Rotary tillage soil throwing linear uniform sowing machine

A technology of soil line type and seeding mechanism, which is applied in the field of agricultural machinery, can solve the problems of not simplifying the energy consumption of crop sowing machinery, unfavorable cultivation of strong seedlings, and crowding between plants, etc., and achieve quick adjustment of covering soil amount, excellent effect and stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

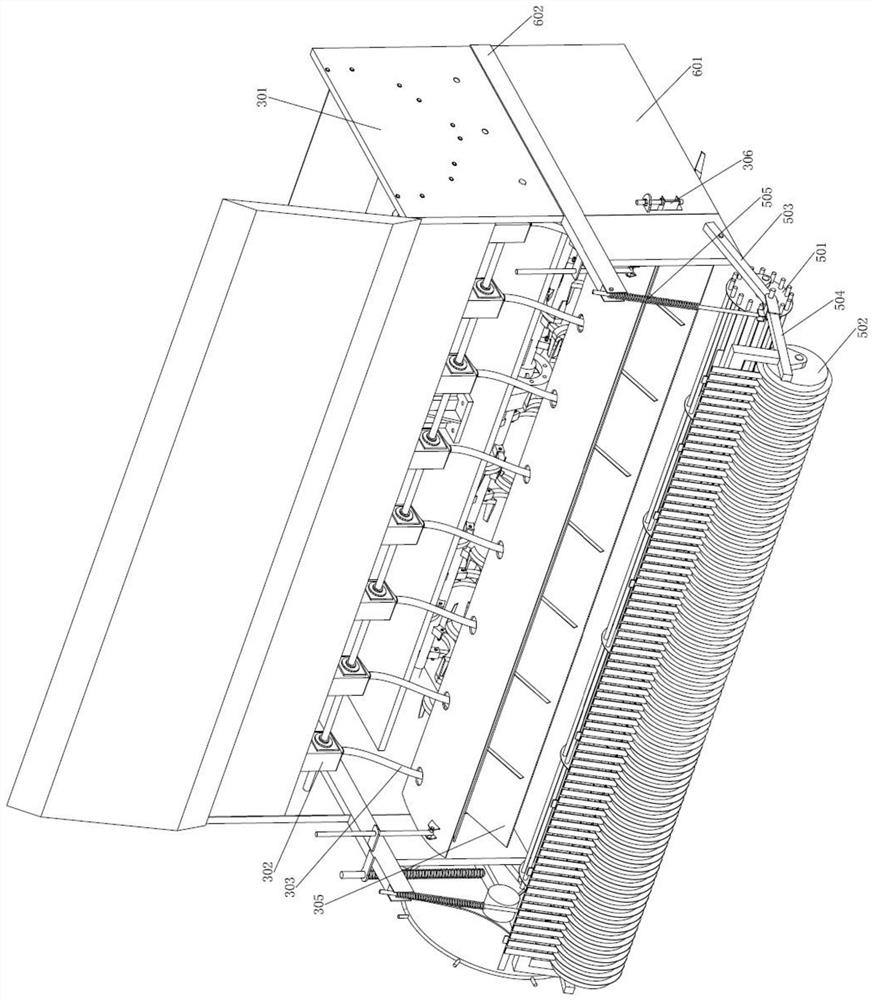

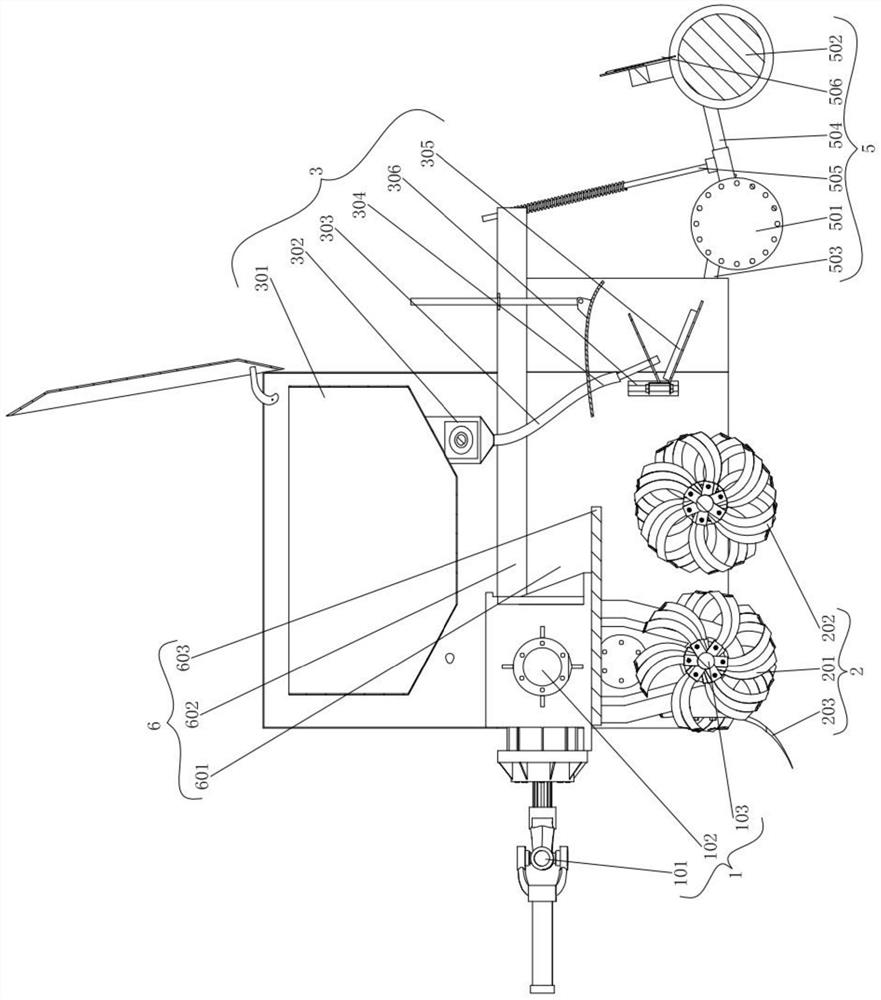

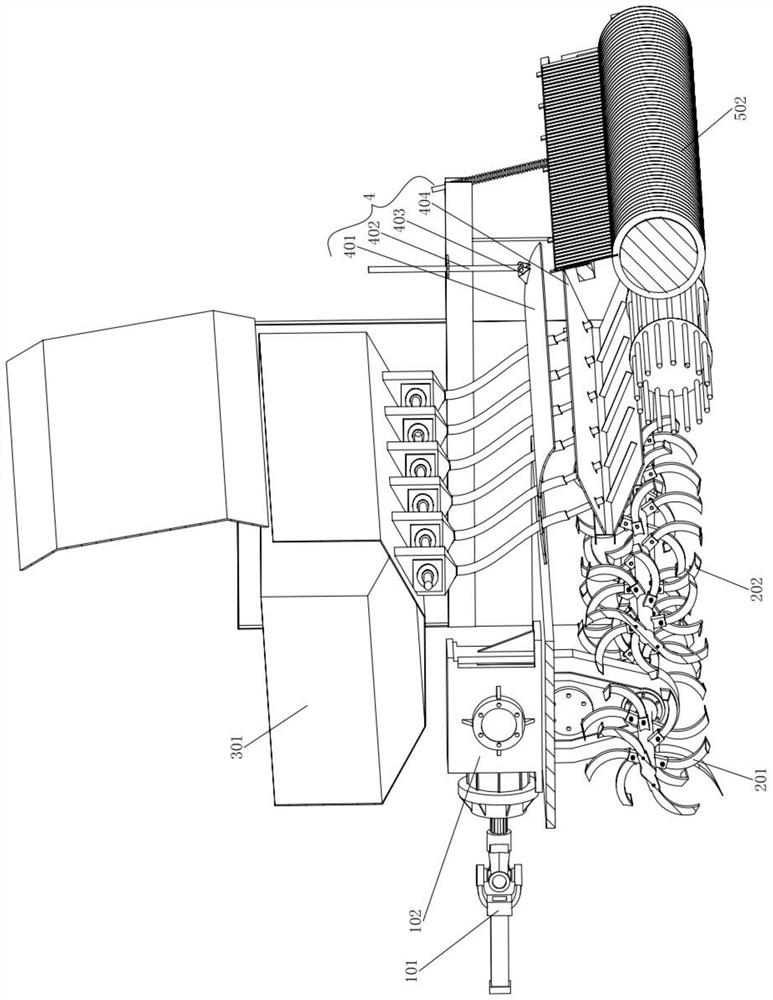

[0022] Example: such as Figure 1-5 As shown, a rotary tillage soil throwing line-type leveling machine includes a power mechanism 1, a rotary tillage mechanism 2, a seeding mechanism 3, a soil covering mechanism 4, a suppression mechanism 5 and a frame body 6, wherein: the frame body 6 includes side plates 601, an upper beam 602 and a horizontal plate 603; there are two side plates 601 arranged symmetrically in a mirror image; an upper beam 602 is fixedly connected directly above the side plate 601; a horizontal plate 603 is fixedly connected between the two side plates 601 , the horizontal plate 603 is arranged parallel to the ground; the horizontal plate 603 is fixedly connected to the front end of the side plate 601; the power mechanism 1 is arranged above the horizontal plate 603, and the rotary tillage mechanism 2 is arranged below; the seeding mechanism 3 is located at two Right above the upper beam 602 and behind the power mechanism 1 and the rotary tillage mechanism 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com