Anti-fouling and water-permeable brick with natural stone imitating effect and preparation method of anti-fouling and water-permeable brick

A technology of imitating natural stone and permeable bricks, applied in the direction of gutter/curb, paving with prefabricated blocks, paving details, etc., can solve the problems of poor water permeability, insufficient aesthetics, poor wear resistance, etc. The effect of dust blocking, long-term water permeability, and improving interface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

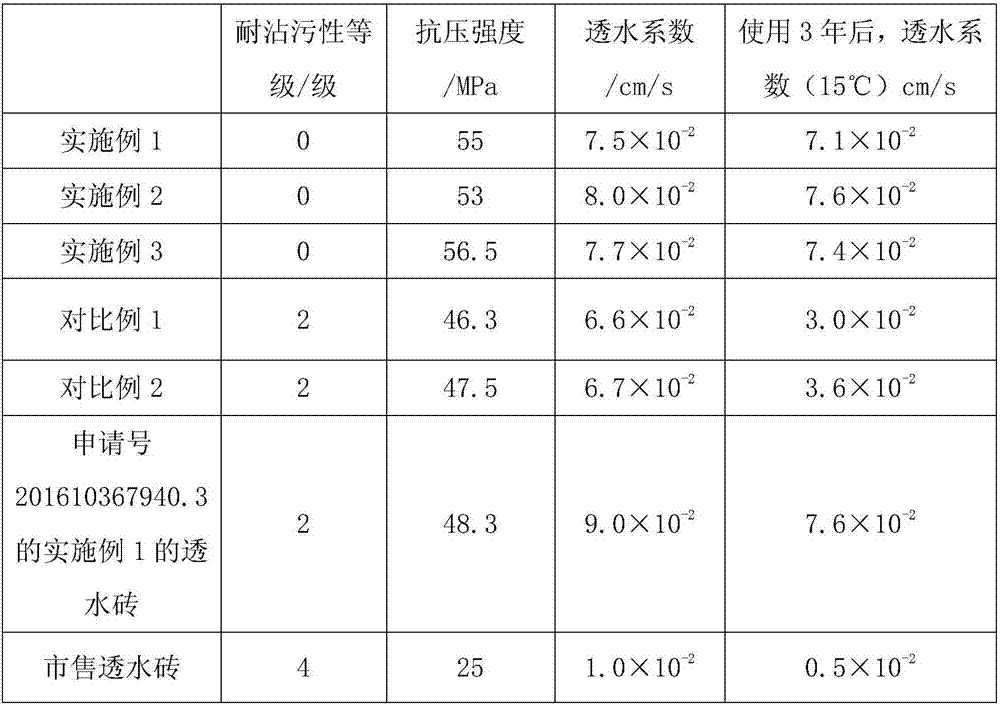

Examples

Embodiment 1

[0040] A pollution-resistant and permeable brick imitating natural stone, including a pollution-resistant and permeable surface layer and a water-permeable base layer. The pollution-resistant and water-permeable surface layer is prepared from the following raw materials in parts by mass: 12 parts of cement, 1 part of water-based binder, modified 70 parts of fine aggregate, 3 parts of water, 1.5 parts of water-permeable agent and 5 parts of pigment; the water-permeable base layer is prepared from the following raw materials in parts by mass: 20 parts of fly ash, 8 parts of cement, 15 parts of carbide slag, and 10 parts of slag , 17 parts of construction waste, 3 parts of water-permeable agent, and 5 parts of water.

[0041] The ratio of the stain-resistant permeable surface layer to the permeable base layer is 1:8.

[0042] The preparation process is as follows:

[0043] (1) Preparation of modified fine aggregate

[0044] According to the ratio of coagulant: water-based binde...

Embodiment 2

[0051] A pollution-resistant and permeable brick imitating natural stone, including a pollution-resistant and permeable surface layer and a water-permeable base layer. The pollution-resistant and permeable surface layer is prepared from the following raw materials in parts by mass: 10 parts of cement, 0.8 parts of water-based binder, modified 65 parts of fine aggregate, 2.5 parts of water, 1.5 parts of water-permeable agent and 5 parts of pigment; the water-permeable base layer is prepared from the following raw materials in parts by mass: 15 parts of fly ash, 5 parts of cement, 15 parts of carbide slag, and 15 parts of slag , 20 parts of construction waste, 3 parts of water-permeable agent, and 5 parts of water.

[0052] The ratio of the stain-resistant permeable surface layer to the permeable base layer is 1:8.

[0053] The preparation process is as follows:

[0054] (1) Preparation of modified fine aggregate

[0055] According to the ratio of coagulant: water-based binder...

Embodiment 3

[0062] A pollution-resistant and permeable brick imitating natural stone, including a pollution-resistant and permeable surface layer and a water-permeable base layer. The pollution-resistant and water-permeable surface layer is prepared from the following raw materials in parts by mass: 15 parts of cement, 1.5 parts of water-based binder, modified 70 parts of fine aggregate, 3.5 parts of water, 2 parts of water-permeable agent and 5 parts of pigment; the water-permeable base layer is prepared from the following raw materials in parts by mass: 25 parts of fly ash, 5 parts of cement, 10 parts of carbide slag, and 10 parts of slag , 15 parts of construction waste, 3 parts of water-permeable agent, and 5 parts of water.

[0063] The ratio of the stain-resistant permeable surface layer to the permeable base layer is 1:8.

[0064] The preparation process is as follows:

[0065] (1) Preparation of modified fine aggregate

[0066] According to the ratio of coagulant: water-based bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com