Method for extracting alumina through coal ash

A fly ash and alumina technology, which is applied in the preparation of aluminum hydroxide, alumina/aluminum hydroxide, etc., can solve the problems of particles sticking together, difficulty in heating mixed materials, and adding acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

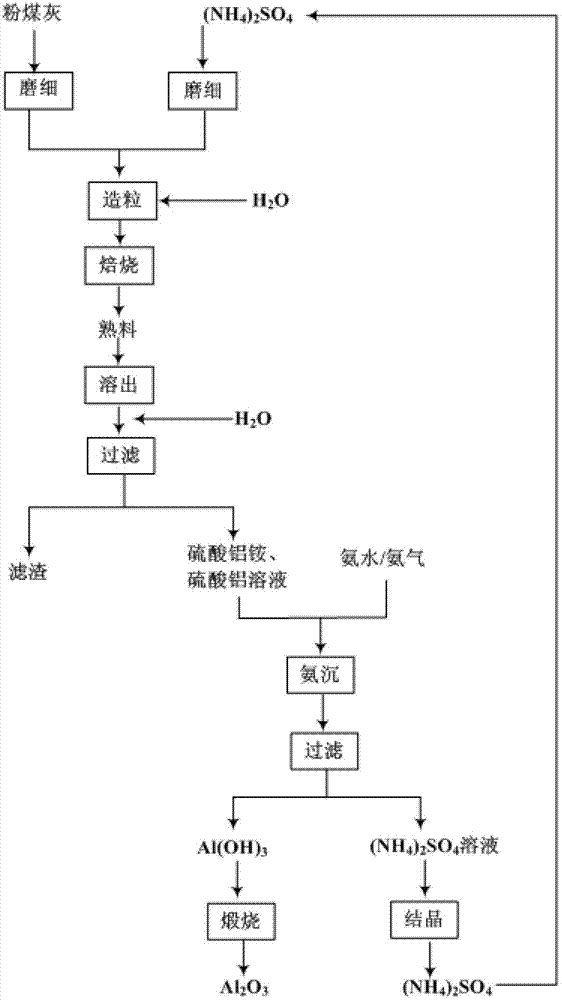

Image

Examples

Embodiment 1

[0043] Grind the fly ash with 21% alumina and 62% silica to 100 mesh, and mix it evenly according to the molar ratio of ammonium sulfate to the alumina in the fly ash 4:1. Add 5% tap water, and then granulate. The particle size is 5mm. The granules enter the rotary kiln, and they are roasted at 360°C for 1 hour and at 410°C for 1 hour. Add deionized water of 3 times the mass of the calcined material, dissolve at 80℃ for 1.5h, filter, add ammonia water to the filtrate to get aluminum hydroxide precipitate, wash and filter, the aluminum hydroxide solid is calcined alumina product , The filtrate is evaporated and crystallized to obtain solid ammonium sulfate for recycling.

Embodiment 2

[0045] Grind the fly ash containing 25% alumina and 60% silica to 120 mesh, and mix it evenly according to the molar ratio of ammonium sulfate to the alumina in the fly ash of 5:1. Add 10% tap water, and then granulate. The particle size is 10mm. The granules enter the rotary kiln and are roasted at 370℃ for 1 hour and at 420℃ for 1 hour. The calcined material is added with deionized water of 4 times the mass of the material, dissolved at 85°C for 1 hour, filtered, and ammonia water is added to the filtrate to precipitate aluminum hydroxide, which is washed and filtered. The aluminum hydroxide solid is calcined alumina product. The filtrate is evaporated and crystallized to obtain solid ammonium sulfate for recycling.

Embodiment 3

[0047] Grind the fly ash containing 30% alumina and 45% silica to 200 mesh, and mix it evenly according to the molar ratio of ammonium sulfate to the alumina in the fly ash of 6:1. Add 15% tap water, and then granulate. The particle size is 15mm. The granules enter the rotary kiln and are roasted at 370℃ for 0.5h and at 410℃ for 1h. Add deionized water 5 times the mass of the calcined material, dissolve it at 90°C for 0.5h, filter, add ammonia to the filtrate to get aluminum hydroxide precipitate, wash and filter, the aluminum hydroxide solid is calcined alumina product , The filtrate is evaporated and crystallized to obtain solid ammonium sulfate for recycling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com