Agricultural high-toughness VMCPP aluminum laminated film and preparation method thereof

A high-toughness, aluminized film technology, applied in botany equipment and methods, agriculture, agricultural machinery, etc., can solve the problems of poor puncture resistance, easy damage, and long-term durable use, etc., to achieve good overall performance, The effect of long service life and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

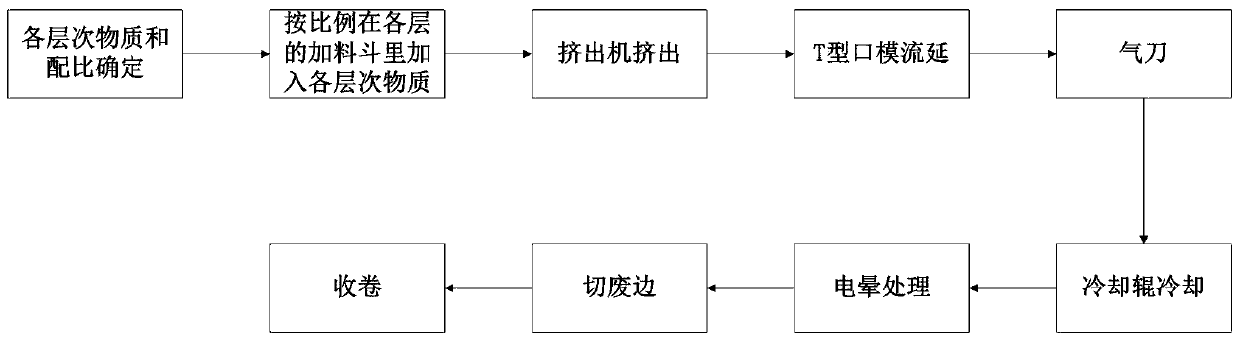

[0038] A preparation method for agricultural high-toughness VMCPP aluminized film, comprising the following preparation steps:

[0039] 1) According to the CPP film type, determine the corona layer, intermediate layer, heat seal layer material and their ratio;

[0040] 2) According to the formula ratio, add the materials of each layer into the hopper of each layer. The hopper of the corona layer is copolymerized polypropylene. Add homopolypropylene and TPE particles into the hopper of the middle layer. polypropylene;

[0041] 3) Set the melting temperature at 190°C to 230°C and the die temperature at 230°C to 232°C. When the temperature reaches the set temperature, put the material in the hopper into the extruder along the pipe to melt and extrude.

[0042] 4) The molten material is cast through a T-shaped die;

[0043] 5) The casted film is cooled by cooling rollers at a temperature of 42°C to 48°C;

[0044] 6) The edge of the cast film is bonded to the cooling roll by an ...

Embodiment 1

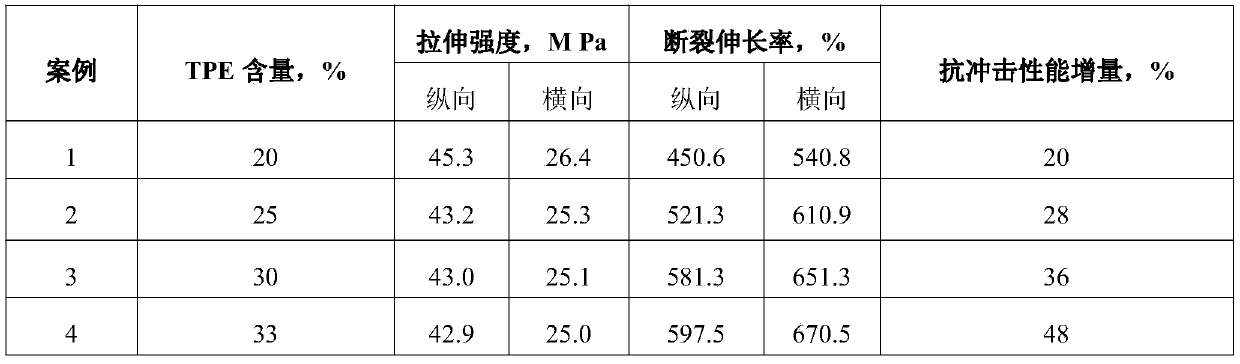

[0051] A / B / (80%PP+20%TPE) / D, the corona layer thickness ratio is 16%, the middle layer thickness ratio is 52%, and the heat seal layer thickness ratio is 32%.

[0052] Wherein, the material of the aluminized layer is polypropylene copolymer; said polypropylene copolymer is formed by binary copolymerization of propylene and ethylene or ternary copolymerization of propylene, ethylene and butene, with a melting point of 120-145°C and a melt index of 4-4. 10g / 10min, density 0.89~0.9g / cm 3 ; The middle layer is composed of homopolypropylene and TPE. The homopolypropylene has a melting point of 155-165°C, a melt index of 4-10g / 10min, and a density of 0.90-0.91g / cm 3 ; The TPE is a thermoplastic elastomer, translucent or transparent round or cylindrical particles, the density is generally 0.9 ~ 1.1g / cm 3 .

[0053] Compared with ordinary VMCPP films, the high-toughness VMCPP film in this case has improved the impact resistance by 20%.

Embodiment 2

[0055] A / B / (75%PP+25%TPE) / D, the corona layer thickness ratio is 16%, the middle layer thickness ratio is 52%, and the heat seal layer thickness ratio is 32%.

[0056] Wherein, the material of the aluminized layer is polypropylene copolymer; said polypropylene copolymer is formed by binary copolymerization of propylene and ethylene or ternary copolymerization of propylene, ethylene and butene, with a melting point of 120-145°C and a melt index of 4-4. 10g / 10min, density 0.89~0.9g / cm 3 ; The middle layer is composed of homopolypropylene and TPE. The homopolypropylene has a melting point of 155-165°C, a melt index of 4-10g / 10min, and a density of 0.90-0.91g / cm 3 ; The TPE is a thermoplastic elastomer, translucent or transparent round or cylindrical particles, the density is generally 0.9 ~ 1.1g / cm 3 .

[0057] Compared with ordinary VMCPP films, the high-toughness VMCPP film in this case has improved impact resistance by 28%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Financial index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com