High-transparency polyvinyl alcohol hydrogel as well as preparation method and application thereof

A polyvinyl alcohol and hydrogel technology, which is used in pharmaceutical formulations, medical preparations with non-active ingredients, prostheses, etc., can solve the problems of difficult promotion and application, inconvenient operation of irradiation cross-linking, and high price. The effect of easy implementation and promotion, green environmental protection implementation and promotion, and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

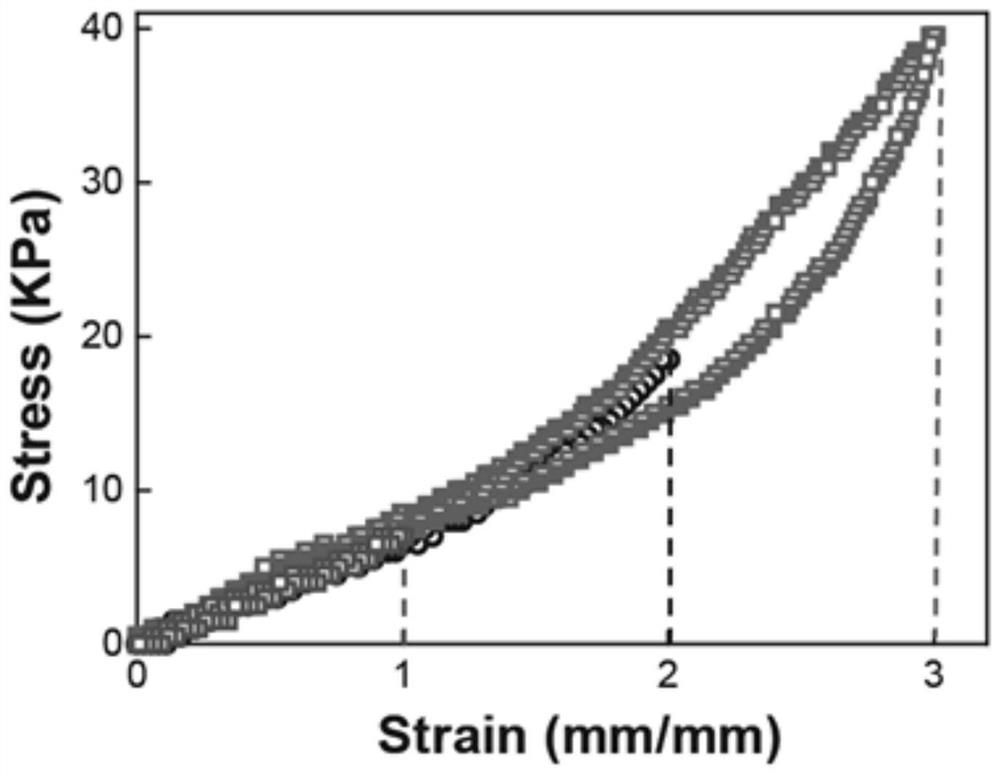

[0042] A mixed solution of 20wt% polyvinyl alcohol (M=70000) / 20wt% calcium chloride is prepared at a high temperature, mixed evenly, and ultrasonically defoamed. The resulting mixed solution is added to a mold and put into a refrigerator for freezing. The freezing temperature is -50°C. Freeze for 24 hours, thaw at 4°C for 6 hours, and the number of freeze-thaw cycles is 1. After testing, the visible light transmittance of the prepared polyvinyl alcohol hydrogel is 91%, and the minimum freezing temperature is -25°C. Its transparency is shown as figure 1 As shown, the tensile recovery properties are as image 3 As shown, the sensing performance is as Figure 4 shown.

Embodiment 2

[0044] Prepare a solution of polyvinyl alcohol (M=140000) with a concentration of 10wt% at high temperature, continue to add 20wt% calcium chloride, mix well, and ultrasonically defoam, add the resulting mixed solution to the mold, and put it in the refrigerator to freeze at -40°C , the freezing time is 24h, thawing at 4°C for 6h, and the number of freeze-thaw cycles is 2. After testing, the visible light transmittance of the prepared polyvinyl alcohol hydrogel is 90%, and the minimum antifreeze temperature is -25°C. Its stretch recovery performance and sensing performance are similar to those of the polyvinyl alcohol hydrogel in Example 1.

Embodiment 3

[0046] Prepare a solution of polyvinyl alcohol (M=70000) with a concentration of 10wt% at high temperature, mix it evenly, and defoam it ultrasonically. Thaw for 6 hours, and the number of freeze-thaw cycles is 3. After testing, the visible light transmittance of the prepared polyvinyl alcohol hydrogel is 92%, and the minimum freezing temperature is -80°C. Its sensing performance is close to that of the polyvinyl alcohol hydrogel in Example 1, but its stretch recovery performance is not as good as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com