Excimer lamp

A technology of excimer lamps and discharge vessels, applied in the field of excimer lamps, can solve the problems of broken discharge vessels 2, achieve the effects of preventing peeling, inhibiting deterioration, and improving close contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

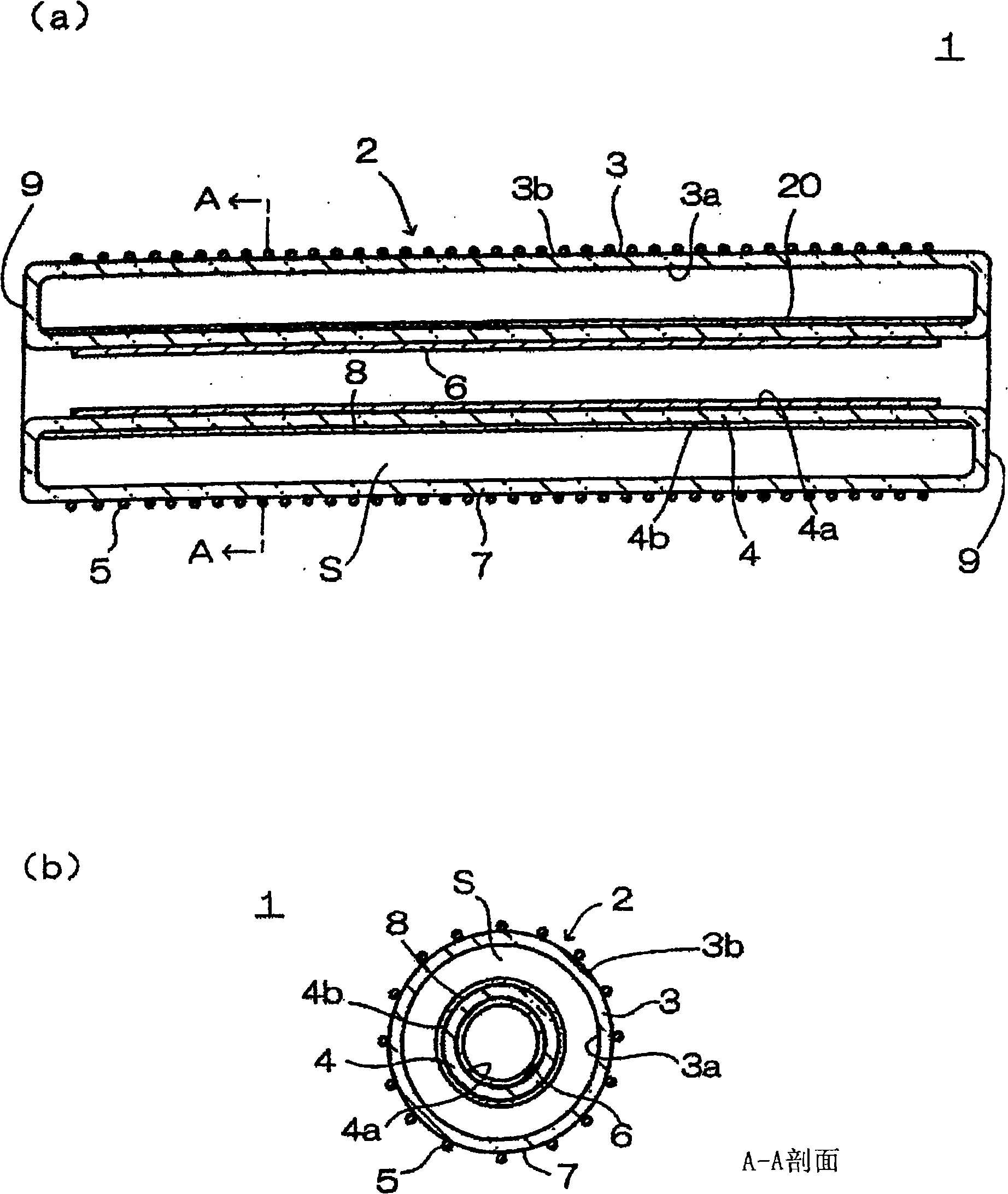

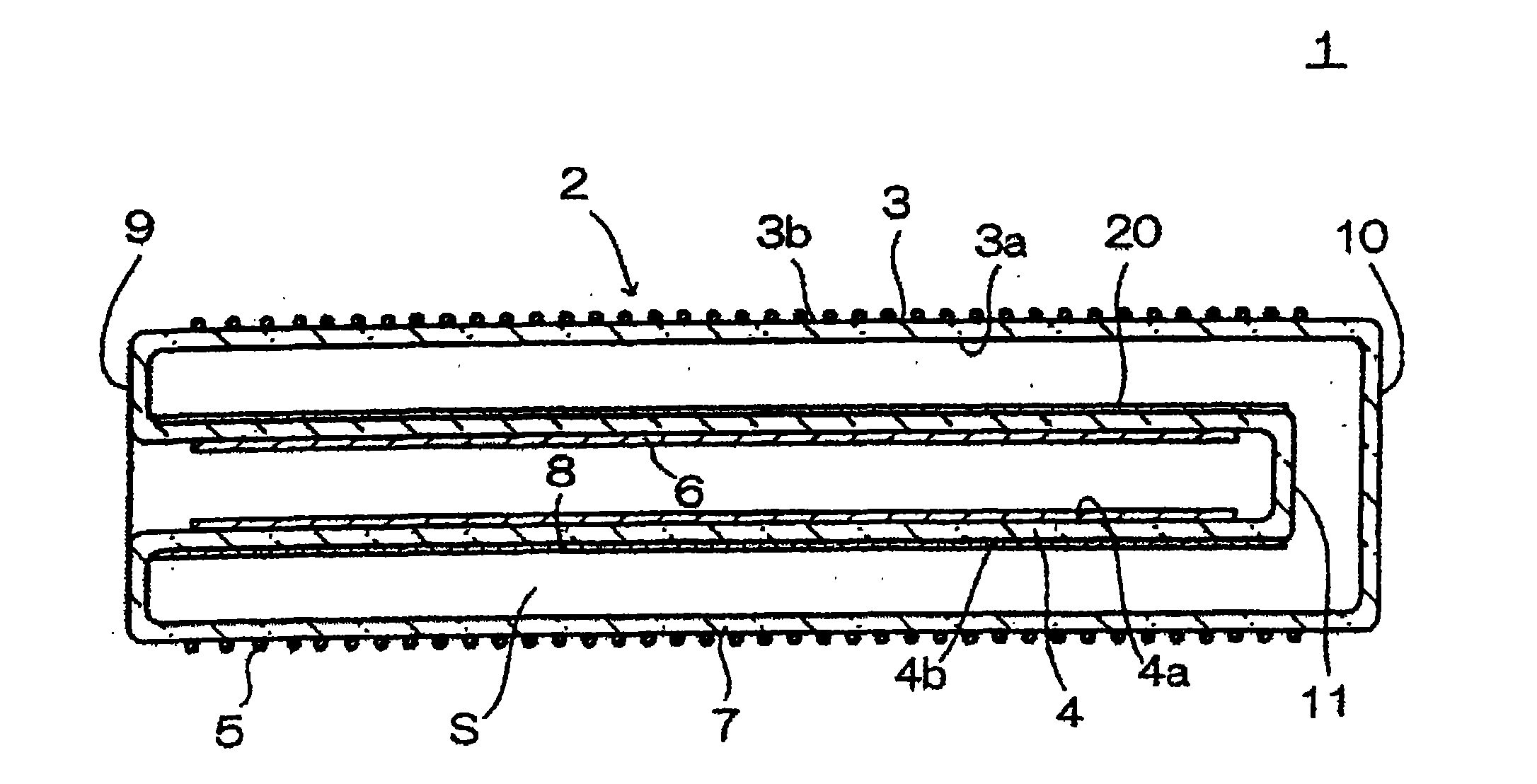

[0025] figure 1 It is an explanatory cross-sectional view showing the structure of the excimer lamp 1, (a) is a transverse cross-sectional view showing a cross-section along the longitudinal direction of the discharge vessel 2, and (b) is a cross-sectional view taken along line A-A of (a).

[0026] The excimer lamp 1 has a discharge vessel 2 composed of a cylindrical outer tube 3 and a cylindrical inner tube 4 . The length of the discharge vessel 2 in the tube axis direction is, for example, 800 to 1600 mm, the diameter of the outer tube 3 is 25 to 40 mm, and the diameter of the inner tube 4 is 15 to 30 mm.

[0027] The diameter of the inner tube 4 is configured to be smaller than that of the outer tube 3 , and the inner tube 4 is disposed inside the outer tube 3 . Since the inner tube 4 is arranged along the tube axis of the outer tube 3 , the discharge vessel 2 has a double tube structure in which the outer tube 3 and the inner tube 4 are arranged in the coaxial direction. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com