Adhesive for building decorative panels and preparation method thereof

A technology for building decoration and board glue, applied in the direction of adhesives, adhesive types, epoxy resin adhesives, etc., can solve the problems of easy aging, easy peeling of adhesives, performance degradation, etc. Effect of photooxidation, uniform hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The specific preparation process of silylated epoxy resin is as follows:

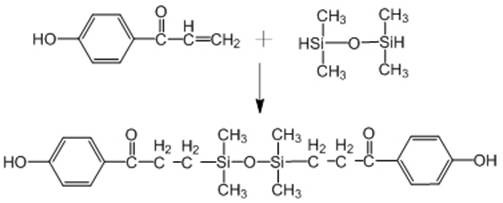

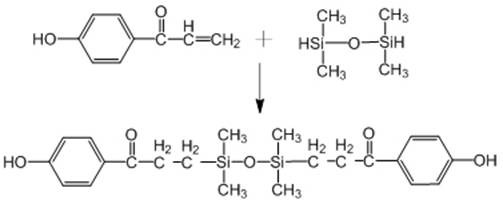

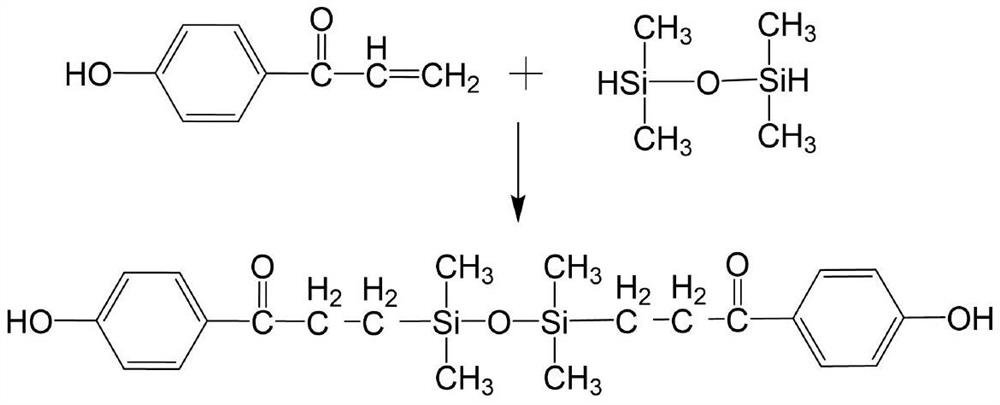

[0026] Step 1: Weigh 100g of phenol and add it to 1L of ethanol, then add 132g of acryloyl chloride to it, and add phosphoric acid solution to it to adjust the pH of the solution to 1, heat up to 50-60°C and stir for 8-9h, then cool down to 25- At 30°C, add 68g of anhydrous aluminum chloride to the reactor in 3 times, the same amount each time, keep warm for 3-4h, then add 1mol / L hydrochloric acid solution, stir for 1-1.5h and then let it stand Separate the layers, and wash the oil phase of the upper layer to neutrality, then carry out vacuum distillation to obtain unsaturated phenol;

[0027] Step 2: Add 100g of the unsaturated phenol prepared in step 1 and 500mL of ether into the reaction kettle at the same time, then add 4g of isopropanol-platinum into it, raise the temperature to 90-95°C and stir for 8-9h, then slowly drop into it Add 39g of tetramethyldisiloxane, after the dropwise addition...

Embodiment 2

[0031] The specific preparation process of the silylated epoxy resin is as follows: Weigh 100g of E-44 type epoxy resin, then add 18g of n-propyltrimethoxysilane into it, mix and stir evenly, and obtain the silylated epoxy resin.

Embodiment 3

[0033] The specific preparation process of the weather-resistant curing agent is as follows:

[0034] ① Add tetramethylpiperidinamine and allyl glycidyl ether into the reaction vessel according to the ratio of the amount of substances of 1:1, stir and react at room temperature for 3-4 hours, and then conduct vacuum distillation to obtain product A;

[0035] ②Put 10g of product A and 80mL of acetone into the reaction kettle at the same time, then add 0.2g of isopropanol-platinum into it, raise the temperature to 90-95°C and stir for 8-9h, then slowly add 3.1g of tetramethyldimethoxy Siloxane, after complete dropwise reaction at constant temperature for 24-25h, then vacuum distillation to obtain weather-resistant curing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com