Flexible base plate and manufacturing method thereof, array base plate, display panel and display device

A technology of a flexible substrate and a manufacturing method, which is applied in the fields of display panels and display devices, flexible substrates and manufacturing methods thereof, and array substrates, can solve the problems of poor adhesion between an organic film layer and an inorganic film layer, etc. The effect of increasing the adhesion and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

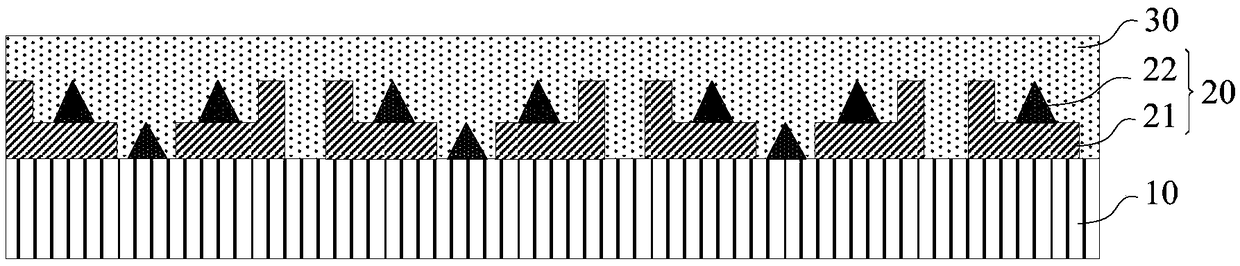

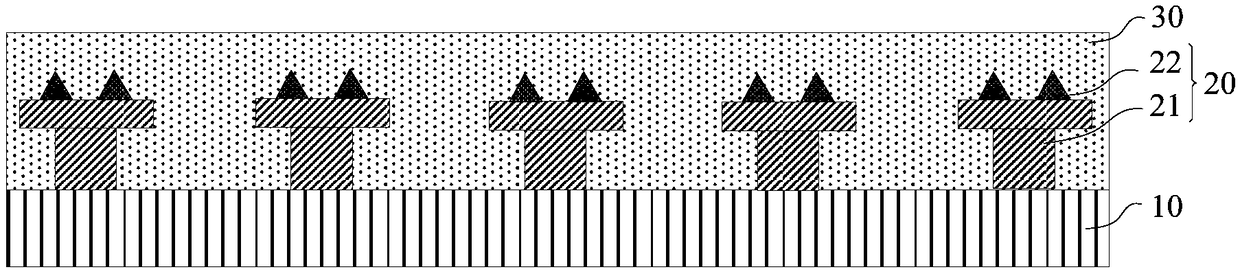

[0074] figure 1 It is a schematic cross-sectional structure diagram of the flexible panel provided by Embodiment 1 of the present invention, figure 2 It is a schematic cross-sectional structure diagram of yet another flexible panel provided by Embodiment 1 of the present invention.

[0075] This embodiment provides a flexible substrate, such as figure 1 As shown, the flexible substrate may specifically include: at least one pattern layer 20 and at least one barrier layer 30 disposed on the substrate 10, that is, there may be one pattern layer 20, or there may be several pattern layers 20, for example, they may be respectively It is the top pattern layer 20b on the upper part of the flexible substrate, the bottom pattern layer 20a on the lower part of the flexible substrate, or the middle pattern layer 20c in the middle of the flexible substrate. In this embodiment, as figure 1 As shown, the pattern layer 20 is one, wherein, since the barrier layer 30 needs to be covered on ...

Embodiment 2

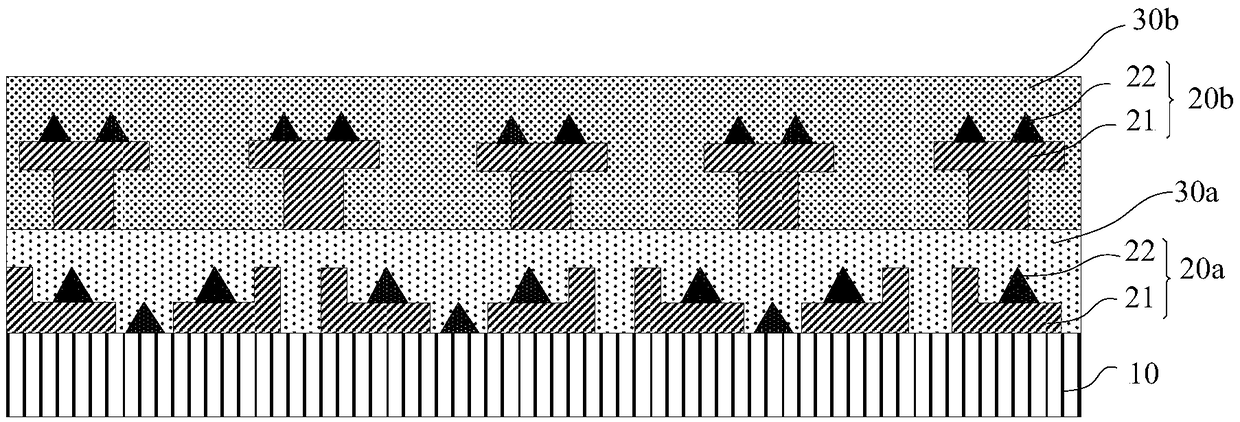

[0083] image 3 It is a schematic diagram of the cross-sectional structure of the flexible panel provided by Embodiment 2 of the present invention, Figure 4 It is a schematic cross-sectional structure diagram of yet another flexible panel provided by Embodiment 2 of the present invention.

[0084] In this example, if image 3 and 4 As shown, there are two pattern layers 20 and two barrier layers 30 in the flexible substrate, that is, the flexible substrate in this embodiment is a substrate with a five-layer structure. Specifically, the two pattern layers 20 are the bottom pattern layer 20a and the top pattern layer 20a respectively. Layer 20b, that is, the pattern layer 20 includes a bottom pattern layer 20a and a top pattern layer 20b, and the barrier layer 30 includes a bottom barrier layer 30a and a top barrier layer 30b, wherein the bottom barrier layer 30a covers the bottom pattern layer 20a and the substrate 10, and the top pattern layer The layer 20b is arranged on ...

Embodiment 3

[0090] Figure 5 It is a schematic diagram of the cross-sectional structure of the flexible panel provided by Embodiment 3 of the present invention, Figure 6 A schematic cross-sectional structure diagram of yet another flexible panel provided by Embodiment 3 of the present invention, Figure 7 A schematic cross-sectional structure diagram of yet another flexible panel provided by Embodiment 3 of the present invention.

[0091] The flexible substrate provided in this embodiment includes at least three pattern layers 20 and at least three barrier layers 30, that is, the flexible substrate can be a 7-layer structure (ie substrate 10+three pattern layers 20+three barrier layers 30) Or a structure with more than 7 layers. Specifically, the pattern layer 20 also includes: at least one intermediate pattern layer 20c, and the barrier layer 30 also includes at least one intermediate barrier layer 30c. In this embodiment, as Figure 5 As shown, there is one middle pattern layer 20c, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com