Method for preparing composite dielectric film

A composite dielectric film and polymer technology, which is applied in the field of composite dielectric film preparation, can solve the problems of poor polymer compatibility, complex preparation method and high sintering temperature, and achieves low composite temperature, environmental friendliness and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

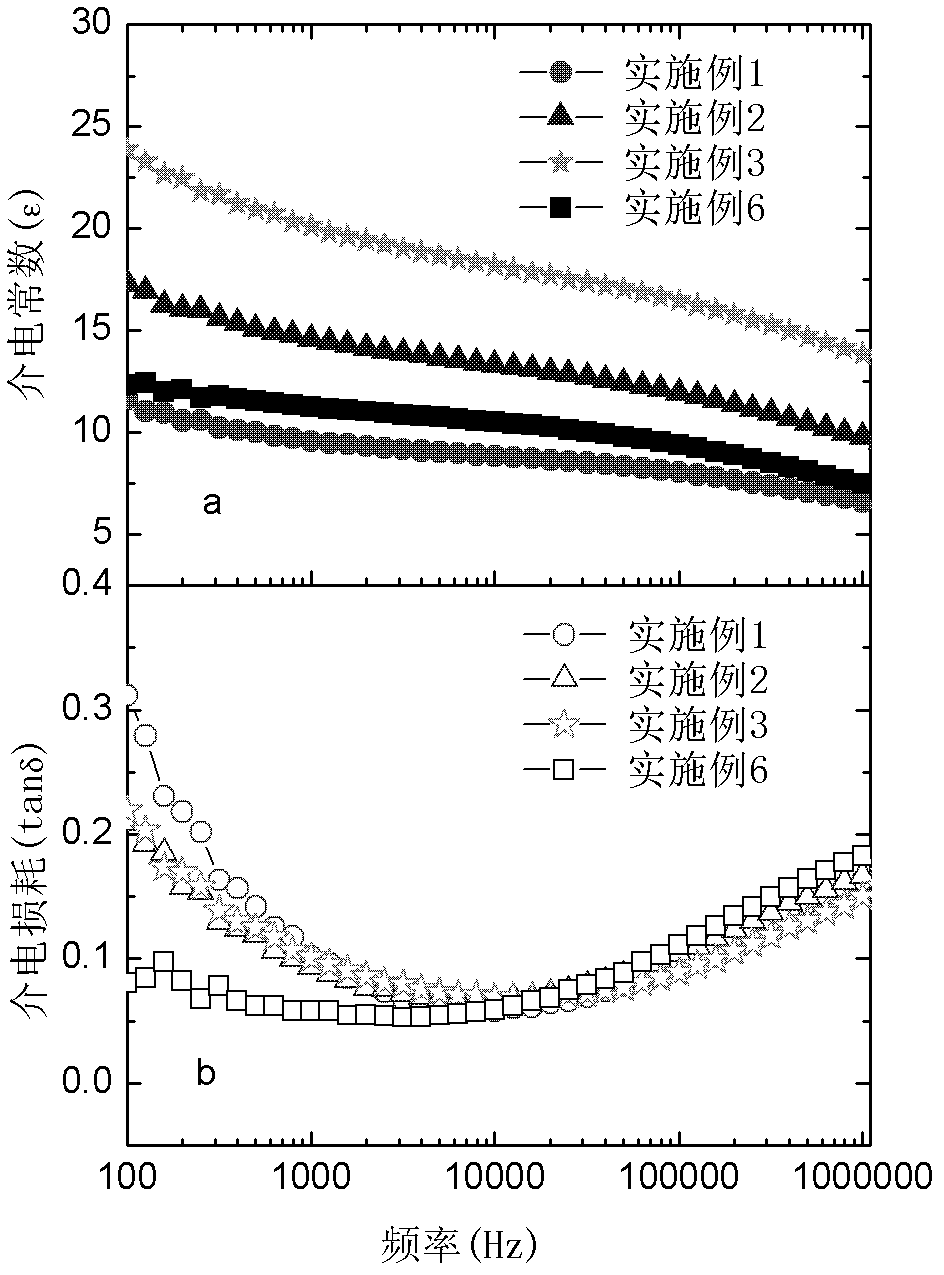

Embodiment 1

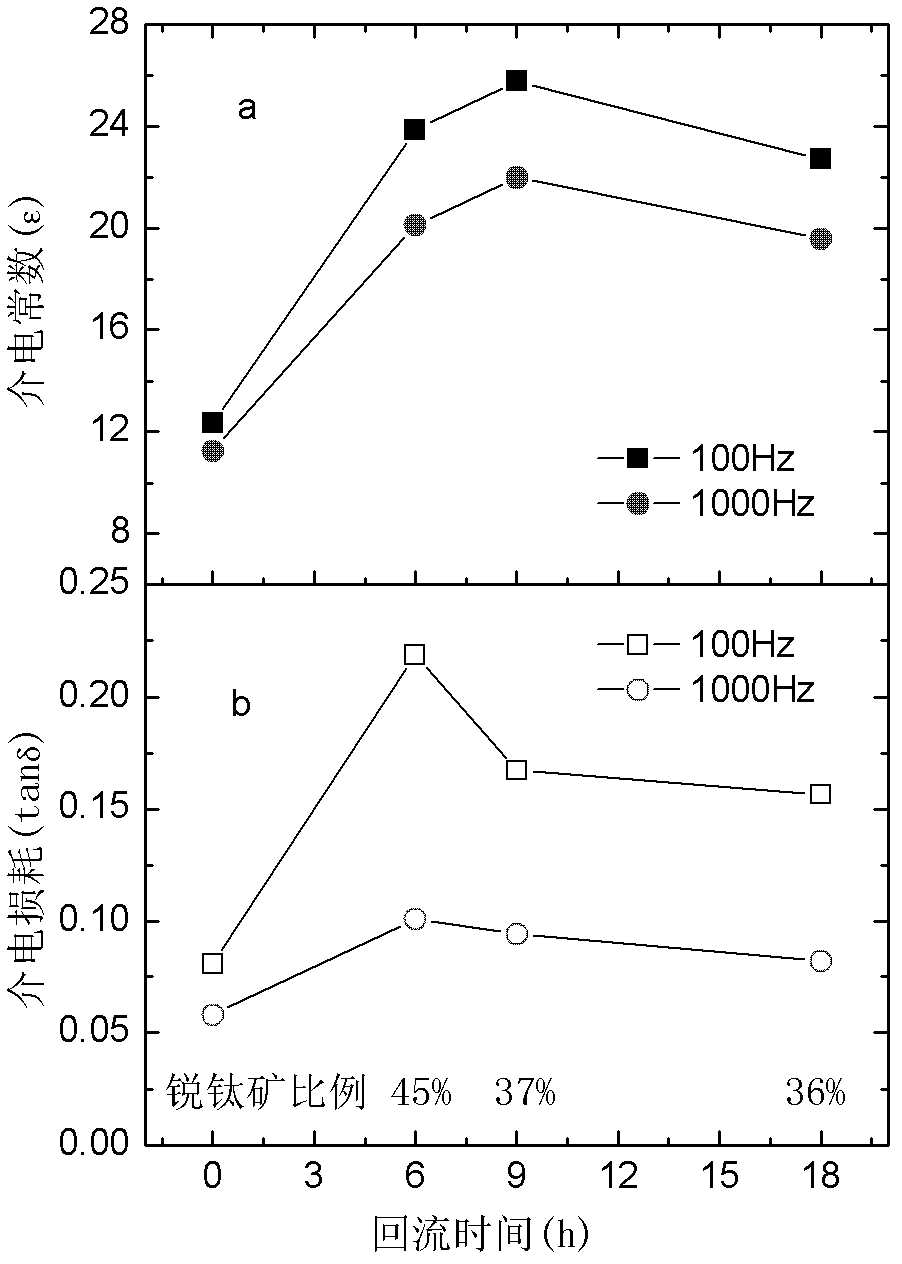

[0028] a. Preparation of mixed crystal nano-TiO by reflux method 2 , the reflux time is 6h, and the molar components of the two crystal forms are:

[0029] 45% for anatase and 55% for rutile;

[0030] This example is for the preparation of mixed crystal TiO2 nanoparticles. 100mL of deionized water and 10mL of hydrogen peroxide were used to make a mixed solvent, and 2.2g of butyl titanate was slowly added dropwise thereto, stirred at room temperature for 30min, and then refluxed at 98°C for 6h, the obtained precipitate was washed away, and dried at 80°C for 20h.

[0031] b. 0.0054g of the mixed crystal TiO prepared in step a 2 , After mixing 0.1000g vinylidene fluoride-trifluoroethylene copolymer [P(VDF-TrFE)] and 1.0005g solvent DMF, the ultrasonic stirring is uniformly dispersed to form a stable sol. The mass percentage of the ingredients is composed of: mixed crystal TiO 2 5% for polymer and 95% for polymer;

[0032] c. Cast the sol prepared in step b on a mold at 80°C t...

Embodiment 2

[0034] a. Preparation of mixed crystal nano-TiO by reflux method 2 , the reflux time is 6h, and the molar components of the two crystal forms are: 45% for anatase and 55% for rutile;

[0035] b. 0.0247g of the mixed crystal TiO prepared in step a 2 , 0.1000g vinylidene fluoride-trifluoroethylene copolymer [P(VDF-TrFE)] and 1.1313g solvent DMF are mixed, ultrasonically stirred and dispersed uniformly to form a stable sol. The mass percentage of the ingredients is composed of: mixed crystal TiO 2 20% for polymer and 80% for polymer;

[0036] c. Cast the sol prepared in step b on a mold at 80°C to form a film, dry for 18h; then cool naturally and anneal at 120°C for 8h to prepare TiO 2 / P(VDF-TrFE) composite dielectric film. The dielectric constant can reach 17.3.

Embodiment 3

[0038] a. Preparation of mixed crystal nano-TiO by reflux method 2 , the reflux time is 6h, and the molar components of the two crystal forms are: 45% for anatase and 55% for rutile;

[0039] b. 0.0667g of the mixed crystal TiO prepared in step a 2 , 0.1000g vinylidene fluoride-trifluoroethylene copolymer [P(VDF-TrFE)] and 1.2830g solvent DMF are mixed, ultrasonically stirred and dispersed uniformly to form a stable sol. The mass percentage of the ingredients is composed of: mixed crystal TiO 2 40% for polymer and 60% for polymer;

[0040]c. Cast the sol prepared in step b on a mold at 80°C to form a film, dry for 18h; then cool naturally and anneal at 120°C for 8h to prepare TiO 2 / P(VDF-TrFE) composite dielectric film. The dielectric constant can reach 23.9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com