Ballastless track structure

A ballastless track and structure technology, which is applied in the field of railway ballastless track, can solve the problems of separation between the track slab and the asphalt mortar adjustment layer, the longitudinal end of the track slab is easy to warp, and the CA mortar construction process is cumbersome, etc., so as to facilitate engineering Quality, convenient construction, and the effect of simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

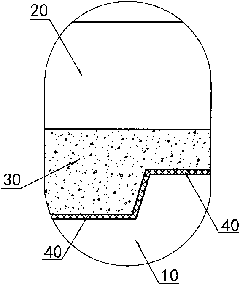

[0015] refer to figure 1 and figure 2 A ballastless track structure according to the present invention includes a bearing layer 10 , a track slab 20 laid longitudinally along the track, and an adjustment layer between the bearing layer 10 and the track slab 20 . The adjustment layer is a self-compacting concrete layer 30, and the track slab 20 and the self-compacting concrete layer 30 are connected as a whole through connecting members to form an integral structure, which can improve the integrity of the track and meet the stability and comfort requirements of the ballastless track. requirements, and can effectively solve the problems that the track slab and the asphalt mortar adjustment layer are easy to peel off, and the longitudinal end of the track slab is easy to warp. The circular convex block structure is canceled on the bearing layer, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com