Surface modified pmma/pvdf hybrid coated lithium battery composite diaphragm and preparation method thereof

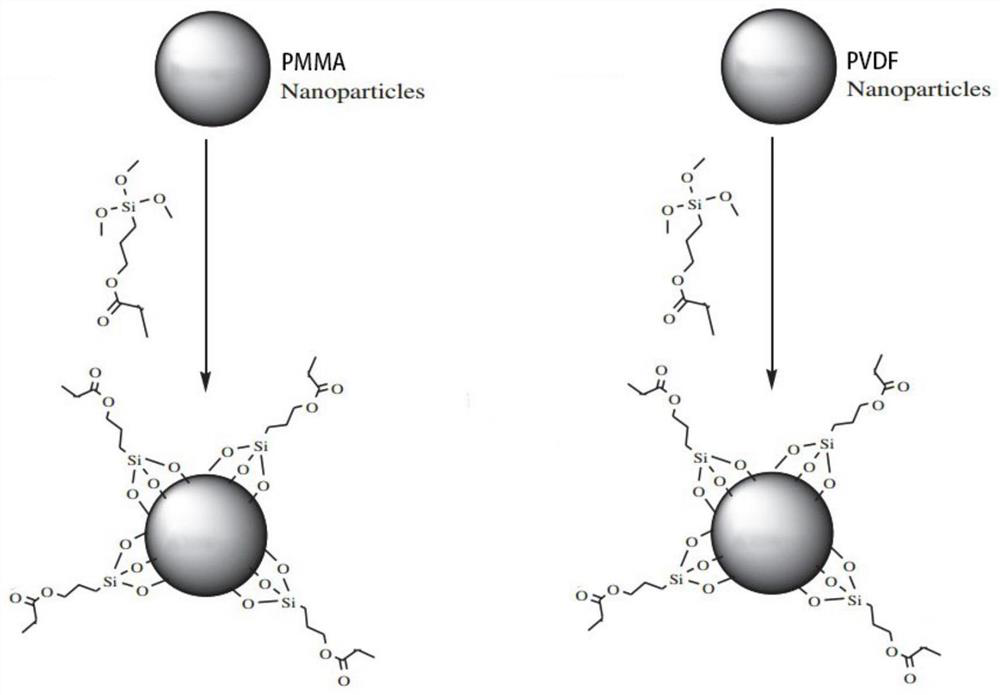

A technology of surface modification and composite diaphragm, applied in lithium batteries, battery pack parts, non-aqueous electrolyte batteries, etc., can solve the problem of uneven mixing of PMMA and PVDF, poor consistency of PMMA electrolyte infiltration, insufficient PVDF adhesion, etc. problems, to achieve the effects of improving mechanical properties and adhesion, high yield, and improving specific surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

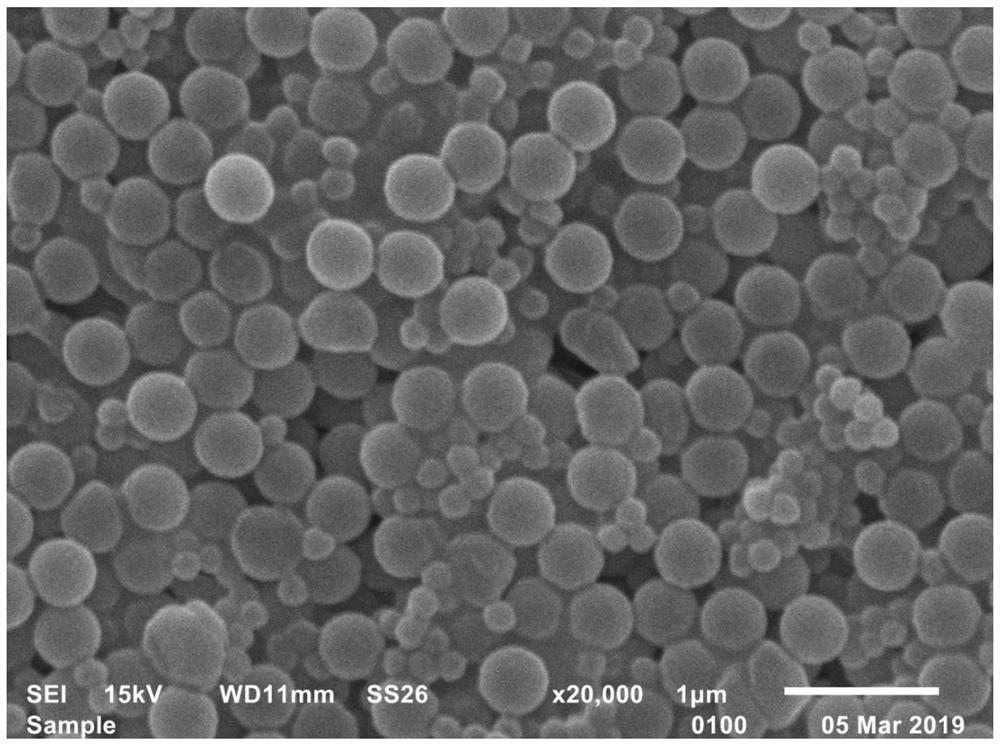

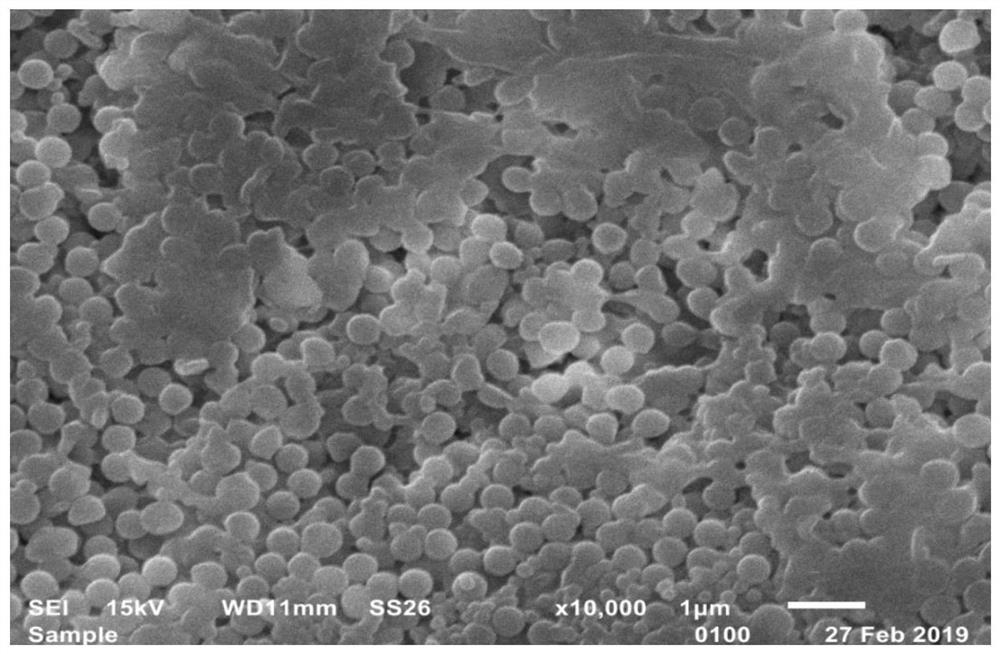

Image

Examples

Embodiment 1

[0031] (1) Preparation of PMMA / PVDF mixture slurry: first 1.55 parts dispersant and 0.44 parts of deionized water was added wetting agent is completely dissolved, then 4.42 parts of PVDF powder after sufficient stirring, milled IH; then 4.42 parts of PMMA powder PVDF body slurry was added lapped sufficiently stirred, and 1.5 parts of a silane coupling agent as the surface modifier, sufficiently stirred, and then triturated 0.5h, finally adding 0.88 parts of adhesive;

[0032] (2) selection of a battery separator film + 2μm 7μm polyvinyl inorganic ceramic particles coated ceramic separator, battery separator into the coating apparatus used in step (1) Preparation of PMMA / PVDF mixture slurry is coated, micro concave roll coating is applied to one side of the battery separator;

[0033] (3) After the step (2) drying the coated battery separator, winding, surface-modified PMMA / PVDF composite membrane lithium mixed-coated products.

Embodiment 2

[0035] This embodiment differs from the embodiment 1 in that Example: preparation PMMA / PVDF mixed slurry, PMMA powder is 5.30 parts, PVDF powder is 3.54 parts, 1.8 parts of a silane coupling agent.

Embodiment 3

[0037] This embodiment differs from the embodiment 1 in that Example: preparation PMMA / PVDF mixed slurry, PMMA powder is 7.07 parts, PVDF powder was 1.77 parts, 1 part of silane coupling agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com