Polyethylene terephthalate (PET) release film replacing graphite sheet protective film and production process thereof

A production process and technology of release film, applied in the direction of coating, etc., can solve the problems of small bubbles on the surface of the finished product, difficulty in separating graphite sheets, and influence on the performance and appearance of graphite sheets, so as to achieve convenient operation, simple production process, and high film surface smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A PET release film replacing the graphite sheet protective film, which comprises the following components in parts by weight: 3 parts of D120 solvent oil, 1 part of toluene, 0.5 part of isopropanol, 0.5 part of silicone oil main agent, and 0.2 part of heavy release additive , 0.05 parts of crosslinking agent, 0.01 part of anchoring agent, and 0.01 part of catalyst.

[0027] The production process of the above-mentioned special PET release film instead of the graphite sheet protective film comprises the following steps:

[0028] Step 1. Coating configuration: First, mix D120 solvent oil, toluene, and isopropanol evenly to form a mixed solution as a solvent; then add silicone oil main agent, heavy stripping additive, crosslinking agent, anchoring agent, and catalyst to stir and mix, 1200 Stir for 30 minutes at rpm, filter with a 200-mesh filter, and use within 3 hours; after adding toluene as a solvent in the mixed solvent, it can inhibit the appearance of rainbow pattern...

Embodiment 2

[0035] A PET release film that replaces the graphite sheet protective film, which includes the following components in parts by weight: 8 parts of D120 solvent oil, 3 parts of toluene, 1 part of isopropanol, 1 part of silicone oil main agent, and 0.6 parts of heavy release additive , 0.09 parts of crosslinking agent, 0.01 part of anchoring agent, and 0.01 part of catalyst.

[0036] The preparation process of the above-mentioned PET release film instead of the graphite sheet protective film is the same as in Example 1.

Embodiment 3

[0038] A PET release film replacing the graphite sheet protective film, which comprises the following components in parts by weight: 5 parts of D120 solvent oil, 2 parts of toluene, 0.7 part of isopropanol, 0.7 part of silicone oil main agent, and 0.4 part of heavy peeling additive , 0.07 parts of crosslinking agent, 0.01 part of anchoring agent, and 0.01 part of catalyst.

[0039] The preparation process of the above-mentioned PET release film instead of the graphite sheet protective film is the same as in Example 1.

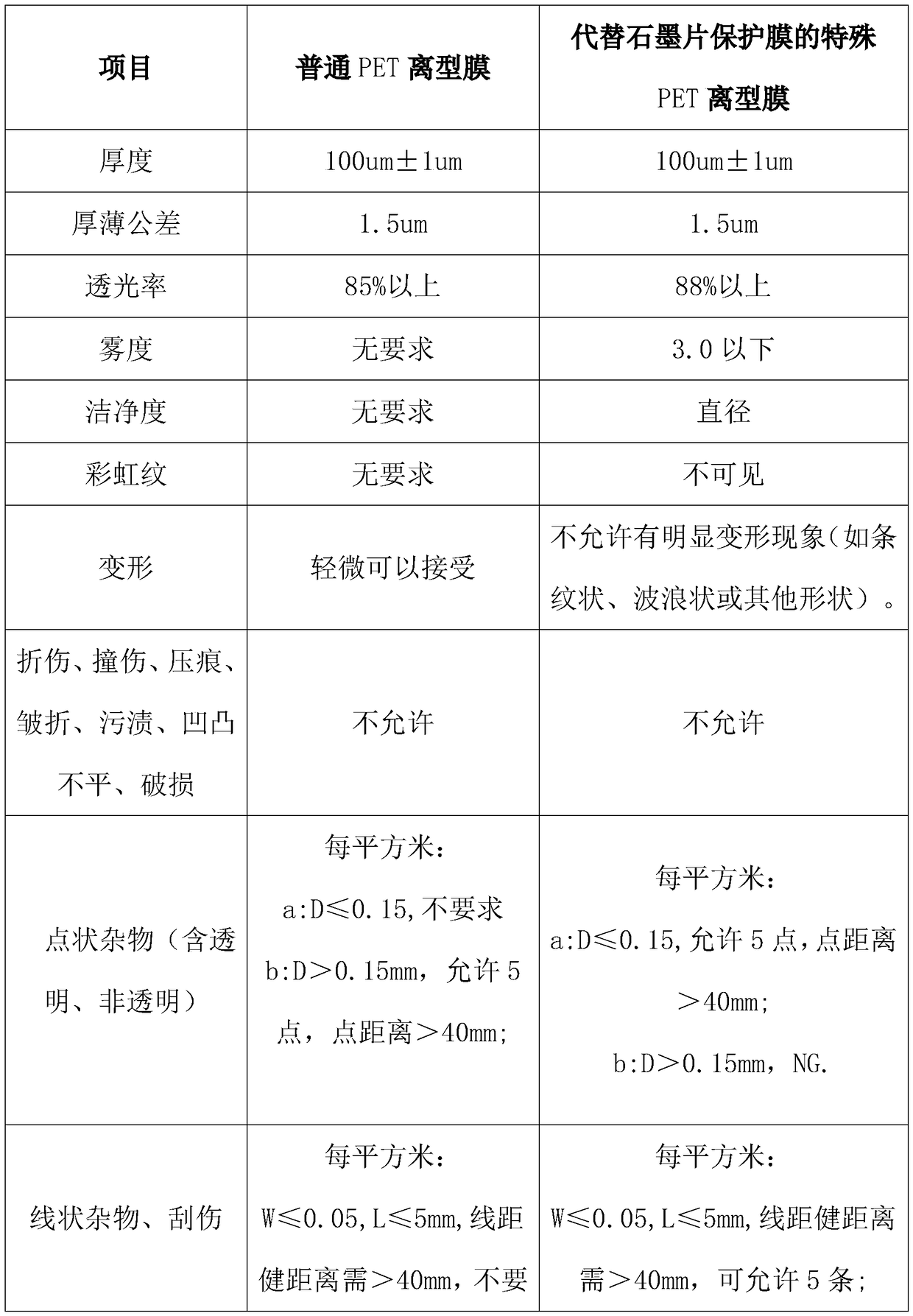

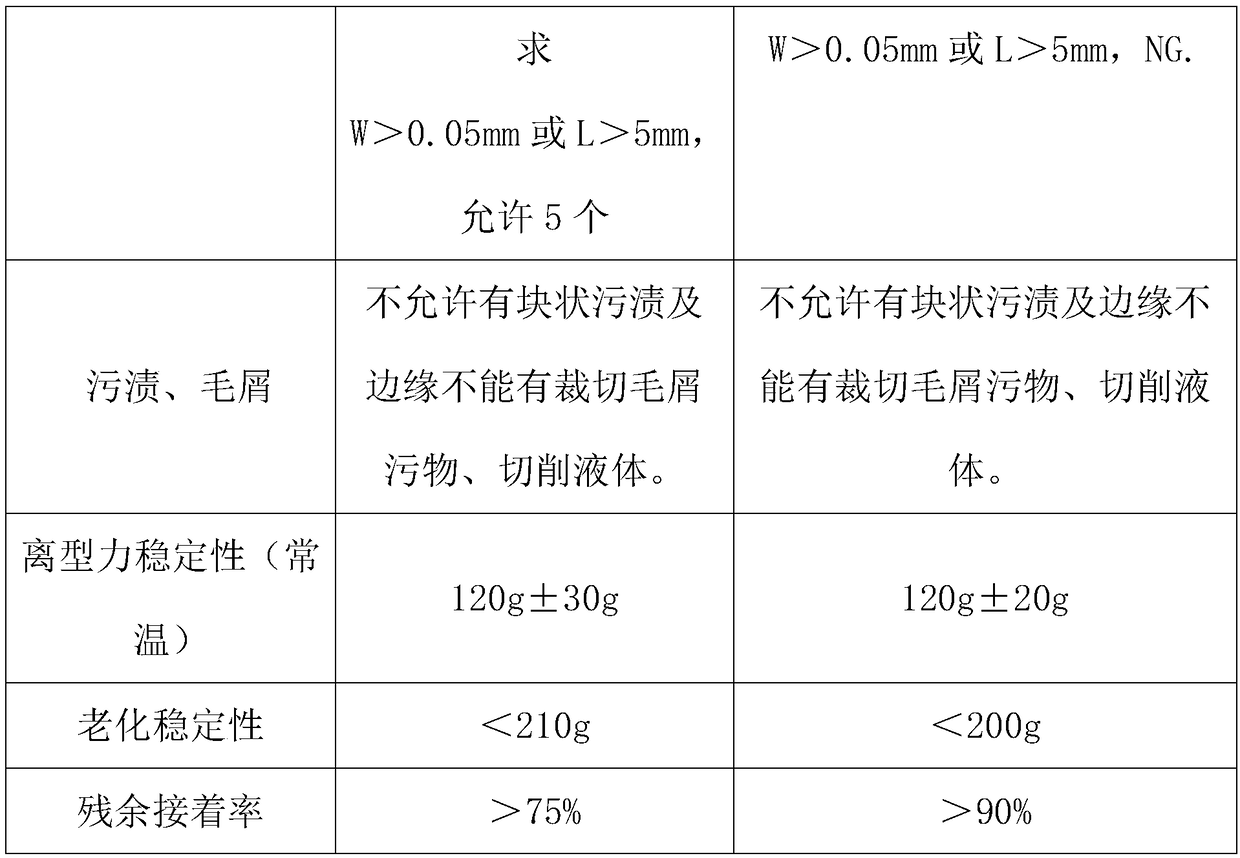

[0040] Table 1 is the performance comparison between the special PET release film made in Examples 1-3 instead of the graphite sheet protective film and the two common PET release films.

[0041]

[0042]

[0043] As can be seen from Table 1, the light transmittance of the special PET release film replacing the graphite flake protective film produced in Examples 1 to 3 is more than 88%, the haze is below 3.0, and the release force stability (normal temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com