Antibacterial and pollution-resistant composite reverse osmosis membrane and production method thereof

A reverse osmosis membrane, pollution-resistant technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of reduced service life, increased operating costs, reduced separation performance, etc. The effect of easy operation and strong antibacterial and anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

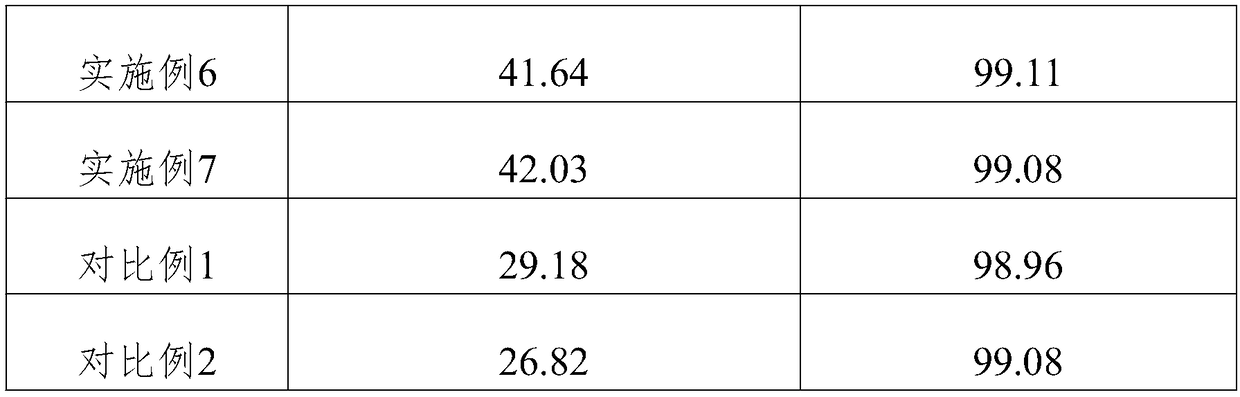

Examples

Embodiment 1

[0029] (1) Preparation of casting solution: mix polymer, silver nitrate, 3-aminopropyltrimethoxysilane (APS), methylcellulose, N,N-dimethylformamide (DMF), Stir at 135°C for 8 hours until the polymer dissolves, then stand in vacuum for 3 hours to obtain the casting solution; the casting solution contains 18.5% polymer, 0.15% silver nitrate, and 0.15% 3-aminopropyltrimethyl Oxysilane (APS), 4% methylcellulose, the solvent is N,N-dimethylformamide (DMF);

[0030] (2) Put the casting solution obtained in step (1) on the non-woven fabric to form a porous support layer through the liquid-solid phase inversion method. The phase inversion time is 0.75min, the water bath temperature is 17.5°C, and the heat curing water bath temperature is 70°C. The thickness of the film is 5.5mil, soaked in deionized water and stored, that is, the preparation of the porous support layer base film is completed;

[0031] (3) Soak the base film in an aqueous solution containing m-phenylenediamine, TAGH,...

Embodiment 2

[0038](1) Preparation of casting solution: mix polymer, silver nitrate, 3-aminopropyltrimethoxysilane (APS), methylcellulose, N,N-dimethylformamide (DMF), Stir at 120°C for 10 hours until the polymer is dissolved, then stand in vacuum for defoaming for 4 hours to obtain a casting solution; the casting solution contains 17% polymer, 0.1% silver nitrate, and 0.1% 3-aminopropyltrimethyl Oxysilane (APS), 2% methylcellulose, the solvent is N,N-dimethylformamide (DMF);

[0039] (2) The casting solution obtained in step (1) is formed on the non-woven fabric through the liquid-solid phase transformation method to form a porous support layer, the phase transformation time is 1min, the temperature of the water bath is 15°C, and the temperature of the thermal curing water bath is 60°C. The thickness is 4mil, soaked in deionized water and stored, that is, the preparation of the porous support layer base film is completed;

[0040] (3) Soak the base film in an aqueous phase solution conta...

Embodiment 3

[0047] (1) Preparation of casting solution: mix polymer, silver nitrate, 3-aminopropyltrimethoxysilane (APS), methylcellulose, N,N-dimethylformamide (DMF), Stir at 150°C for 6 hours until the polymer dissolves, then stand in vacuum for 2 hours to obtain the casting solution; the casting solution contains 20% polymer, 0.2% silver nitrate, and 0.2% 3-aminopropyltrimethyl Oxysilane (APS), 6% methylcellulose, the solvent is N,N-dimethylformamide (DMF);

[0048] (2) Put the casting solution obtained in step (1) on the non-woven fabric to form a porous support layer through the liquid-solid phase inversion method. The phase inversion time is 0.5min, the water bath temperature is 20°C, and the heat curing water bath temperature is 80°C. Control the membrane The thickness is 7mil, soaked in deionized water and stored, that is, the preparation of the porous support layer base film is completed;

[0049] (3) Soak the base film in an aqueous phase solution containing m-phenylenediamine,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com