Rolling connection method for dissimilar refractory metal molybdenum and stainless steel composite board

A technology of refractory metal and connection method, applied in metal rolling, roll speed control, temperature control and other directions, can solve the problems of low low temperature impact toughness of intermetallic compounds and molybdenum, large difference in physical properties between molybdenum and stainless steel, and high welding stress , to achieve the effect of high application value, high bonding strength and high impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

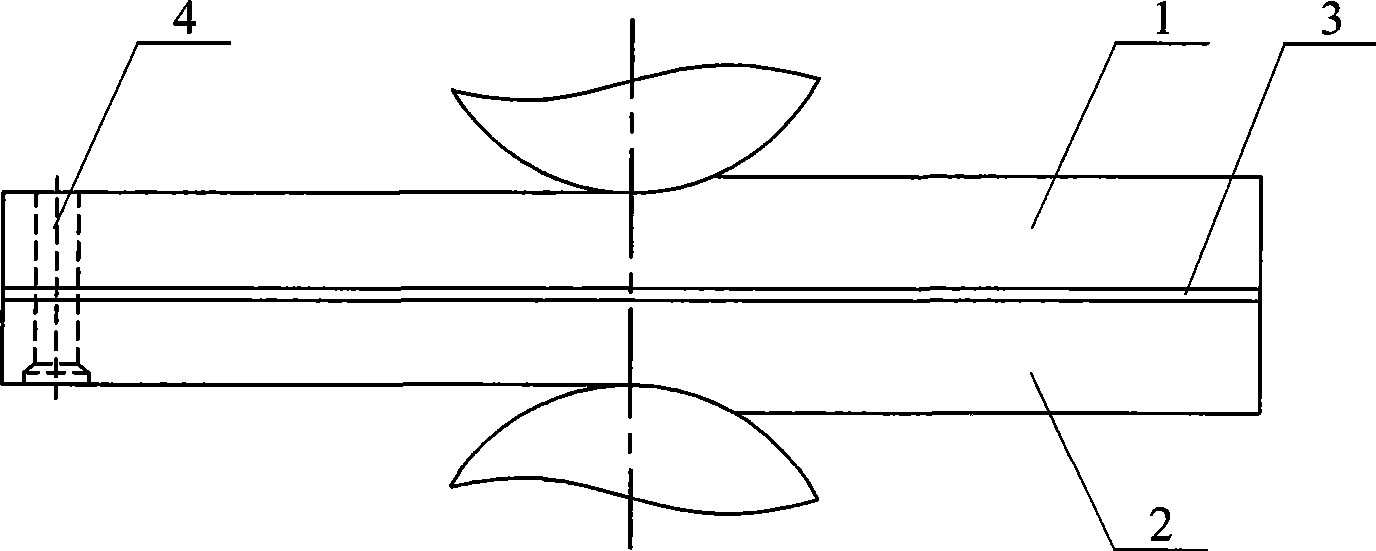

[0010] Specific implementation mode one: combine figure 1 Illustrate present embodiment, the rolling connection method of present embodiment is finished like this: one, get stainless steel plate 1, molybdenum plate 2 and red copper foil 3 stand-by, earlier connect the connection surface of stainless steel plate 1 and molybdenum plate 2 Milling and flattening, pickling the stainless steel plate 1, molybdenum plate 2 and copper foil 3, then stacking the stainless steel plate 1 and molybdenum plate 2 together, sandwiching the copper foil 3 between the stainless steel plate 1 and the molybdenum plate 2 to form three layers Metal plate, one end of the three-layer metal plate is fixed together by two rivets 4 to form a composite plate; 2. Put the above-mentioned composite plate into a vacuum chamber, when the vacuum degree reaches (1~3)×10 -3 When Pa starts to heat the clad plate, the heating temperature is 850-1050°C, and the heating rate is 300-600°C / h, after that, the clad plate ...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination figure 1 To illustrate this embodiment, in step 1 of this embodiment, the thickness of the copper foil 3 used is 0.1-0.5 mm, and the thickness of the milled stainless steel plate 1 and the molybdenum plate 2 are 1-20 mm respectively. The reliable connection between the titanium alloy plate 2 and the stainless steel plate 1 can be ensured. Other rolling connection methods are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination figure 1 Describe this embodiment, in step one of this embodiment, drill two through holes on the upper surface of one end of the three-layer metal plate, press two rivets 4 into the two through holes respectively, and the two ends of the rivets 4 are connected to the three through holes. The upper and lower surfaces of the layer metal plates are flush.

[0014] In this embodiment, a hydraulic universal testing machine is used to press the rivet 4 into the three-layer metal plate. After the rivet 4 is compressed, the cross-sectional area expands to fix the plate to be rolled and connected, and prevent it from being rolled during the rolling process. separated under the action of force. Other rolling connection methods are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com