Filtering film bag and film bioreactor using the filtering film bag

A membrane bioreactor and filtration membrane technology, applied in biological water/sewage treatment, membrane technology, semi-permeable membrane separation, etc. The problem of short service life of hollow fiber membranes has achieved the effect of easy popularization, compact structure and long service life of membranes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

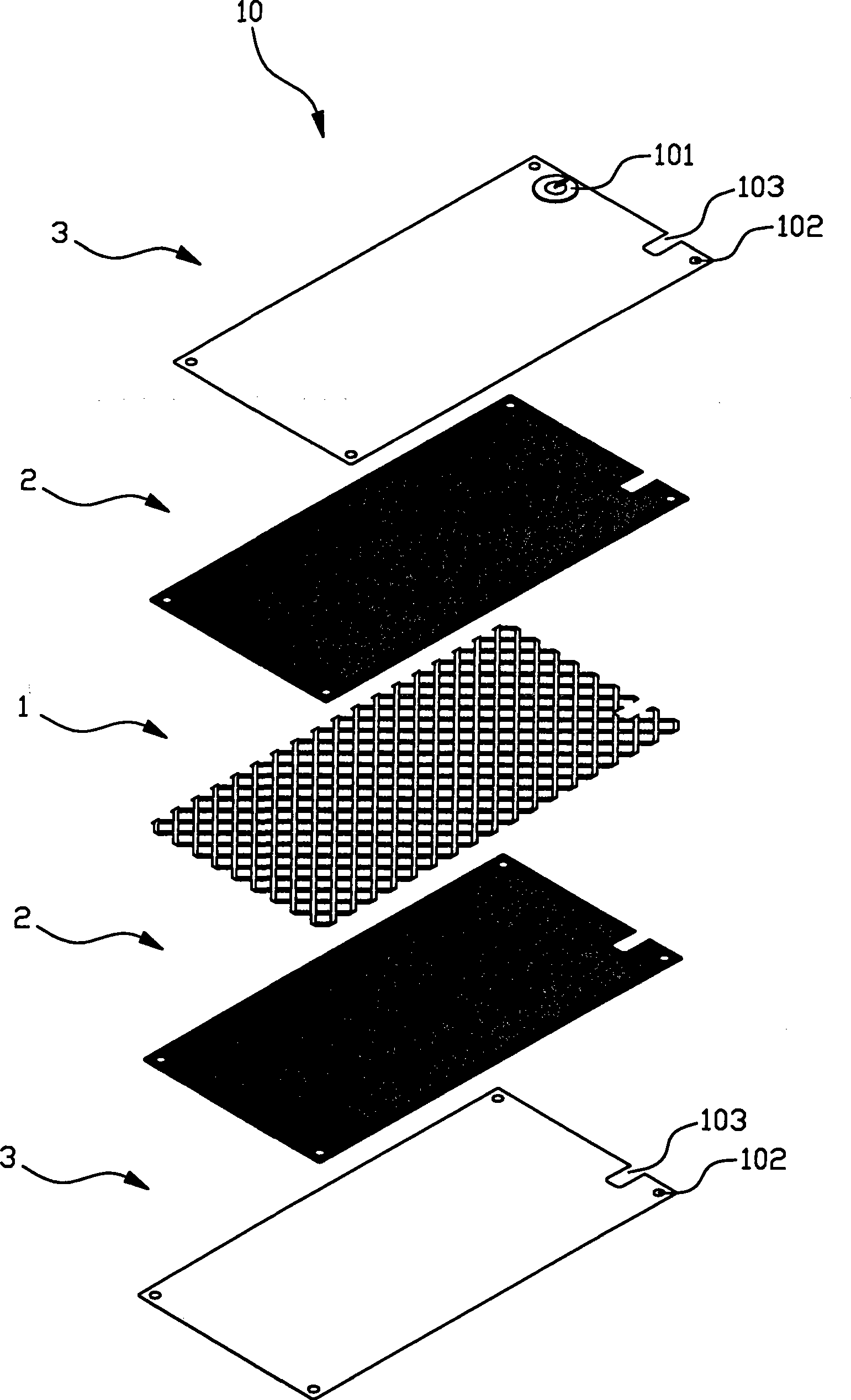

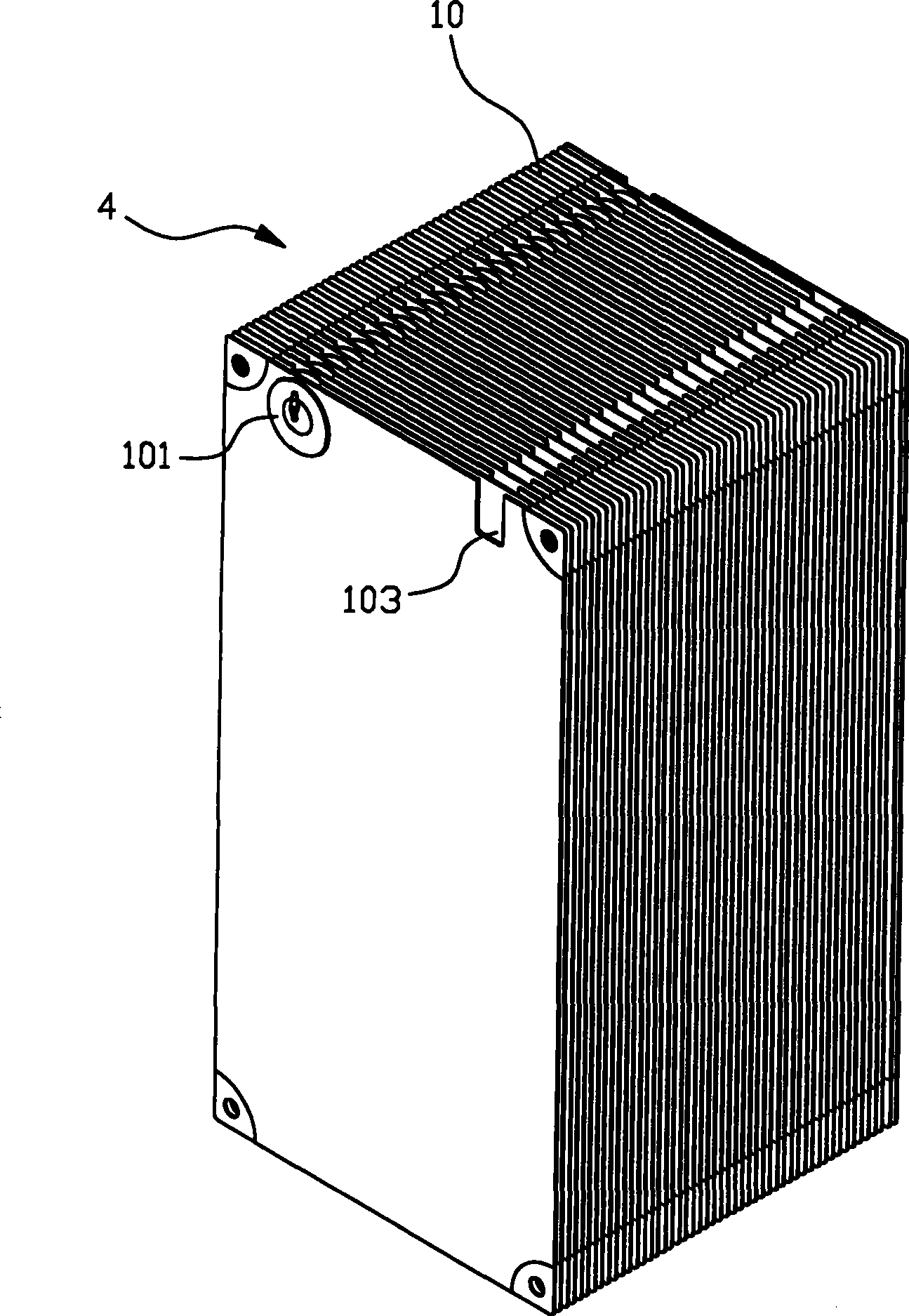

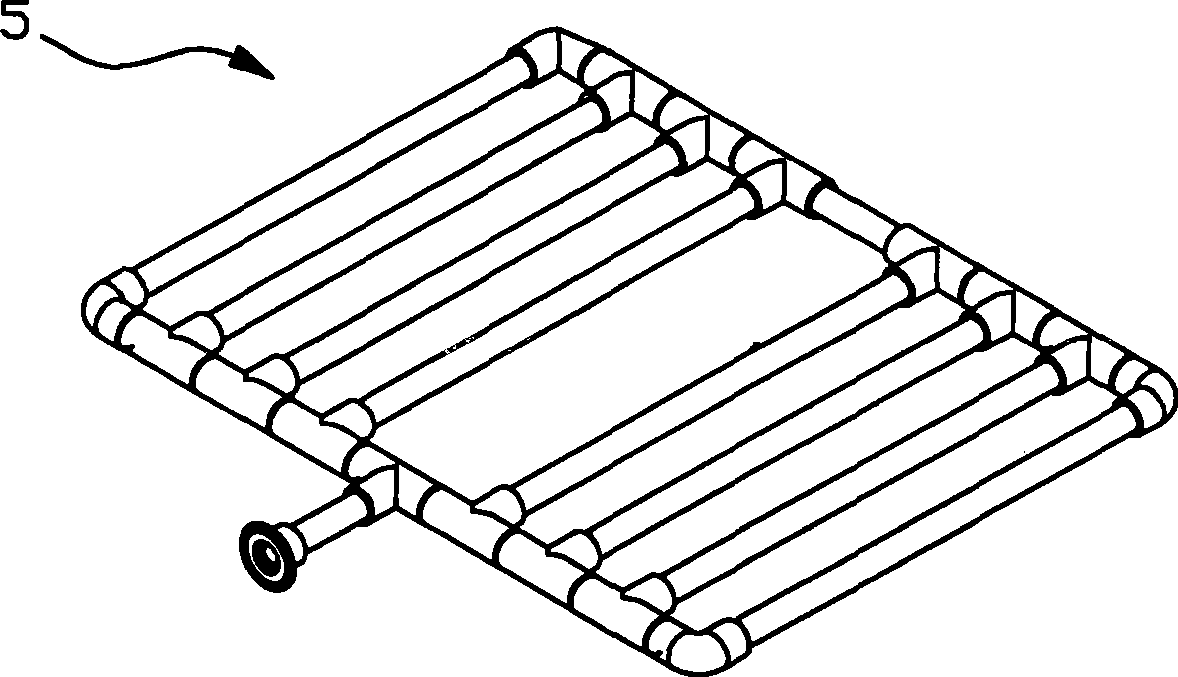

[0034] Specific embodiment one, a kind of filter membrane bag 10 of the present invention, refer to figure 1 , a total of 5 layers of materials, the central layer is a filter support grid 1, two layers of filter support cloth 2 on both sides of the filter support grid 1, and two layers of filter membrane 3 on the outside of the filter support cloth 2, the 5 layers The material constitutes a membrane pack 10 of integrally sealed construction.

[0035] The filter membrane bag of the present invention is composed of 5 layers of materials: filter support grid, filter support cloth, and filter membrane, so that the filter membrane surfaces on both sides of the membrane bag are smooth and flat, not easy to hide dirt, and the inside of the membrane bag has complete and effective filtration liquid channel.

[0036] The filter support grid, filter support cloth and filter membrane of the present invention are made of five layers of materials by ultrasonic welding or thermocompression ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com