Electrospinning nanofiber membrane-fabric composite coating material and preparation method

A nanofiber membrane and composite coating technology, applied in electrospinning, alcoholic beverage preparation, fiber processing, etc., can solve the problem of high production cost, achieve long working life, good acid and alkali resistance, and shorten the process flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

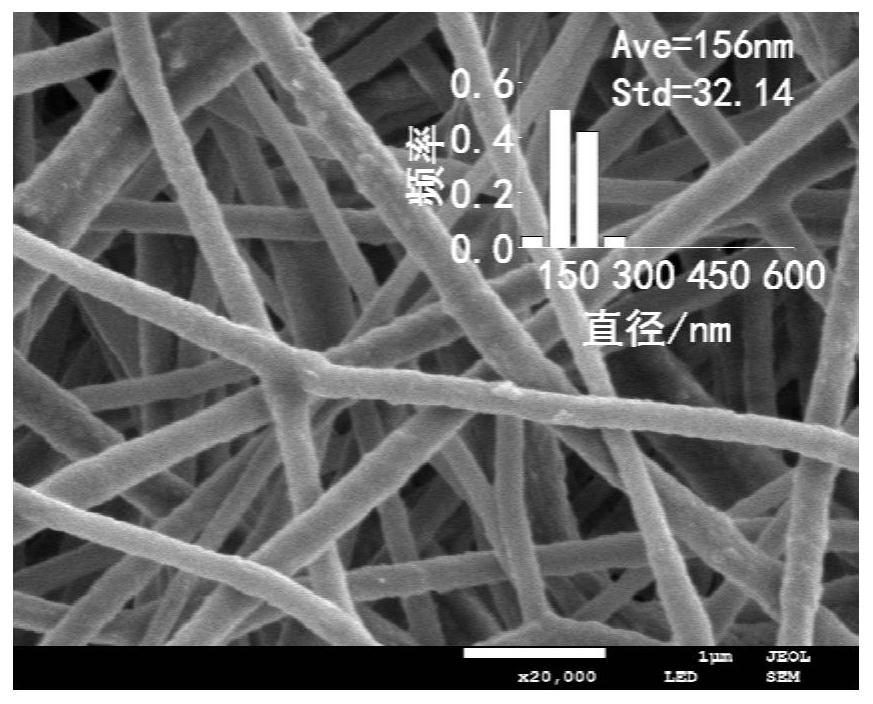

[0037] PVDF-HFP was dissolved in DMAC to obtain a 20 wt% PVDF-HFP solution. PVP was dissolved in DMAC to obtain a 6 wt% PVP solution. Then mix the PVDF-HFP solution and the PVP solution at a volume ratio of 7:3 to prepare a PVDF-HFP / PVP composite spinning solution. The PVDF-HFP / PVP composite spinning solution was subjected to needle-free electrospinning under the conditions of a voltage of 80kV, a solution box speed of 80mm / s, and a spinning time of 40min to obtain a PVDF-HFP / PVP nanocomposite membrane. The fracture strength of PVDF-HFP / PVP nanocomposite film is 4.6202MPa, the average diameter of nanofibers is 113nm, and the thickness is 0.054mm. SEM shows figure 1shown. Combine PVDF-HFP / PVP nanocomposite film with polyester woven fabric (polyester: polyester filament 300DX5, weft yarn: polyester filament, 300DX4; warp density: 307 threads / 10cm, weft density: 122 threads / 10cm, 2 / 2 twill) , placed in parallel up and down, and attached to each other, the surrounding edges are...

Embodiment 2

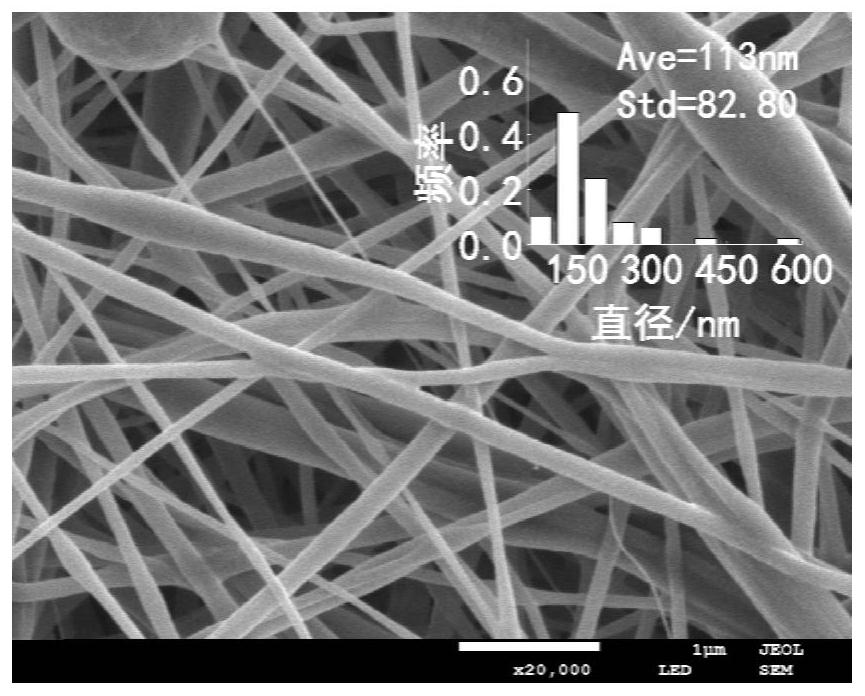

[0039] PVDF-HFP was dissolved in DMAC to obtain a 20wt% PVDF-HFP solution. 6 wt% of PVP was dissolved in DMAC to obtain a PVP solution. Then PVDF-HFP solution and PVP solution were mixed at a volume ratio of 9:1 to prepare PVDF-HFP / PVP composite spinning solution. The PVDF-HFP / PVP composite spinning solution was subjected to needle-free electrospinning under the conditions of a voltage of 80kV, a solution box speed of 80mm / s, and a spinning time of 40min to obtain a PVDF-HFP / PVP nanocomposite membrane. The fracture strength of the PVDF-HFP / PVP nanocomposite film is 9.1565MPa, the average diameter of nanofibers is 156nm, and the thickness is 0.114mm. SEM shows figure 2 shown. Combine PVDF-HFP / PVP nanocomposite film with polyester woven fabric (warp: polyester filament 300DX5, weft: polyester filament, 300DX4; warp density: 307 threads / 10cm, weft density: 122 threads / 10cm, 2 / 2 twill) , placed in parallel up and down, and attached to each other, clamped around the edge with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com