Double-row filter bag embedded type electric bag compound dust catcher with electric field area at front stage

An embedded electric bag and filter bag technology, which is applied in the direction of combined devices, chemical instruments and methods, and climate change adaptation, can solve the problem that the concentration of flue gas emission is difficult to meet the national pollutant discharge standard, the specific resistance of fine dust is large, and the filter bag To solve problems such as short service life, improve reliability and dust removal performance, increase flue gas treatment capacity, and reduce floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

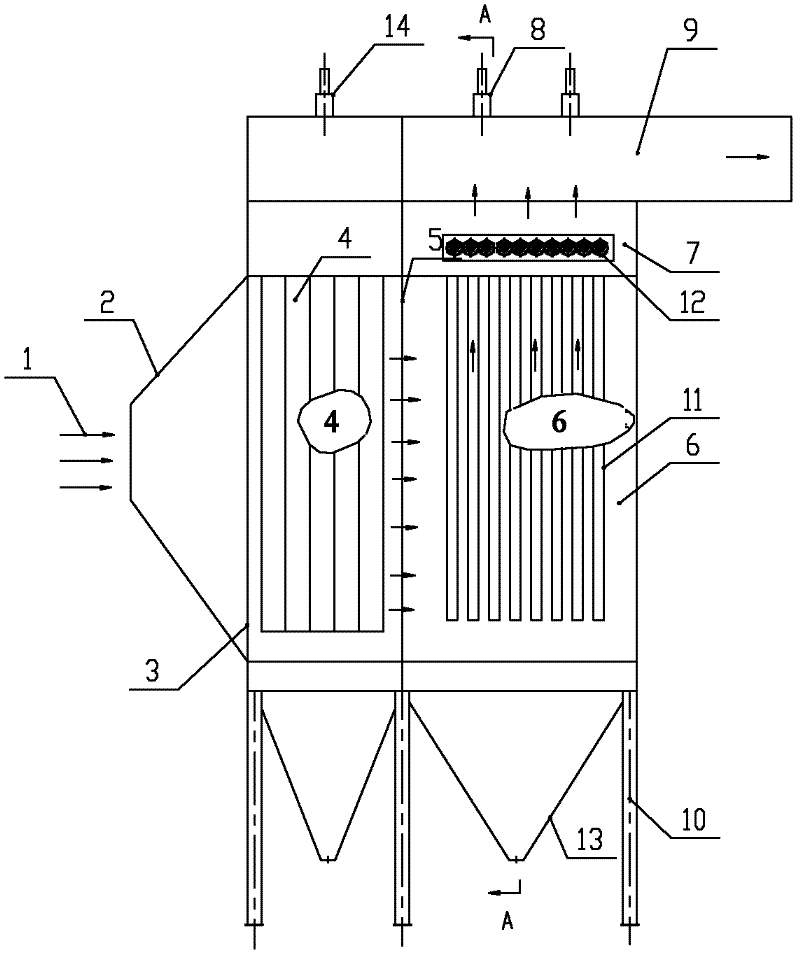

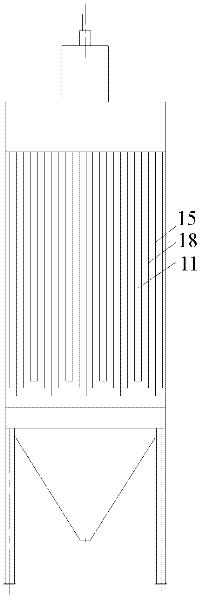

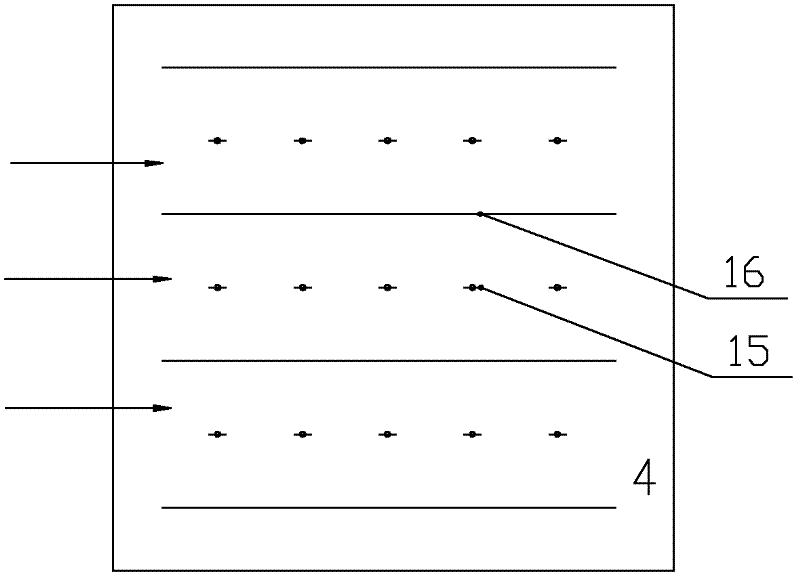

[0022] see Figure 1~5 , the embodiment of the present invention is provided with inlet horn 2, housing 3, flue 9, support 10, filter bag 11, cleaning system 12, ash hopper 13, discharge electrode 15, dust collection plate 16, rear discharge electrode 17 and Dust collection orifice 18; housing 3 is provided with front-stage electric field area 4 and rear-stage embedded electric bag dust removal area 6, the air inlet of front-stage electric field area 4 is connected with the air outlet of imported horn 2, and the rear-stage embedded A diversion adjustment plate 5 is provided between the air inlet of the electric bag dust removal area 6 and the air outlet of the front-stage electric area 4; the upper part of the housing 3 is provided with a clean air chamber 7, and the air inlet of the clean air chamber 7 is connected to the The gas outlet of the post-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com