Pneumatic tire assembly

A technology for pneumatic tires and components, applied in tire parts, with multiple inflatable chambers, with independent inflatable cushions, etc., can solve the problem of no solution provided, and achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

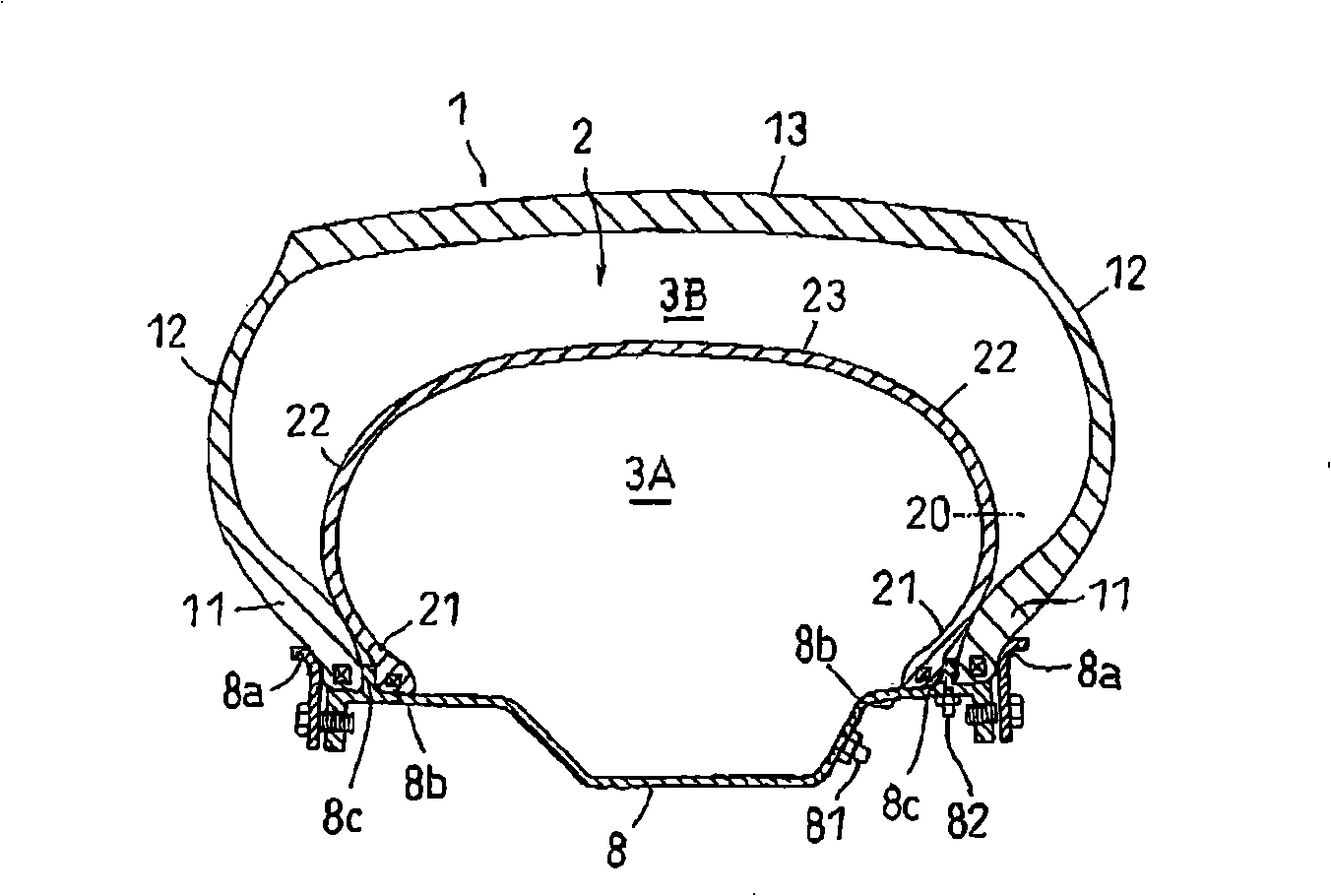

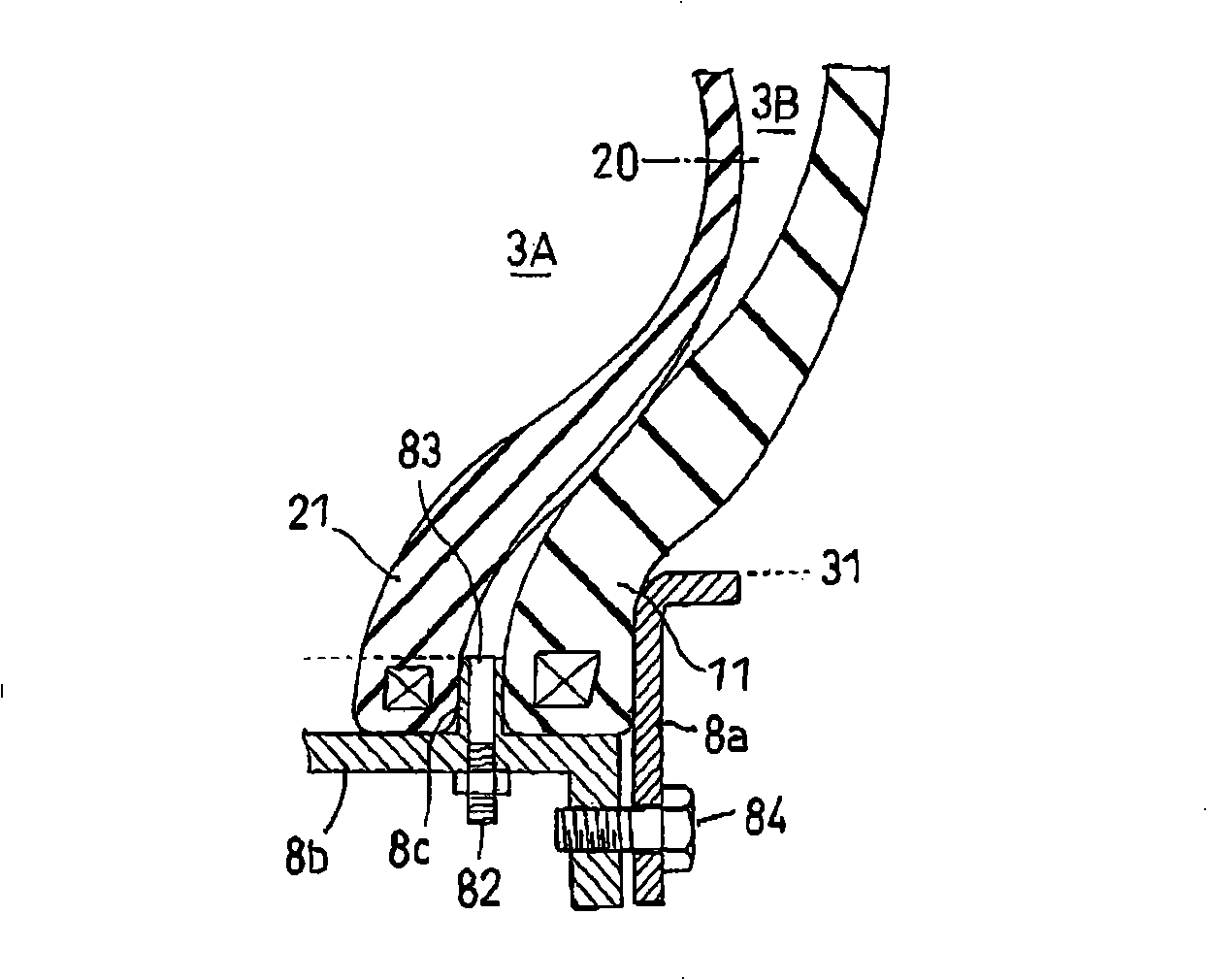

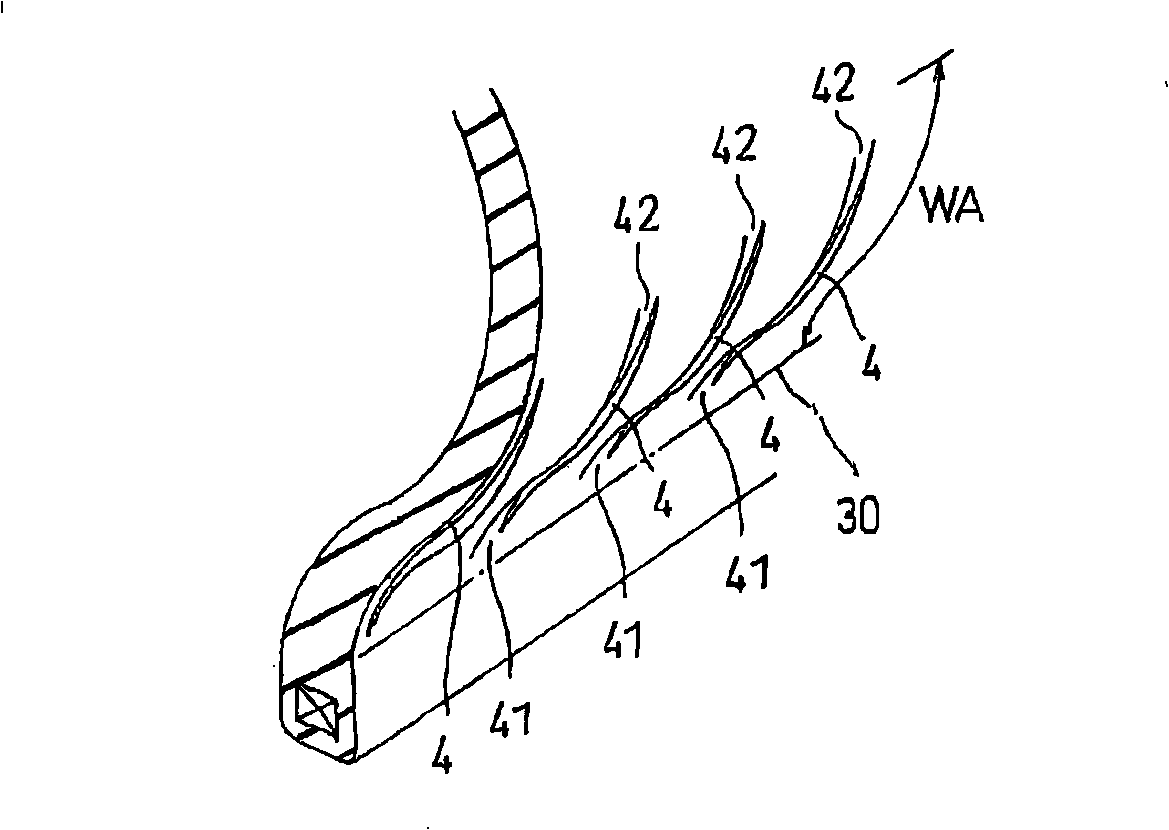

[0023] Embodiments of the present invention will now be described with reference to the accompanying drawings. figure 1 is a sectional view along a tire meridian showing an example of a pneumatic tire assembly according to the present invention. figure 2 yes figure 1 An enlarged view of the main part in .

[0024] Such as figure 1 and figure 2 As shown, the pneumatic tire assembly according to the present invention includes a rim 8 and a pneumatic tire having a double-layer structure consisting of a tire casing 1 and an inner tube 2 inserted into the casing and assembled with the rim 8 . The tire casing 1 is a tubeless tire including a pair of bead portions 11, sidewall portions 12 each extending outward in the tire diameter direction from the corresponding bead portions 11, and a tire disposed between the sidewall portions 12. The tread portion 13 . Likewise, the inner tube 12 is a tubeless tire including a pair of bead portions 21, sidewall portions 22 each extendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com