Power-assisted mulching film machine

A technology of film laying machine and mulching film, which is applied in the direction of plant protection cover, etc., can solve the problems of difficult adjustment of the depth of the cover blade and difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

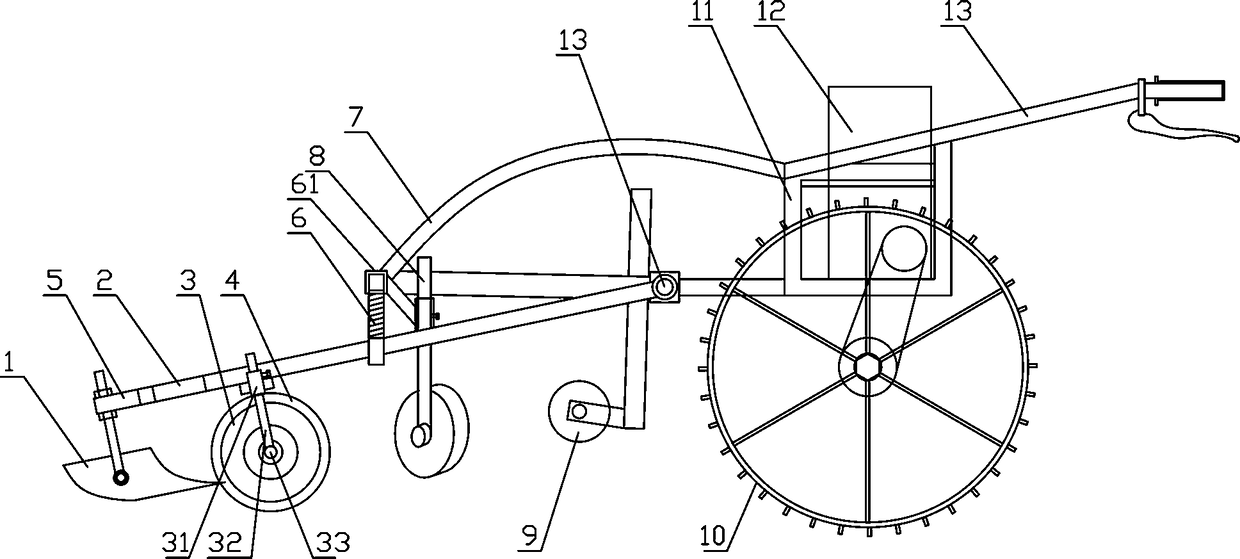

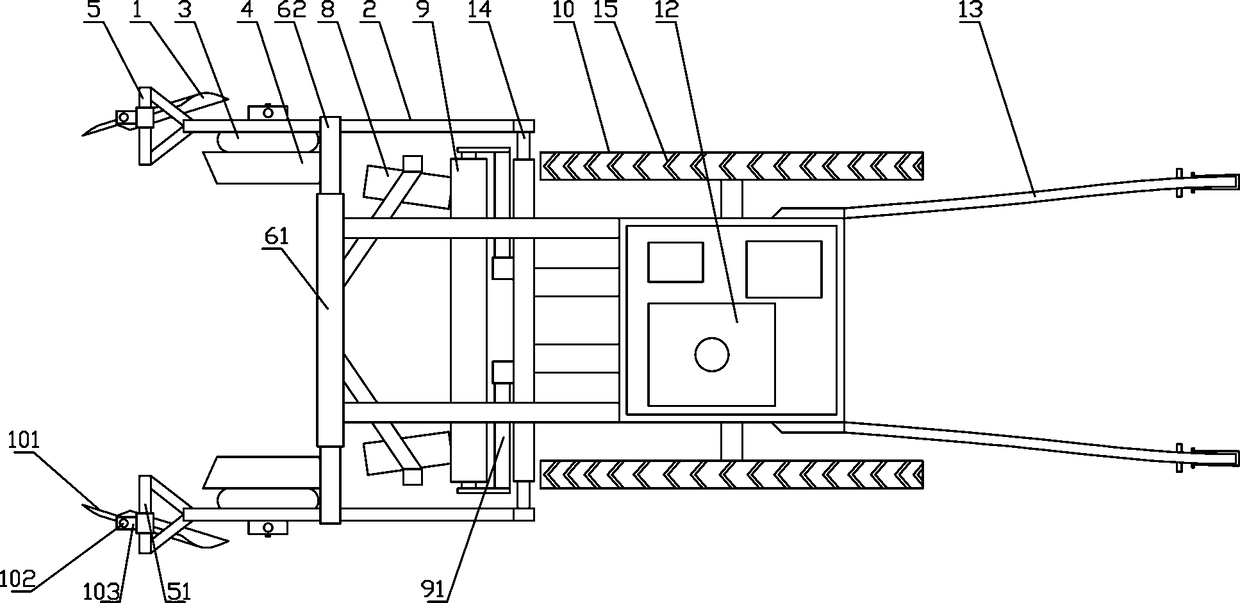

[0020] like figure 1 , 2 Among them, a power-assisted mulching film spreading machine includes a frame 11, on which a traveling wheel 10 is arranged, and a film roller 9 is connected to the frame 11 through a film roller bracket 91, and an automatic adjustment rod is provided on both sides of the frame 11 2. One end of the automatic adjustment rod 2 is hinged with the frame 11, and the other end is equipped with a soil cover assembly 1, and a liftable positioning wheel 3 and a lamination roller 4 are arranged before the soil cover assembly 1; the front in this example refers to figure 1 On the right side in the center, during operation, the soil cover assembly 1 is located at the rear. The provided positioning wheel 3 is used to limit the soil-eating depth of the soil-covering blade 101 in the soil-covering assembly 1 .

[0021] The frame 11 is also provided with a suspension frame 7, one end of the suspension frame 7 is fixedly connected with the frame 11, and the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com