Adding and push-out device suitable for plate-type reagent

A reagent adding and ejecting device technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of low manual operation efficiency, many mechanical gripper components, easy pollution, etc., and achieves the effect of simple structure, low cost, and automatic collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Referring to Figure 1 to Figure 9 The present invention will be described in detail.

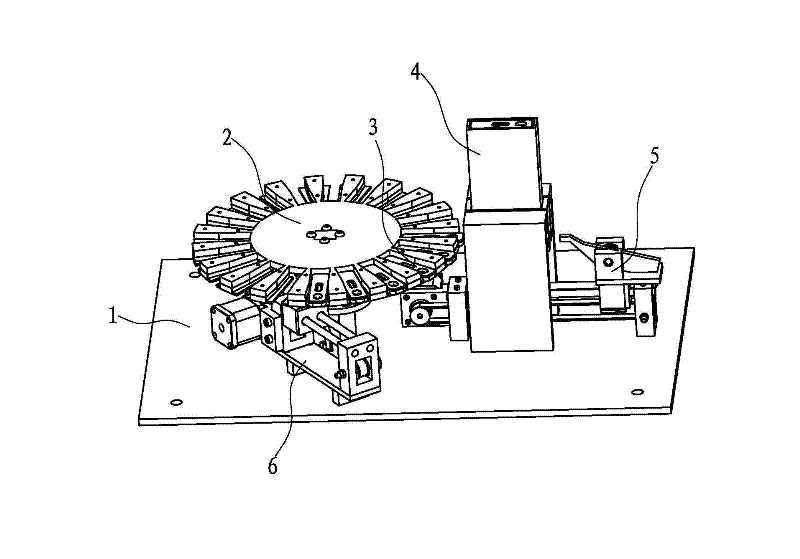

[0035] A device suitable for adding and pushing out plate-type reagents, comprising a fixed plate 1 , a plate-type reagent placing tray 2 , a reagent box placing mechanism 4 , a pushing mechanism 5 , and a pushing mechanism 6 .

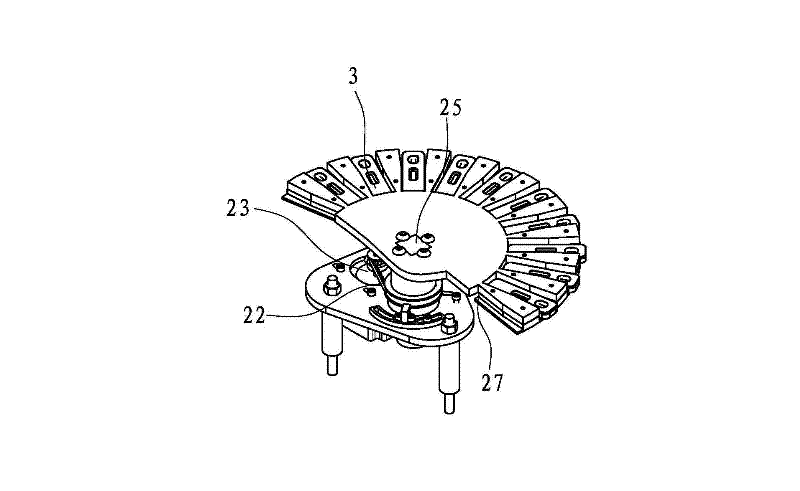

[0036] The plate-type reagent placing tray 2 is installed on the fixed plate 1 by means of the rotating shaft 25, and the plate-type reagent placing tray 2 is driven to rotate by the motor 23 and the transmission mechanism (synchronous belt 22), and the periphery of the plate-type reagent placing tray 2 forms several reagent grooves along the radial direction 27.

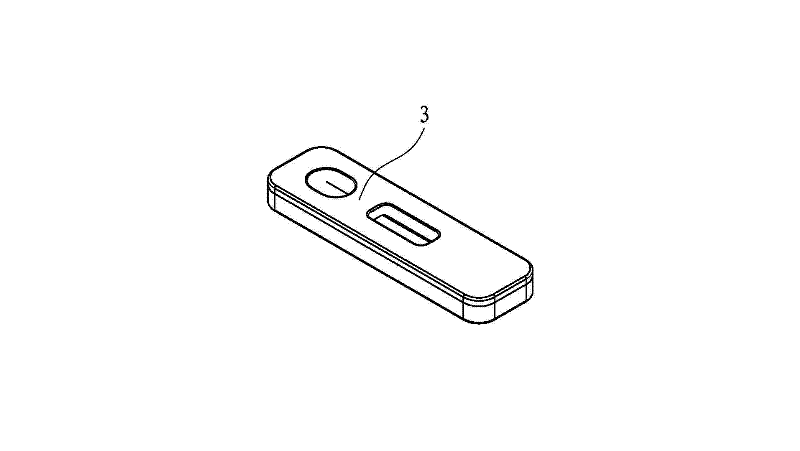

[0037] The reagent box placing mechanism 4 is installed on the fixed plate 1, and the reagent box placing mechanism 4 is located beside the plate reagent placing tray 2, and the plate reagent 3 is stacked in the reagent box 42, and the bottom of the reagent box 42 corresponds to the plate reagent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com