Method for preparing high-activity powder by using dry blast furnace slag

A blast furnace dry slag and powder preparation technology, applied in the direction of process efficiency improvement, recycling technology, etc., can solve the problems of ineffective excavation of blast furnace dry slag, insufficient crushing of dry slag, and insufficient utilization, so as to save raw material consumption , Improve the strength, corrosion resistance and durability, and realize the effect of resource recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

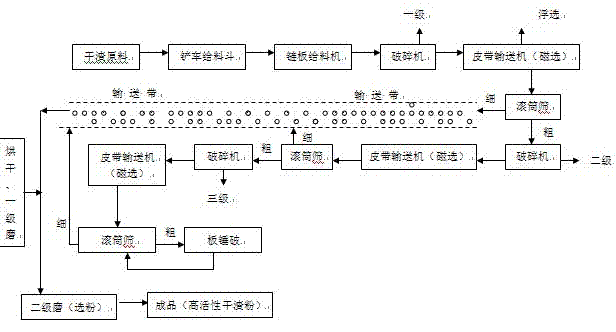

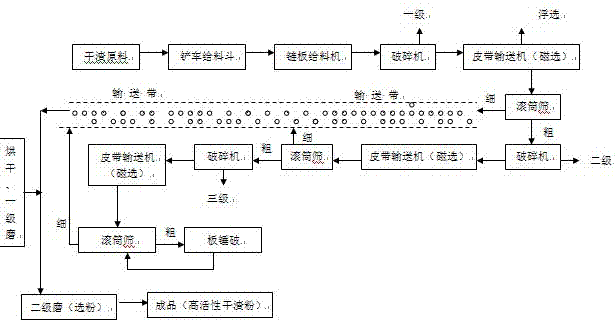

Image

Examples

Embodiment 1

[0018] Embodiment 1: The blast furnace dry slag that contains a certain amount of moisture is first crushed, and then enters the magnetic separation belt conveyor, and the dry slag after magnetic separation of metal iron enters the elevator, and is transported into the drum screen, and the particles are screened. The dry slag with a diameter greater than 10 mm is returned to the ultra-fine crusher for re-crushing, and the particle size is less than 10 mm and directly enters the finished product warehouse, and the dry slag enters the dryer through a vibrating feeder, and the dry slag with a moisture content of less than 2.0% is mixed with The dust-laden water vapor in the ventilation system of the dryer passes through the dust collector, and the collected dust is mixed into the hoist and transported to the finished product warehouse;

Embodiment 2

[0019] Embodiment 2: The dry slag in the finished product warehouse is measured by a belt scale, and the composite activator and activator in the storage tank enters the ball mill at the same time. After grinding, the dry slag is transported to the powder separator through the elevator, and the qualified powder is directly transported to the finished product warehouse. The unqualified coarse powder is sent back to the first-level ball mill and the second-level ball mill for grinding. At this time, the qualified powder reaches 99.5% and is transported to the finished product warehouse;

Embodiment 3

[0020] Embodiment 3: The patent of the present invention can also be implemented on the basis of Embodiment 1: the dry slag powder in the finished product warehouse is measured by a screw feeder, sent into a high-fine ball mill, added grinding aids and activators, and ground to obtain a specific surface area ≥500㎡ / kg powder enters the elevator and transports to the finished product warehouse, the dust collector of the ventilation system of the high-fine mill, and the induced draft fan is discharged into the atmosphere, and the collected dust enters the air chute, and is sent to the finished product warehouse by the blower;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com