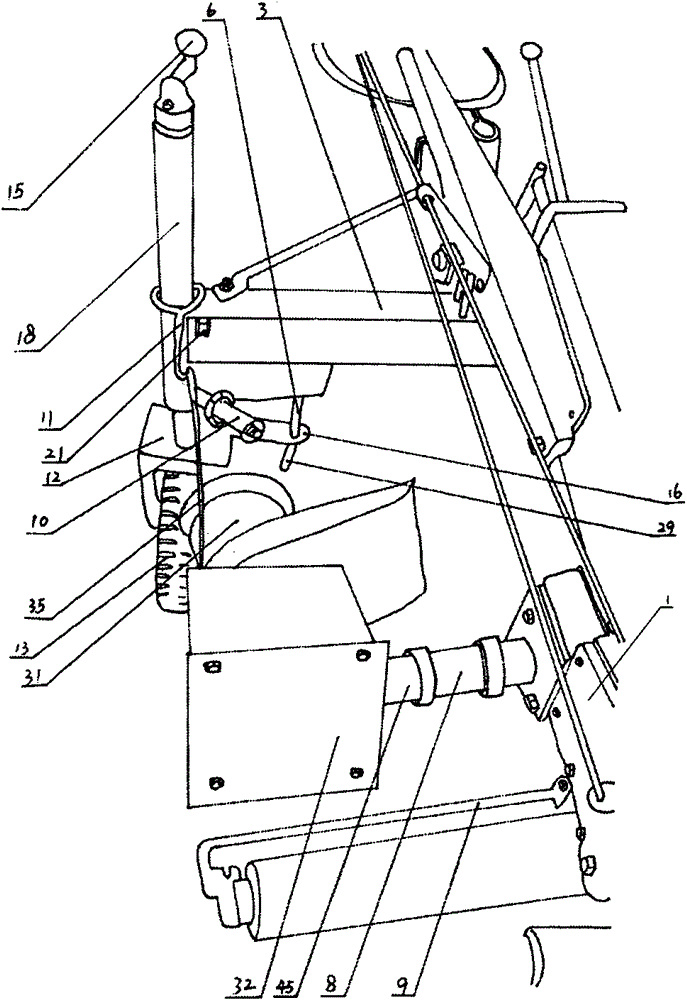

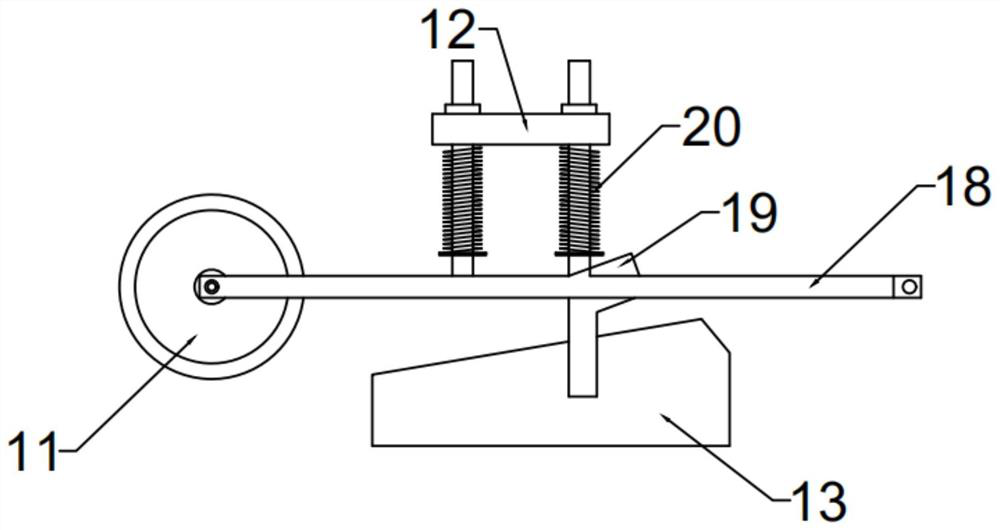

Power-assisted plastic film mulching machine

ActiveCN105284505ALimited working heightUniform coveringPlant protective coveringsAgricultural engineeringPlastic film

The invention discloses a power-assisted plastic film mulching machine. The power-assisted plastic film mulching machine comprises a rack. Travel wheels are arranged on the rack. A film roller is connected with the rack through film roller brackets. Automatic adjusting rods are arranged on the two sides of the rack. One end of each automatic adjusting rod is hinged to the rack. A soil covering assembly is mounted at the other end of the automatic adjusting rod. A liftable positioning wheel and a film pressing roller are arranged in front of each soil covering assembly. A suspension frame is also arranged on the rack. One end of the suspension frame is fixedly connected with the rack and the other end of the suspension frame is movably connected with the middle of the automatic adjusting rod. A buffer spring is arranged between the end of the suspension frame and the middle of the automatic adjusting rod. The power-assisted plastic film mulching machine provided by the invention has following beneficial effects: by arranging the independently suspended automatic adjusting rods, the height of each soil covering blade can be automatically adjusted according to the topographical change during film mulching in combination with the suspension frame and buffer springs, so that the power-assisted plastic film mulching machine is suitable for mountain topography, especially slope topography; due to the arrangement of the height-adjustable positioning wheels, the working height of the soil covering blade can be limited, so that the soil covering blades can be used for uniformly covering soil.

Owner:CHANGYANG SHENGDA CHEERFUL AGRI MACHINERY

Automatic film-mulching and soil-covering machine

InactiveCN104025957ASimple structureReduce manufacturing costPlant protective coveringsBogieFixed frame

Owner:覃达尧

Landscape design method for leisure square in urban planning

InactiveCN108505774AEfficient preparationEasy to observe workSecateursSpadesLandscape designWater resources

The invention discloses a landscape design method for a leisure square in urban planning. The landscape design method comprises the following steps that (1) the leisure square is divided into a squareentrance landscape area, a theme culture square landscape area, an old-age people activity landscape area, a young children activity landscape area, a middle-young age people activity landscape areaand a ring square landscape area; (2) the theme culture square landscape area is designed; (3) the ring square landscape area is designed; (4) the young children activity landscape area is designed; (5) the old-age people activity landscape area is designed; (6) the middle-young age people activity landscape area is designed; and (7) the square entrance landscape area is designed. According to activity characteristics of crowds, the multiple activity areas and matched public facilities are designed; and water resources in the leisure square are reasonably utilized by designing a plurality of sets of fountain drainage pipelines, a truncated-cone-shaped landscape platform protruding out of the ground is designed and can be watched from a long distance, and accidents are avoided.

Owner:XINYANG AGRI & FORESTRY UNIV

Soil coverer of built-in hole wheel type seeder

InactiveCN112449799AReduced wear damageEasy to usePlantingWatering devicesSeederAgricultural engineering

The invention relates to the technical field of agricultural planting, and discloses a soil coverer of a built-in hole wheel type seeder. The soil coverer comprises a cross beam, wherein the lower part of the cross beam is fixedly connected with a travelling wheel carrier, the inner side of the travelling wheel carrier is movably connected with a travelling wheel, the left and right sides of the cross beam are provided with seed boxes, traction rods are movably connected to the left end and the right end of the cross beam, a water tank is movably connected to the ends, away from the cross beam, of the traction rods, a soil covering device is fixedly connected to the rear end of the water tank, a press wheel is movably connected into the soil covering device, the soil covering device comprises a reinforcing plate, a supporting rod is movably connected to the right end of the reinforcing plate, a soil covering plate is movably connected to the one-third position, close to the supportingrod, of the reinforcing plate, a thin plate is welded to the upper side of the soil covering plate, a flexible belt is arranged at the right end of the thin plate, and pressing wheel frames are in threaded connection with the upper end and the lower end of the supporting rod. The soil coverer is consistent in covering, uniform in soil covering, convenient to adjust, good in integrity and beneficial to actual use.

Owner:田泽林

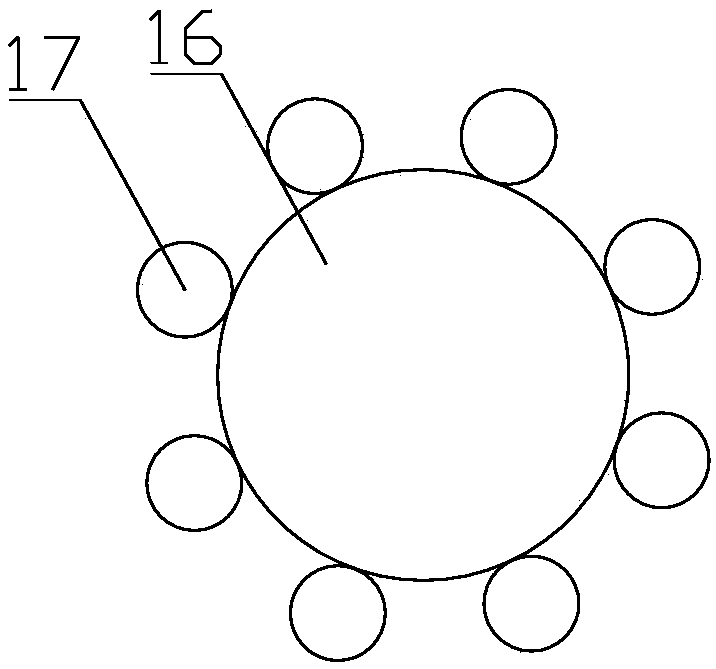

Hole boring soil casting device used in ginger plantation

The invention discloses a hole boring soil casting device used in ginger plantation. The hole boring soil casting device used in ginger plantation comprises a supporting assembly, a boss, a through hole, a hole boring mechanism, a hydraulic oil cylinder, and a soil casting mechanism; a soil receiving tank is connected with the supporting assembly through hinge joint; a telescopic rod assembly is fixedly connected with the soil receiving tank and the supporting rod assembly; a rotating disk is arranged in the boss; a driving shaft is fixedly connected with the rotating disk; a plurality of fixing rods are fixedly connected with a dispersion barrel and the driving shaft, and are arranged on the periphery of the internal wall of the dispersion barrel, between the dispersion barrel and the driving shaft; each mobile rod is fixedly connected with a corresponding fixed rod; each soil casting brush is connected with a corresponding mobile rod through threaded connection; the boss and a motorin the supporting assembly are used for driving the telescopic rod assembly to move upward and downward, and the rotating disk to rotate, so that uniform soil casting is realized, and ginger survivalrate is increased.

Owner:CHONGQING UNIV OF ARTS & SCI

Method for sowing and propagating emmenopterys henryi

InactiveCN108496678AEfficient preparationEasy to observe workSecateursSpadesFruit treeEmmenopterys henryi

The invention discloses a method for sowing and propagating emmenopterys henryi. The method comprises the following steps: (A) seed pretreatment; (B) substrate preparation; (C) seedbed levelling; (D)sowing and earthing; (E) nursery management; (F) sapling transplantation; and (G) sapling tending and management and protection. The method disclosed by the invention has a high germination rate and neat seedling emergence, and is suitable for large-scale sowing and propagating of the emmenopterys henryi in forestry.

Owner:XINYANG AGRI & FORESTRY UNIV

Agriculture and forestry combined ecological economic system

InactiveCN108575492AEfficient preparationEasy to observe workSeed and root treatmentClimate change adaptationForest industryFruit tree

The invention discloses an agriculture and forestry combined ecological economic system comprising the following steps: (A) seed pretreatment; (B) substrate preparation; (C) seedbed leveling; (D) sowing and soil covering; (E) seedling nursery management; (F) sapling seedling transplanting; and (G) sapling seedling nursing as well as management and protection. The method disclosed by the inventionis suitable for planting emmenopterys henryi in the forestry on a large scale, and at the young seedling stage of the emmenopterys henryi, the emmenopterys henryi and peanuts are shaded by corns, thepeanuts are used for fixing nitrogen in the corns, and the emmenopterys henryi, the peanuts and the corns are coordinated with each other to develop; and the emmenopterys henryi is high in germinationrate, ordered in seedling emergence and suitable for large-scale sowing and reproduction in the forestry.

Owner:XINYANG AGRI & FORESTRY UNIV

Cultivation method for sweet scented osmanthus trees

InactiveCN108464181AEfficient preparationEasy to observe workSeed and root treatmentGrowth substratesObserved SurvivalOsmanthus

The invention discloses a cultivation method for sweet scented osmanthus trees. The method comprises the following steps: (A) seed pretreatment; (B) substrate preparation; (C) seedbed levelling; (D) sowing and earthing; (E) nursery management; (F) sapling transplantation; and (G) sapling tending, management and protection. When the method disclosed by an embodiment of the invention is used for cultivation of the sweet scented osmanthus trees, a germination rate of seeds of the sweet-scented osmanthus trees is 97.3%, germination potential is 96.2%, and a survival rate is as high as 99.1% after30 days of germination; and 3 months after sowing is performed, the quantity of sweet-scented osmanthus tree seedlings with a height of 90%-110% of an average seedling accounts for 92.7% of the quantity of total sweet-scented osmanthus tree seedlings, and the quantity of sweet-scented osmanthus tree seedlings with a ground diameter of 90%-110% of an average ground diameter accounts for 97.8% of the quantity of the total sweet-scented osmanthus tree seedlings.

Owner:XINYANG AGRI & FORESTRY UNIV

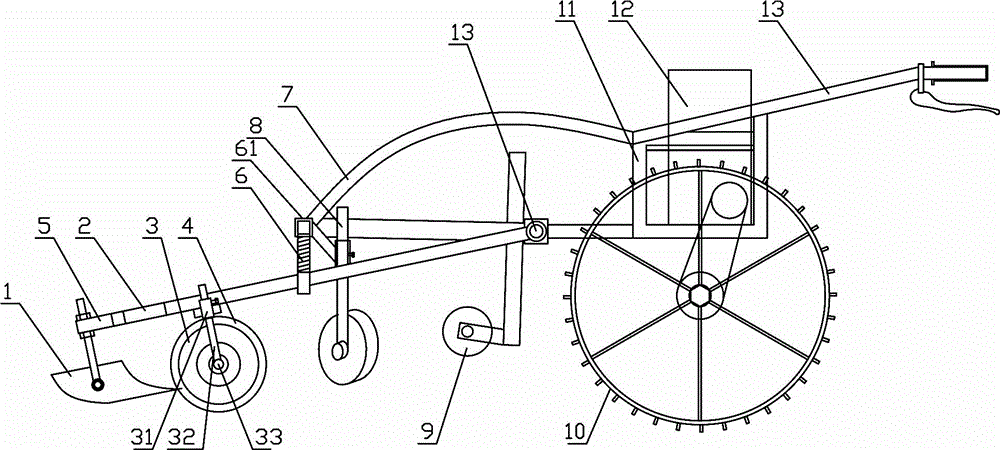

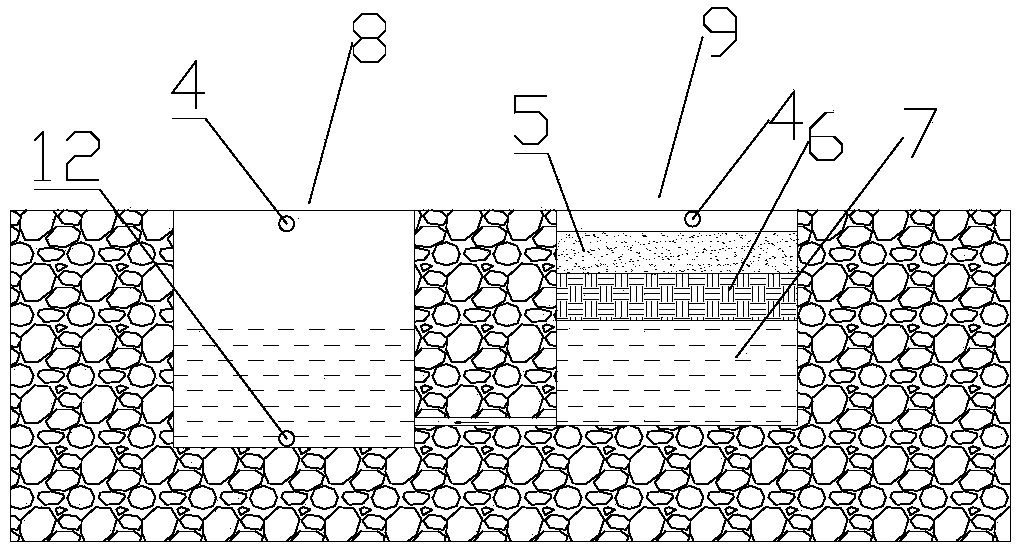

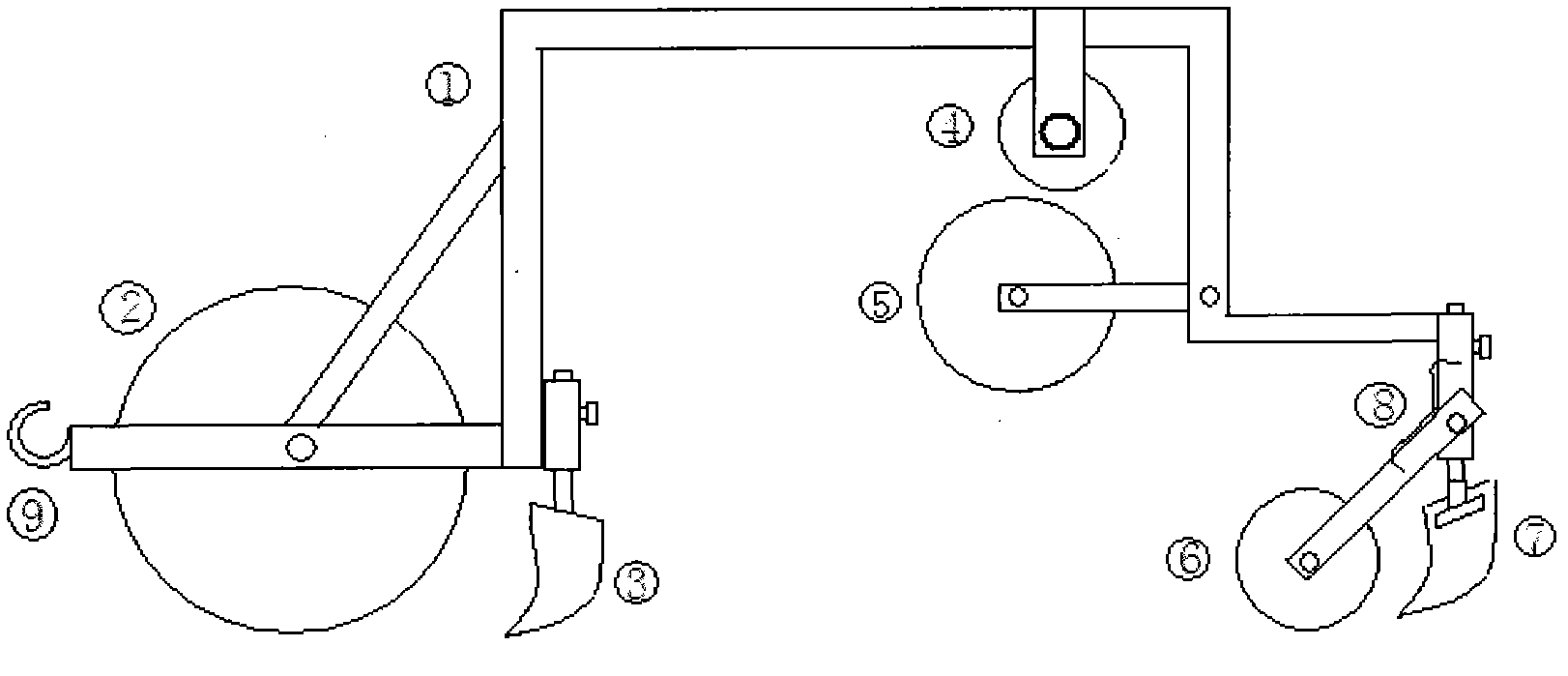

High ridge plastic film mulching machine

InactiveCN102577893ASmooth laminating operationMembrane surface smoothPlant protective coveringsSheet mulchingAgricultural engineering

The invention relates to agricultural machinery for mulching a plastic film on ridge culture crops. A draw hook (9) and a front bracket wheel (2) are arranged at the front end of a small-specification steel pipe bracket (1); an opener (3) is arranged at the rear of the small-specification steel pipe bracket (1); a film expansion mechanism is formed by a film bearing frame (4), a film expansion roller (5), a film pressing wheel (6) and a torsion spring (8); and finally a covering device (7) is arranged. Due to the adoption of the special film expansion mechanism, the operation can be smooth to carry out when the plastic film is mulched for the ridge culture crops such as potatoes, ridge culture peanuts and the like in a protected field, the soil is uniform to cover, the plastic film has proper tightness degree, and the film surface is flat like a mirror. The agricultural machinery for mulching the plastic film on the ridge culture crops needs small traction power and can be operated by both women and children.

Owner:时迎伟

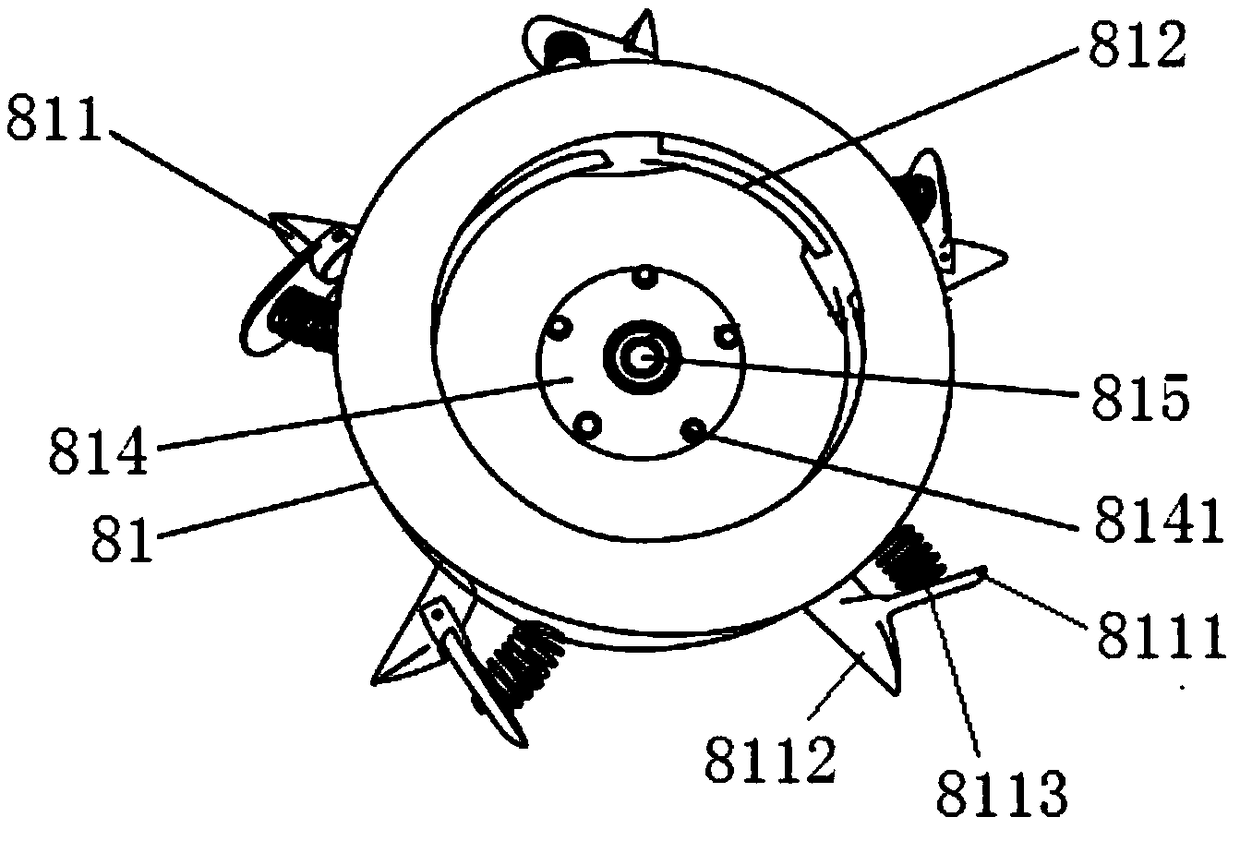

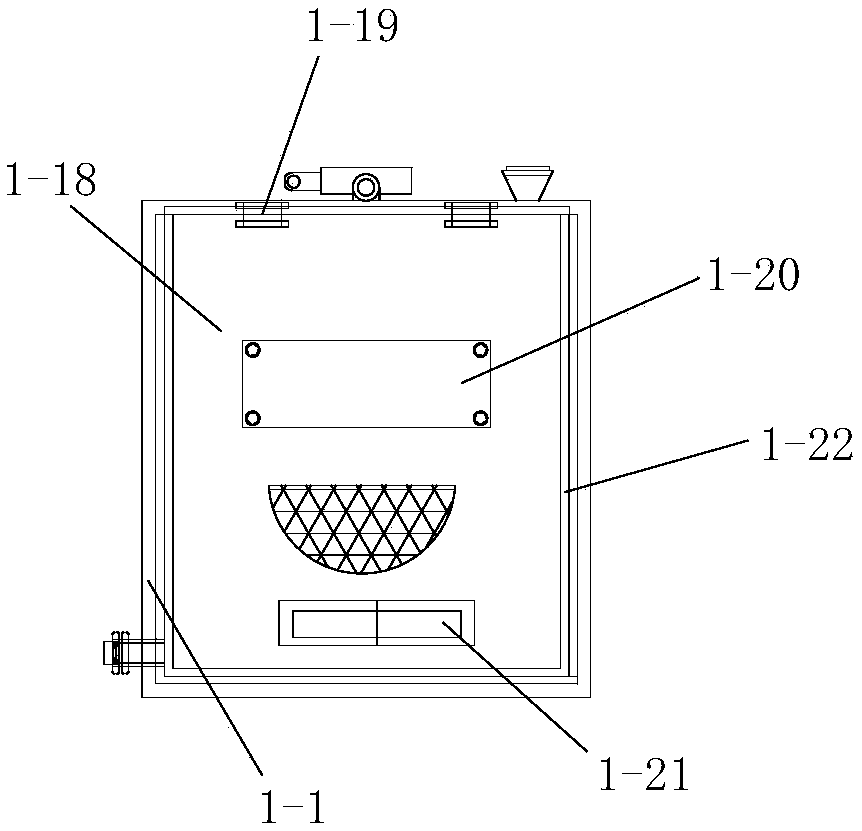

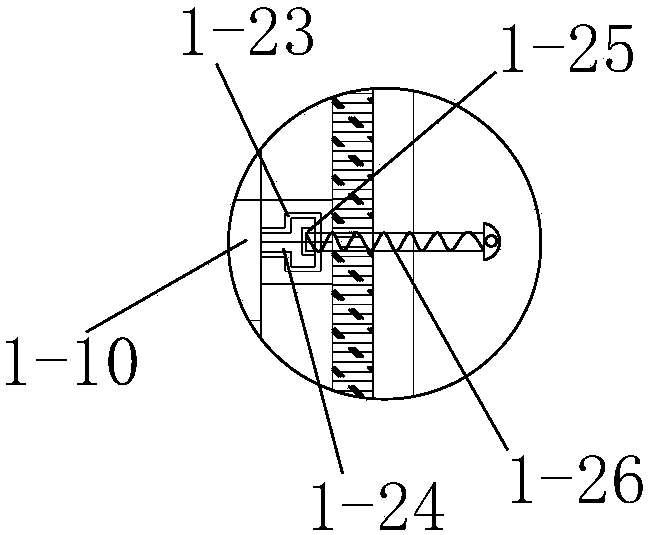

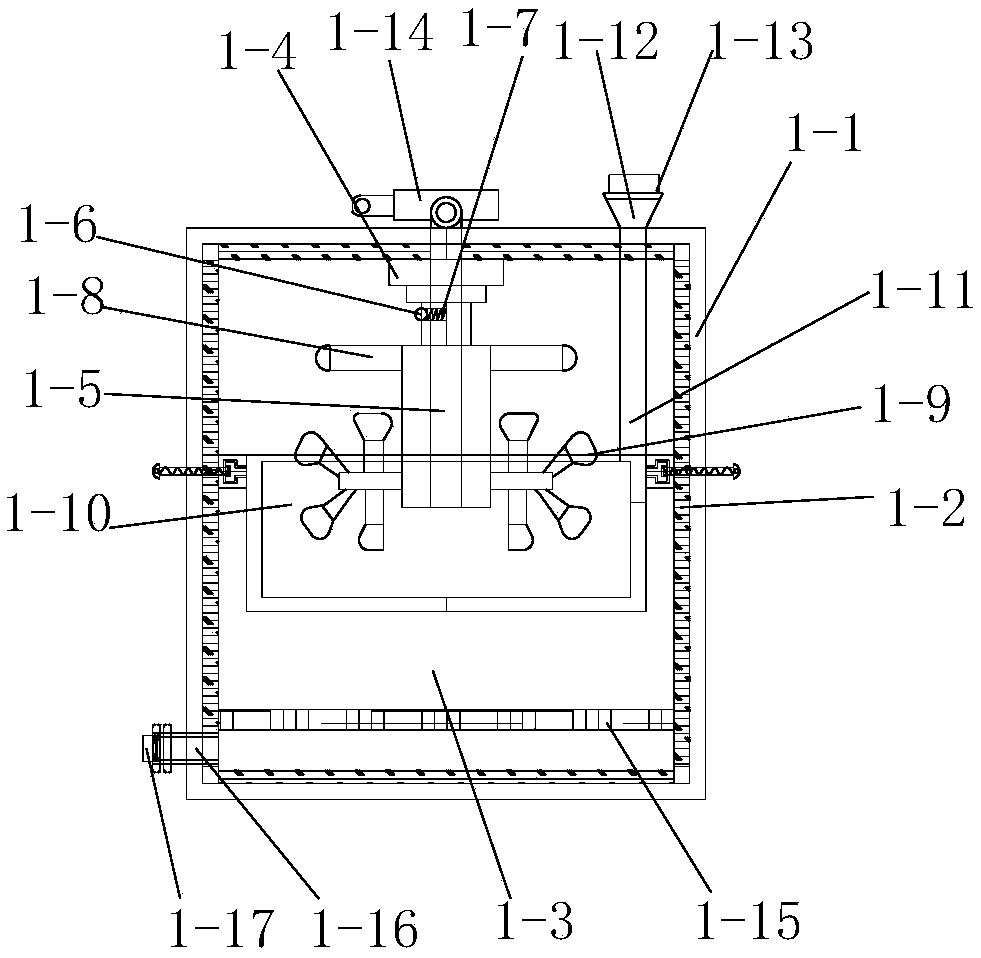

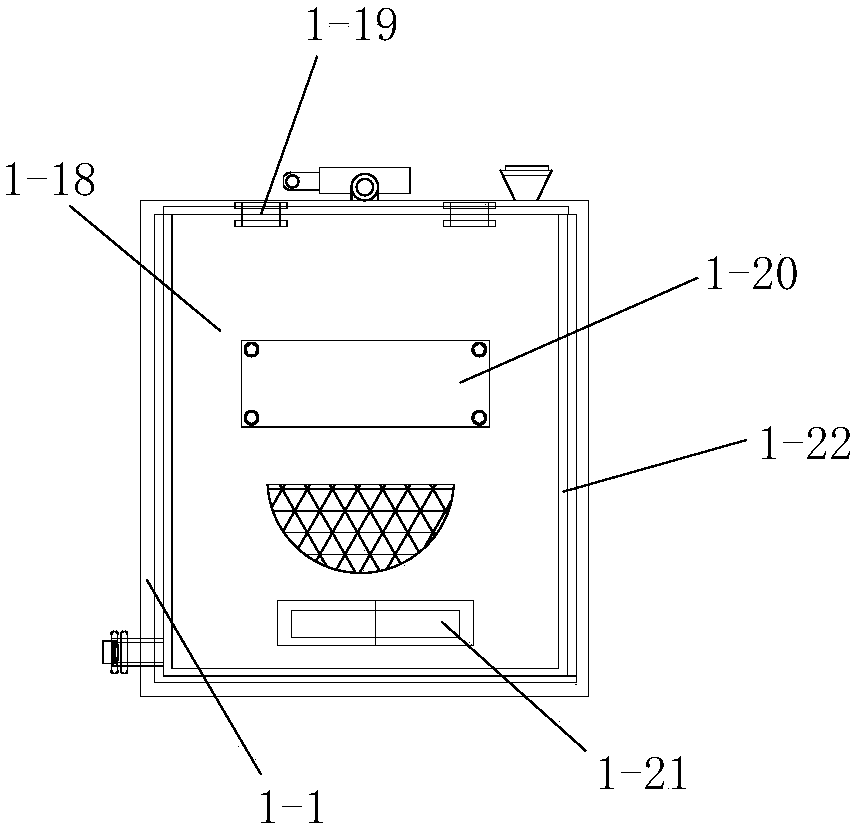

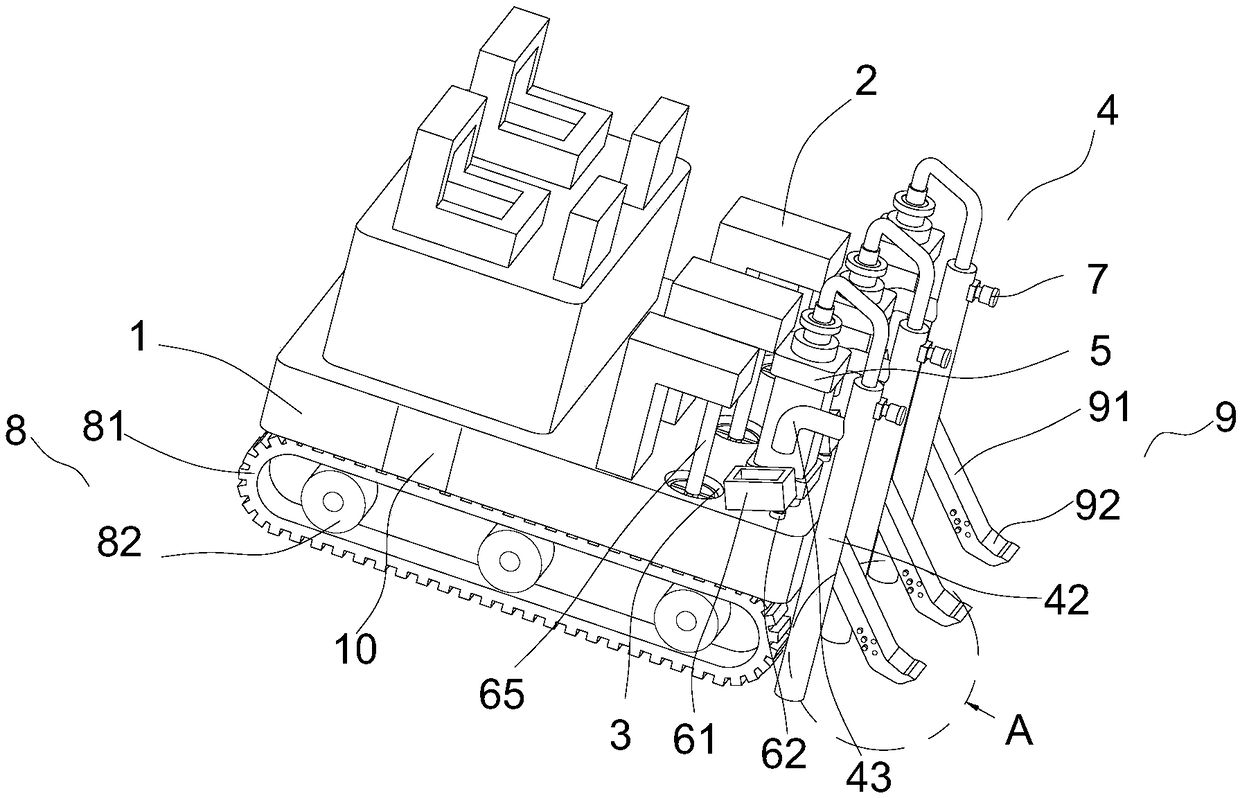

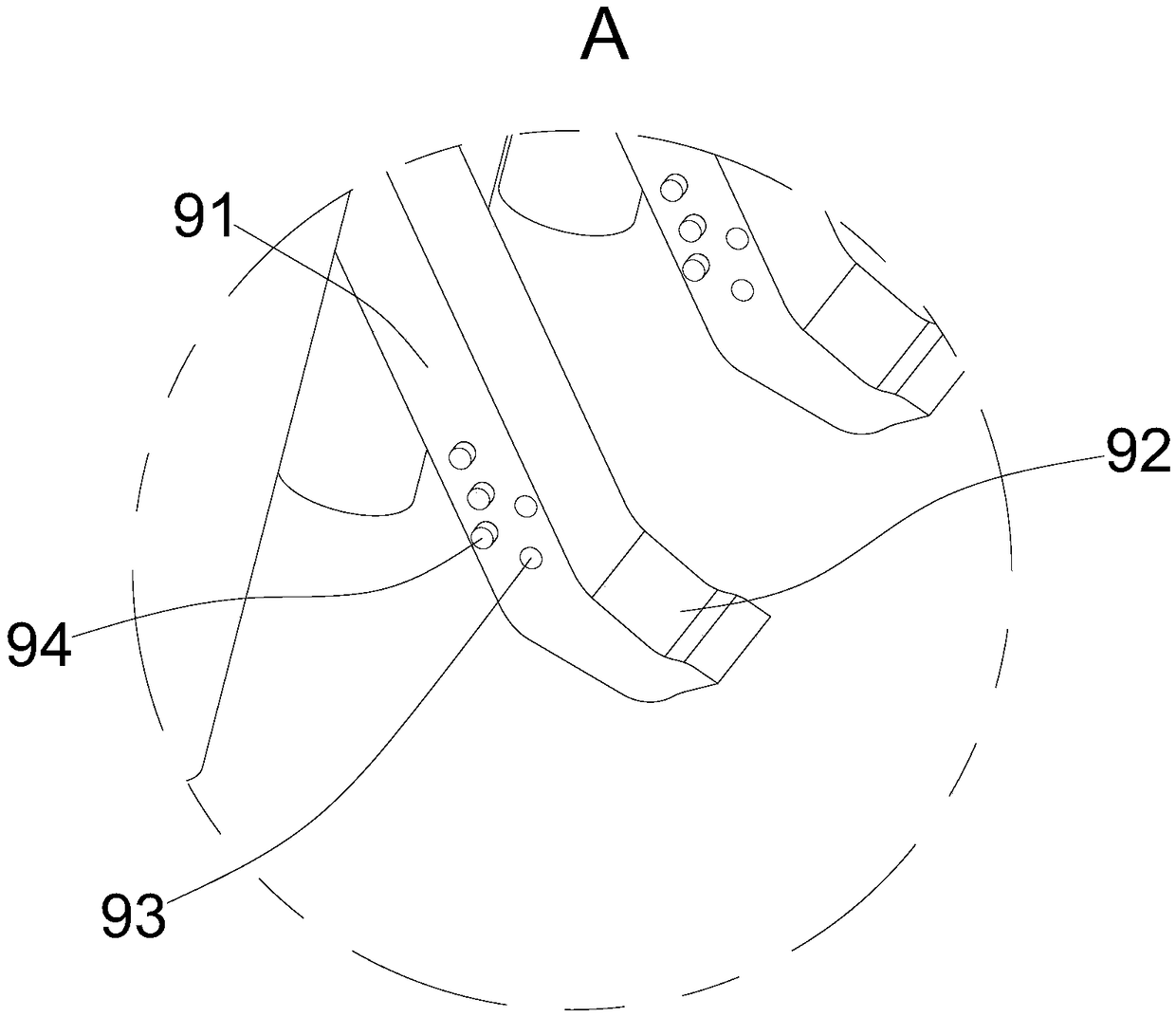

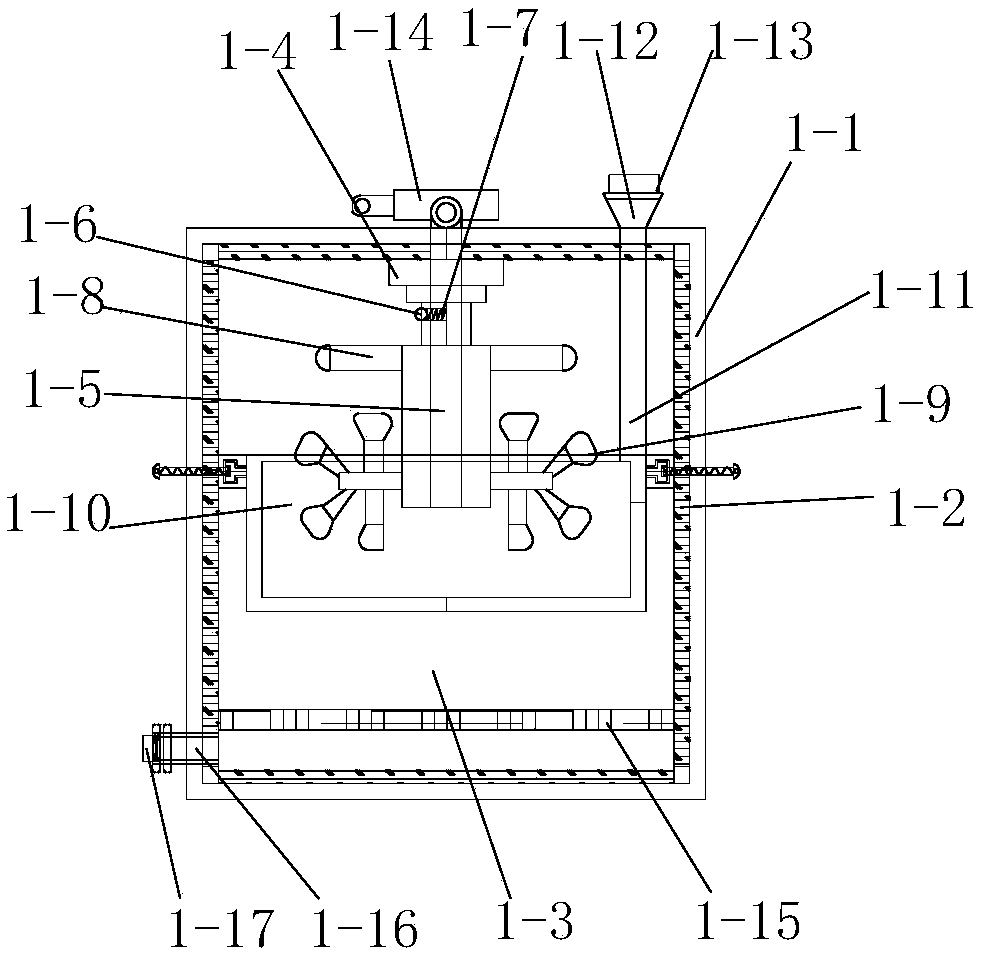

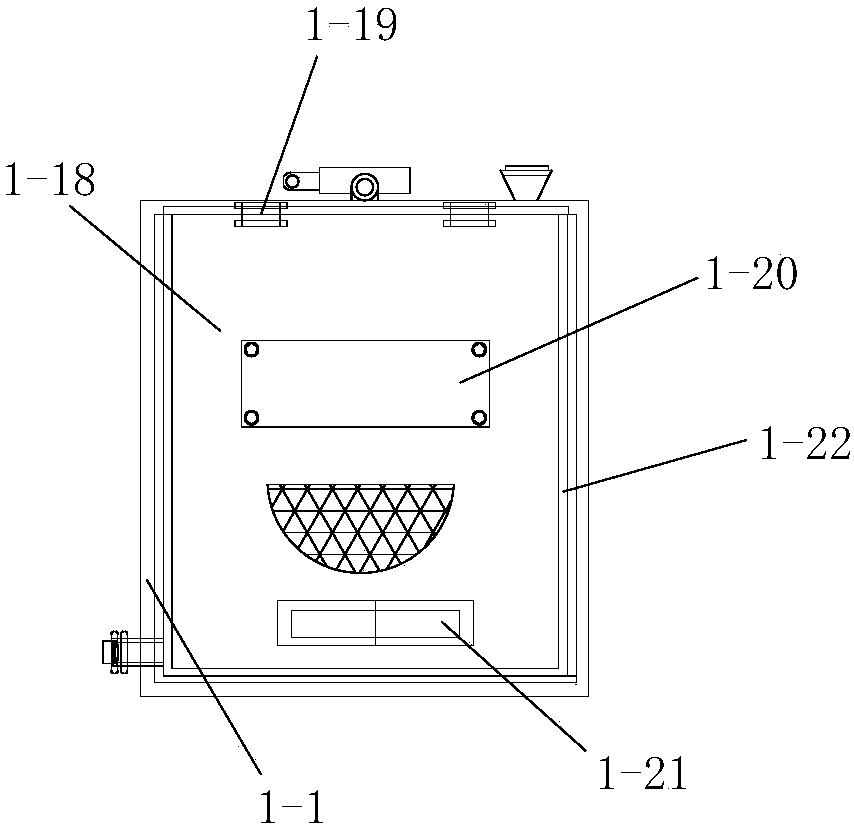

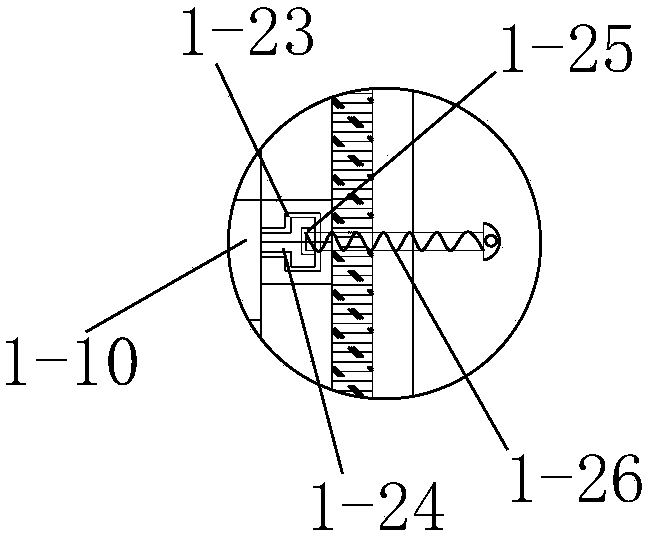

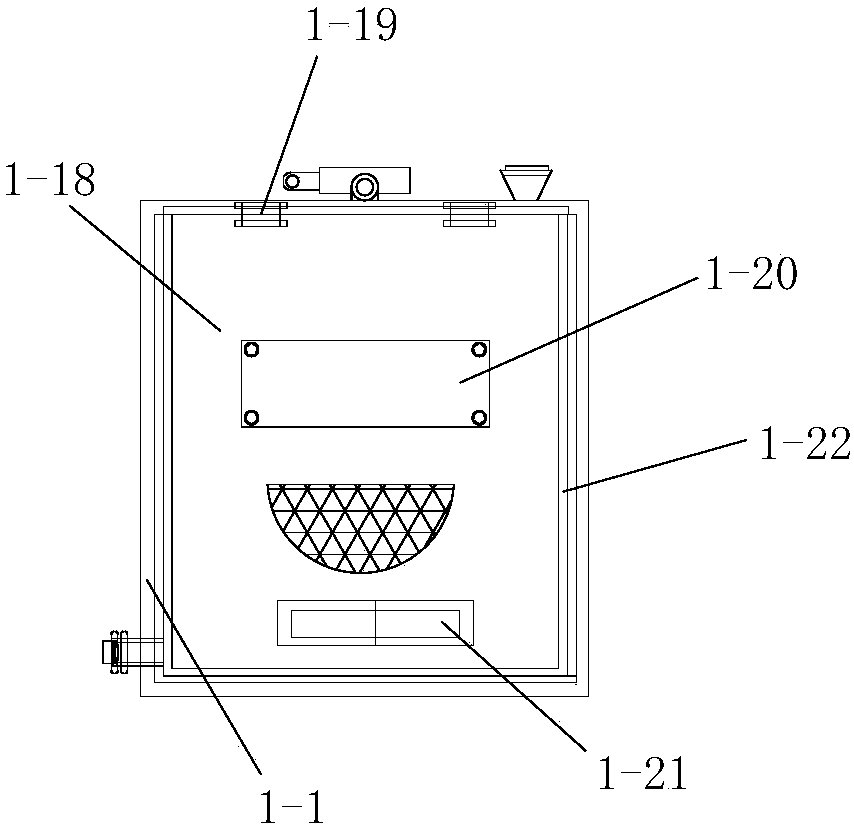

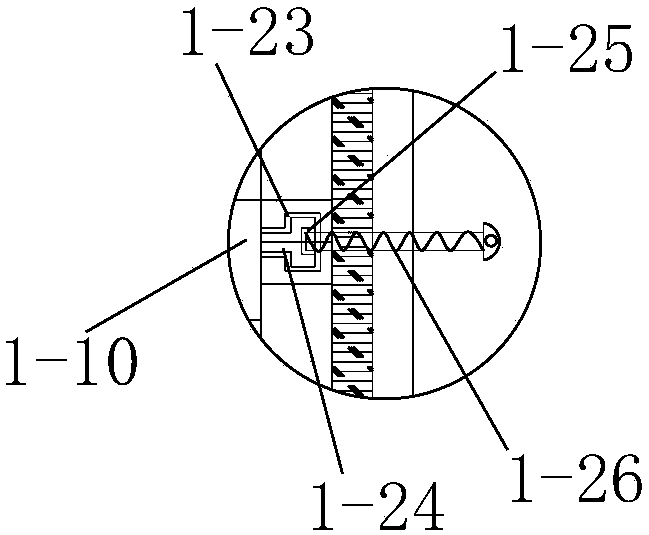

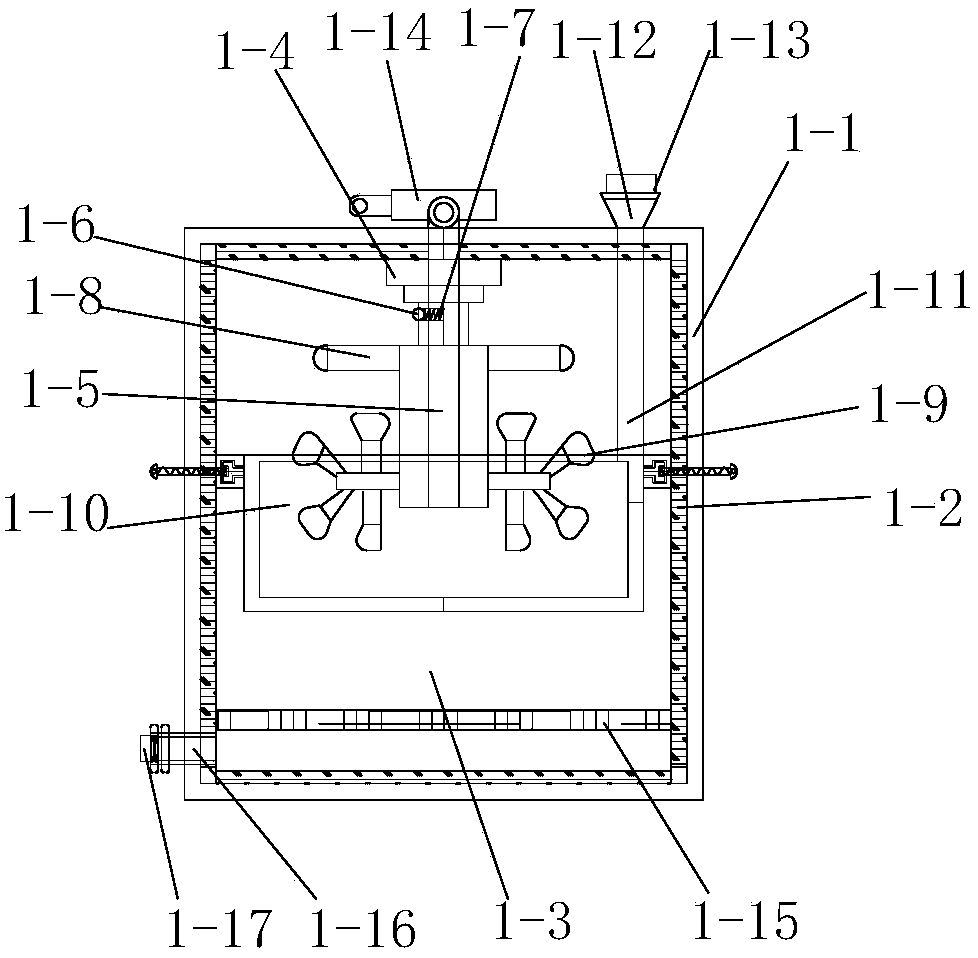

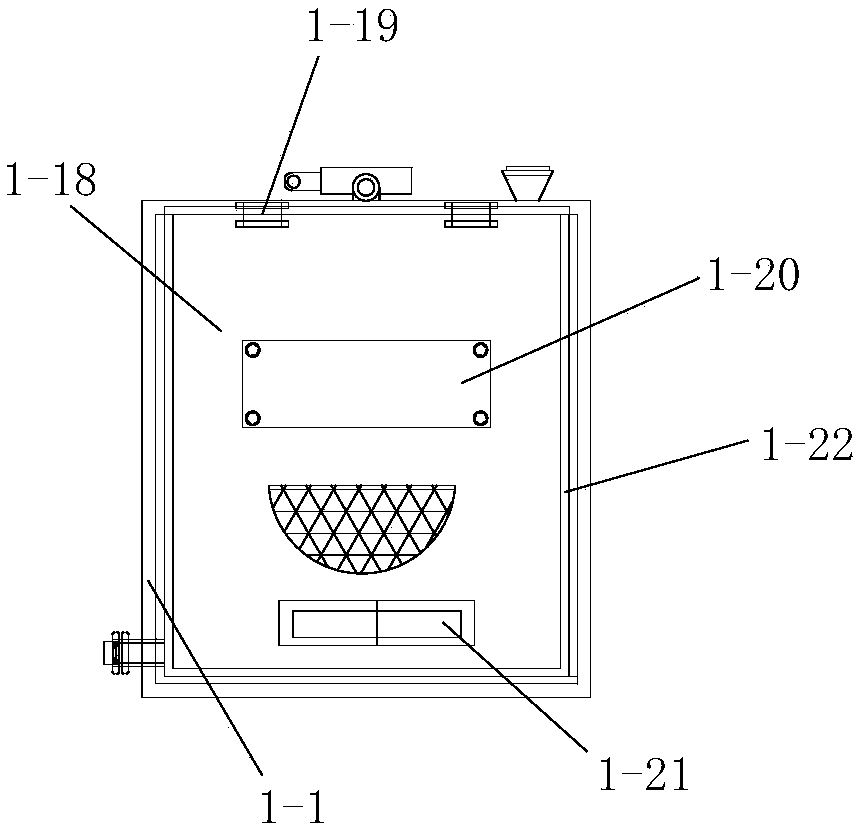

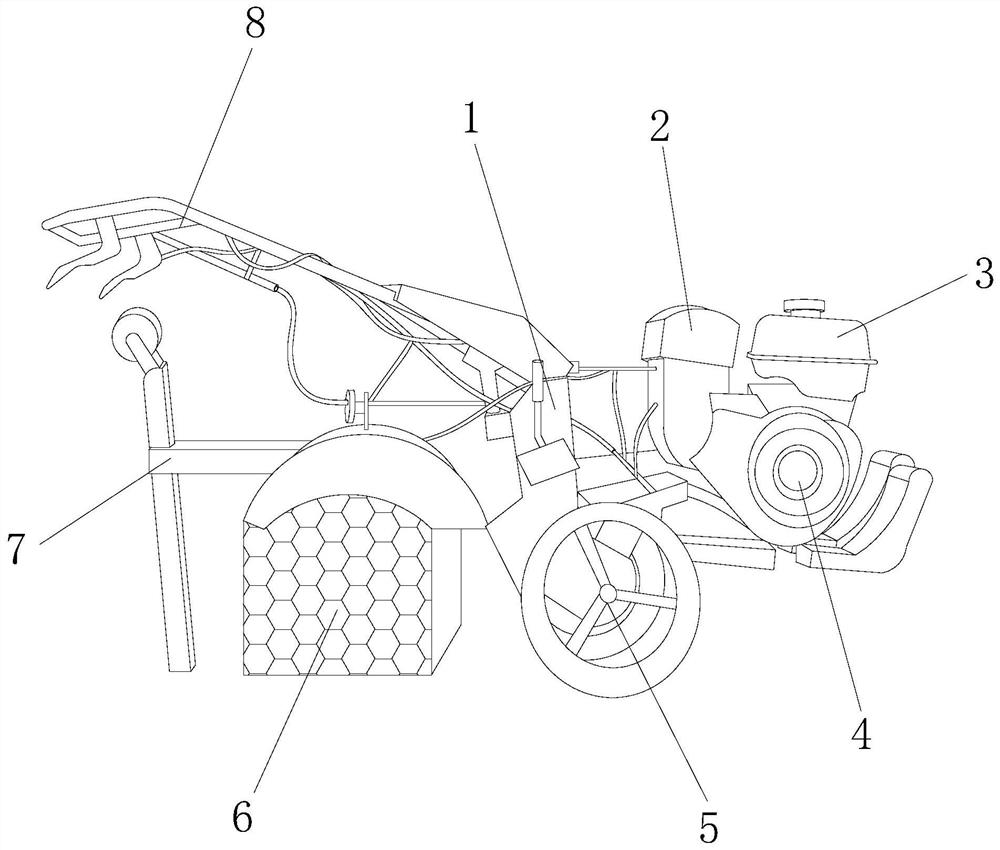

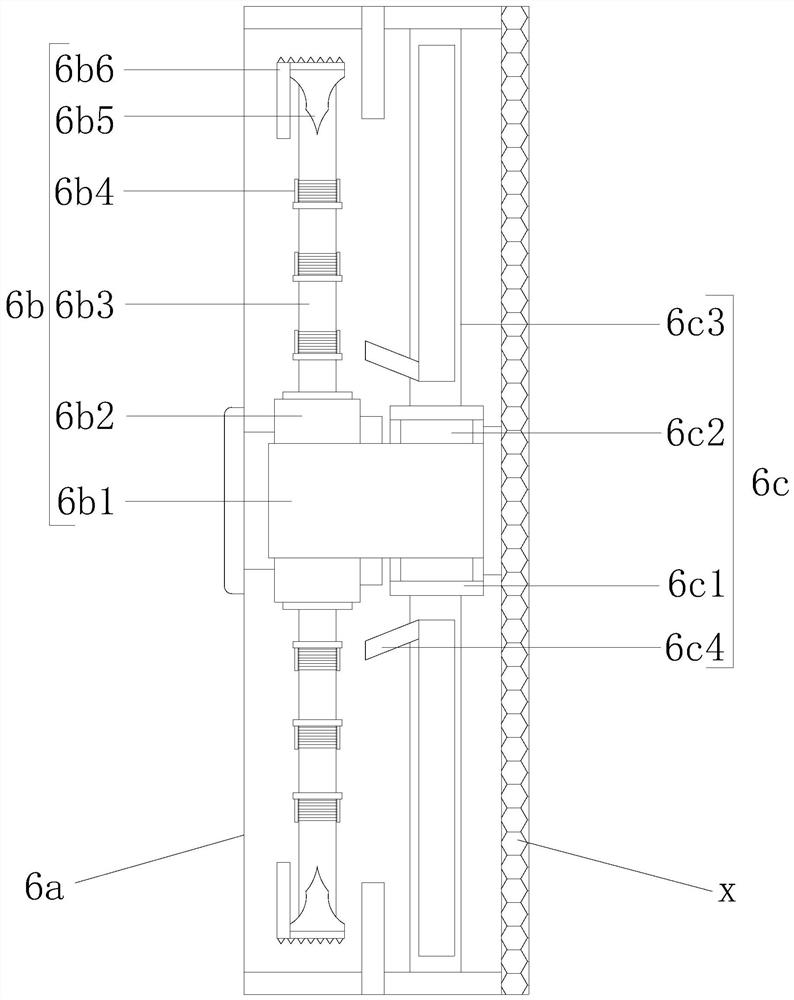

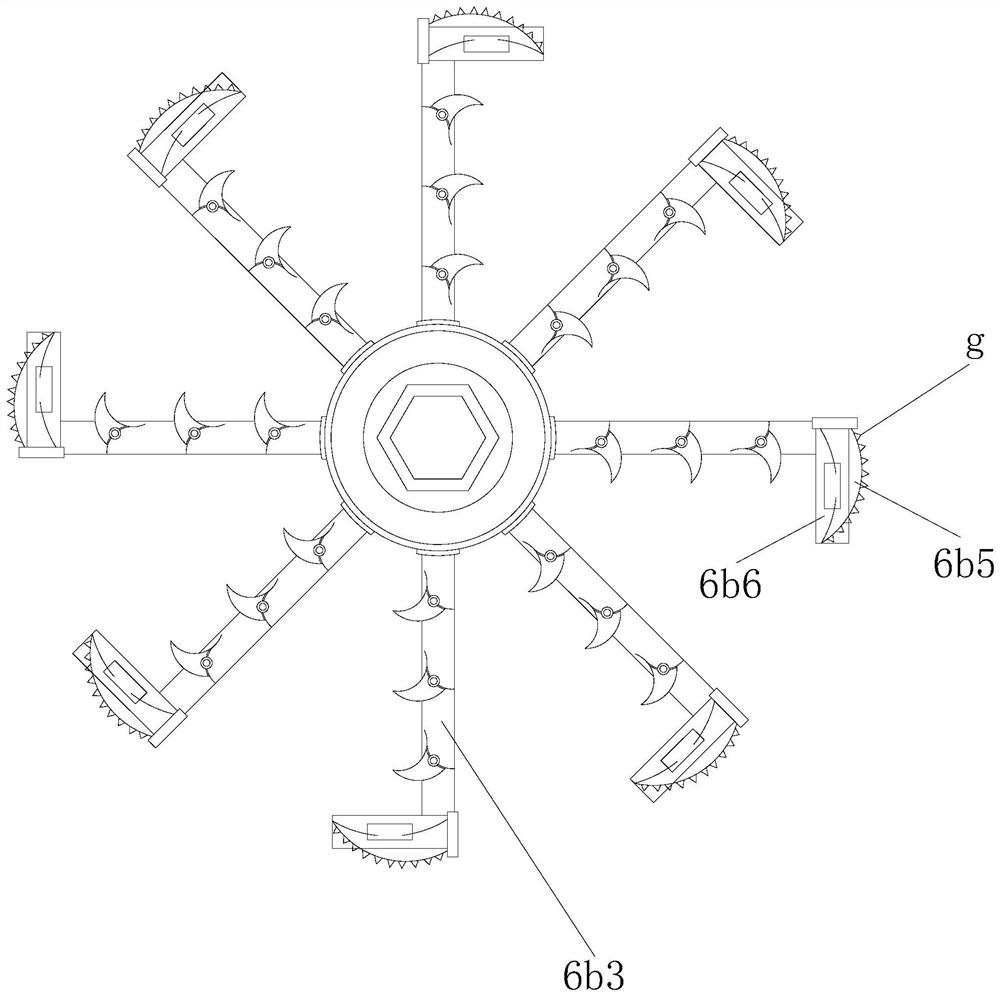

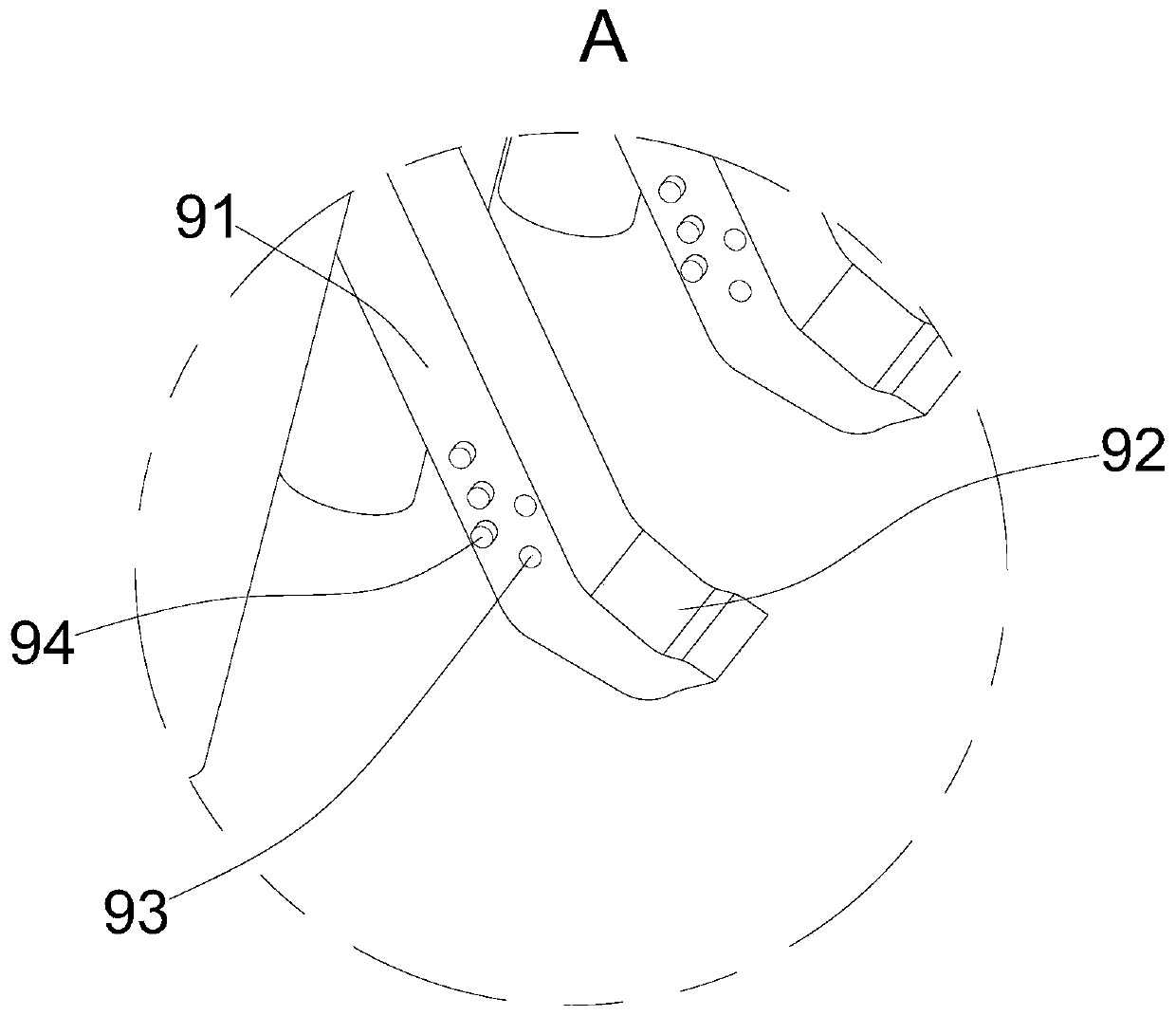

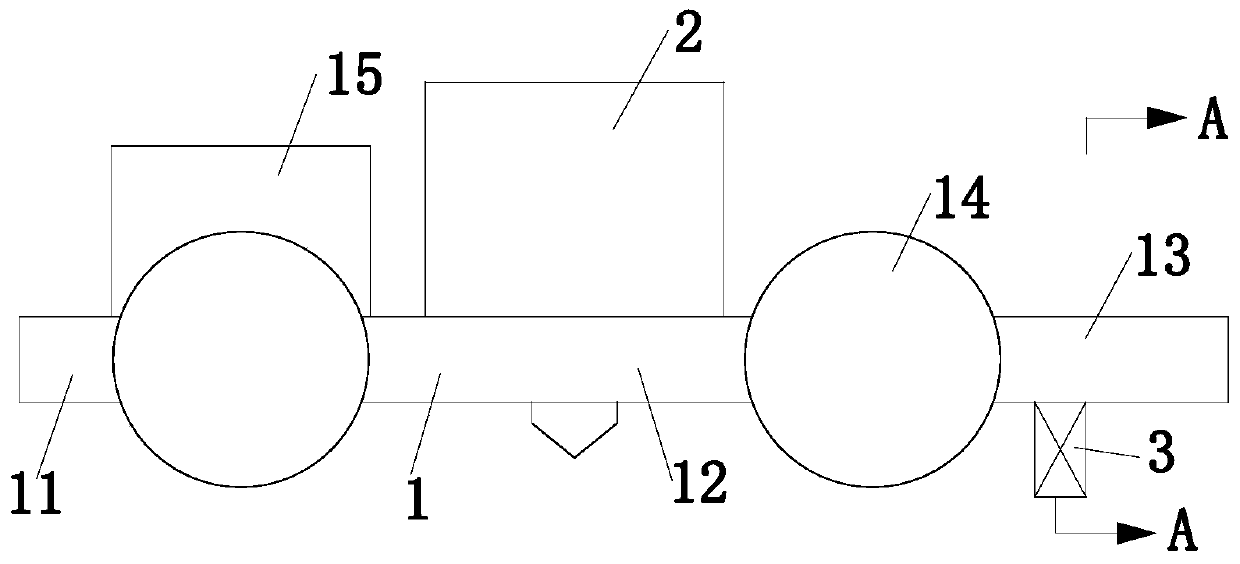

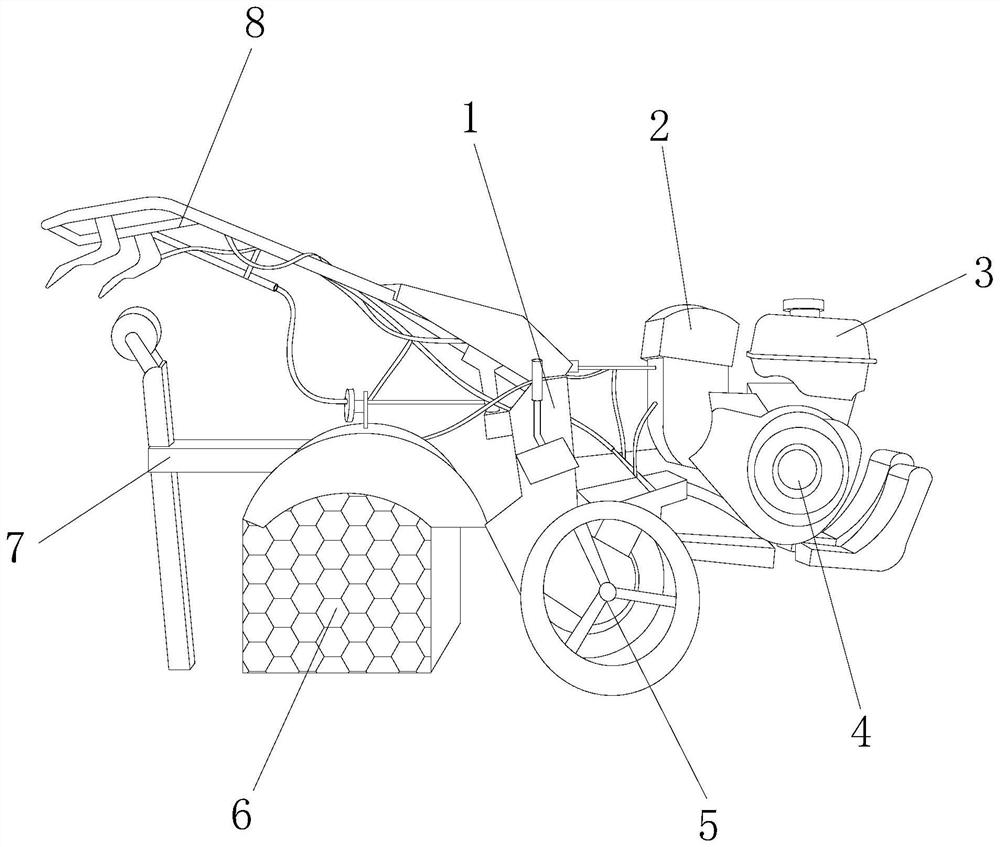

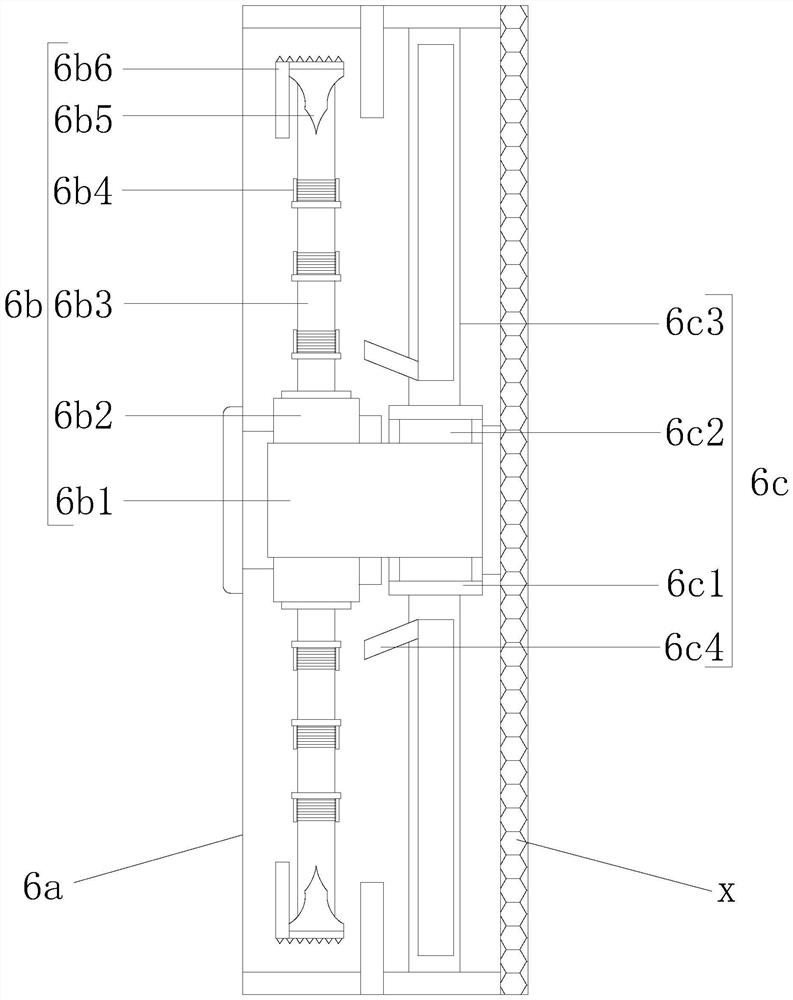

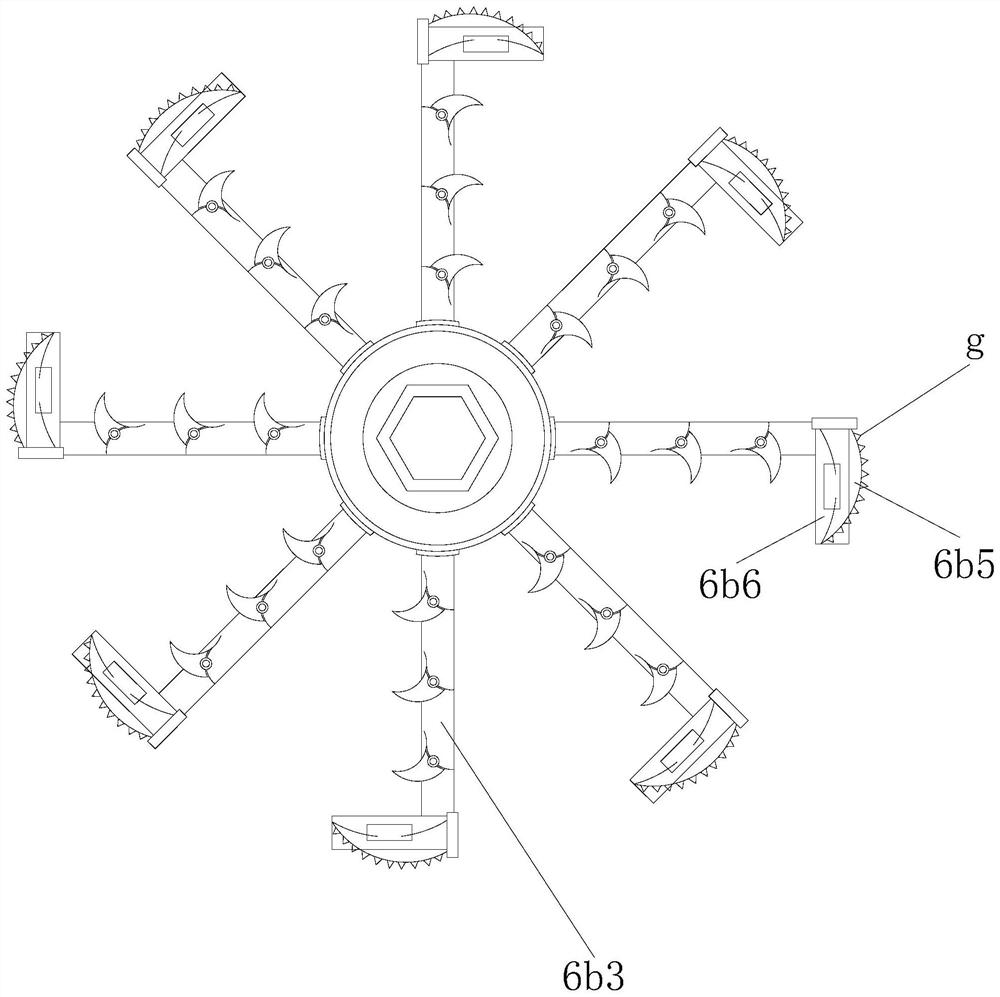

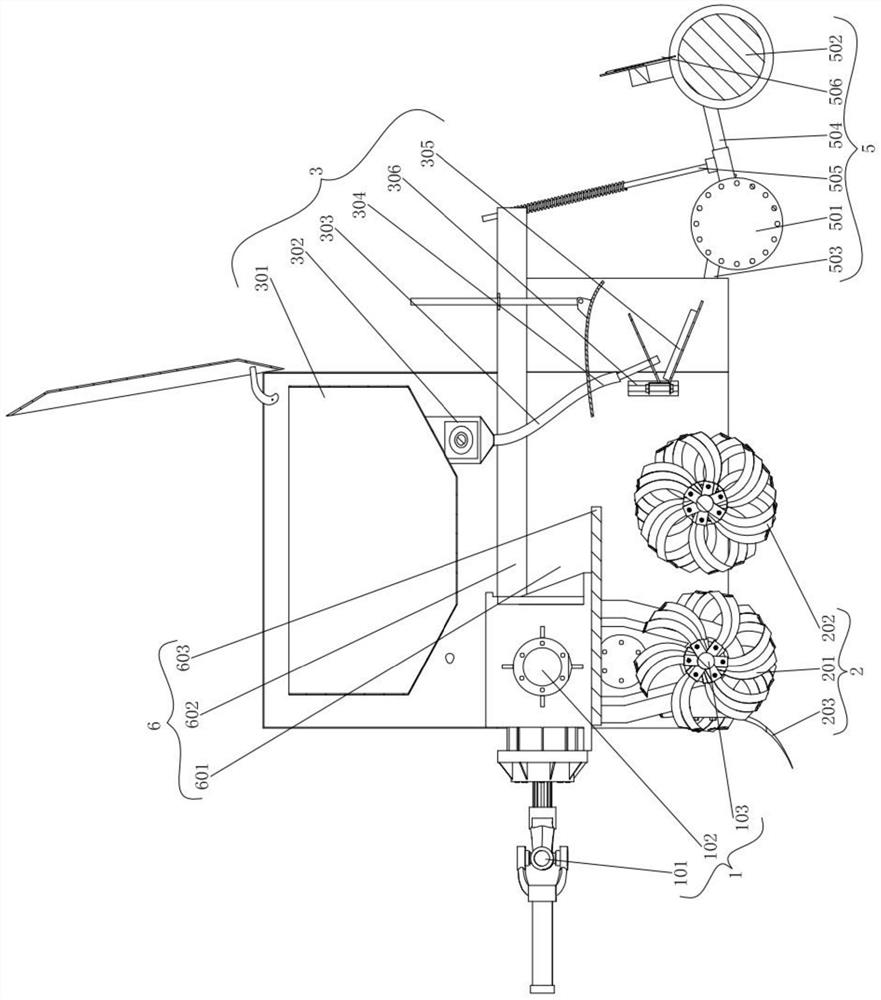

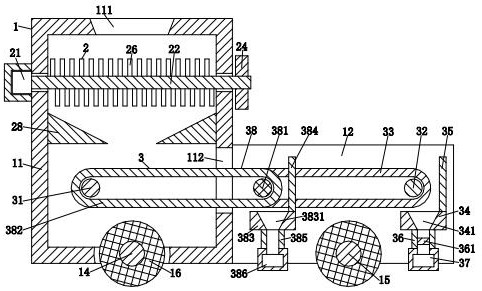

A modern agricultural soil-covering mechanical vehicle with uniform covering and resistance

ActiveCN110972608BPrevent throwingLong growth cyclePlantingFurrow making/coveringAgricultural engineeringMachine

The invention discloses a modern agricultural soil-covering mechanical vehicle with uniform covering and anti-blocking. The structure includes a main body, an electric control box, a diesel box, a drive box, moving wheels, a covering device, a stop bolt and a push handle. Beneficial effects: the present invention utilizes the scattered excavation structure, under the interaction of the hard cutting parts and the triangular cone, to loosen the excavated soil capsules used as coverings, so as to avoid the hard agglomerated soil capsules mixed in the excavation It is thrown directly to the surface of the plant planting place, thereby prolonging the growth cycle of the plant or causing a decrease in its survival rate. The present invention utilizes the anti-splash mechanism provided to excavate and loosen the soil capsule through the loose excavation structure, and then combine it with the The interaction of the spraying stencils achieves a uniform covering of the area required to be covered at the planting site, thereby preventing it from being affected by the large spraying range of the traditional covering equipment and affecting the well-covered plants at a distance .

Owner:蒙城县十速信息科技有限公司

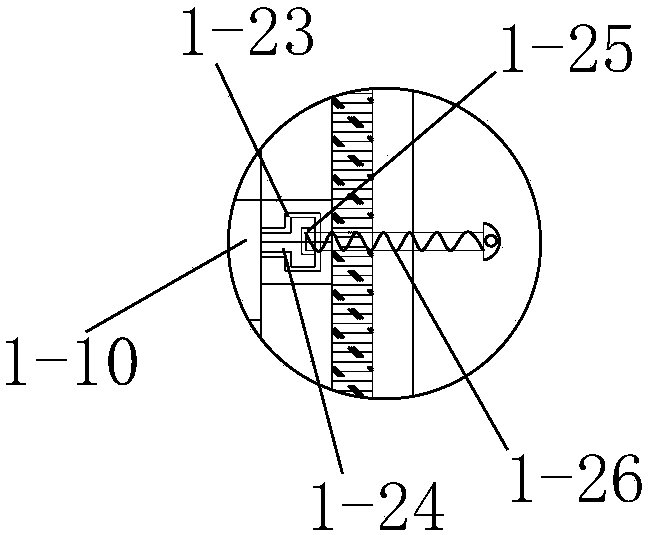

Drilling hole soil covering device for ginger planting

ActiveCN109168437BImprove survival rateUniform coveringSpadesPlantingDrive shaftAgricultural engineering

The invention discloses a hole boring soil casting device used in ginger plantation. The hole boring soil casting device used in ginger plantation comprises a supporting assembly, a boss, a through hole, a hole boring mechanism, a hydraulic oil cylinder, and a soil casting mechanism; a soil receiving tank is connected with the supporting assembly through hinge joint; a telescopic rod assembly is fixedly connected with the soil receiving tank and the supporting rod assembly; a rotating disk is arranged in the boss; a driving shaft is fixedly connected with the rotating disk; a plurality of fixing rods are fixedly connected with a dispersion barrel and the driving shaft, and are arranged on the periphery of the internal wall of the dispersion barrel, between the dispersion barrel and the driving shaft; each mobile rod is fixedly connected with a corresponding fixed rod; each soil casting brush is connected with a corresponding mobile rod through threaded connection; the boss and a motorin the supporting assembly are used for driving the telescopic rod assembly to move upward and downward, and the rotating disk to rotate, so that uniform soil casting is realized, and ginger survivalrate is increased.

Owner:CHONGQING UNIV OF ARTS & SCI

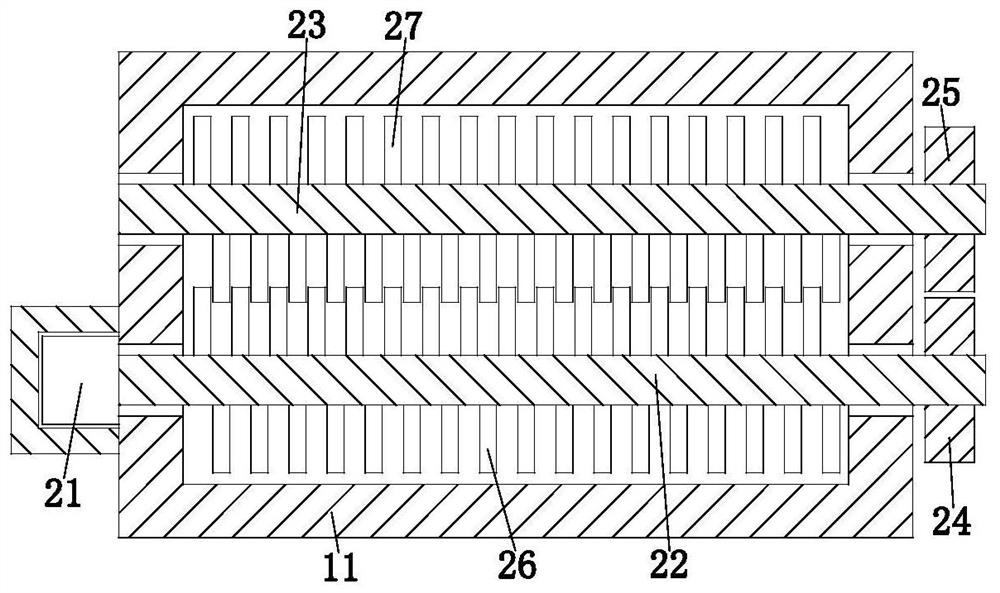

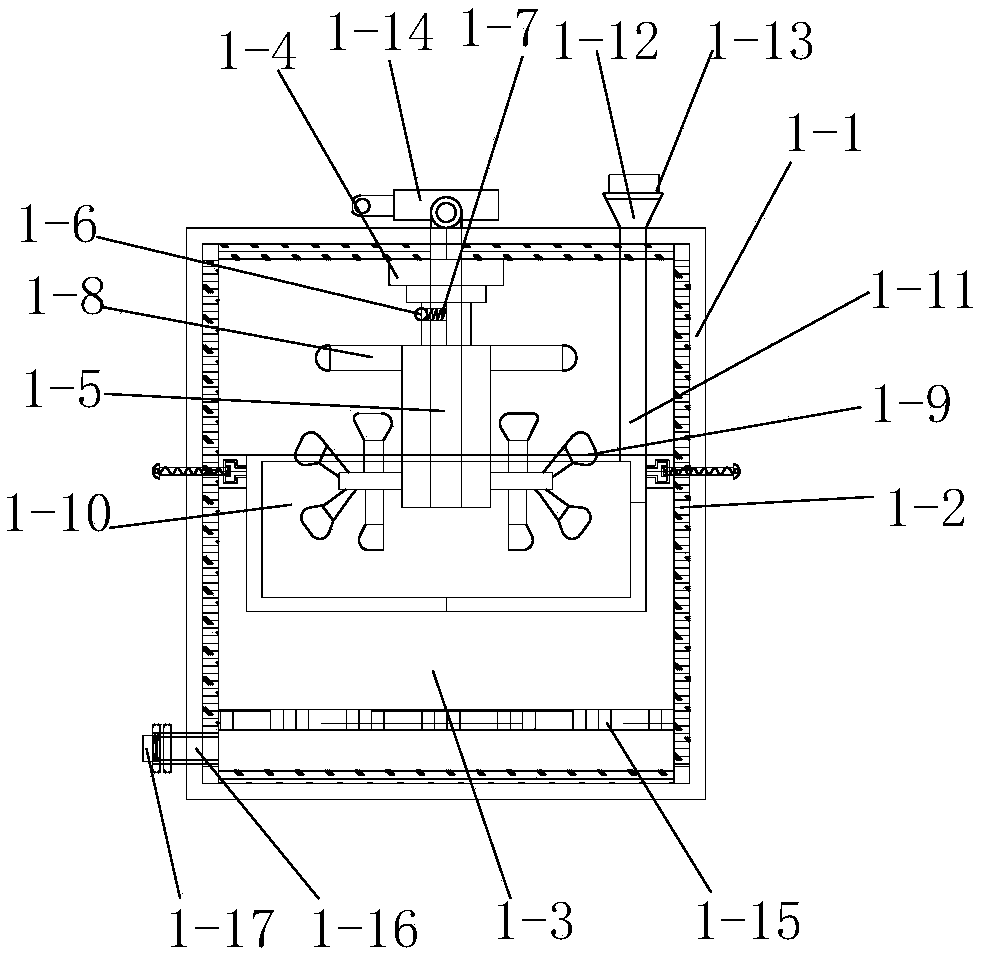

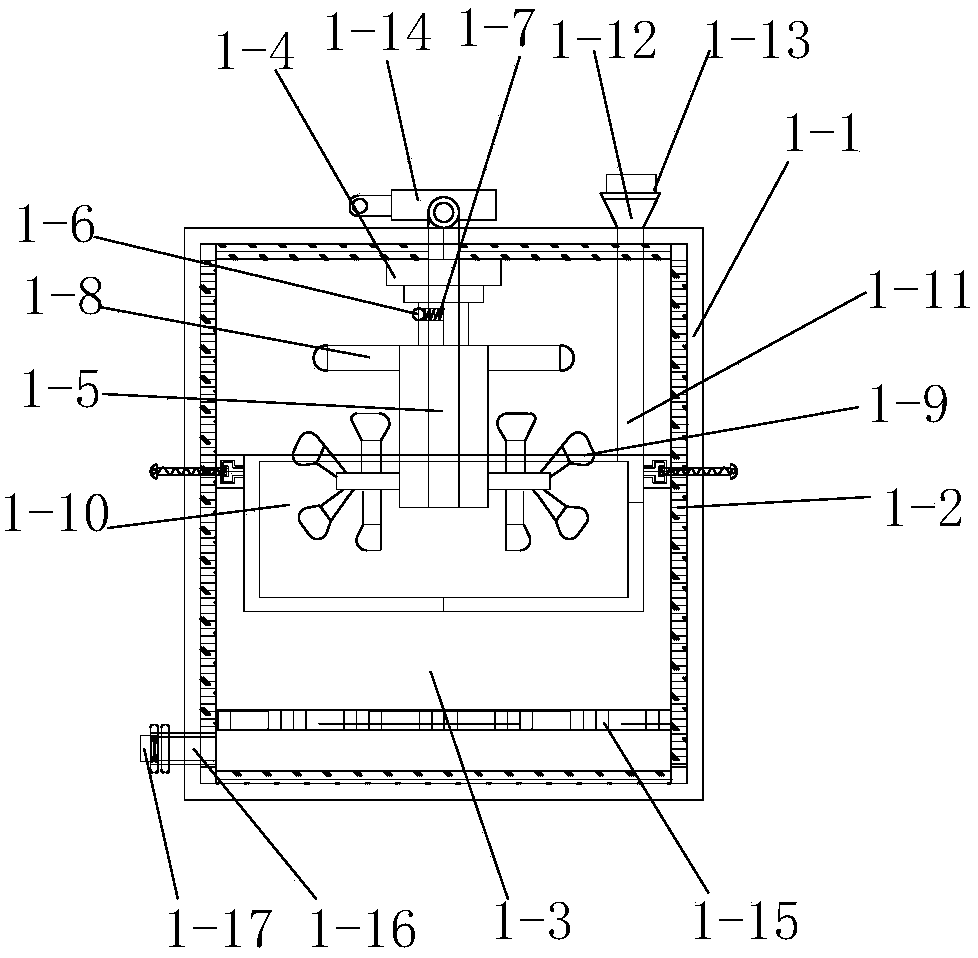

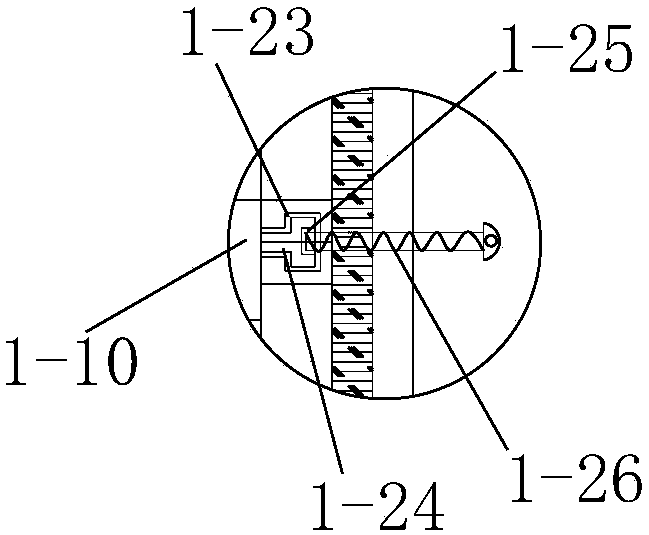

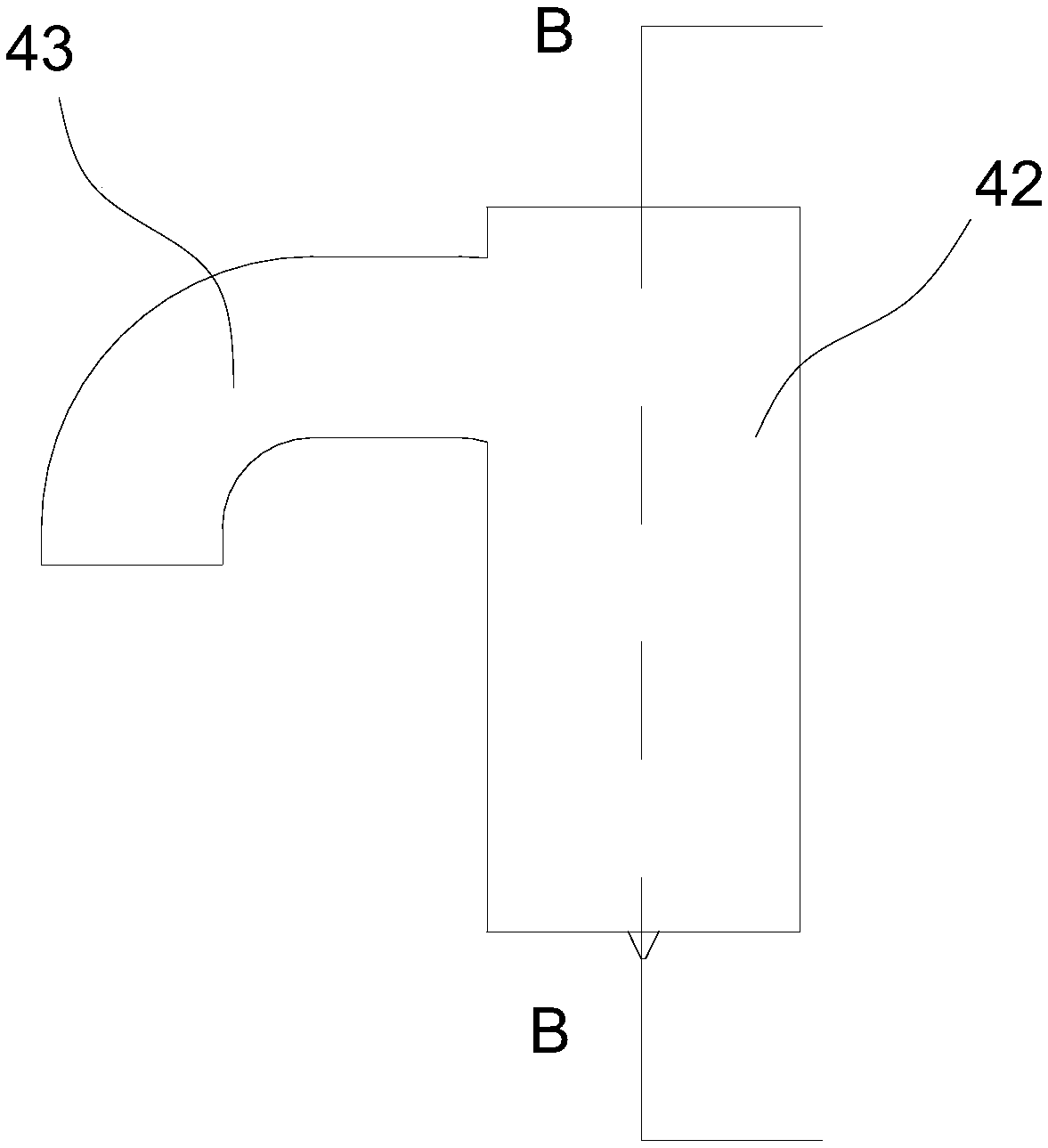

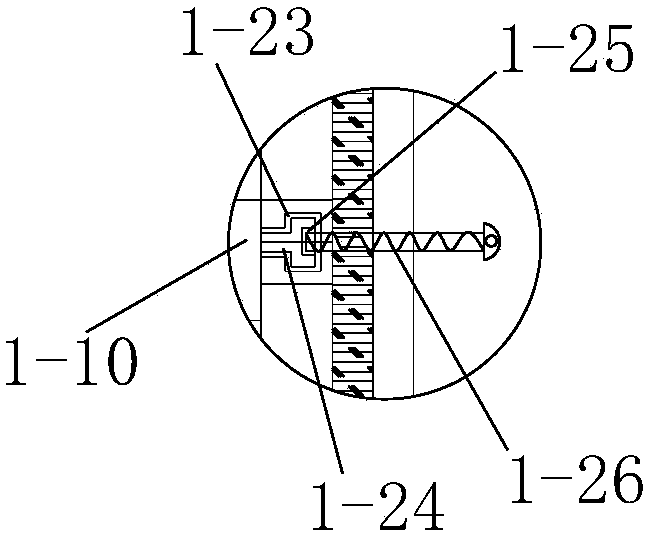

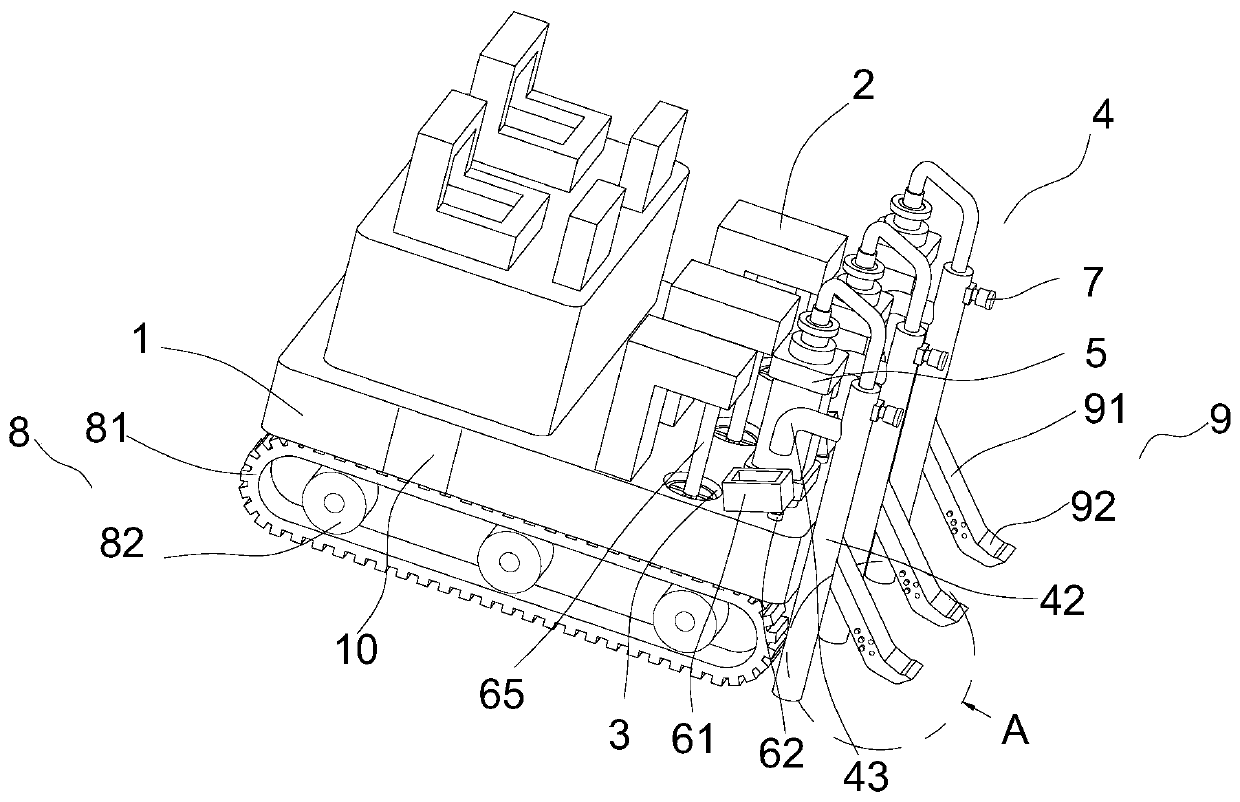

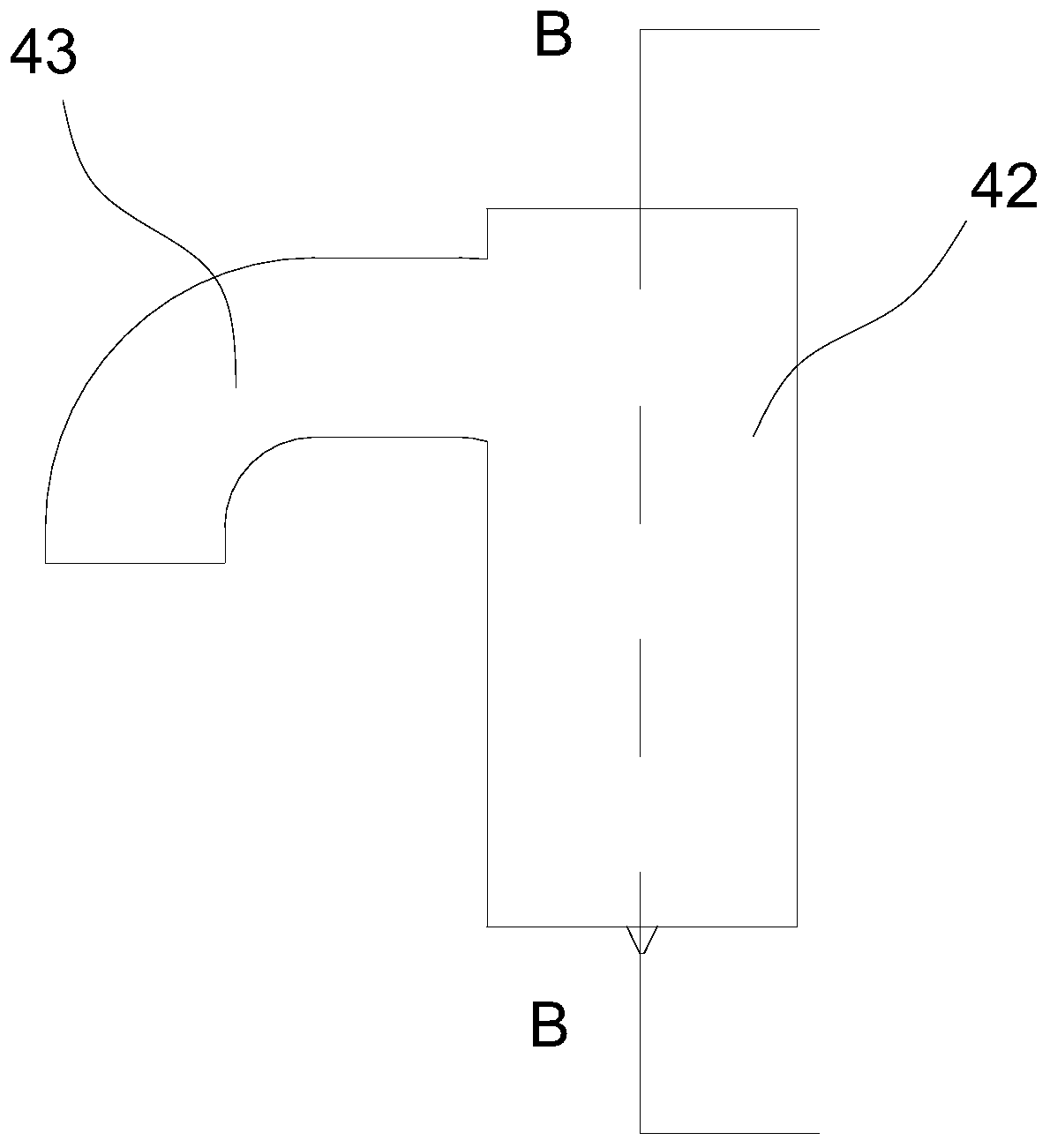

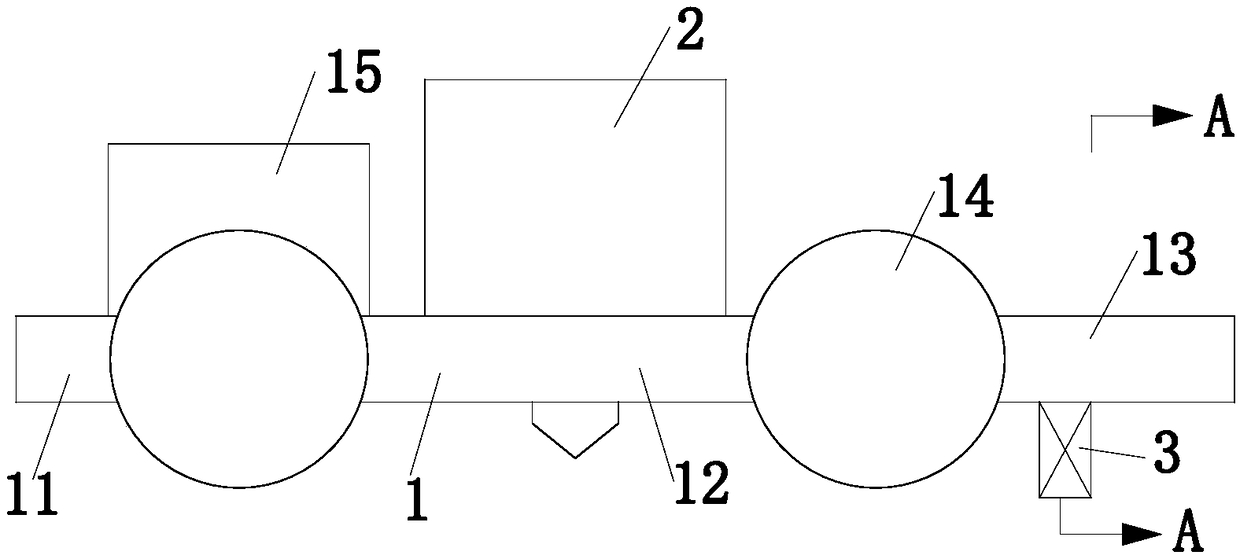

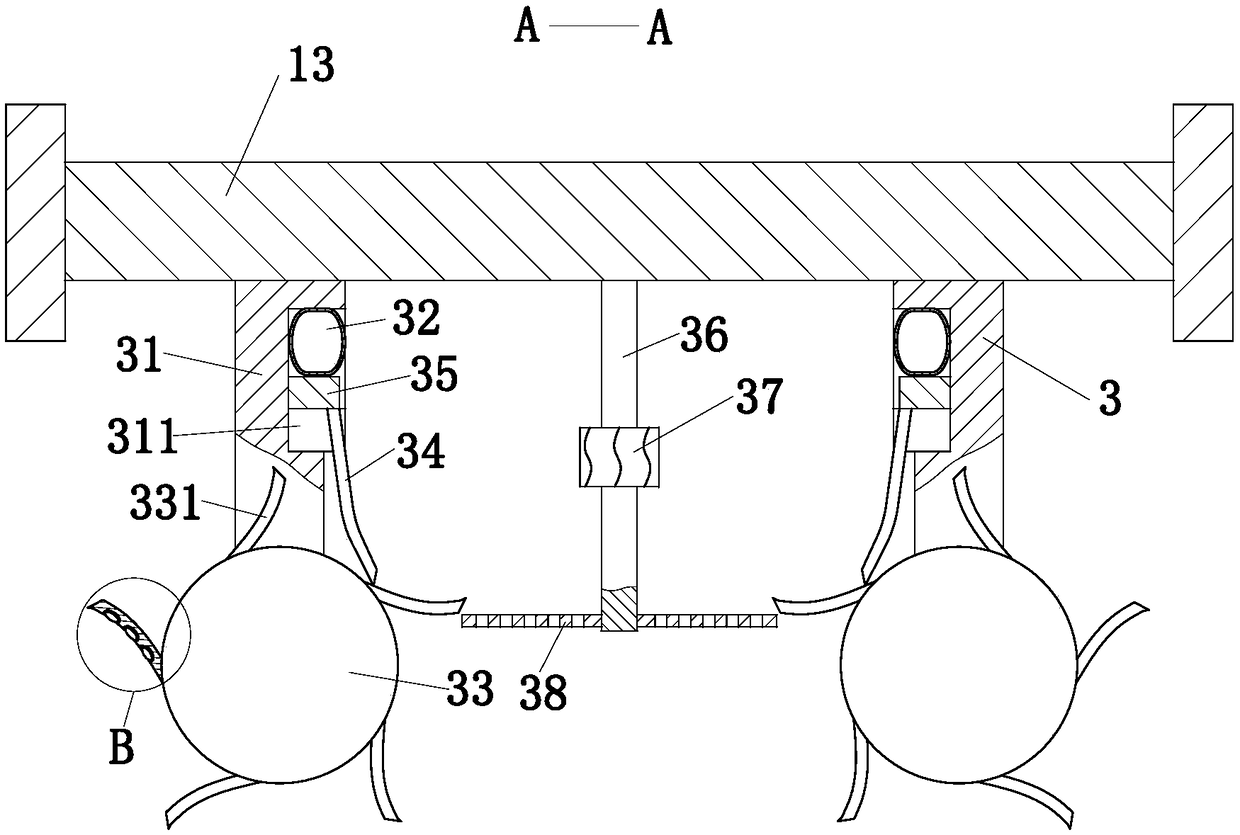

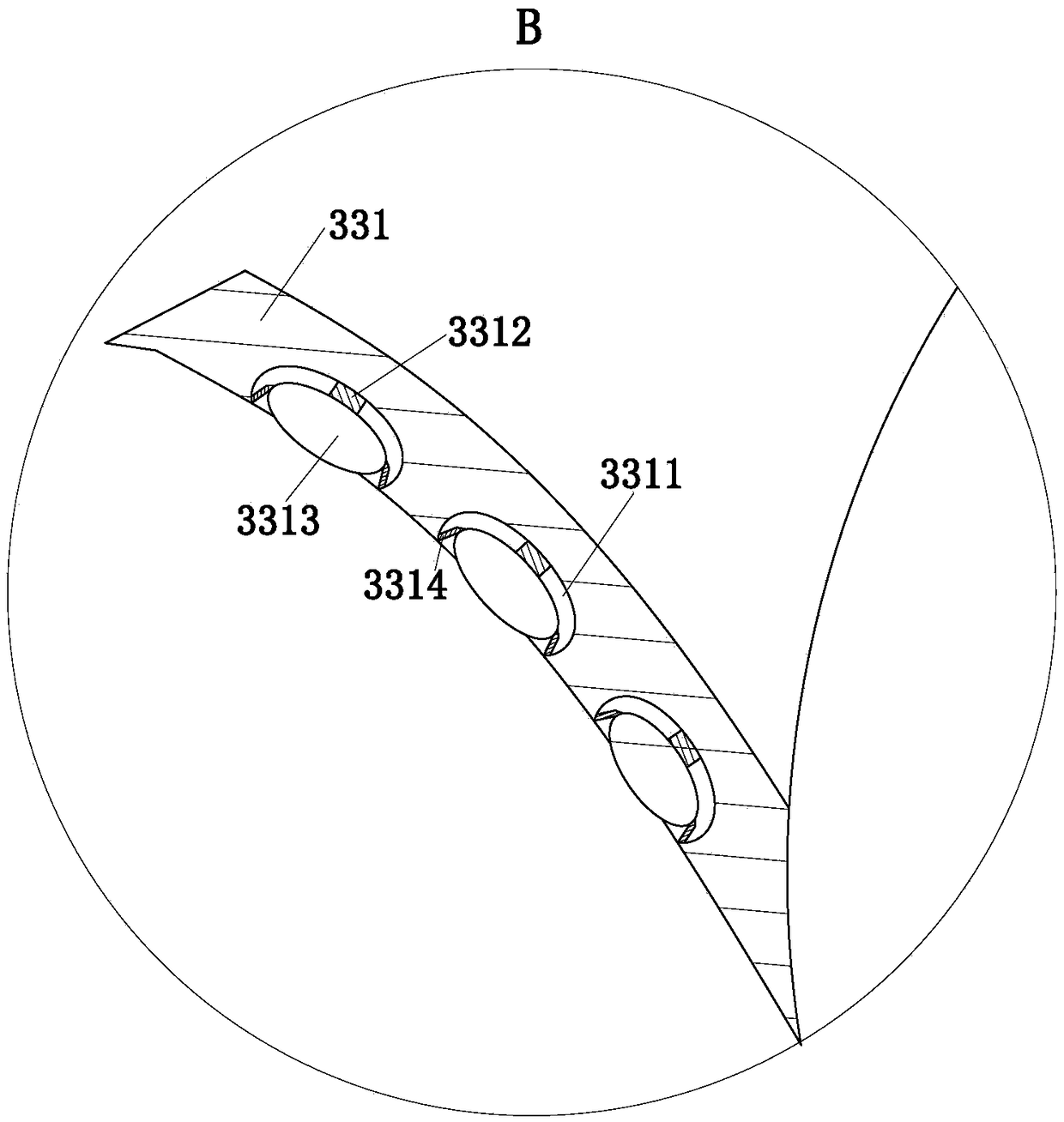

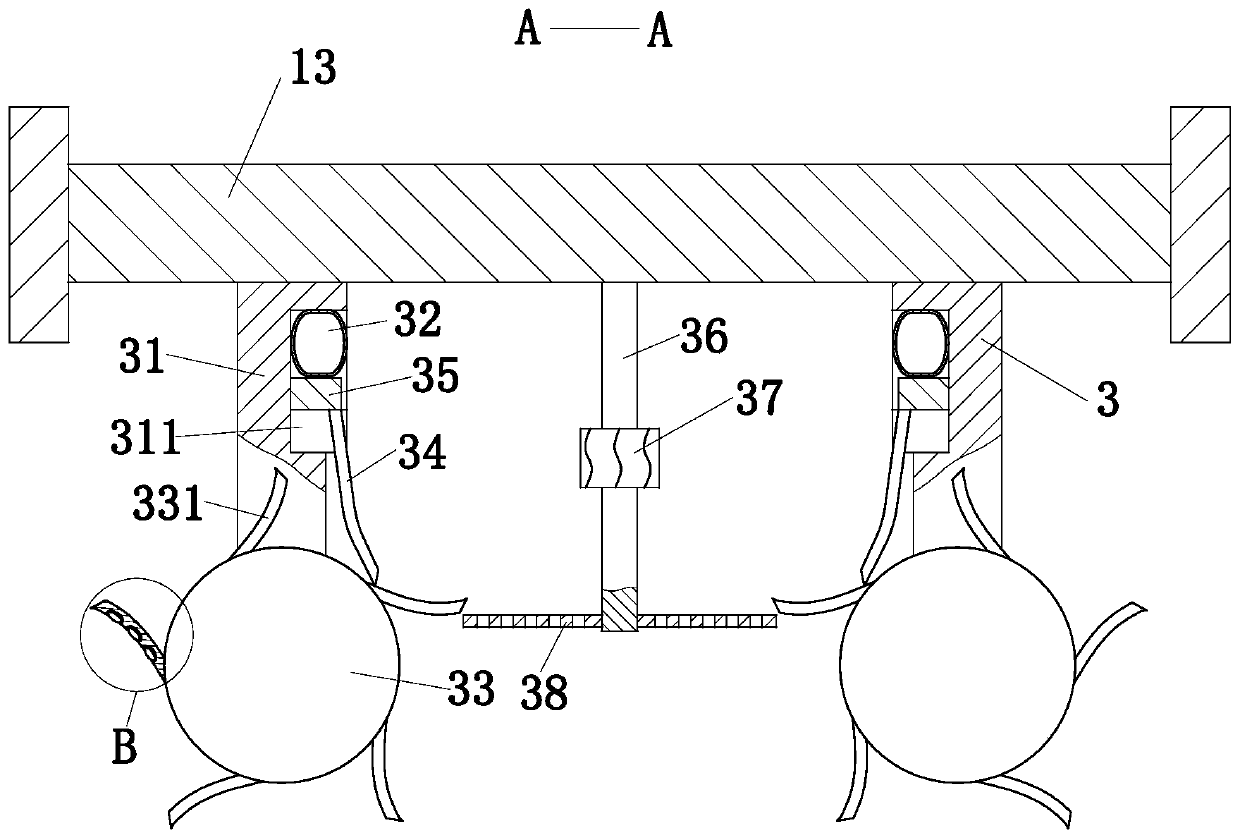

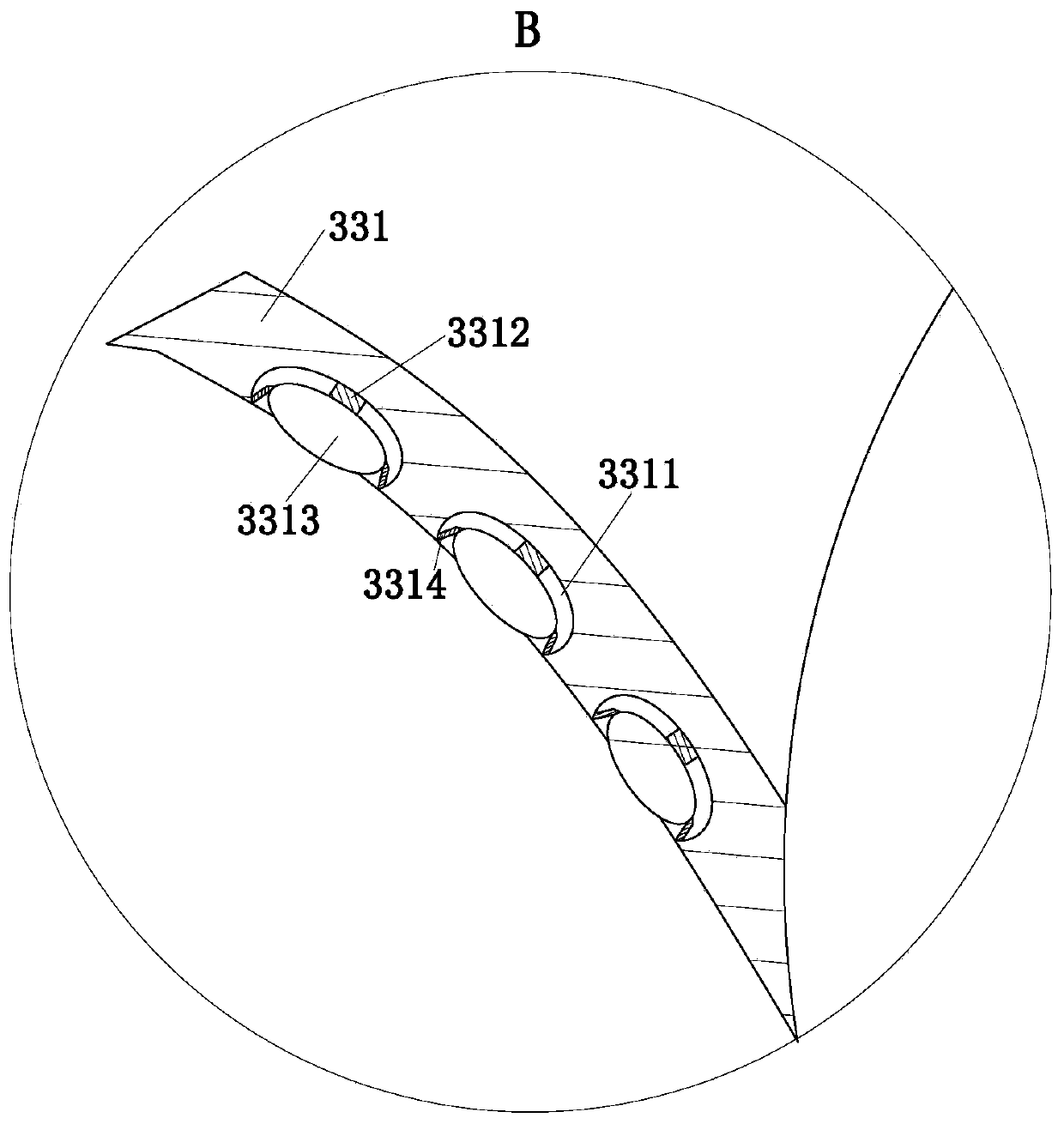

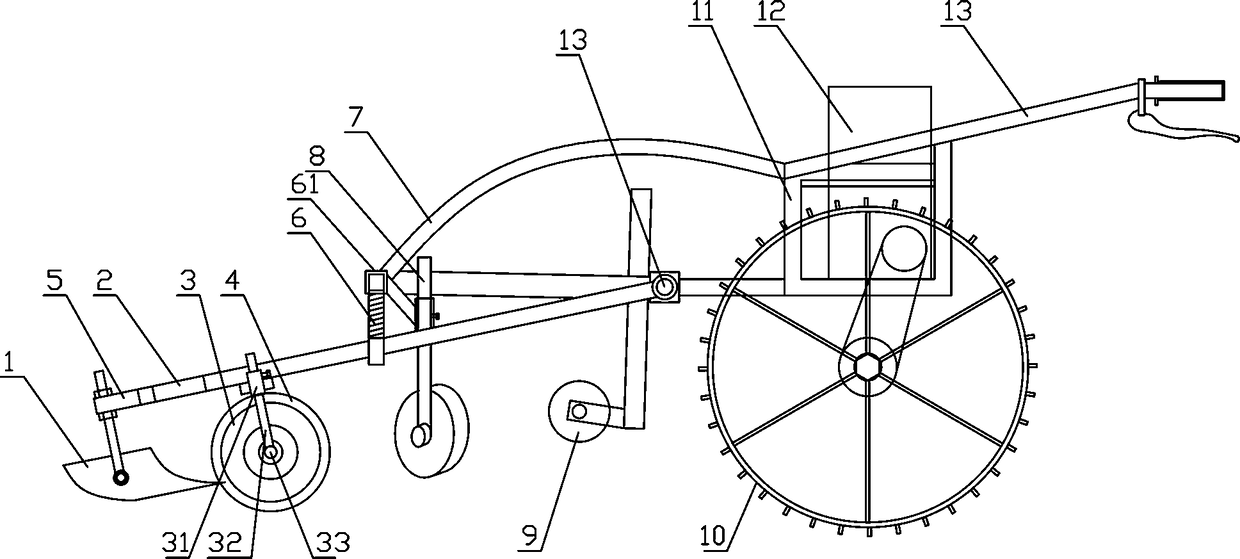

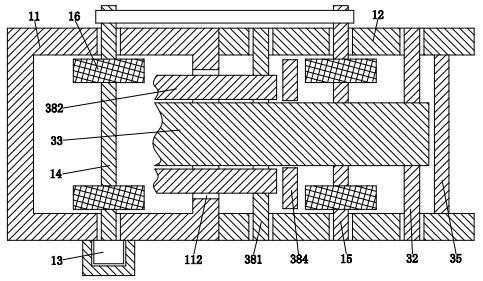

Electric fertilizing and soil-covering machine

ActiveCN109168503AUniform coveringFalling smoothlyPlantingFertiliser distributersAgricultural landAgricultural engineering

The invention belongs to the technical field of agricultural machines, and concretely relates to an electric fertilizing and soil-covering machine. The machine comprises a frame, road wheels, a controller, a fertilizing device and a soil covering device, the frame walks through the rotation of the walking wheels, and the frame comprises a machine head, a machine body and a machine tail; the controller is used for controlling the fertilizing device to automatically fertilize and the soil covering device to cover soil, and the controller is mounted at the machine head; the fertilizing device ismounted on the machine body, and the fertilizing device is used for automatically spraying a fertilizer on agricultural land; and the soil covering device is used for uniformly covering the fertilizedagricultural land with broken soil. The controller controls the fertilizing device and the soil covering device to work, so the electric fertilizing and soil-covering machine can perform fertilization and soil-covering synchronously; and the driving motor drives a soil-covering shovel to rotate, a soil covering plate on the soil covering shovel continuously picks up the soil on the agricultural land and makes the soil reach a scraper plate, the scraper plate scrapes the soil on the soil covering plate to a sieve plate, and a vibrator vibrates to make the broken soil on the sieve plate evenlyfall and cover the fertilizer, so the uniform soil coverage of the electric fertilizing and soil-covering machine is achieved.

Owner:杭州市临安区农林技术推广中心

An Electric Fertilizer and Soil Covering Machine

ActiveCN109168503BUniform coveringFalling smoothlyPlantingFertiliser distributersAgricultural landAgricultural science

The invention belongs to the technical field of agricultural machines, and concretely relates to an electric fertilizing and soil-covering machine. The machine comprises a frame, road wheels, a controller, a fertilizing device and a soil covering device, the frame walks through the rotation of the walking wheels, and the frame comprises a machine head, a machine body and a machine tail; the controller is used for controlling the fertilizing device to automatically fertilize and the soil covering device to cover soil, and the controller is mounted at the machine head; the fertilizing device ismounted on the machine body, and the fertilizing device is used for automatically spraying a fertilizer on agricultural land; and the soil covering device is used for uniformly covering the fertilizedagricultural land with broken soil. The controller controls the fertilizing device and the soil covering device to work, so the electric fertilizing and soil-covering machine can perform fertilization and soil-covering synchronously; and the driving motor drives a soil-covering shovel to rotate, a soil covering plate on the soil covering shovel continuously picks up the soil on the agricultural land and makes the soil reach a scraper plate, the scraper plate scrapes the soil on the soil covering plate to a sieve plate, and a vibrator vibrates to make the broken soil on the sieve plate evenlyfall and cover the fertilizer, so the uniform soil coverage of the electric fertilizing and soil-covering machine is achieved.

Owner:杭州市临安区农林技术推广中心

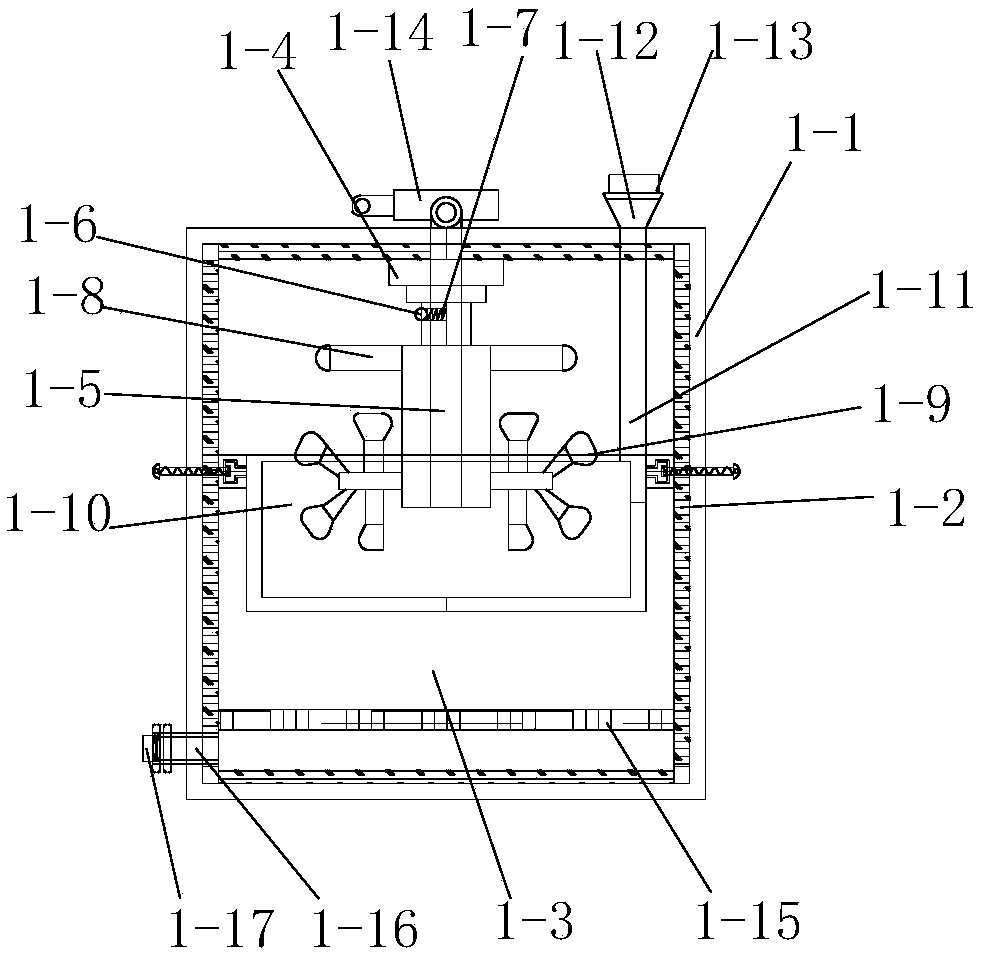

Agricultural soil covering mechanical vehicle and using method

InactiveCN112868313APrevent throwingLong growth cyclePlantingFurrow making/coveringAgricultural engineeringStructural engineering

The invention discloses an agricultural soil covering mechanical vehicle and a using method. The agricultural soil covering mechanical vehicle structurally comprises a machine body, an electric control box, a diesel oil tank, a driving box, moving wheels, a uniform covering device, a stopping bolt and a hand pushing handle. The mechanical vehicle has the beneficial effects that under the interaction of a hard cutting piece and a triangular cone, a scattered digging structure is used for loosening dug soil pockets used for covering, so that the situation that hard caked soil pockets doped in digging are directly thrown to the surface of a plant planting position, and then the growth cycle of plants is prolonged or the survival rate of the plants is reduced is avoided; and according to the device, under mutual cooperation effect of an anti-splashing mechanism and a spraying net plate, an area, needing to be covered, of the planting position is uniformly covered with soil after the soil pockets are excavated by the scattering structure and is loosened, so that the situation that the spraying range of the soil pockets under traditional soil covering equipment is large and plants which are well covered at intervals are affected.

Owner:张自明

Power-assisted mulching film machine

ActiveCN105284505BLimited working heightUniform coveringPlant protective coveringsAgricultural engineeringPlastic film

The invention discloses a power-assisted plastic film mulching machine. The power-assisted plastic film mulching machine comprises a rack. Travel wheels are arranged on the rack. A film roller is connected with the rack through film roller brackets. Automatic adjusting rods are arranged on the two sides of the rack. One end of each automatic adjusting rod is hinged to the rack. A soil covering assembly is mounted at the other end of the automatic adjusting rod. A liftable positioning wheel and a film pressing roller are arranged in front of each soil covering assembly. A suspension frame is also arranged on the rack. One end of the suspension frame is fixedly connected with the rack and the other end of the suspension frame is movably connected with the middle of the automatic adjusting rod. A buffer spring is arranged between the end of the suspension frame and the middle of the automatic adjusting rod. The power-assisted plastic film mulching machine provided by the invention has following beneficial effects: by arranging the independently suspended automatic adjusting rods, the height of each soil covering blade can be automatically adjusted according to the topographical change during film mulching in combination with the suspension frame and buffer springs, so that the power-assisted plastic film mulching machine is suitable for mountain topography, especially slope topography; due to the arrangement of the height-adjustable positioning wheels, the working height of the soil covering blade can be limited, so that the soil covering blades can be used for uniformly covering soil.

Owner:CHANGYANG SHENGDA CHEERFUL AGRI MACHINERY

No-tillage tomato cultivation method

InactiveCN109429756AAdapt to the environmentImprove survivabilityGraftingPlant protective coveringsRootstockZoology

The invention discloses a no-tillage tomato cultivation method. The no-tillage tomato cultivation method comprises the following steps of 1, seedling raising preparation, wherein high-quality stocks are selected, and ventilating cultivation is kept; 2, grafting management, wherein scions are grafted to the stocks by adopting a sun-shading technology, sun-shading culture and appropriate watering are executed, then lighting time is gradually increased, and meanwhile the irrigation water amount is increased; 3, film laying and transplantation, wherein a herbicide is sprayed, cultivated land is covered by film, irrigation pipes are erected and laid, holing, fertilization and film laying are executed, and grafted stocks are transplanted into holes; 4, field management after transplantation, wherein ventilation and lighting are kept, injurious insects are prevented and controlled, irrigation is executed at fixed period, old leaves are removed, pruning and vine binding are executed, and thentomatoes are ripe and are harvested. Compared with traditional ploughing, the planting yield is increased by 5%-6% and labor and the labor cost are saved by adopting the efficient tomato cultivation method.

Owner:GUANGXI UNIV

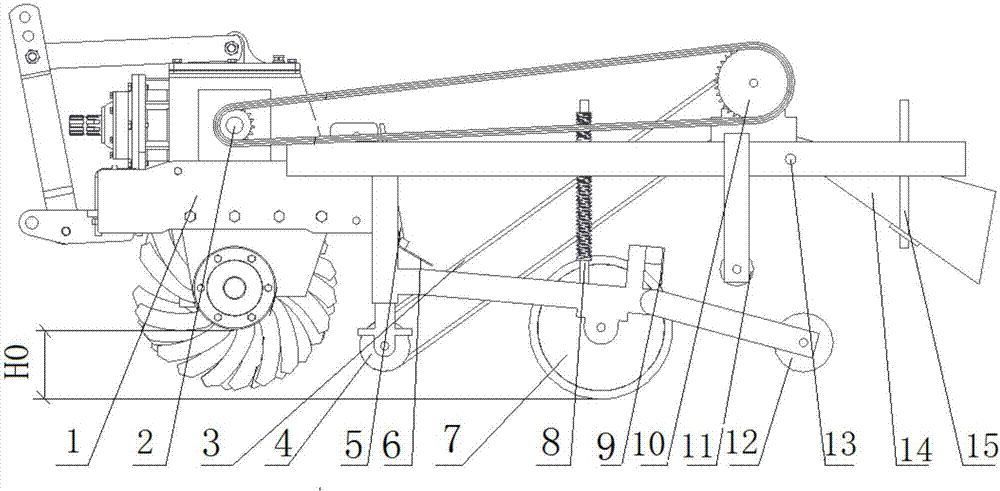

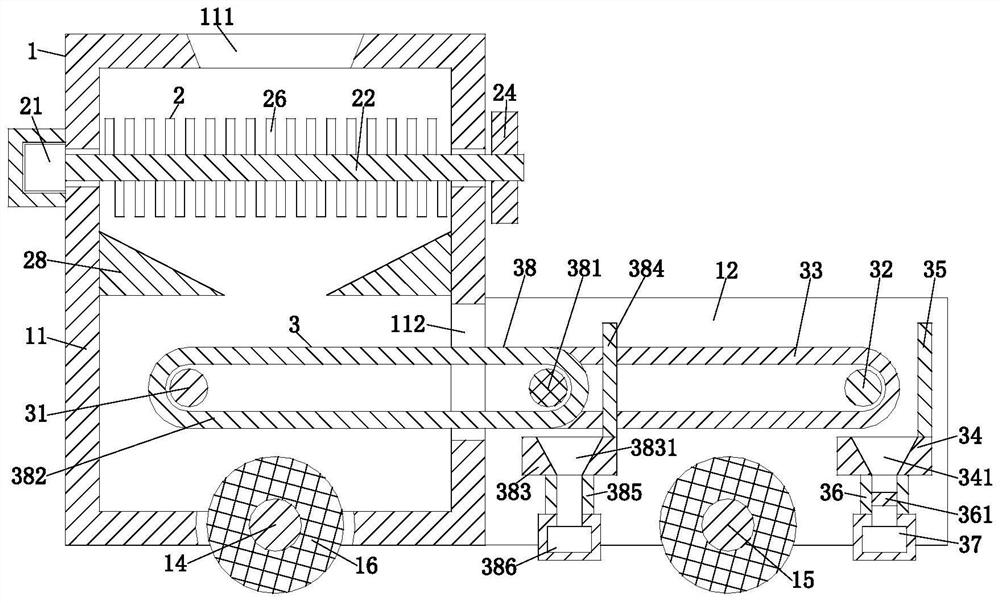

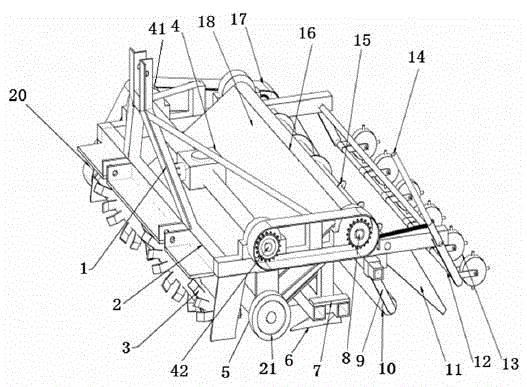

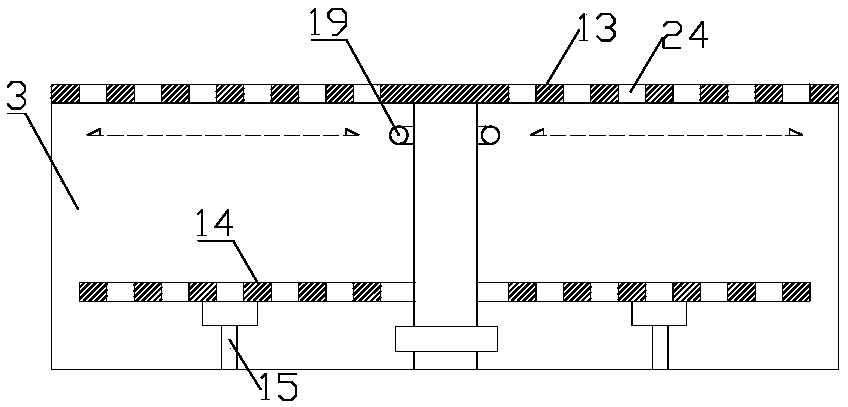

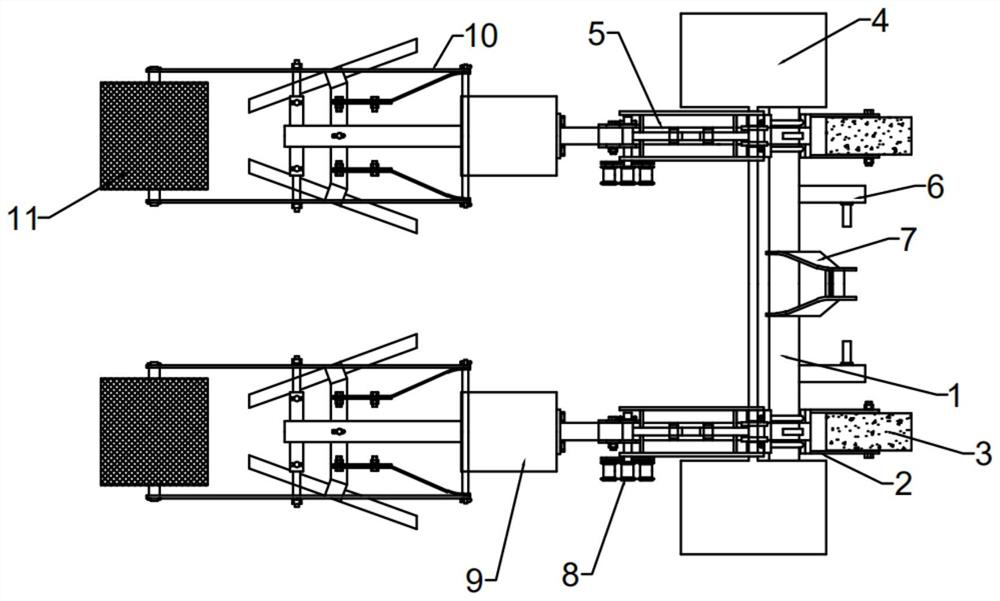

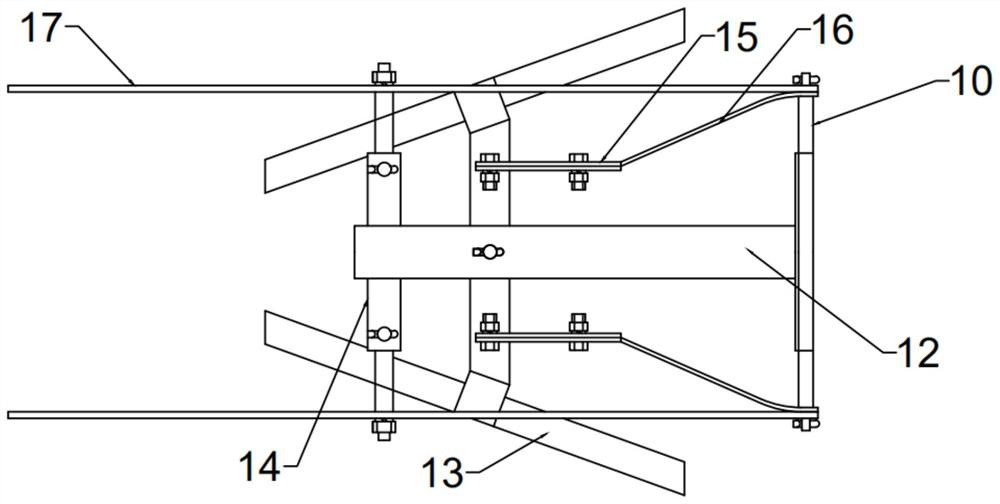

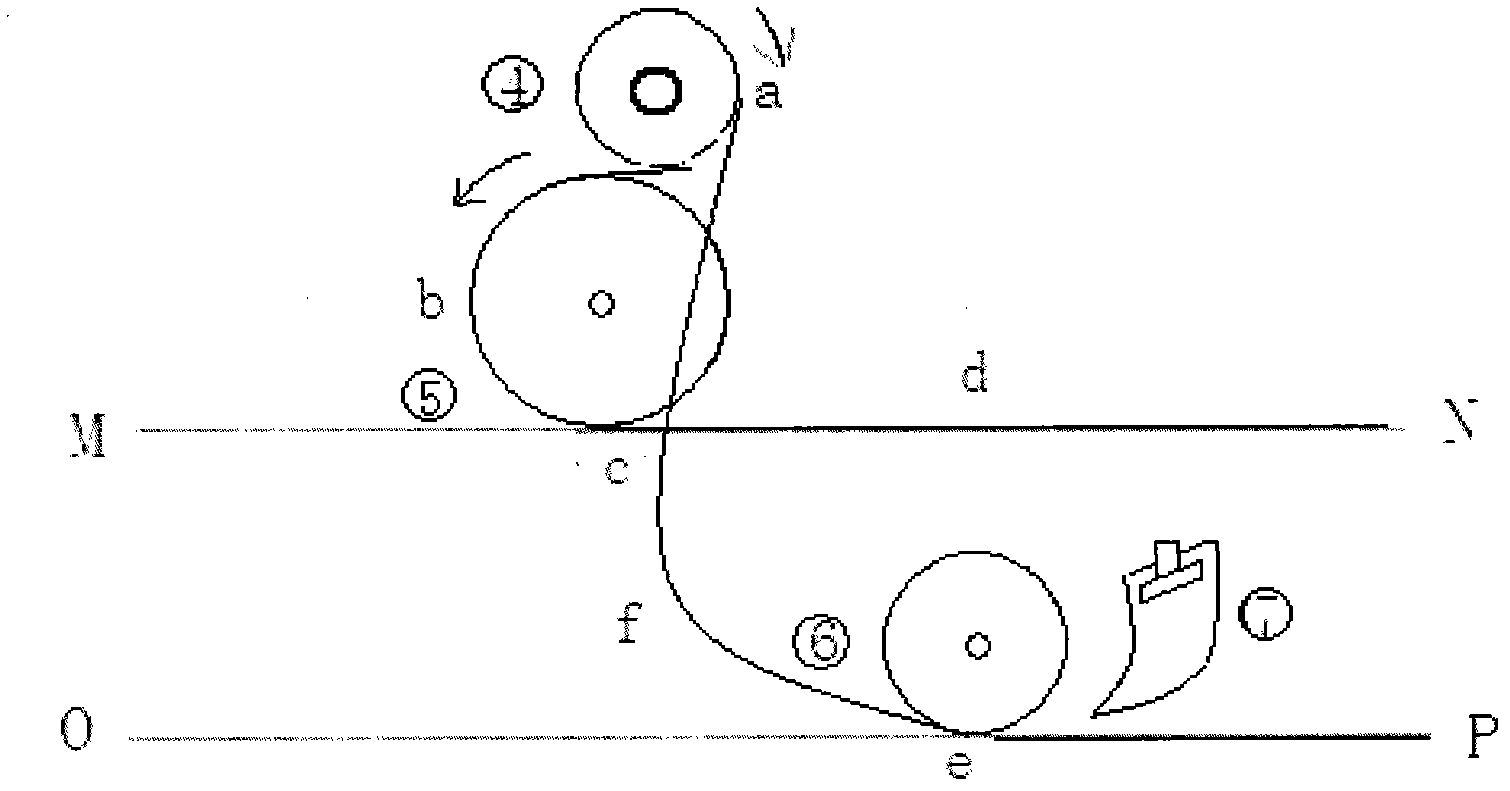

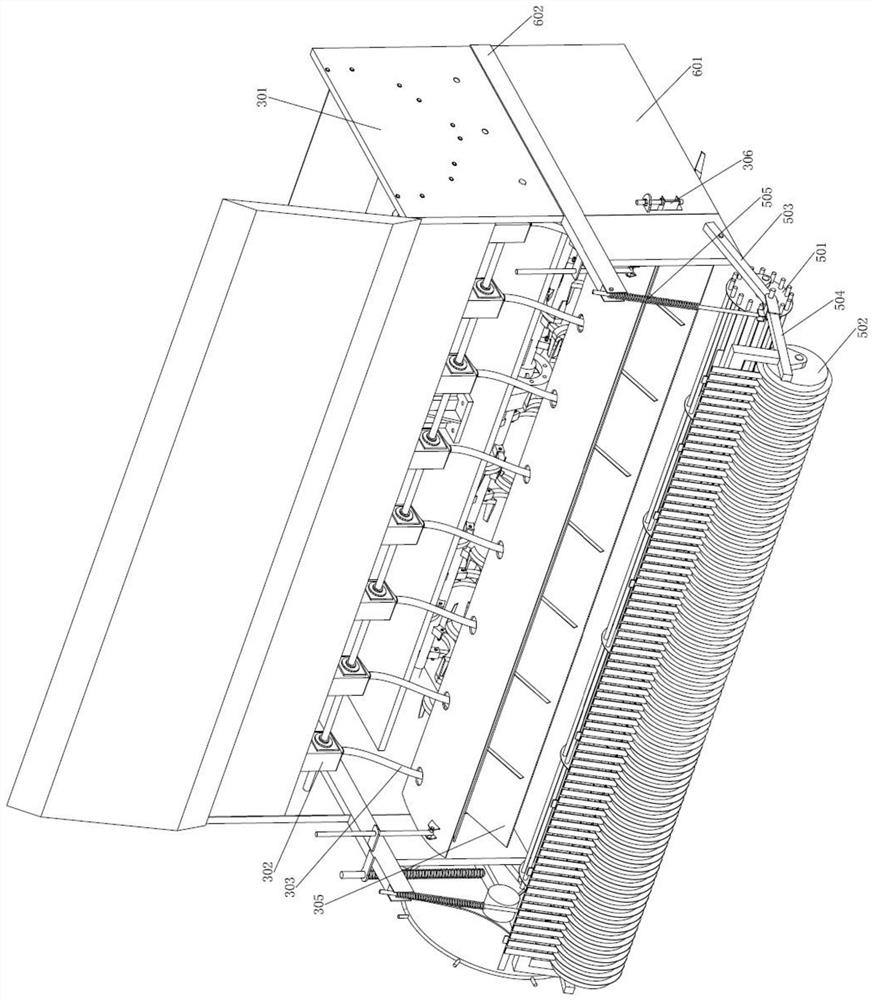

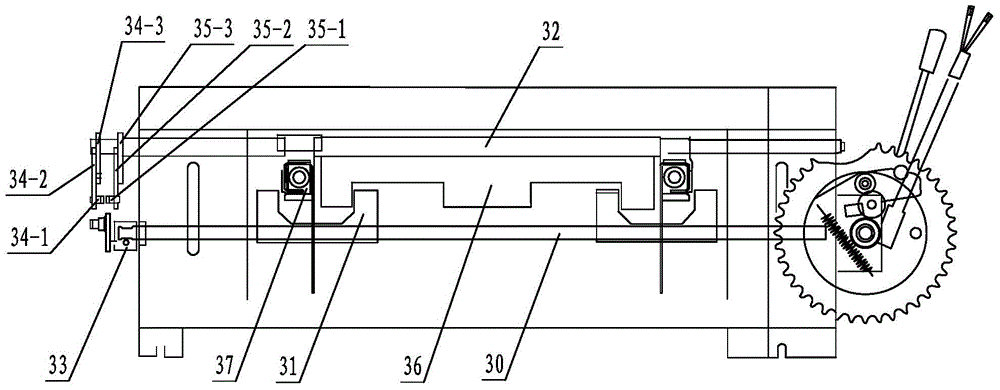

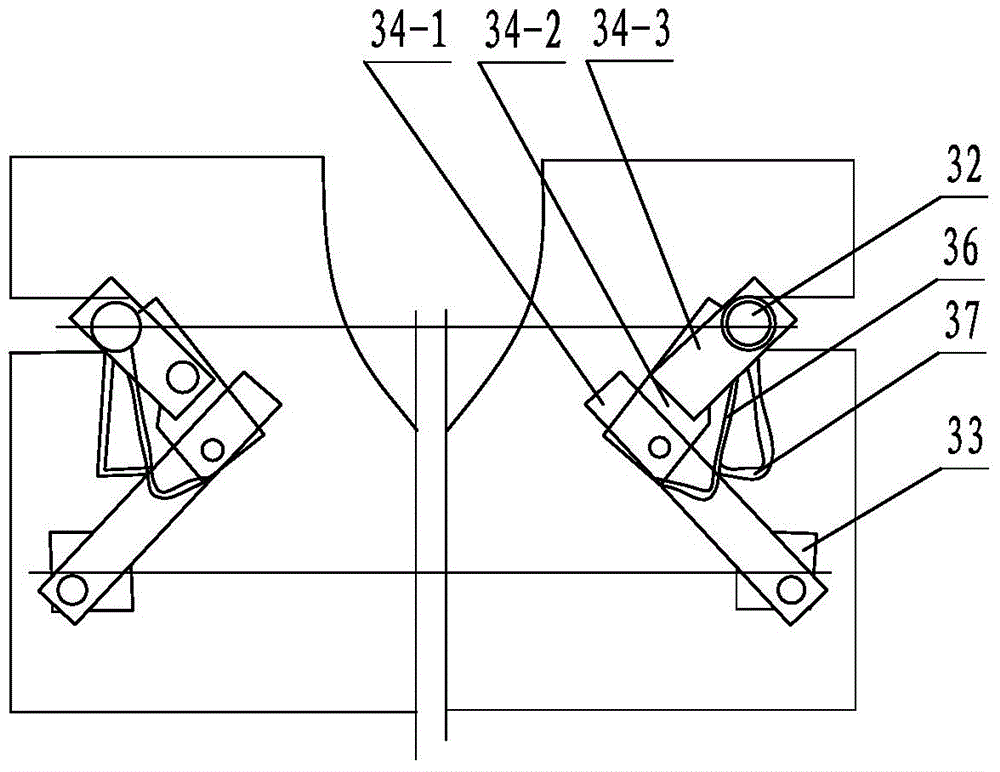

Rotary tillage soil throwing linear uniform sowing machine

PendingCN112042297AGood even broadcasting effectReasonable structureSpadesPloughsAgricultural engineeringStructural engineering

The invention discloses a rotary tillage soil throwing linear uniform sowing machine. The uniform sowing machine comprises a power mechanism, a rotary tillage mechanism, a seed metering mechanism, a soil covering mechanism, a pressing mechanism and a frame body, wherein the frame body comprises side plates, upper beams and a transverse plate; the two side plates are arranged in a mirror symmetry mode, and one upper beam is fixedly connected to the position right above the corresponding side plate; one transverse plate is fixedly connected between the two side plates and is arranged parallel tothe ground, the transverse plate is fixedly connected to the front end positions of the side plates, the power mechanism is arranged above the transverse plate, and the rotary tillage mechanism is arranged below the transverse plate; and the seed metering mechanism is located right above the two upper beams and behind the power mechanism and the rotary tillage mechanism, and is fixedly connectedbetween the two side plate, the soil covering mechanism is arranged on the seed metering mechanism, and the pressing mechanism is fixedly connected to the rear portions of the two upper beams. The rotary tillage soil throwing linear uniform sowing machine has the beneficial effects that structure is reasonable, operation is stable, multiple functions are integrated, soil covering is uniform, seeduniform sowing effect is excellent, and the sowing density and the soil covering amount can be rapidly adjusted.

Owner:INST OF CROP SCI NINGXIA ACADEMY OF AGRI & FORESTRY SCI +1

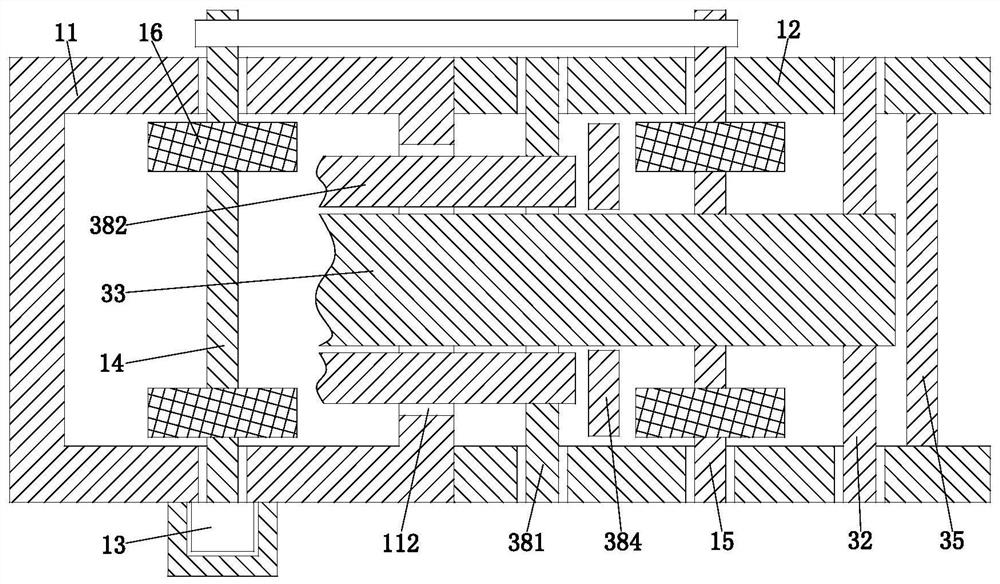

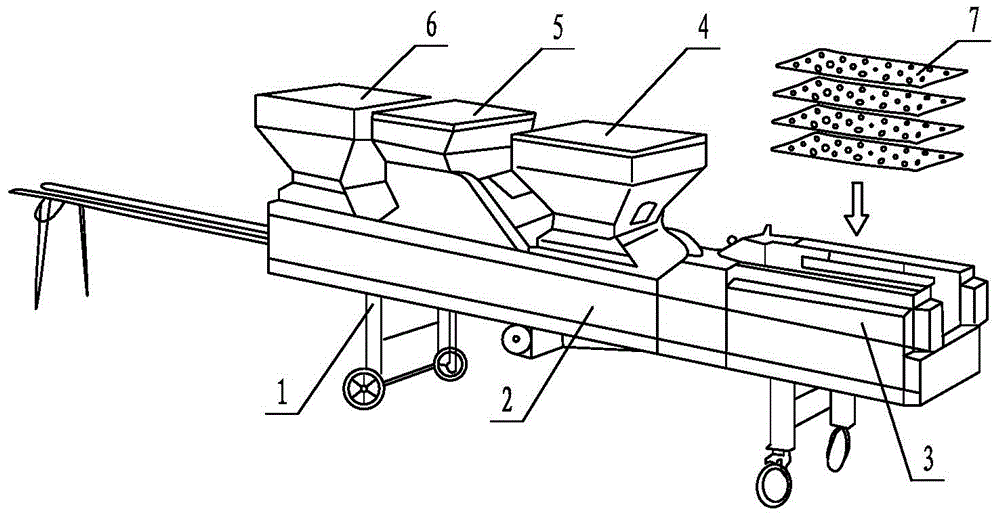

Bowl sports seedling precision seeding line

ActiveCN103749047BImprove breeding success rateReduce processing costsPlantingCultivating equipmentsPunchingAgricultural engineering

The invention discloses a precision seeding assembly line for pot seedling. The precision seeding assembly line comprises a frame and a seedling plate conveyer belt, wherein the seedling plate conveyer belt is arranged on the frame; an automatic seedling plate feeding device, a seedbed soil pressing device, a precision seeding device and an earthing device are orderly fixed on the frame above the seedling plate conveyer belt; seedling plates with holes are regularly arranged above the automatic seedling plate feeding device and orderly conveyed to the subsequent devices by virtue of the seedling plate conveyer belt; finally, automatic line production of seedling plate conveying, substratum filling, punching, precision seeding, panning and earthing is finally achieved. By adopting the precision seeding assembly line, the germination rate and the seedling rate of sprout cultivation are further improved, and the root of a rice seedling is increased, so that the survival rate and the mechanical operation level after seedling planting are improved, the working hours are saved, the operation cost is reduced, and the work efficiency of seedling cultivation is effectively improved.

Owner:常州亚美柯机械设备有限公司

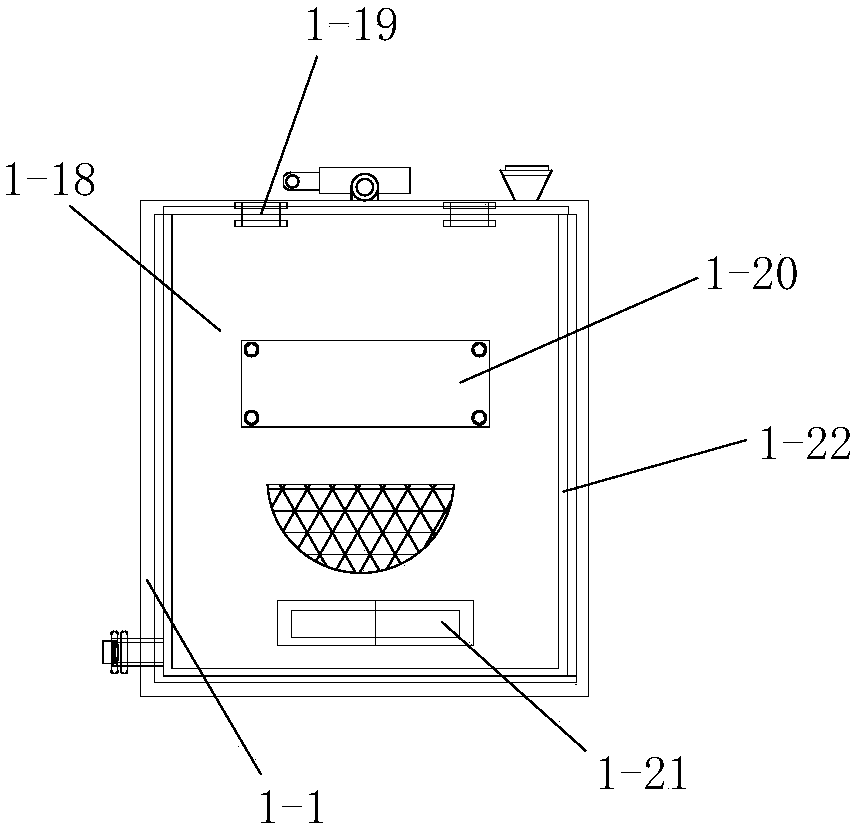

Soil covering device for strawberry planting

ActiveCN112616368BEasy to cover with soilReduce utilizationPlantingSoil-working equipmentsFragariaAgricultural engineering

A soil covering device for strawberry planting provided by the present invention comprises a frame, a crushing unit and a paving and filling unit, and is characterized in that: the upper end of the frame is provided with a feeding port, the crushing unit is installed on the inner wall of the frame, and the paving and filling unit is arranged on On the outer wall of the right end of the frame; the present invention can solve the problem that "most of the existing strawberry seedlings are planted with artificial covering soil to pave and fill it with soil, but the artificial covering soil cannot completely pulverize the massive soil inside the soil, so it cannot It plays a better covering role, thereby reducing the utilization rate of the soil, and the strawberry seedlings are easily smashed by the lumpy soil during filling, which wastes costs; and manual operation cannot effectively control the uniformity of the filling soil, so it is easy to reduce The survival rate of strawberry seedlings, and the need to replenish the seedlings, increase the workload, and waste the cost of employment" and other issues.

Owner:FUYANG HONGFU AGRI SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com