Micro-ridge full film-mulching and banking machine

A technology of soil covering machine and film covering mechanism, which is applied in the direction of agricultural machinery and tools, excavation/covering ditches, shovels, etc., and can solve the problem of not being able to achieve large-scale planting of densely planted crops, large limitations of water-saving cultivation, and low degree of mechanization. problems, to achieve the effect of reducing labor intensity, standardizing ridges, and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

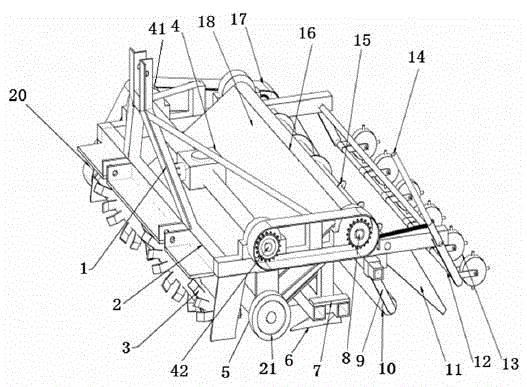

[0022] like figure 1 As shown, a full-film micro-ridge mulching soil covering machine includes a frame 2, a suspension frame 1, a differential case 4, a rotary tillage mechanism, a film covering mechanism, and a soil covering mechanism, and the differential case 4 is output through a universal joint and a tractor Power shaft is connected, is provided with left sprocket wheel 41, right sprocket wheel 42, and rotary tillage mechanism is located at the front bottom of frame 2, and rotary tillage mechanism comprises rotary tiller 3, rotary tiller sprocket wheel 20, and soil covering mechanism is located at machine Above the middle part of the frame 2, the film covering mechanism is located at the rear of the frame 2, and also includes a film binding mechanism and a ditching plow 6. The film binding mechanism includes a film rolling wheel frame 12 and a film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com