Doping dye sensitized solar cell photo anode, preparation method and application thereof

A technology of solar cells and dye sensitization, applied in the field of solar cells, can solve the problems of unsatisfactory complexity and product performance, and achieve the effects of improving photoelectric conversion performance, suppressing dark current and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

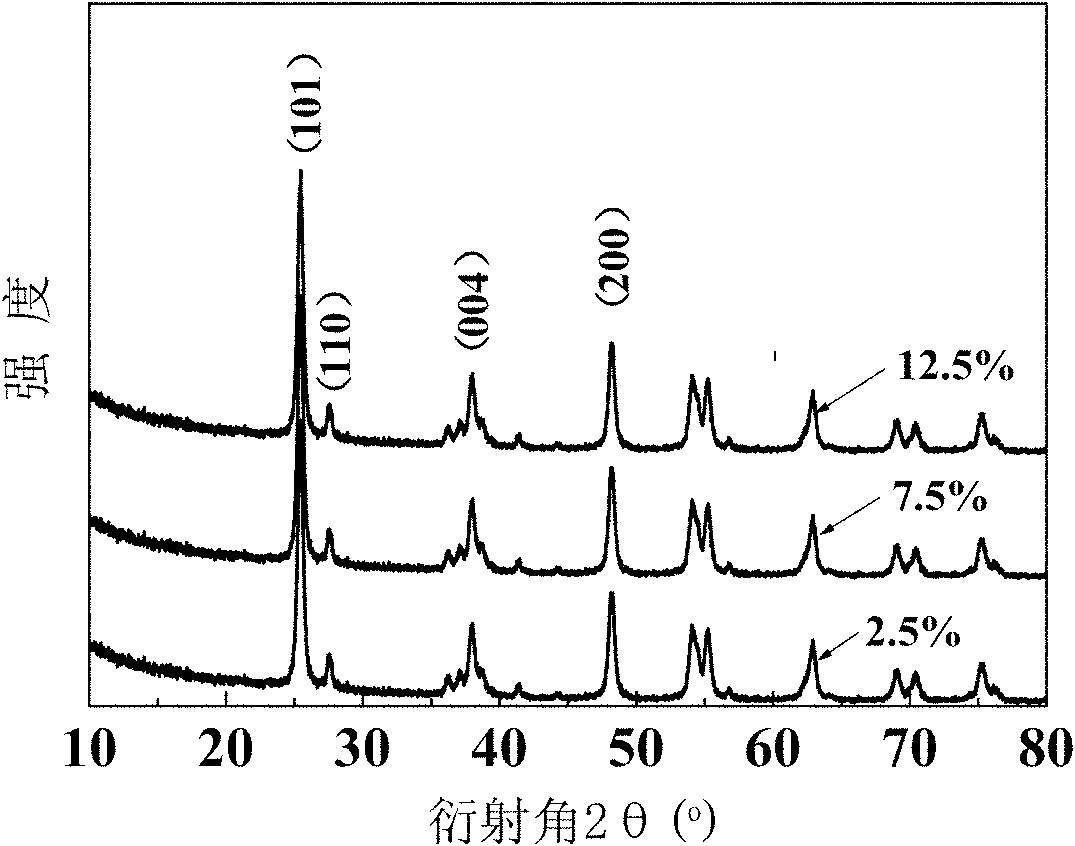

Embodiment 1

[0038] a. Preparation of doped SiO 2 TiO 2 Slurry:

[0039] Take 5g of P25 powder, SiO 2 with TiO 2 Mix well, SiO 2 The mass of TiO 2 2.5% of the mass, add 1mL acetic acid in turn, add 5ml deionized water in 5 times at 1mL each time, add 15mL absolute ethanol in 15 times at 1mL each time, add 15mL in 6 times at 2.5mL each time For absolute ethanol, stir for 3 minutes each time liquid is added; then add 100 mL of absolute ethanol to obtain a slurry; stir the slurry magnetically for 10 minutes at a stirring speed of 300 rpm; then disperse by ultrasonic for 60 minutes; then add 20 g Terpineol, repeated magnetic stirring and ultrasonic dispersion; then added 3g of ethyl cellulose and 30g of absolute ethanol to repeat magnetic stirring and ultrasonic dispersion; finally in a rotary evaporator at 40 ° C for 6 hours to obtain the available for screen printing Slurry, denoted as slurry B.

[0040] b. Preparation of doped SiO 2 TiO 2 The nanocrystalline porous composite film: ...

Embodiment 2

[0046] The preparation method of the present embodiment is the same as embodiment 1, and the difference is that SiO 2 The amount of addition is TiO 2 5% of the mass, the slurry that can be used for screen printing obtained in step a is denoted as slurry C.

Embodiment 3

[0048] The preparation method of the present embodiment is the same as embodiment 1, and the difference is that SiO 2 The amount of addition is TiO 2 7.5% of the mass, the slurry that can be used for screen printing obtained in step a is denoted as slurry D.

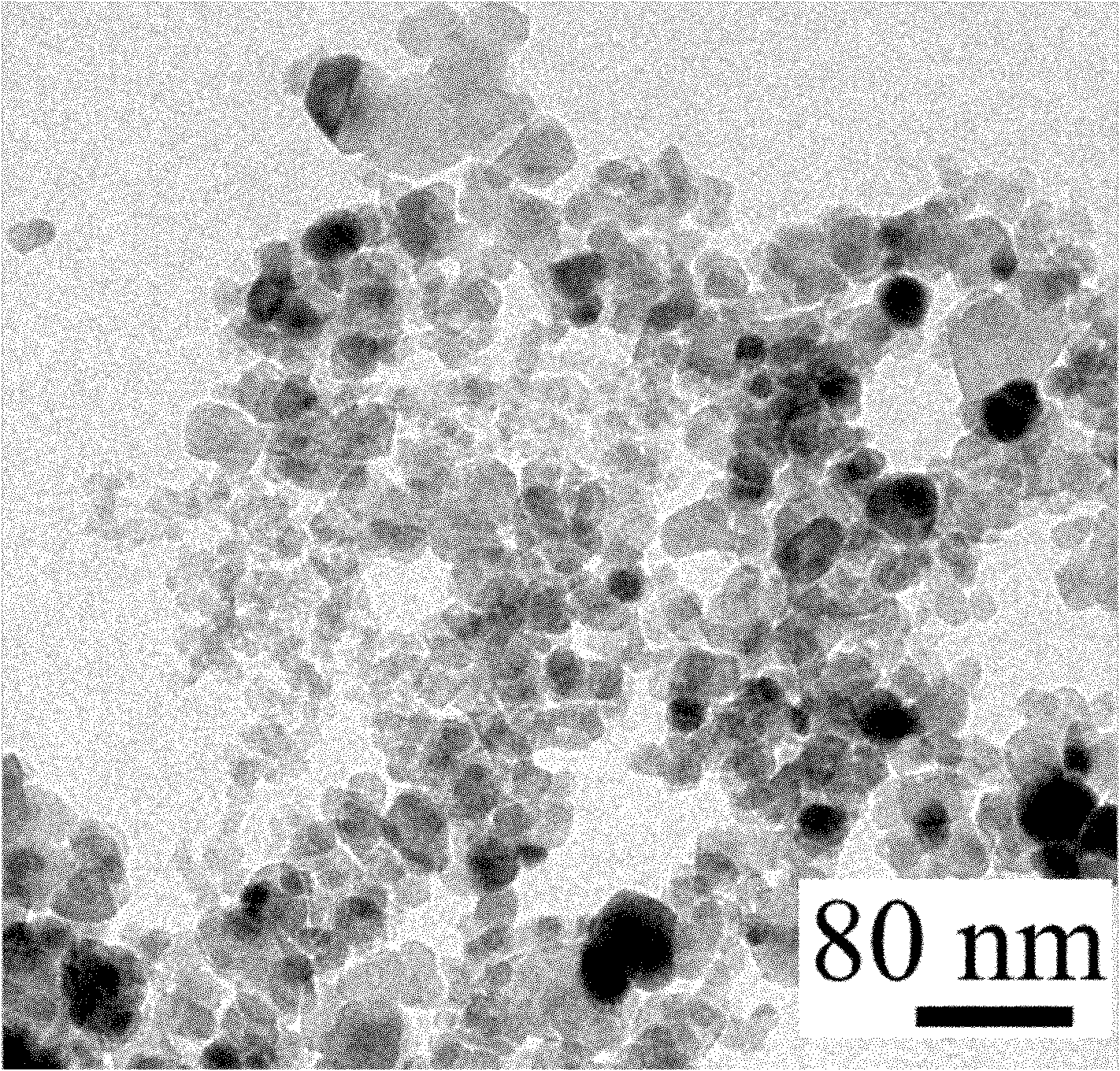

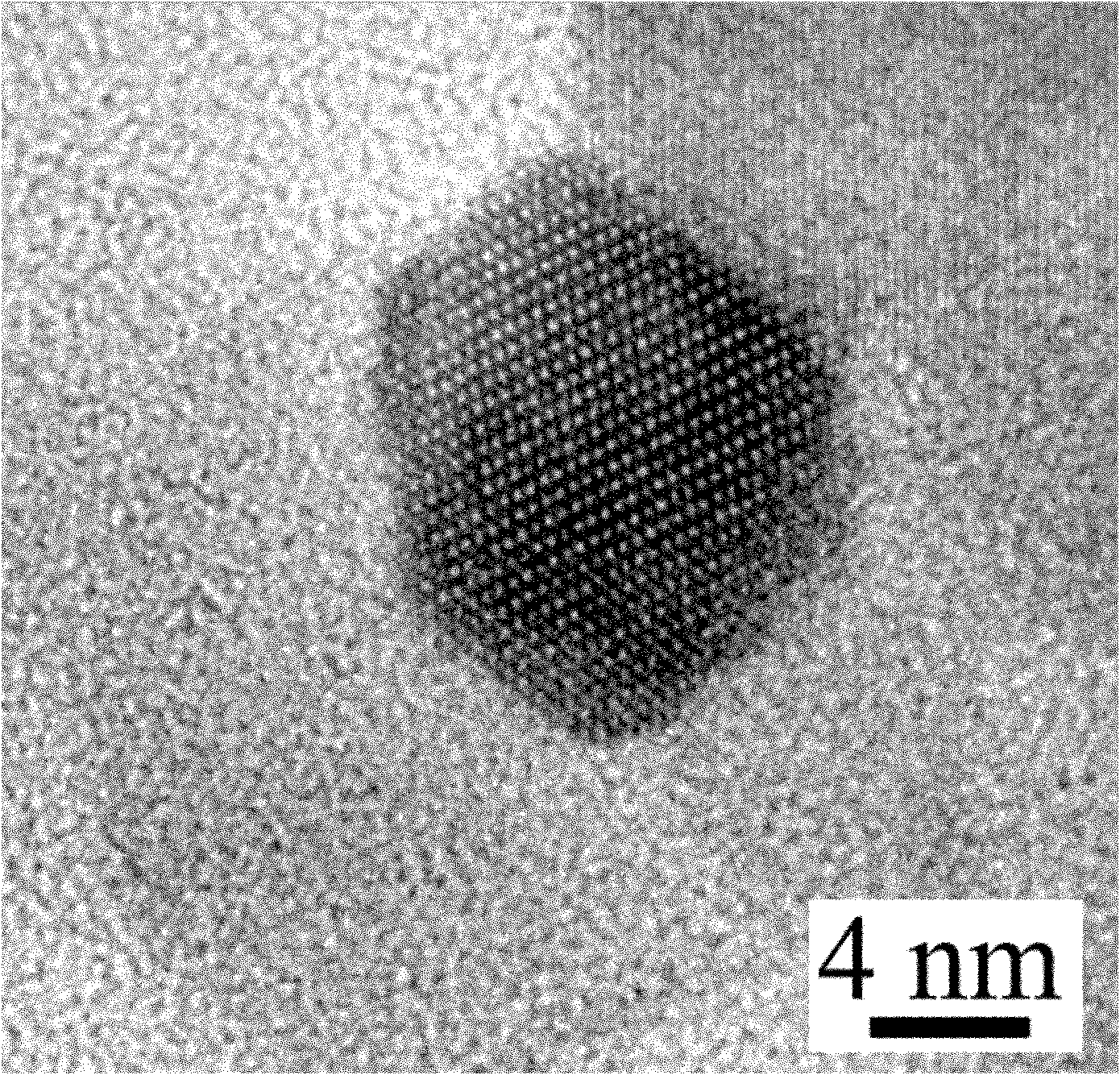

[0049] The printed four-layer SiO 2 / TiO 2 The paste has a film thickness of about 17.9 μm after sintering. Depend on Figure 4 , 5. It can be seen that the composite film is smooth, the nanoparticles are evenly distributed, and form a network structure connected to each other. In the case of relatively large particles (TiO 2 ) around the distribution is relatively small (for SiO 2 ) particles, the small particles not only increase the TiO 2 efficient connection between the particles, and also enables the TiO 2 The bond with conductive glass is stronger.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Short circuit current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com