Composite flexible high-dielectric film and preparation method and application thereof

A composite flexible and high-dielectric technology, which is applied in the components of fixed capacitors and the dielectric of fixed capacitors, etc., can solve the problems of the decrease of dielectric breakdown strength of composite materials, the difficulty of improving energy storage density, and the influence of composite material structure flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

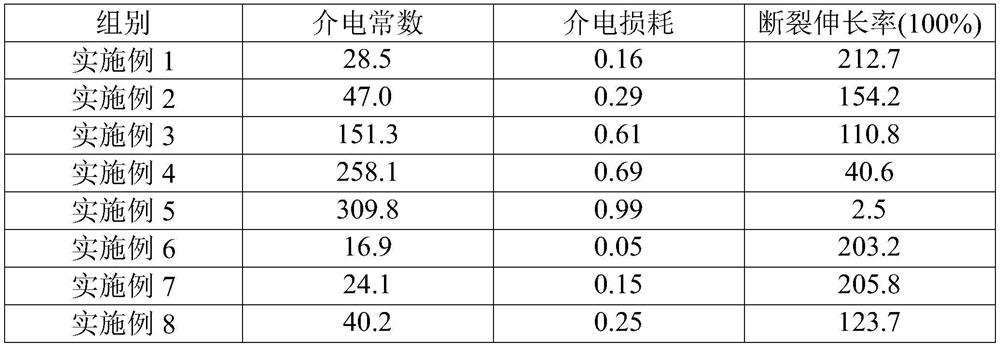

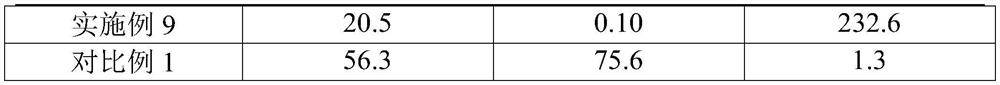

Examples

preparation example Construction

[0039] An embodiment of the present invention also provides a method for preparing a composite flexible high-dielectric film, including the following steps S100-S200.

[0040] Step S100, mixing the MXene nanomaterial suspension with the polymer solution to obtain a composite suspension.

[0041] Wherein, based on the total mass of the polymer and the MXene nanomaterial, the mass percentage of the above-mentioned MXene nanomaterial is 0.5% to 20%.

[0042] In the preparation method of the above-mentioned composite flexible high-dielectric film, the MXene nanomaterial suspension is first mixed with the polymer solution to obtain a composite suspension; wherein, the total mass of the polymer and the MXene nanomaterial is used as a benchmark to control the MXene nanomaterial The mass percentage is 0.5% to 20%. Compared with the existing polymer composite film, the composite flexible high-dielectric film prepared by the preparation method not only has the advantages of high dielec...

Embodiment 1

[0065] 1) Dissolving polyvinyl alcohol in deionized water to prepare polyvinyl alcohol aqueous solution, the concentration of polyvinyl alcohol aqueous solution is 5wt%.

[0066] 2) Prepare Ti by acid etching and stripping 3 C 2 T x Suspension; Ti 3 C 2 T x The concentration of the suspension is 0.1 wt%. Specific steps are as follows:

[0067] Dissolve 0.666 parts by mass of LiF in 10 parts by mass of hydrochloric acid with a concentration of 6 mol / L, and then dissolve 1 part by mass of Ti 3 AlC 2 The powder was slowly added to the above solution, stirred and corroded for 24 hours under the water conditions of 35°C, the corroded mixed liquid was washed with 95% ethanol, and centrifuged until the pH of the supernatant after centrifugation was about 7, and then centrifuged to obtain Dilute the black paste with pure water to a total mass of 300 parts, ultrasonically peel the diluted liquid for 1 h, then centrifuge the liquid at a speed of 3500 r / min for 1 h, and collect t...

Embodiment 2

[0071] 1) Dissolving polyvinyl alcohol in deionized water to prepare polyvinyl alcohol aqueous solution, the concentration of polyvinyl alcohol aqueous solution is 10wt%.

[0072] 2) Prepare Ti by acid etching and stripping 3 C 2 T x Suspension; Ti 3 C 2 T x The concentration of the suspension was 0.2 wt%. Specifically refer to embodiment 1 step 2).

[0073] 3) Get the above-mentioned polyvinyl alcohol aqueous solution of 4.4 parts of quality, the above-mentioned Ti of 11.6 parts of quality 3 C 2 T x The suspension was placed in a beaker, stirred by magnetic force for 30 minutes, and then ultrasonically degassed for 5 minutes to obtain a suspension.

[0074] 4) The mixed suspension was made into a coating film by the coating method, and then placed in a vacuum oven for drying for 8 hours at a temperature of 40° C. and a vacuum pressure of -0.09 MPa. Ti after drying 3 C 2 T x / Polyvinyl alcohol composite flexible high dielectric film, Ti in the composite film 3 C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com