Patents

Literature

32results about How to "Increase the filtration speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

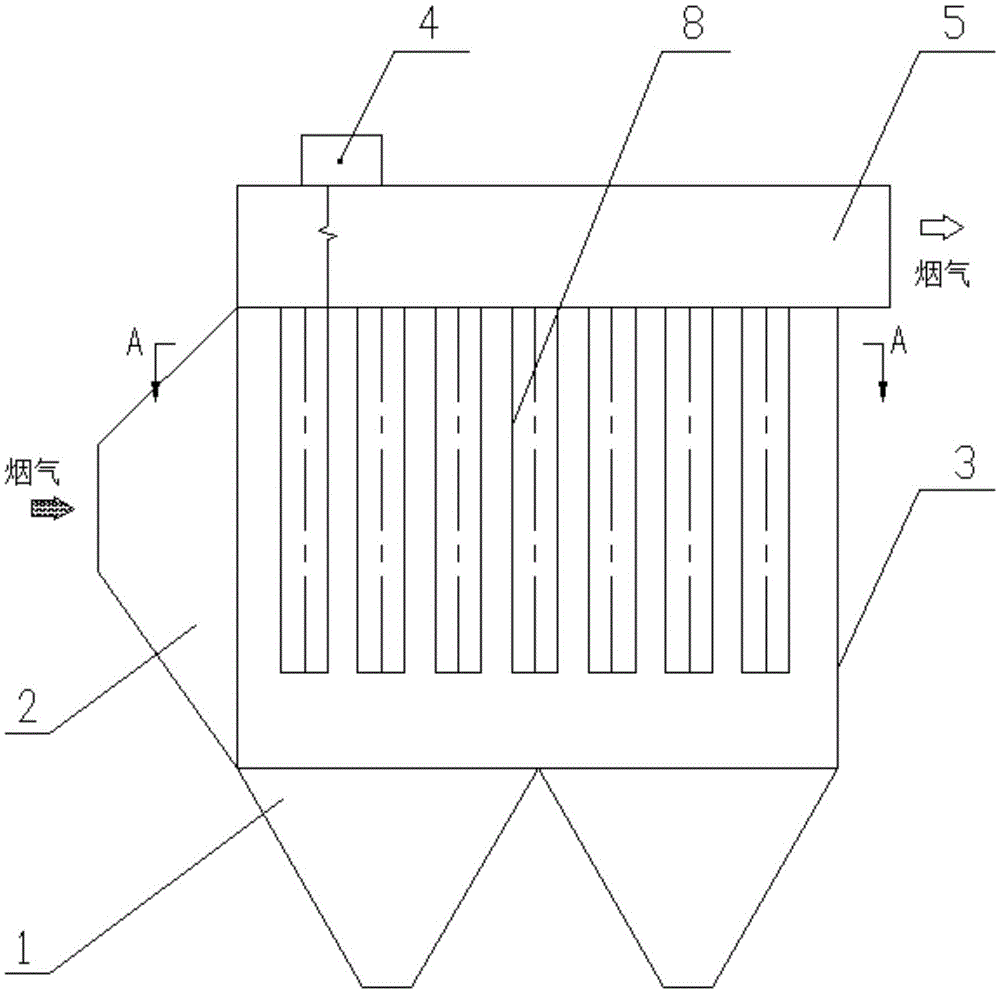

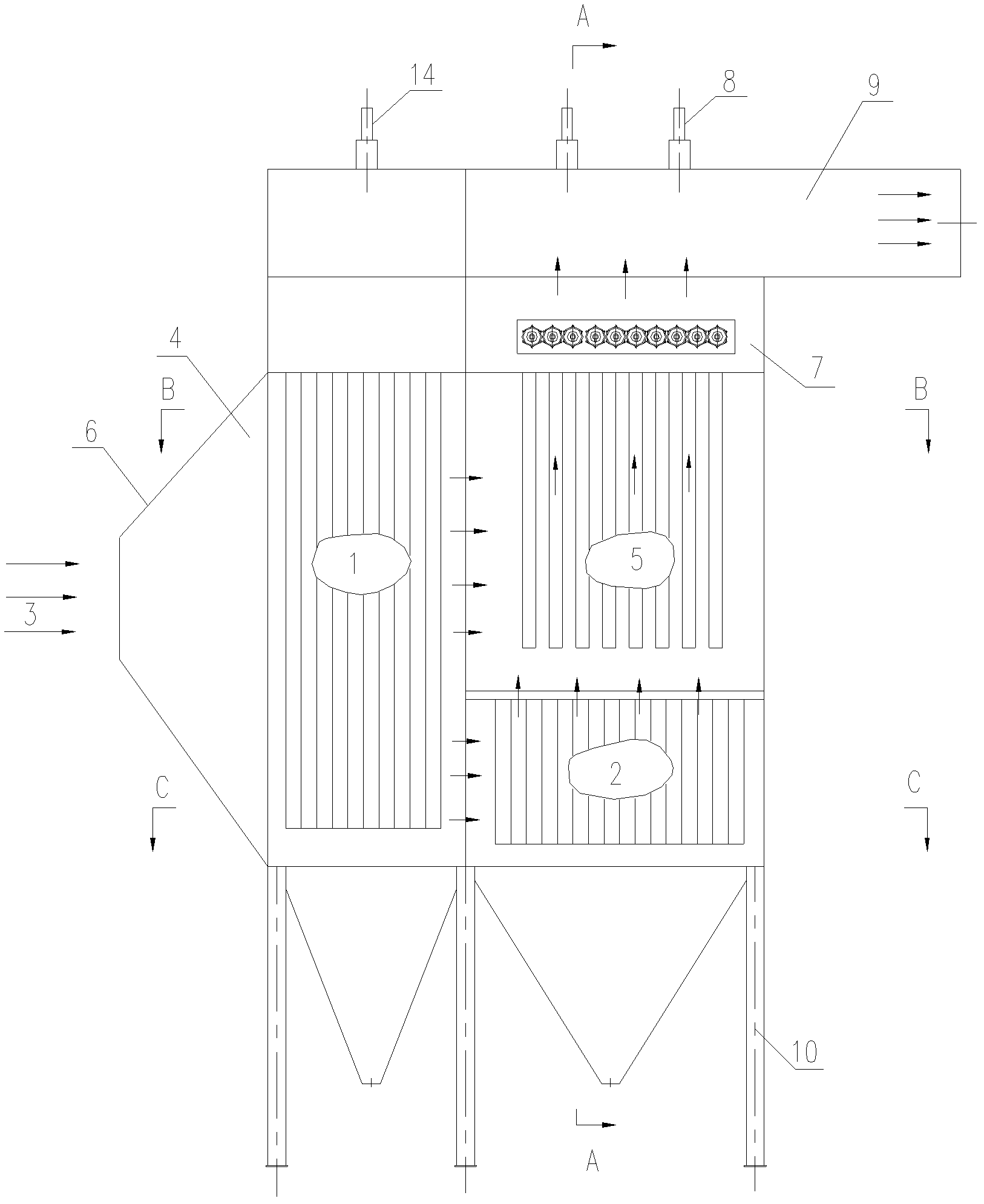

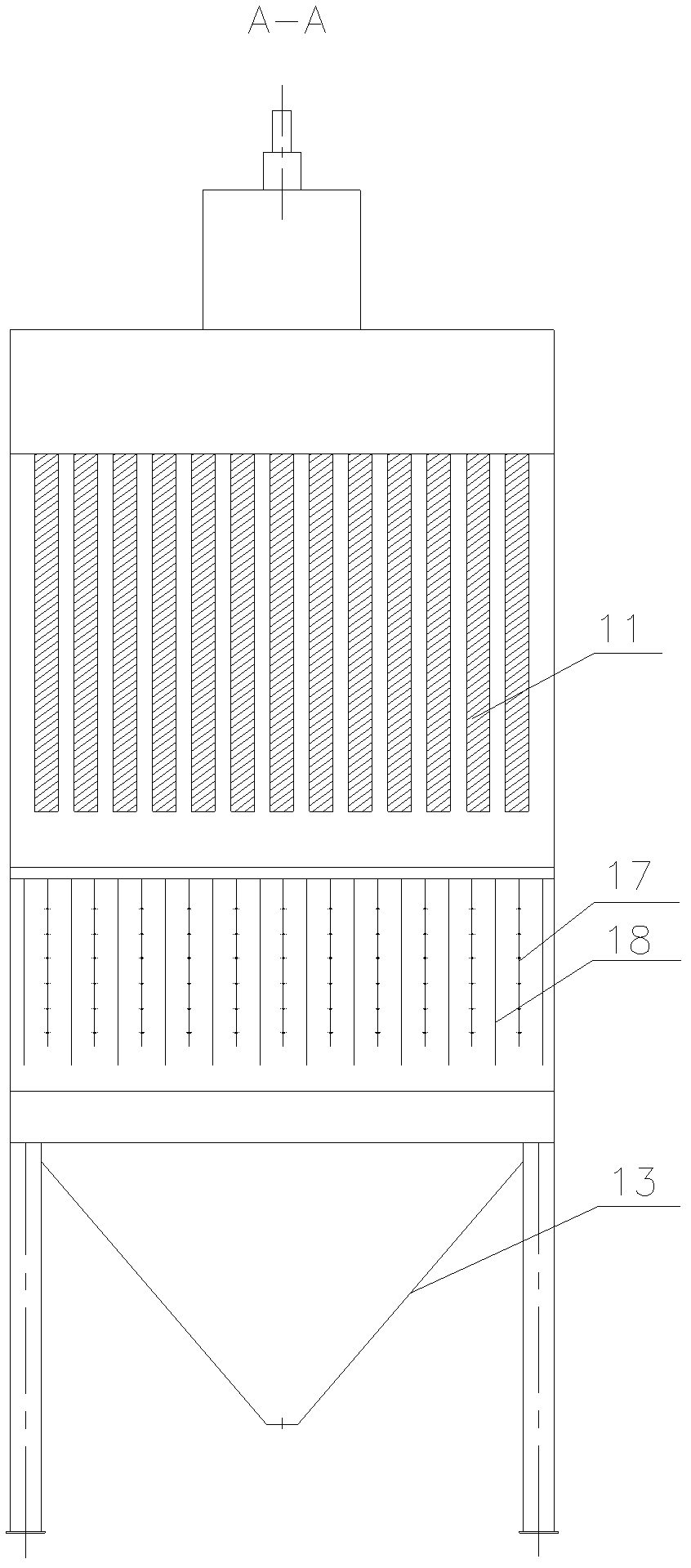

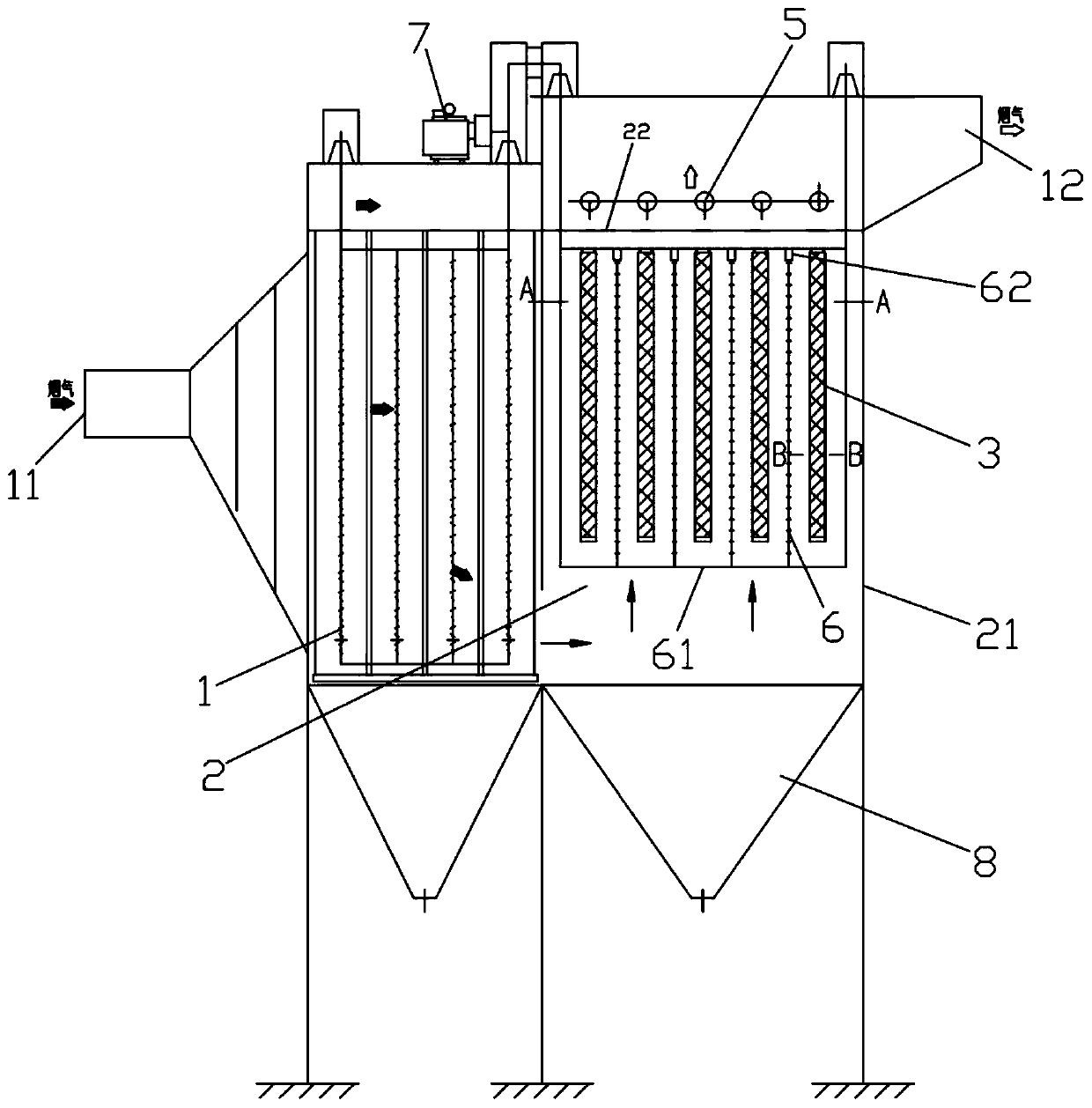

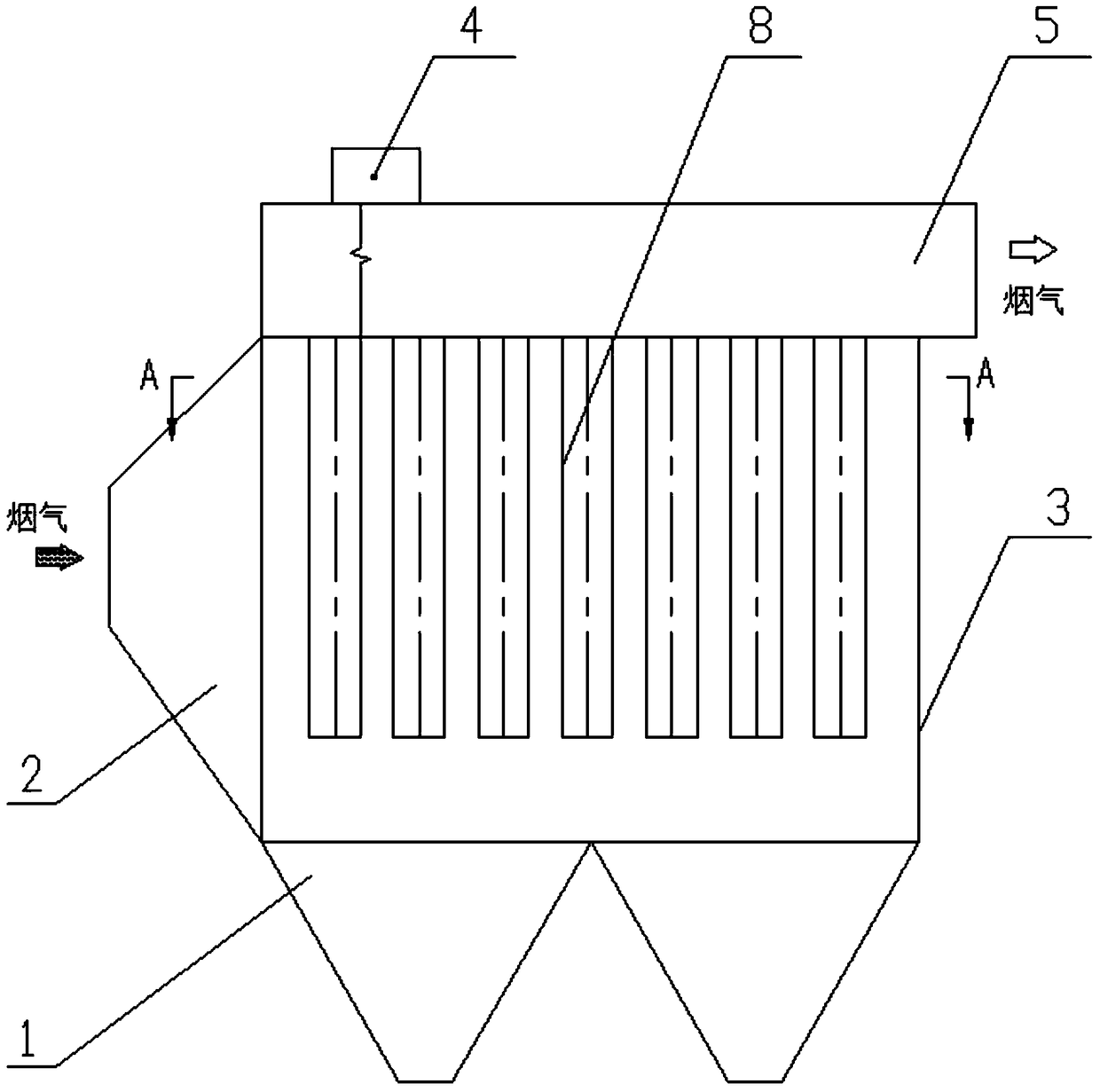

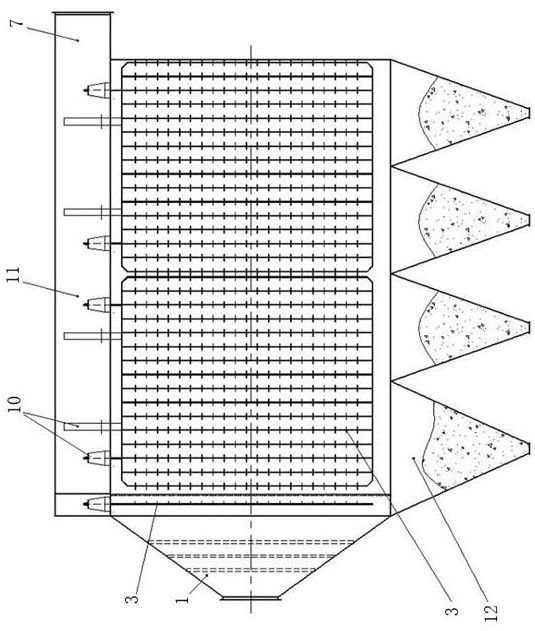

Electric-bag composite dust collector

ActiveCN102327724AIncrease the filtration speedReduce processingCombination devicesEngineeringDust emission

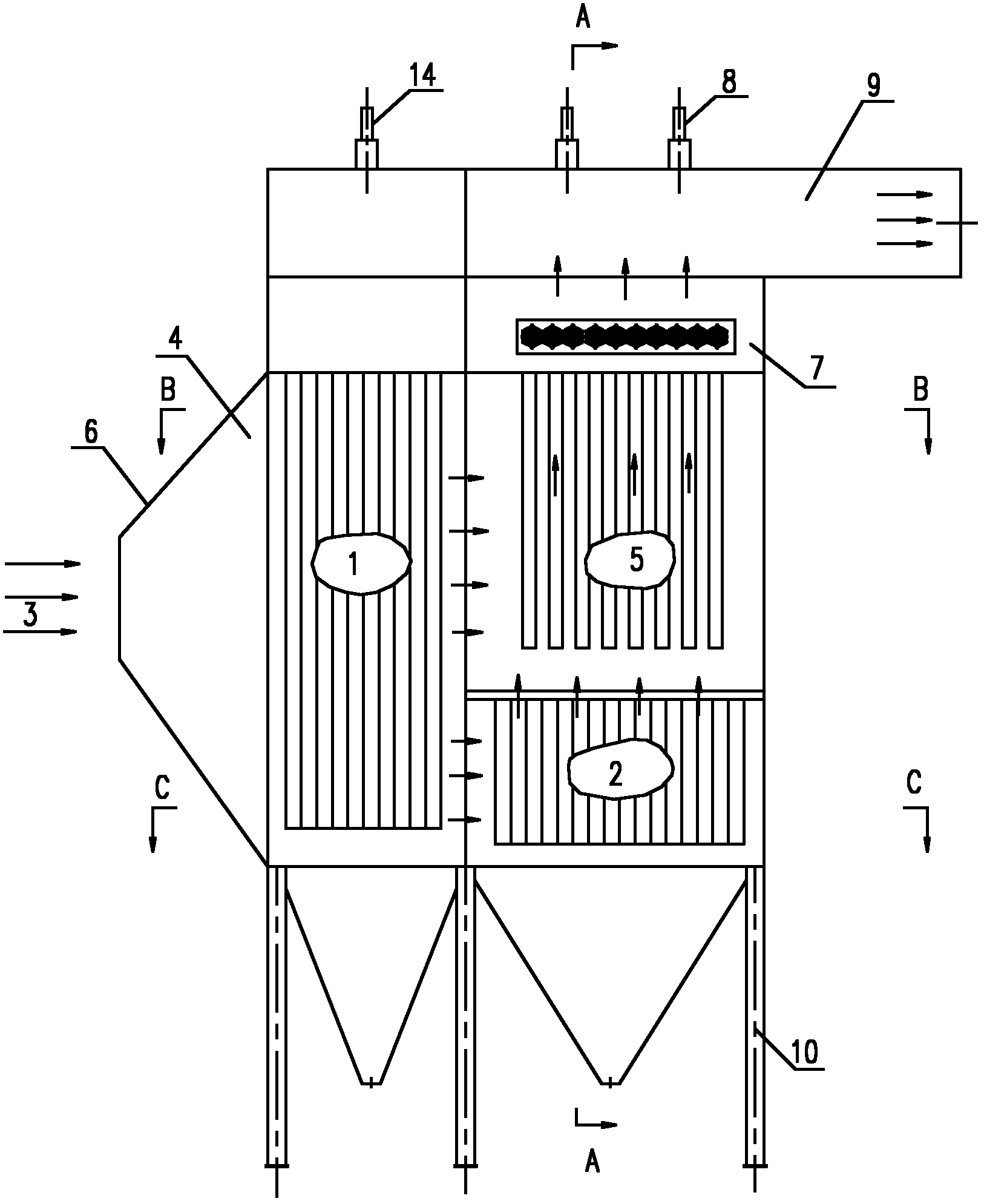

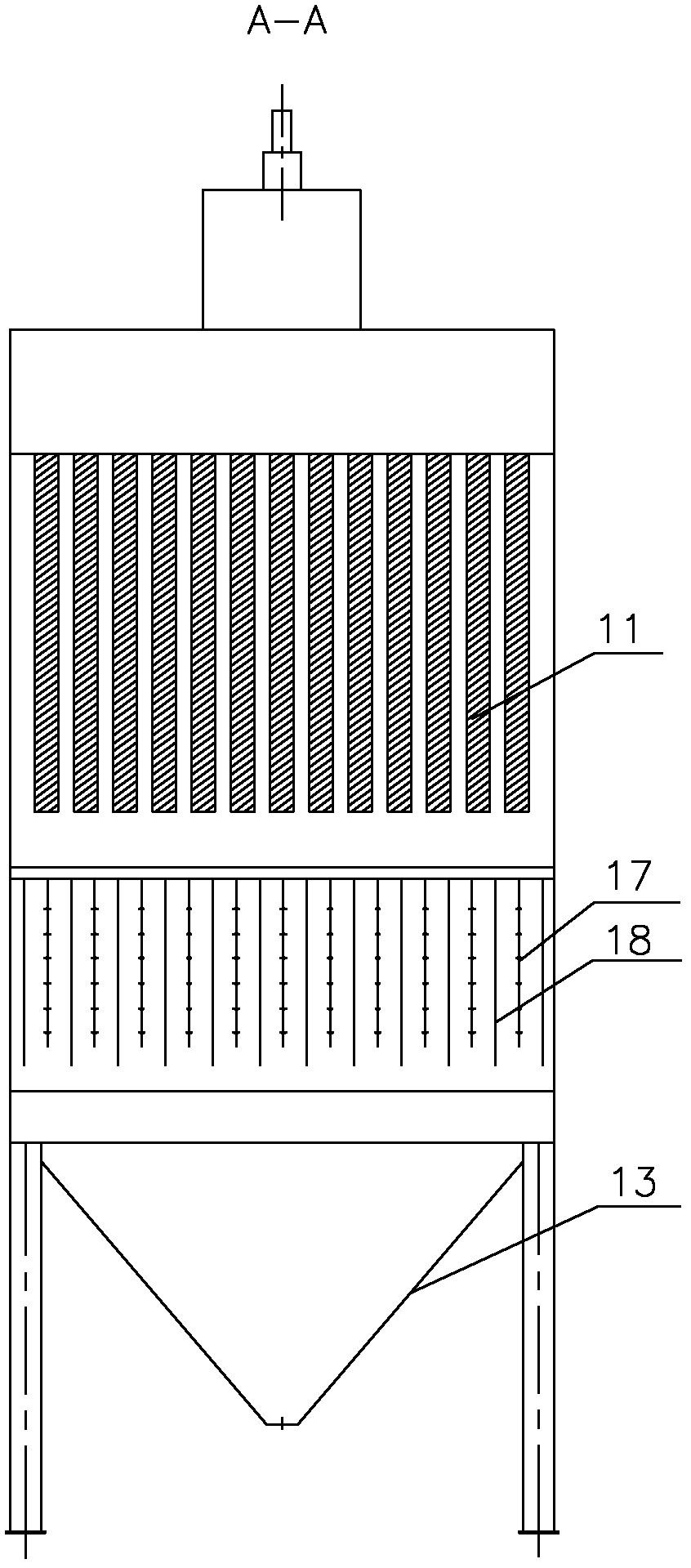

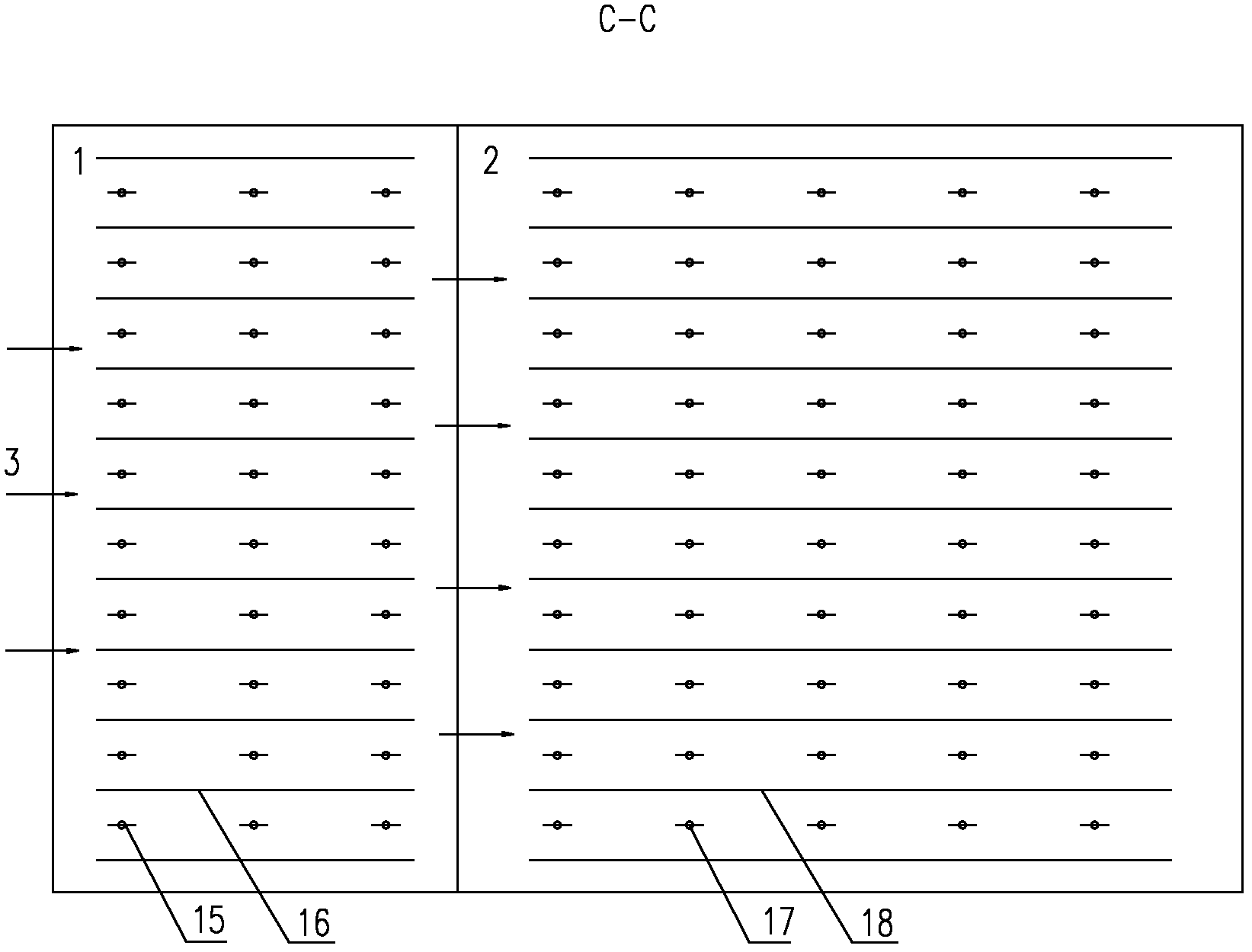

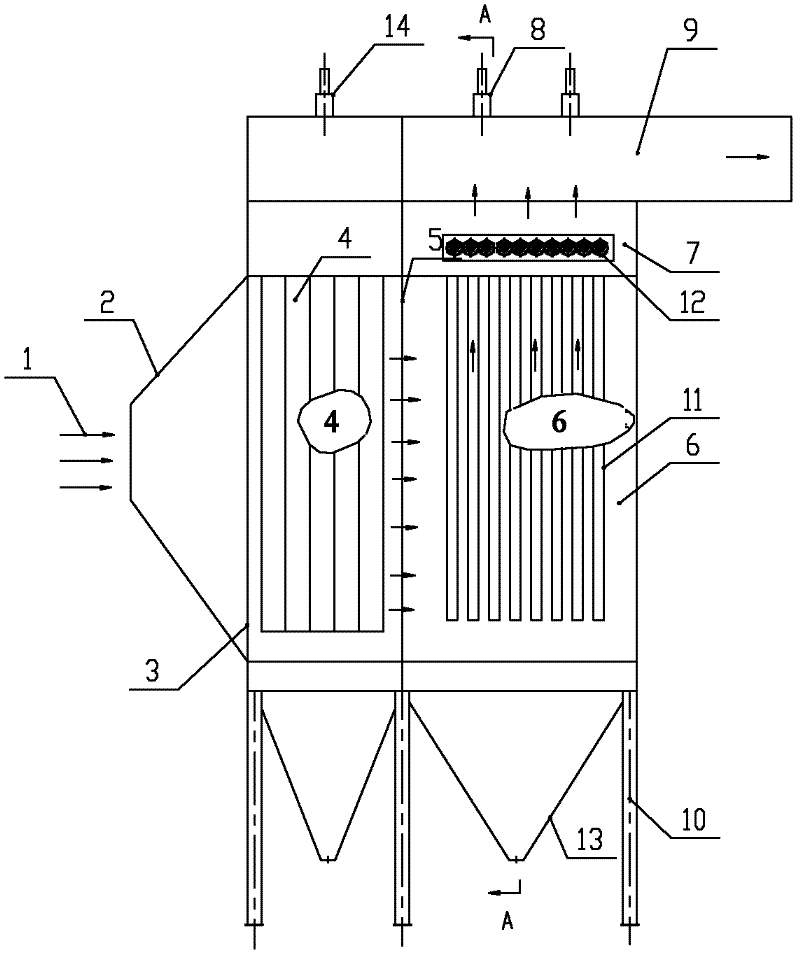

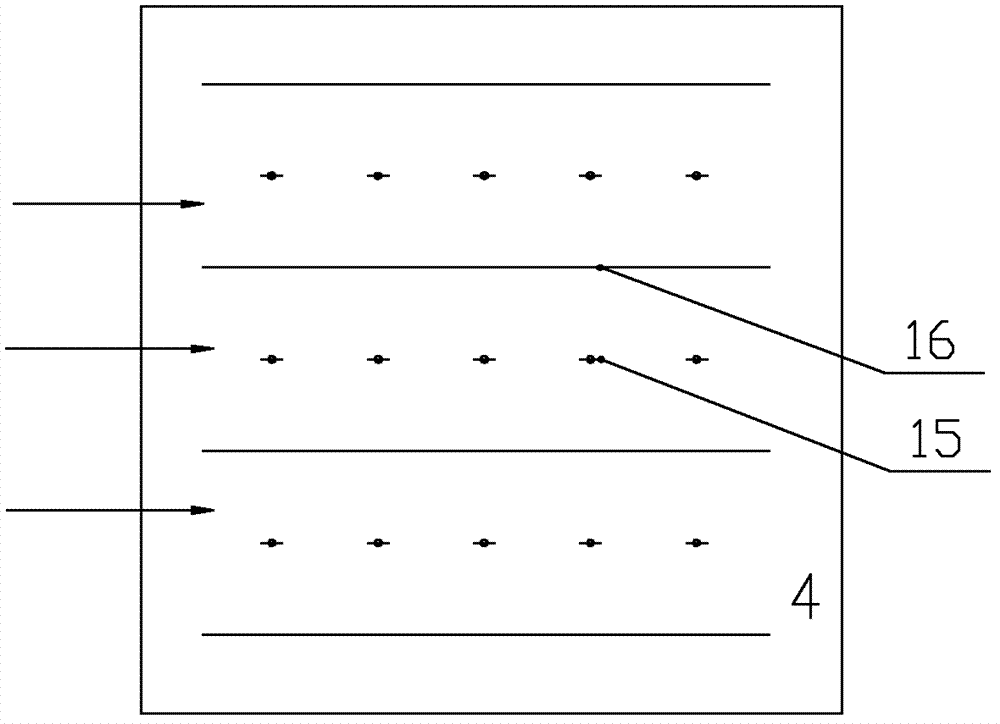

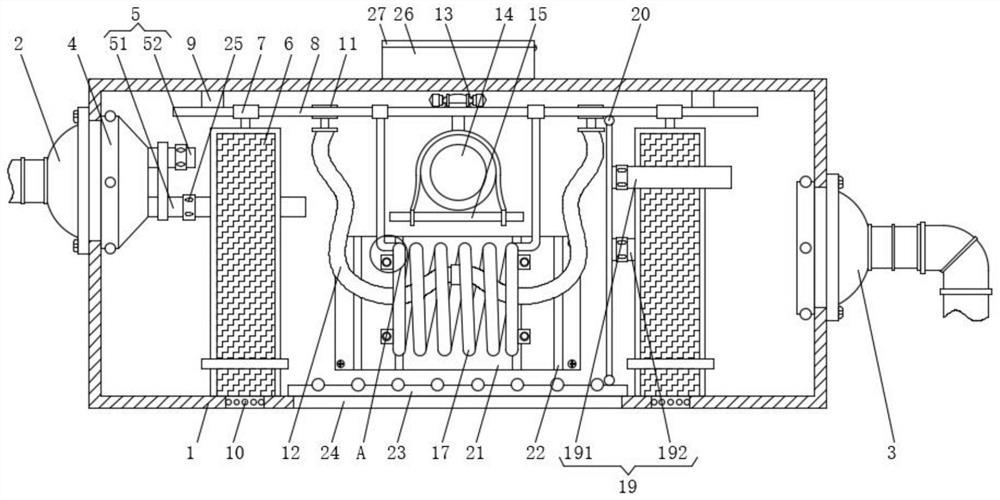

The invention discloses an electric-bag composite dust collector. The electric-bag composite dust collector comprises a composite dust collecting region in a housing, wherein the composite dust collecting region comprises an electric bag dust collecting region and a first electric field dust collecting region; the electric bag dust collecting region comprises a filter bag region and a second electric field dust collecting region; a filter bag dust collecting device is arranged in the filter bag region, and located on the upper end of the electric bag dust collecting region; an electric field dust collecting device is arranged in the second electric field dust collecting region, which is communicated with the filter bag region and located on the lower end of the electric bag dust collecting region; and an electric field dust collecting device is arranged in the first electric field dust collecting region, which is communicated with the electric bag dust collecting region and located onthe front end of the electric bag dust collecting region. In the electric-bag composite dust collector provided by the invention, the second electric field dust collecting region is arranged on the lower end of the electric bag dust collecting region, so that the dust can be recharged when a portion of smoke flows from the first electric field dust collecting region to the second electric field dust collecting region, thereby enhancing the dust charging strength. Additionally, the second electric field dust collecting region can effectively collect dust dropping from the filter bag region when the dust is removed, thereby reducing secondary dust emission, prolonging dust removal period, prolonging the service life of the filter bag, reducing the whole dust removing resistance, and improving the overall performance of the dust collector.

Owner:FUJIAN LONGKING

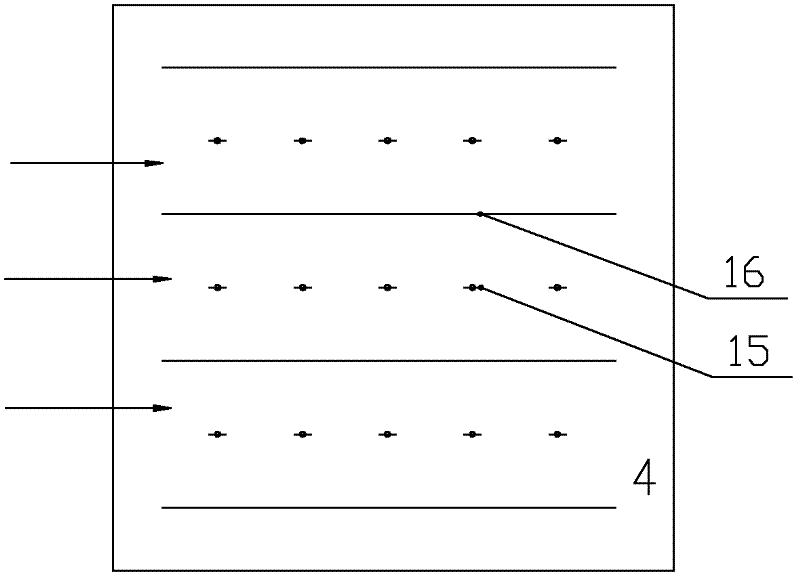

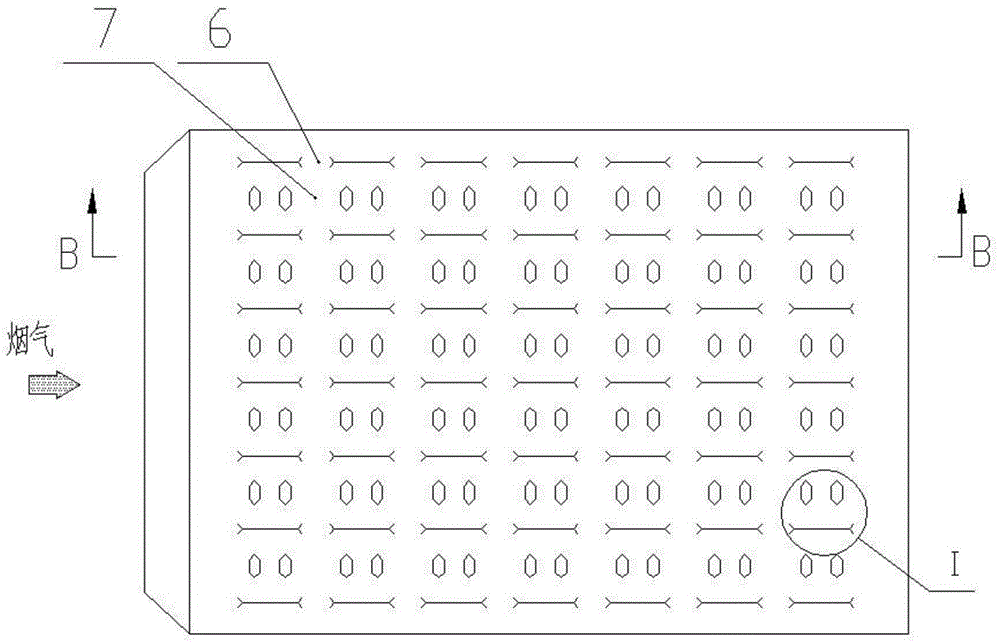

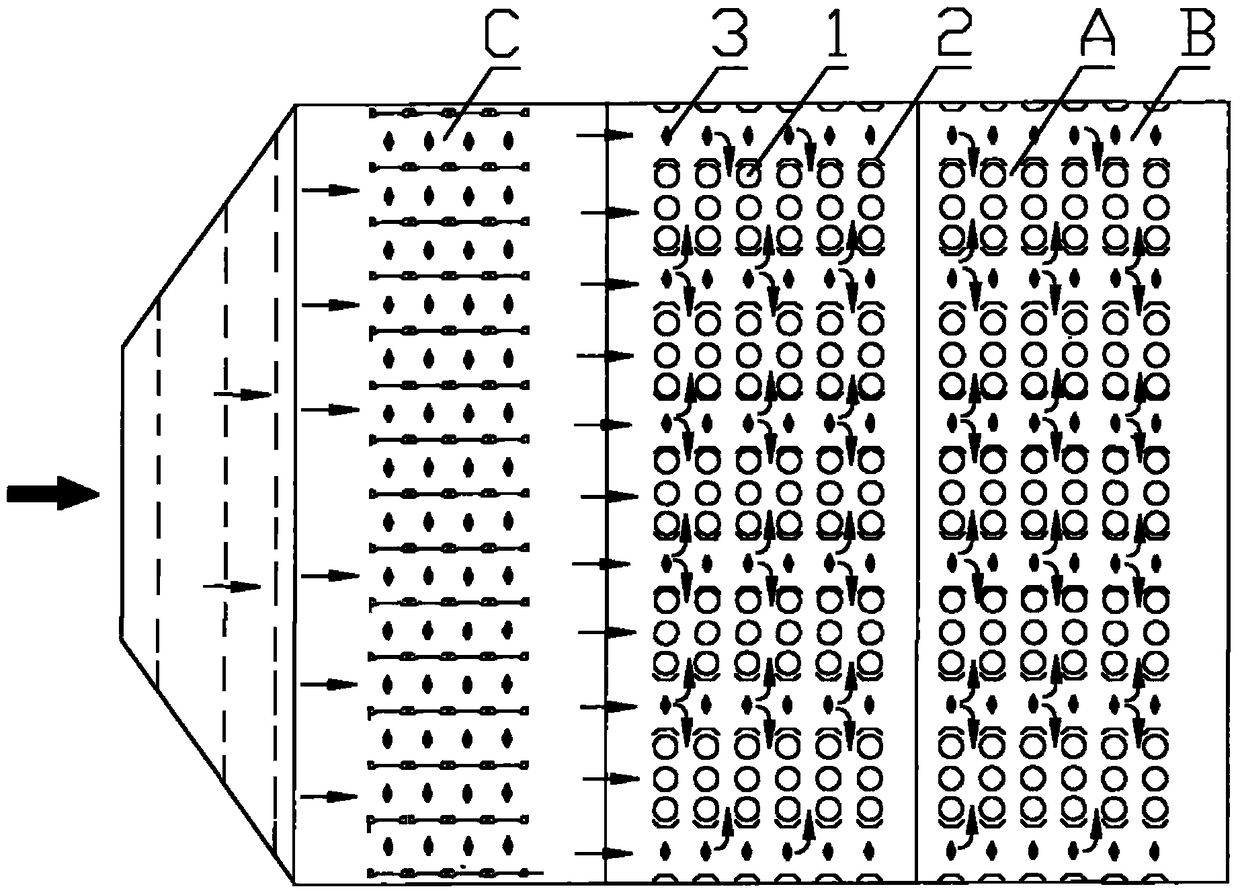

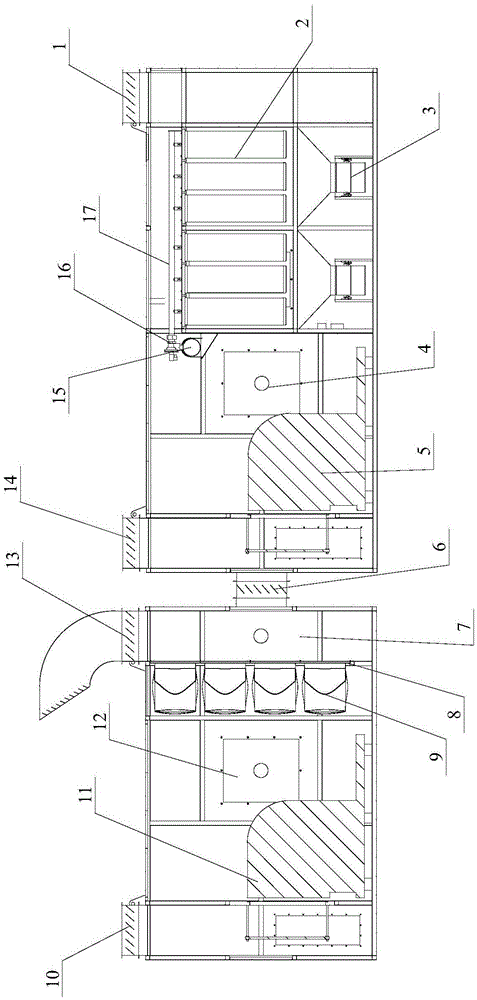

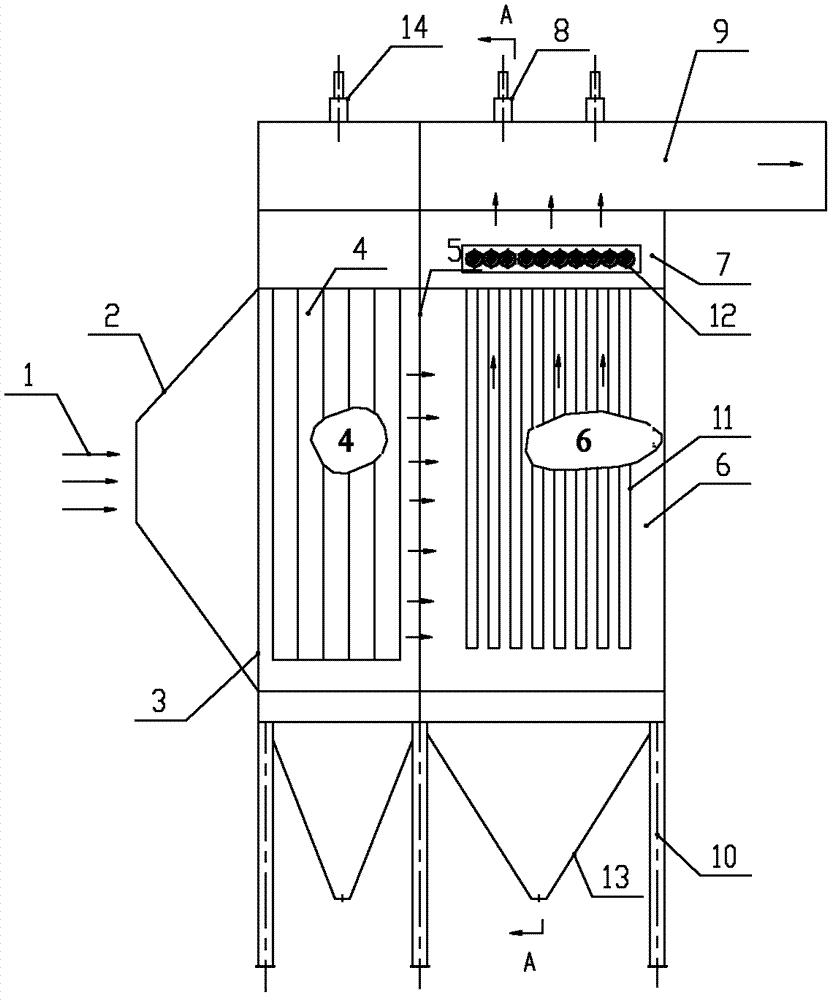

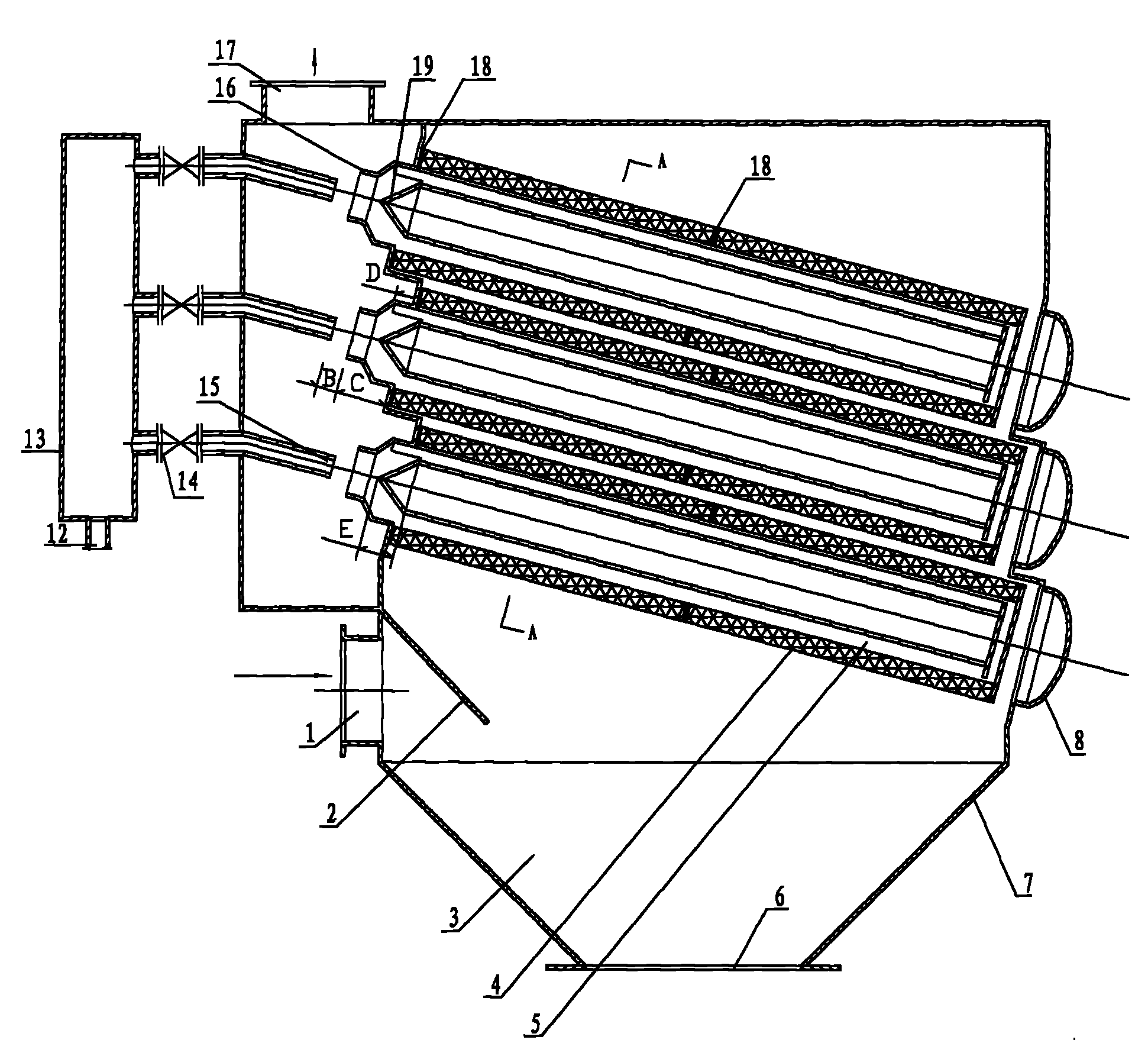

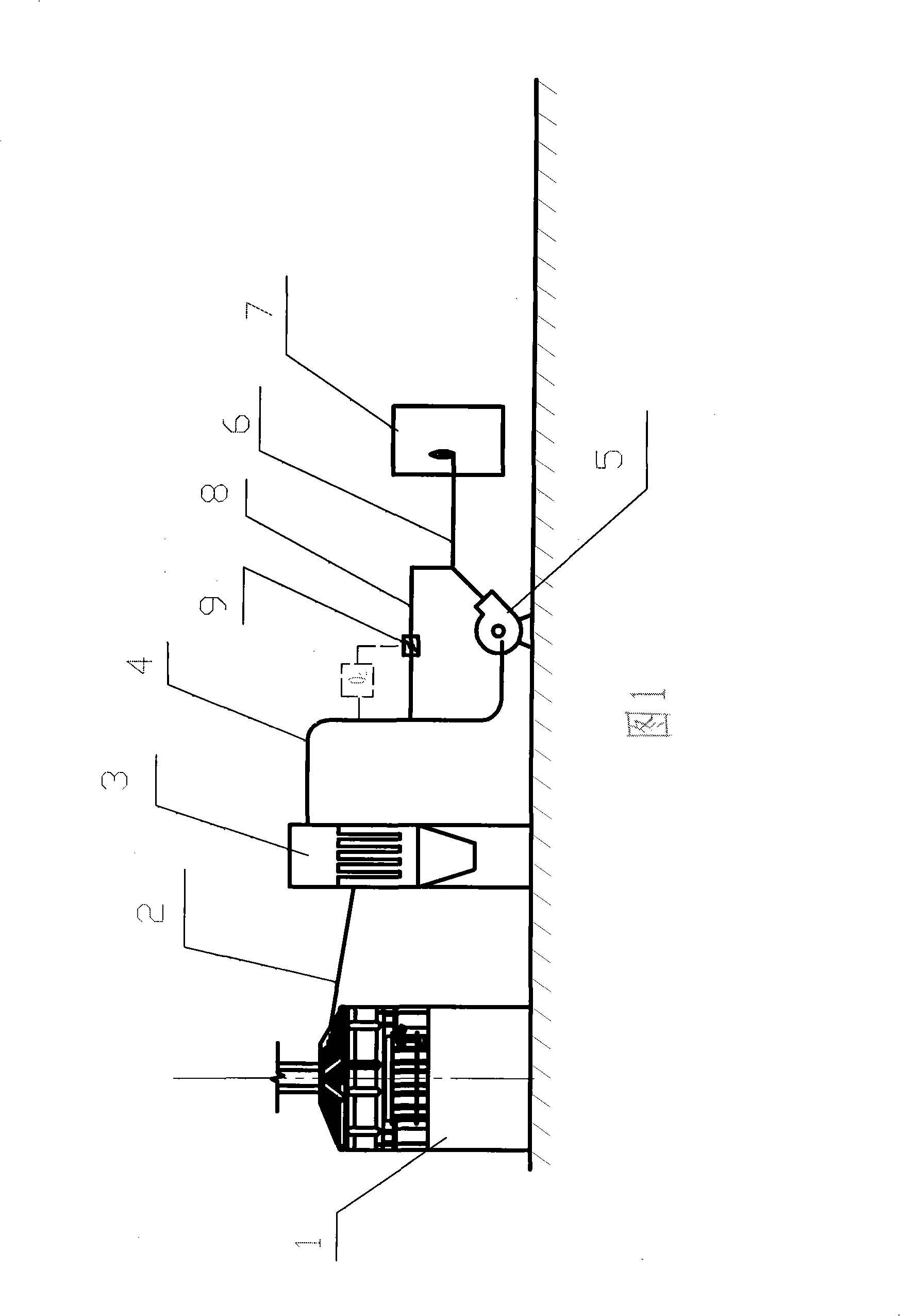

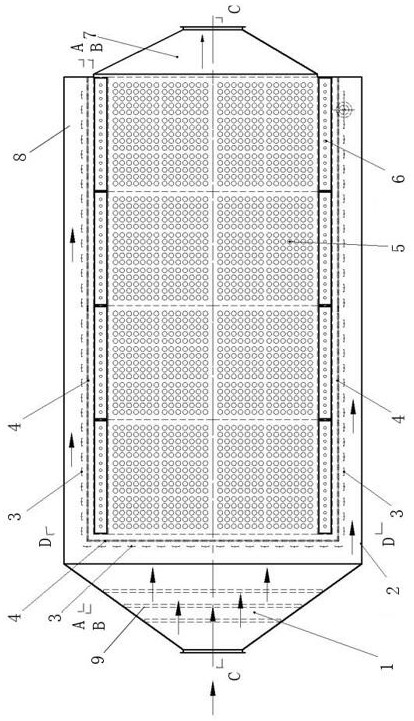

Double-row filter bag embedded type electric bag compound dust catcher with electric field area at front stage

ActiveCN102553382AExtended service lifeAchieve emission standardsHuman health protectionCombination devicesEngineeringAir purification

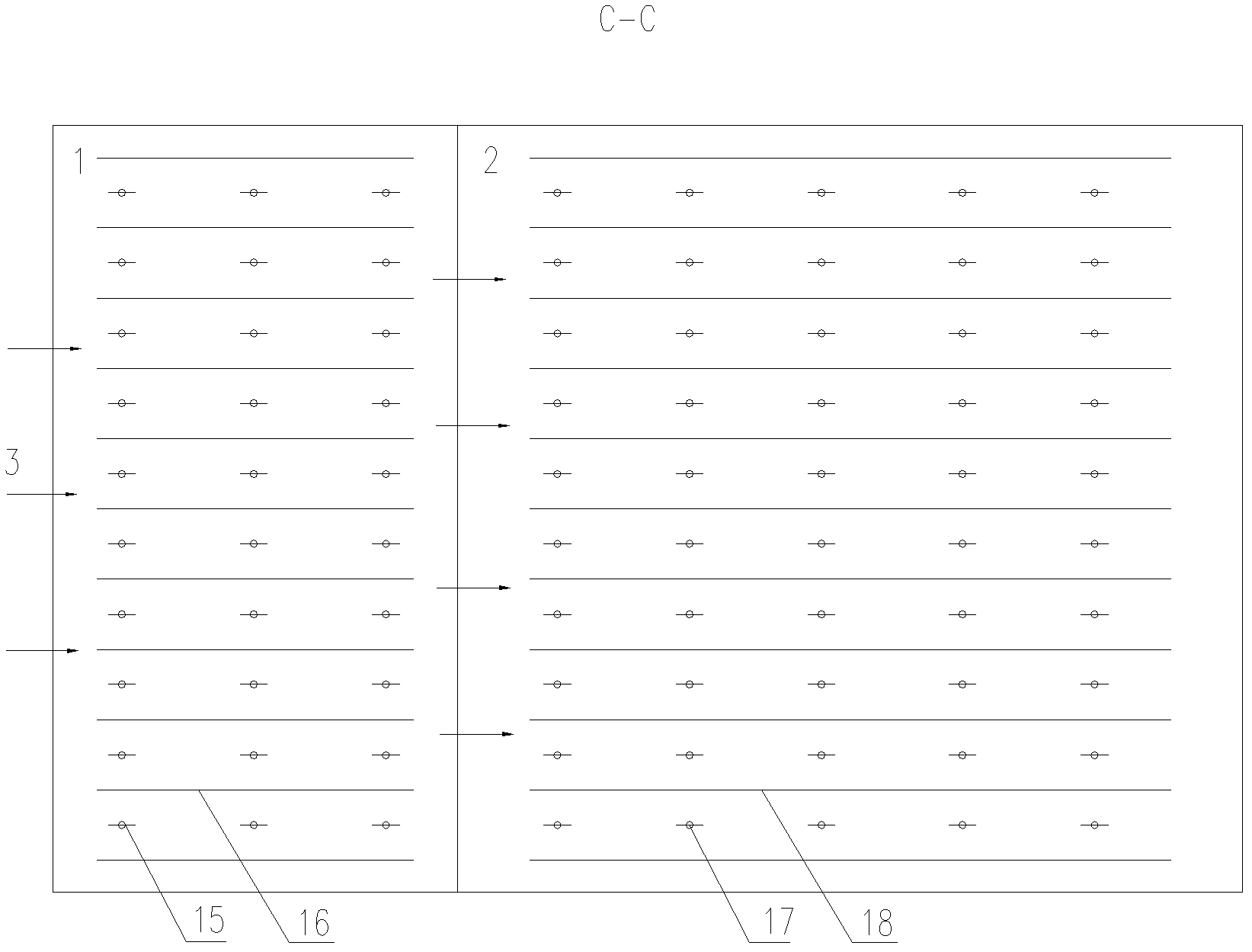

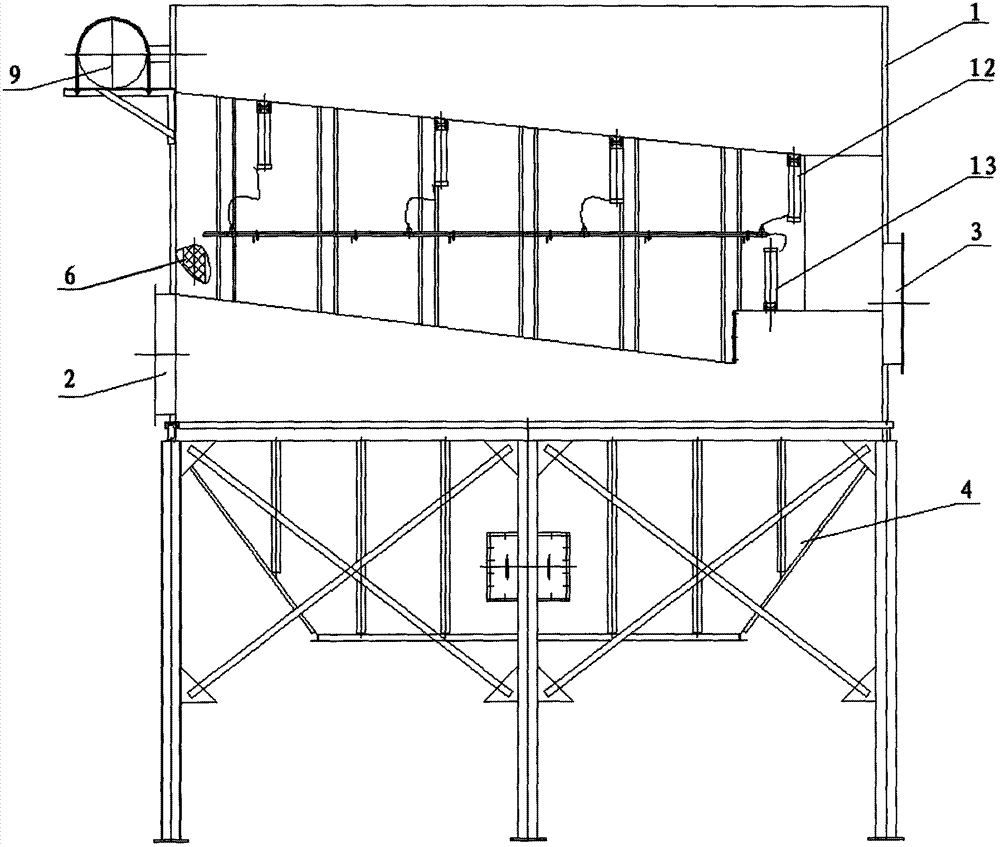

The invention discloses a double-row filter bag embedded type electric bag compound dust catcher with an electric field area at the front stage, and relates to an industrial dust catcher. The dust catcher is provided with an inlet horn, a casing, a smoke duct, a filter bag, an ash cleaning system, an ash hopper, a discharge electrode, a dust absorbing polar plate, a rear discharge electrode and dust collecting pore plates; the front end and the rear end in the casing are provided with an electric field area at the front stage and an embedded electric bag dedusting area at the rear stage, an air inlet of the electric field area is connected with the inlet horn, and a flow guiding adjusting plate is arranged between an air inlet of the dedusting area and an air outlet of the electric field area; an air purification chamber is arranged at the upper part in the casing, and the air inlet of the air purification chamber is connected with an air outlet of the dedusting area; the air inlet ofthe smoke duct is connected with the air outlet of the air purification chamber, and a lifting valve device is arranged at the top of the smoke duct; the ash hopper is arranged at the bottom of the casing; a bypass valve device is arranged at the top of the electric field area of the front stage, the discharge electrode and the dust absorbing polar plate are arranged at the front end of the casing to form the electric field area of the front stage; the rear discharge electrode and the dust collecting pore plates are arranged at the rear end of the casing to form an electric field of the rear stage; the filter bag is arranged between the two dust collecting pore plates to form a filter area of the filter bag; and the electric field area of the rear stage and the filter bag area form the embedded electric bag dedusting area.

Owner:FUJIAN LONGKING

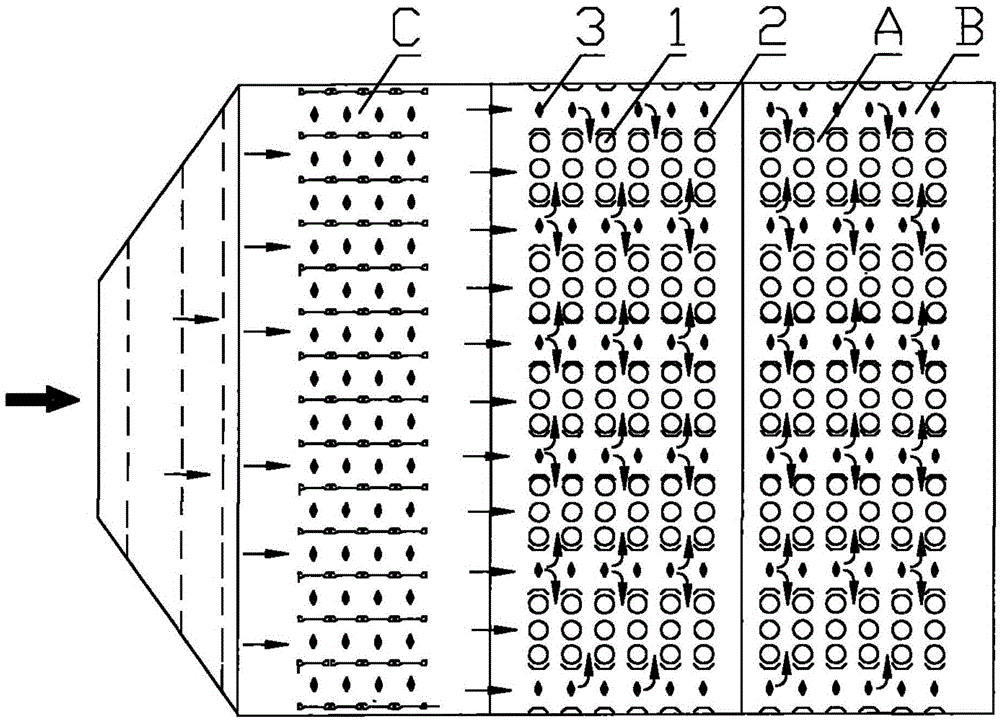

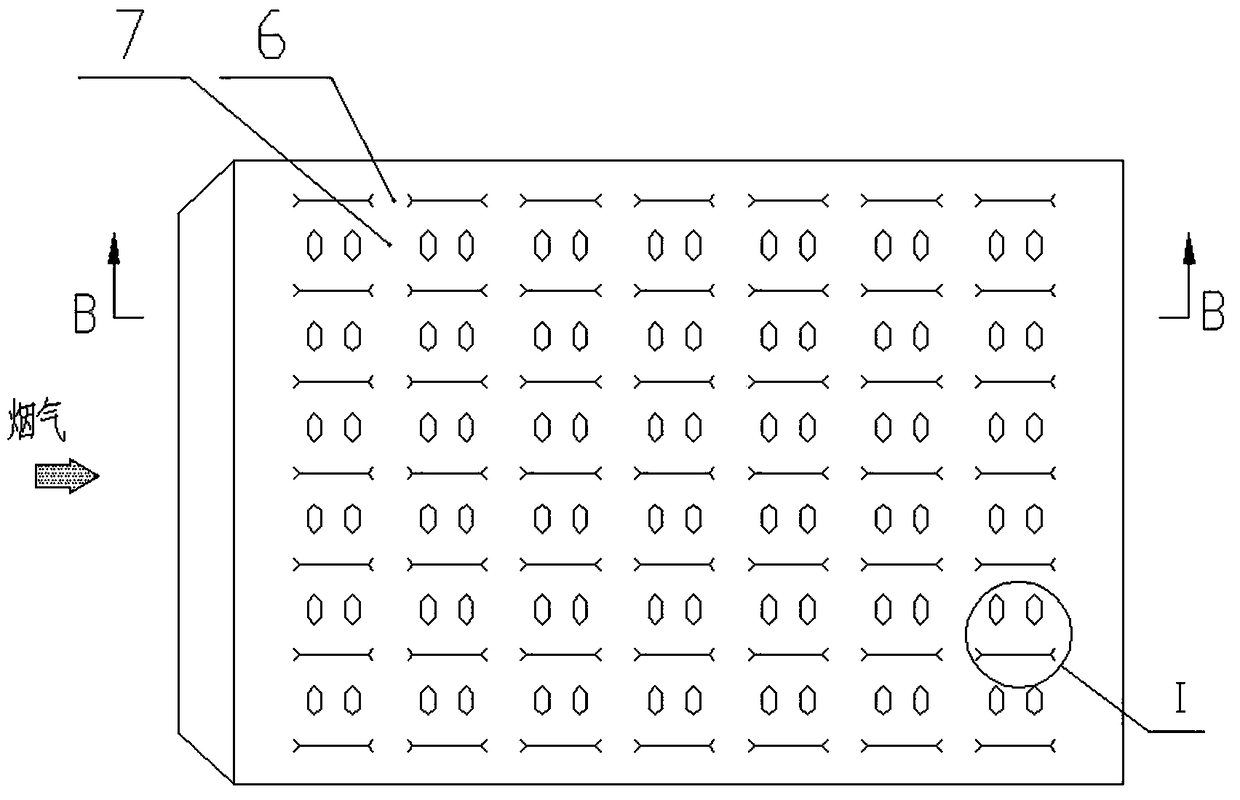

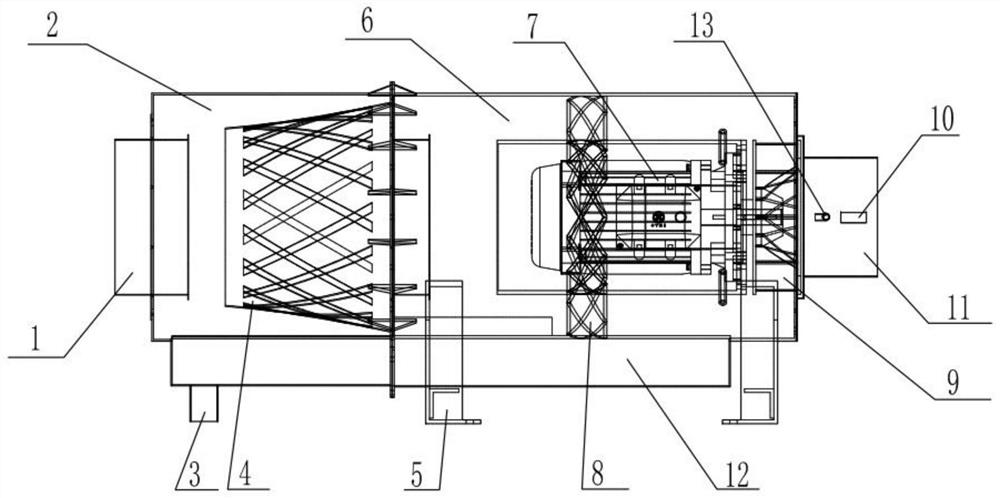

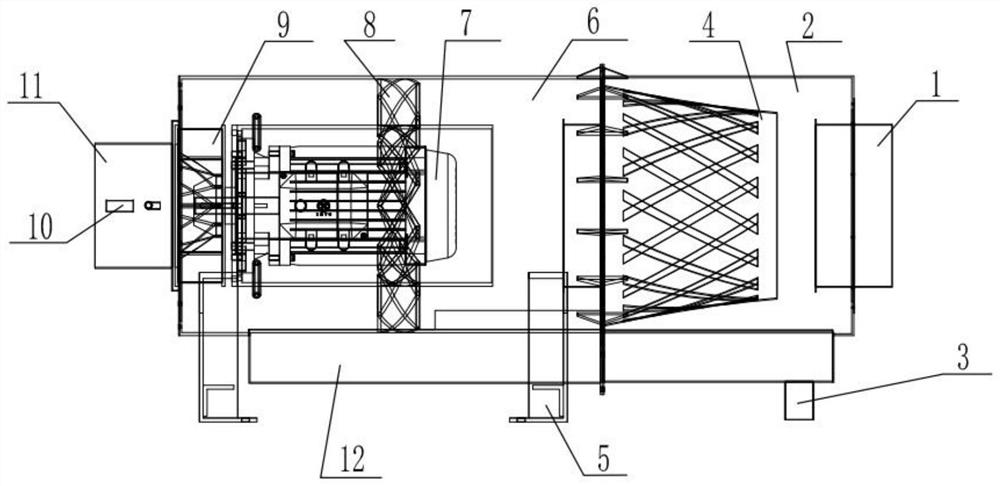

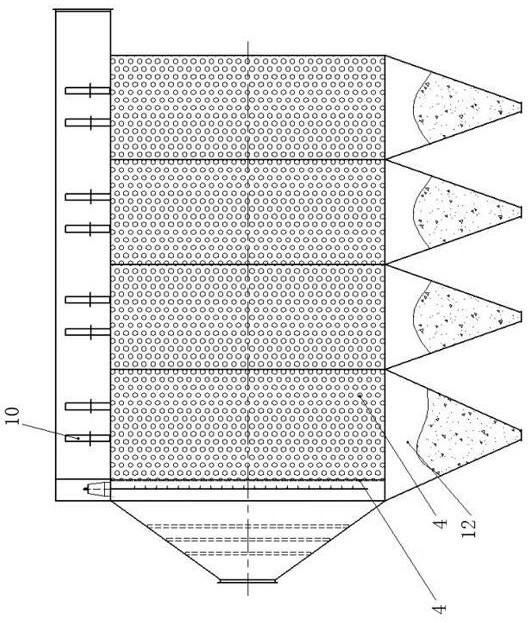

Electrostatic-bag composite dust collector

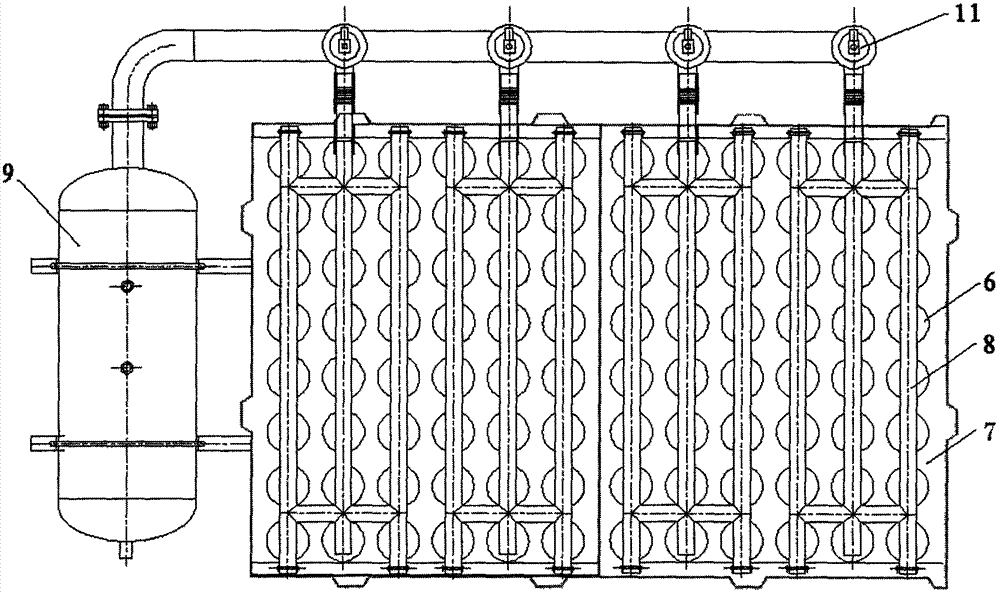

ActiveCN106552469AGuaranteed service lifeImprove charging effectCombination devicesAir velocityFlue gas

The invention discloses an electrostatic-bag composite dust collector which includes an electrostatic-bag mixing area provided with a filter bag and electric field. The filter bag is a metal filter bag. A negative discharge pole is arranged on the periphery of the metal filter bag. A positive pole plate is disposed in the electrostatic-bag mixing area and is corresponding to the negative discharge pole, so that the electric field is formed by the discharge pole and the positive pole plate. A negative pole system is formed by the metal filter bag, which is corresponding to the positive pole plate, so that friction on the filter bag is avoided in the technical scheme and service life of the filter bag is ensured. The electric field is formed by the metal filter bag and the discharge pole, so that charging property of dust is improved, and when the dust is captured by the filter bag, a loose dust layer is formed on the surface of filter bag due to the principle of like charge repelling each other, thereby preventing dust caking and improving dust removal efficiency. The metal filter bag is a negative pole system, so that under the constraint of electric field force, speed of the charged dust is reduced and the dust is remained in and even deposited in the electric field, while flue gas can flow towards the metal filter bag at high speed, so that the dust collector also can increase the air flowing speed in the filter bag area, thereby increasing utilization ratio of the filter bag and utilization ratio of space.

Owner:FUJIAN LONGKING

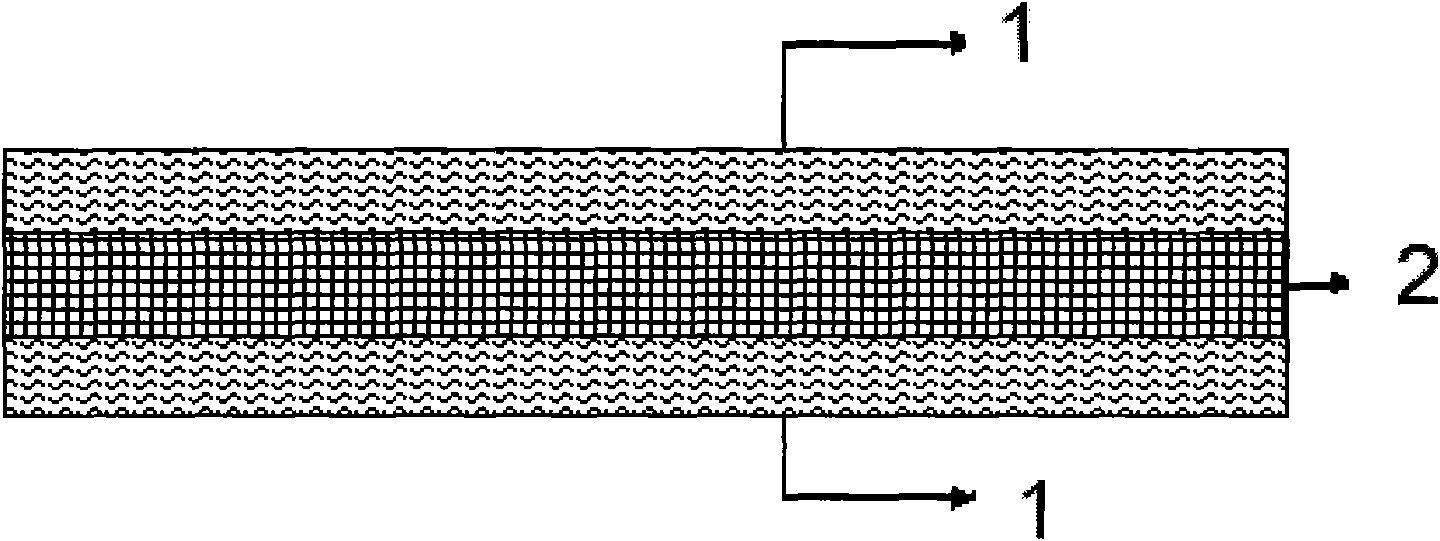

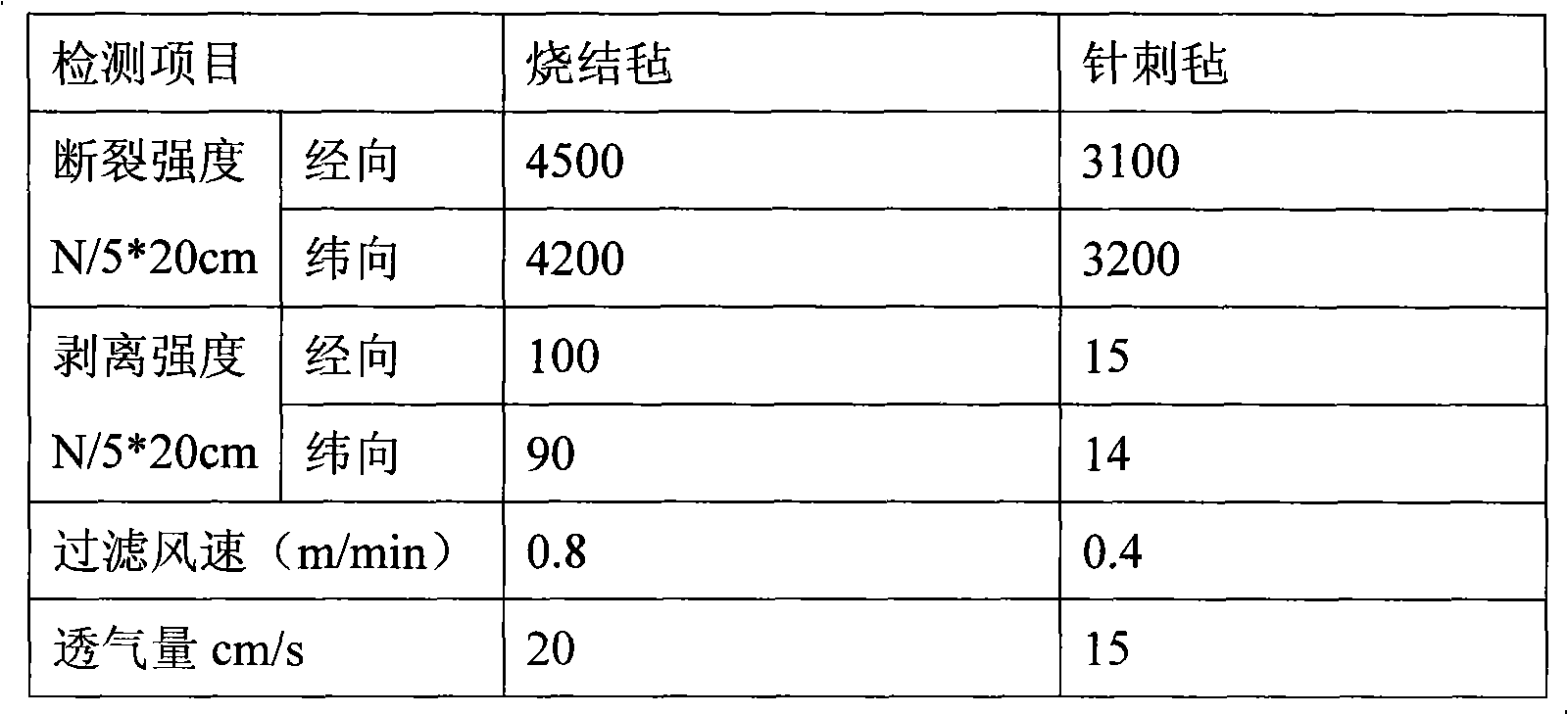

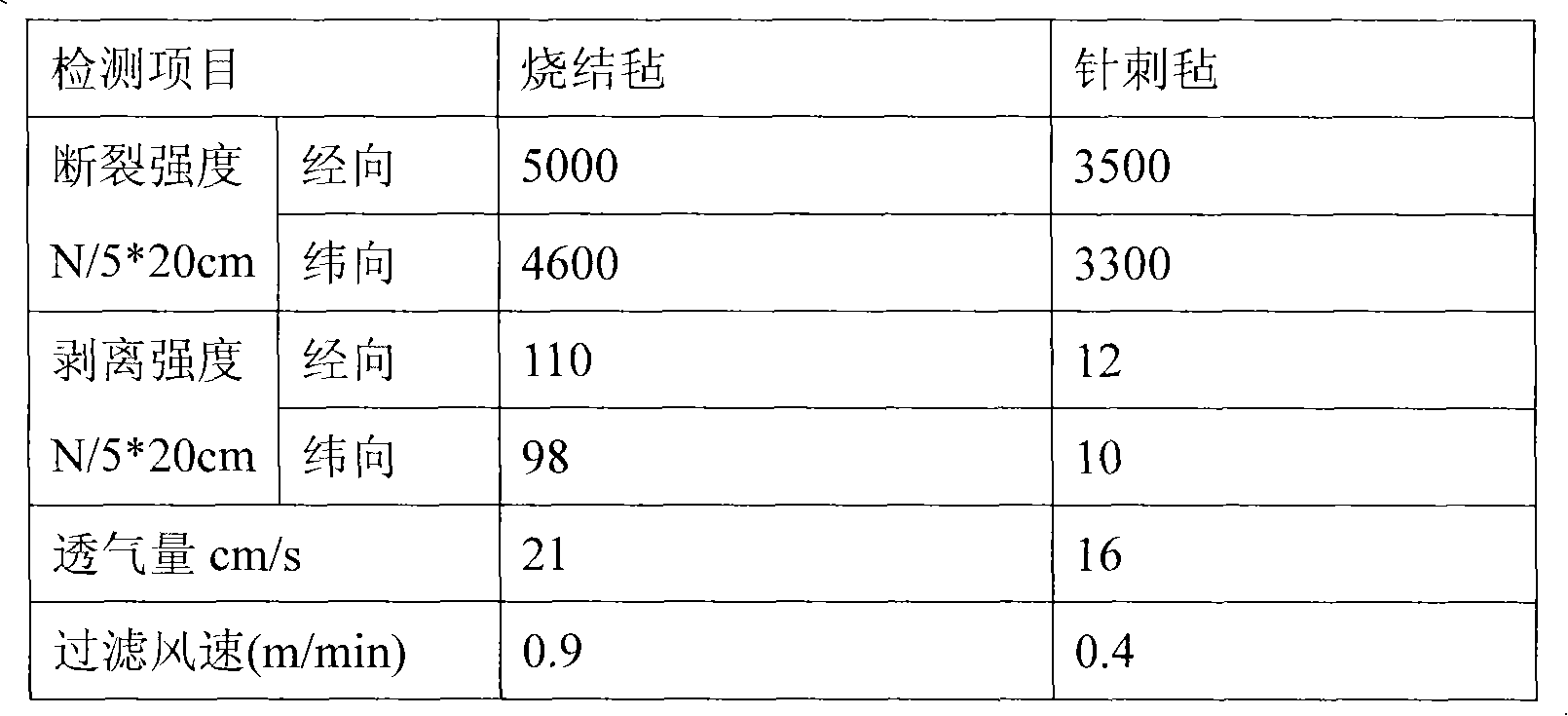

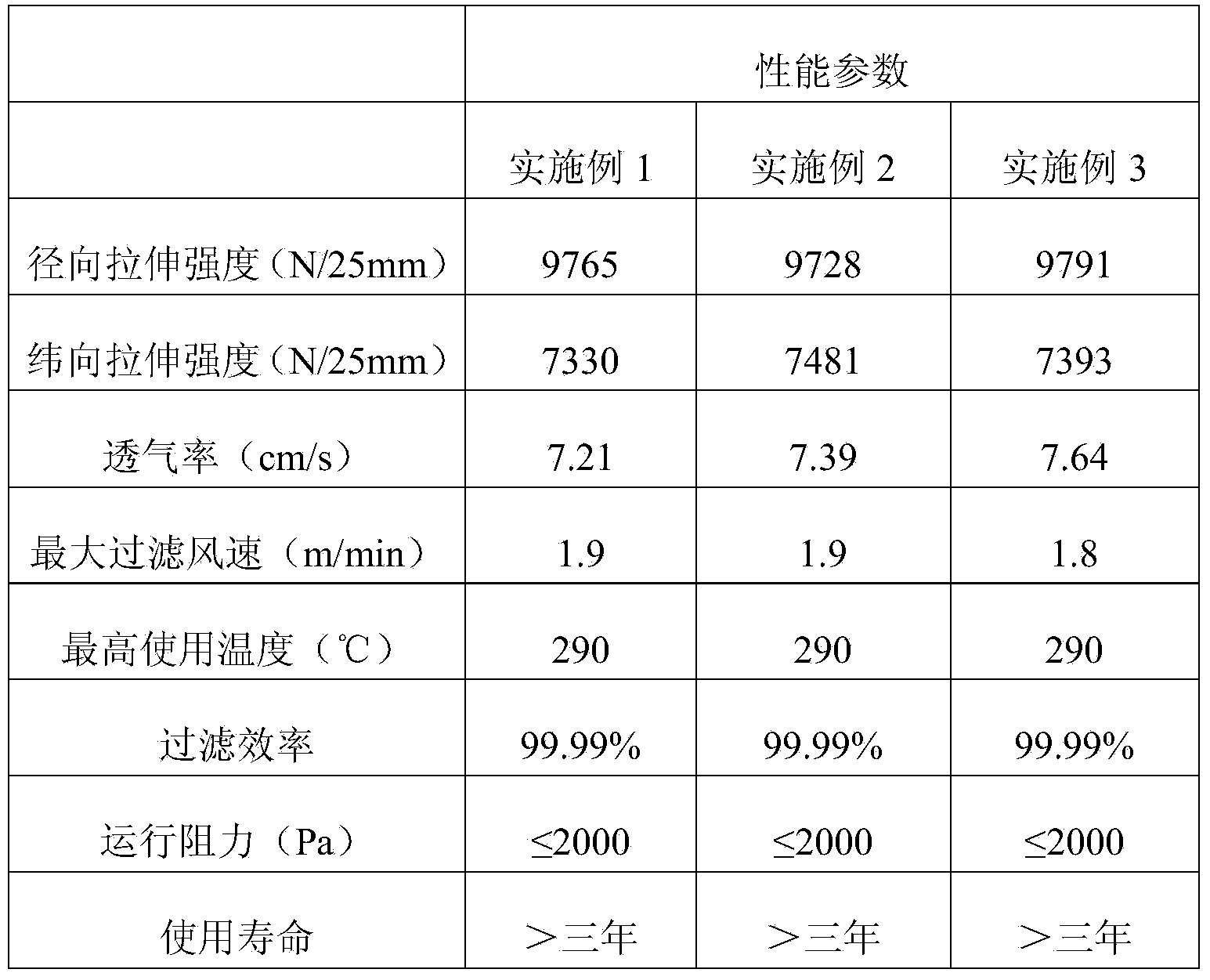

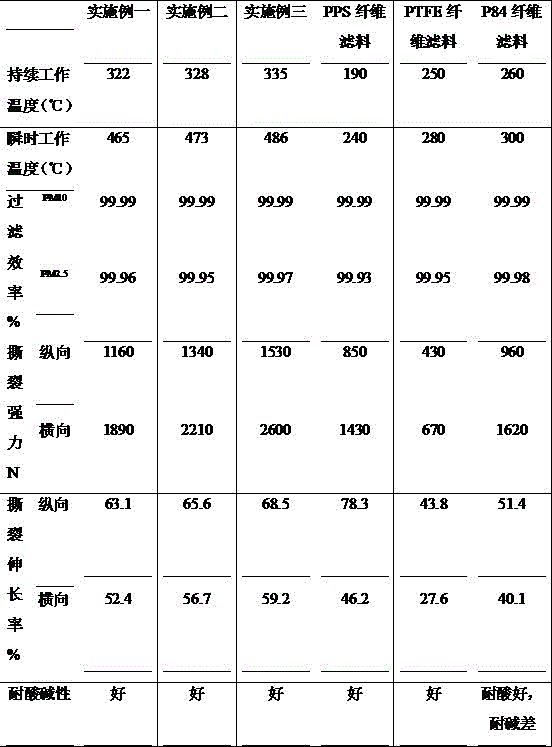

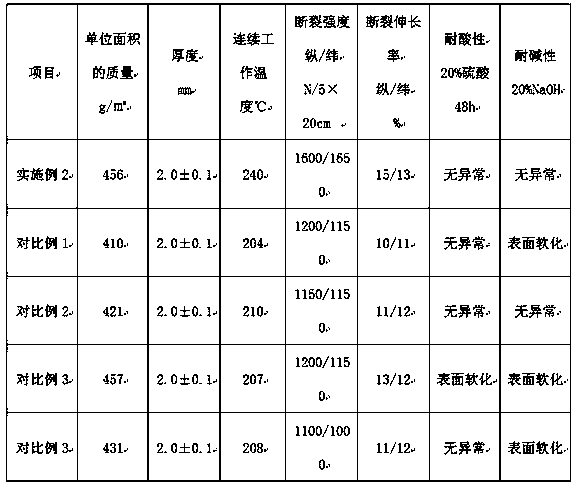

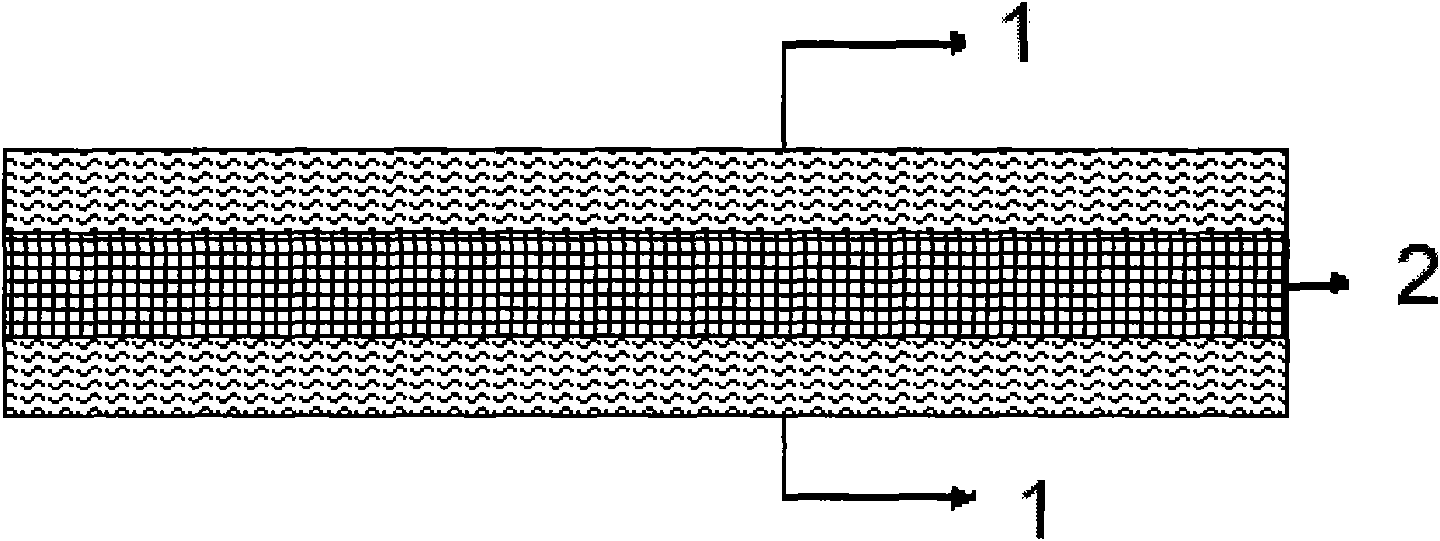

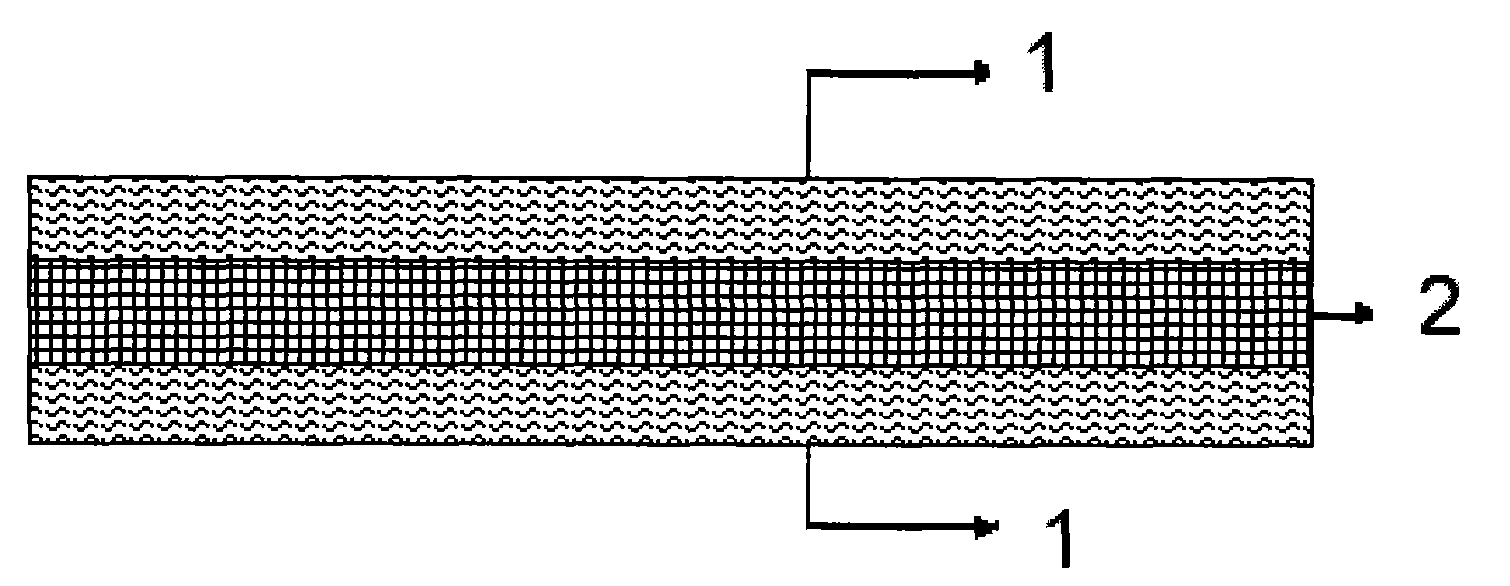

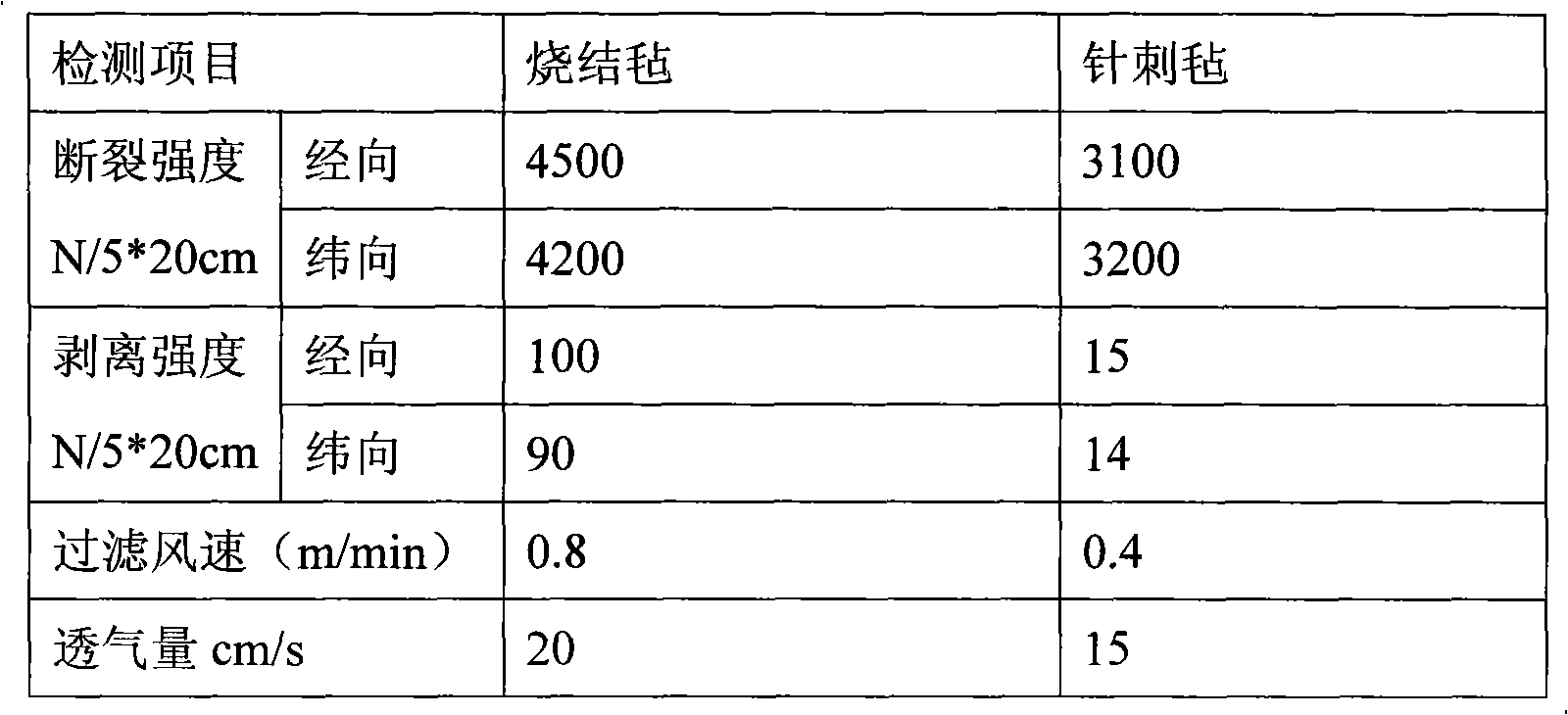

Inorganic-fiber ultra-high temperature composite filter material

ActiveCN101612497AIncrease the filtration speedExtended service lifeFiltration separationFiltrationFlue gas

The invention discloses an inorganic-fiber ultra-high temperature composite filter material comprising a base cloth layer and felt layers. The base cloth layer is arranged between the two felt layers and is made of inorganic fiber; the felt layers are made of stainless steel composite filter; the inorganic fiber is basalt fiber or ceramic fiber; and the stainless steel composite filter is formed by mixing stainless steel fiber and the basalt fiber or the stainless steel fiber and the ceramic fiber, wherein the proportion of the stainless steel fiber is 10-30 percent. The stainless steel fiber is melted and sintered at a high temperature so that the stainless steel fiber is welded on crossing points of warp yarn and weft yarn of base cloth to form nodes and accordingly form a sintered filter felt. The invention effectively improves the anti-filtration airspeed capability, the fracture strength and the peeling strength of the filter material, prolongs the service life and satisfies the requirements of the ultra-high temperature flue gas abatement field.

Owner:南京际华三五二一环保科技有限公司

Modified PPS (polyphenylene sulfide) and PTFE (polytetrafluoroethylene) layered coating method for glass fiber filter material

InactiveCN104233817AImprove thermal stabilityImprove the level ofFibre treatmentFiltration separationFiberPolytetrafluoroethylene

A modified PPS (polyphenylene sulfide) and PTFE (polytetrafluoroethylene) layered coating method for a glass fiber filter material comprises the following steps: glass fiber needled base cloth is selected and prepared into filter material base cloth after carding, lapping and needling processes; linear PPS and hyperbranched PPS are mixed to prepare modified PPS emulsion; the modified PPS emulsion, PTFE emulsion and a fluorine-containing silane coupling agent are mixed to prepare priming paint; the PTFE emulsion, the fluorine-containing silane coupling agent and F46 emulsion are mixed to prepare surface paint; the filter material base cloth is dipped in the priming paint and subjected to high-temperature curing and furnace cooling to prepare a bottom layer; and the surface paint is sprayed to the surface of the bottom layer by a spray gun, and a finished product is obtained after high-temperature plasticizing. With adoption of the preparation method, the produced composite filter material has good thermal stability, corrosion resistance and higher mechanical strength, fiber dispersion and density of the finished product are improved, the manufacture process is simple and lower in cost, and large-scale industrial production is facilitated.

Owner:九江市欧信得环保技术有限公司

High-temperature dust-removing filter material and preparation method thereof

InactiveCN105642019AImprove high temperature resistanceImprove ductilitySynthetic resin layered productsLaminationMetal fibersTemperature resistance

The invention discloses high-temperature dust-removing filter material and a preparation method thereof. The high-temperature dust-removing filter material is characterized by comprising a metal fiber felt layer, a PTFE membrane layer and a PPS fiber layer which are sequentially arranged. The PTFE membrane layer is adhered to the metal fiber layer through an adhesive-free hot pressing technology. The PPS fiber layer is tangled with the PTFE membrane layer through a spunlace process. The high-temperature dust-removing filter material has the advantages that the metal fiber layer is used as the windward side of the filter material to effectively increase the high temperature resistance of the filter material, the composite structure of the metal fiber felt layer, the PTFE membrane layer and the PPS fiber layer allows the filter material to be good in filter efficiency and tearing resistance, high temperature delay can be filtered effectively, and long service life is achieved.

Owner:LIGHTING TAIWAN

Electric-bag composite dust collector

ActiveCN102327724BIncrease the filtration speedReduce processingCombination devicesEngineeringDust charge

The invention discloses an electric-bag composite dust collector. The electric-bag composite dust collector comprises a composite dust collecting region in a housing, wherein the composite dust collecting region comprises an electric bag dust collecting region and a first electric field dust collecting region; the electric bag dust collecting region comprises a filter bag region and a second electric field dust collecting region; a filter bag dust collecting device is arranged in the filter bag region, and located on the upper end of the electric bag dust collecting region; an electric field dust collecting device is arranged in the second electric field dust collecting region, which is communicated with the filter bag region and located on the lower end of the electric bag dust collecting region; and an electric field dust collecting device is arranged in the first electric field dust collecting region, which is communicated with the electric bag dust collecting region and located onthe front end of the electric bag dust collecting region. In the electric-bag composite dust collector provided by the invention, the second electric field dust collecting region is arranged on the lower end of the electric bag dust collecting region, so that the dust can be recharged when a portion of smoke flows from the first electric field dust collecting region to the second electric field dust collecting region, thereby enhancing the dust charging strength. Additionally, the second electric field dust collecting region can effectively collect dust dropping from the filter bag region when the dust is removed, thereby reducing secondary dust emission, prolonging dust removal period, prolonging the service life of the filter bag, reducing the whole dust removing resistance, and improving the overall performance of the dust collector.

Owner:FUJIAN LONGKING

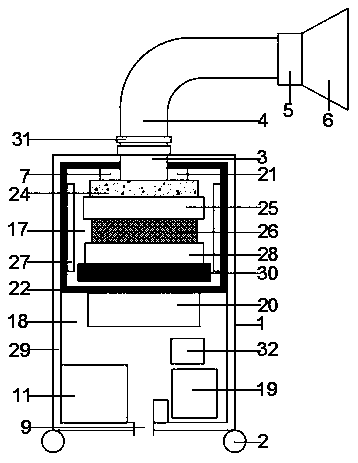

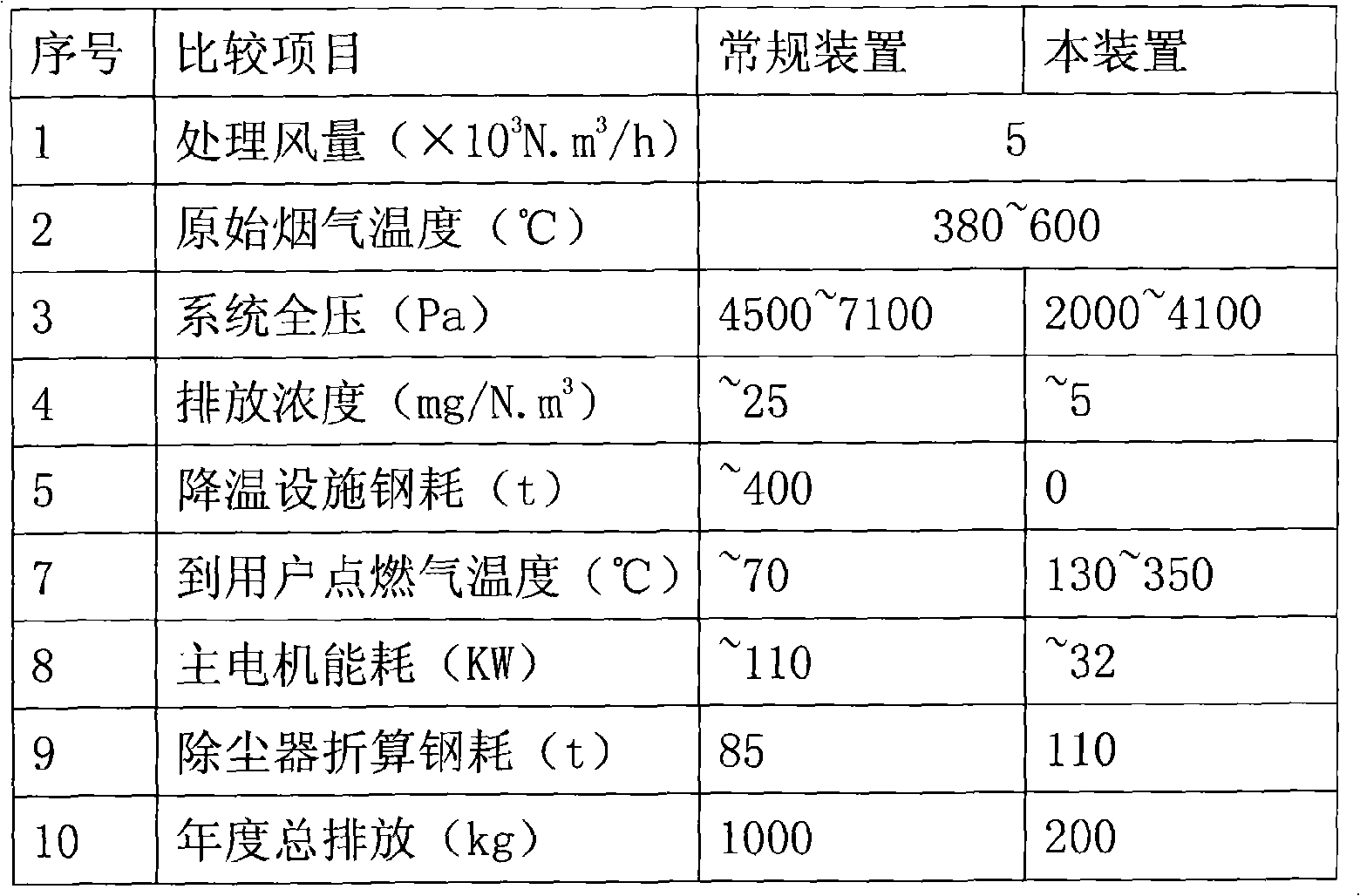

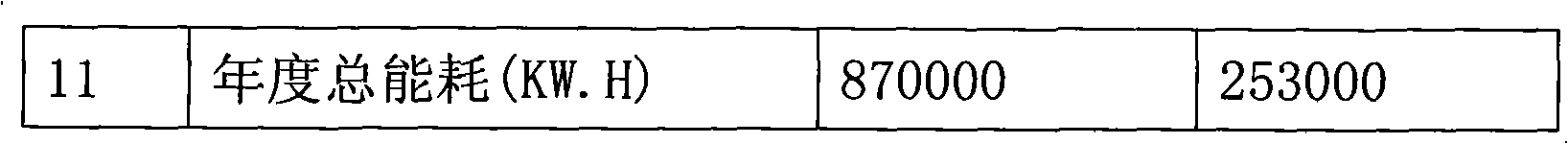

High-temperature smoke purifier

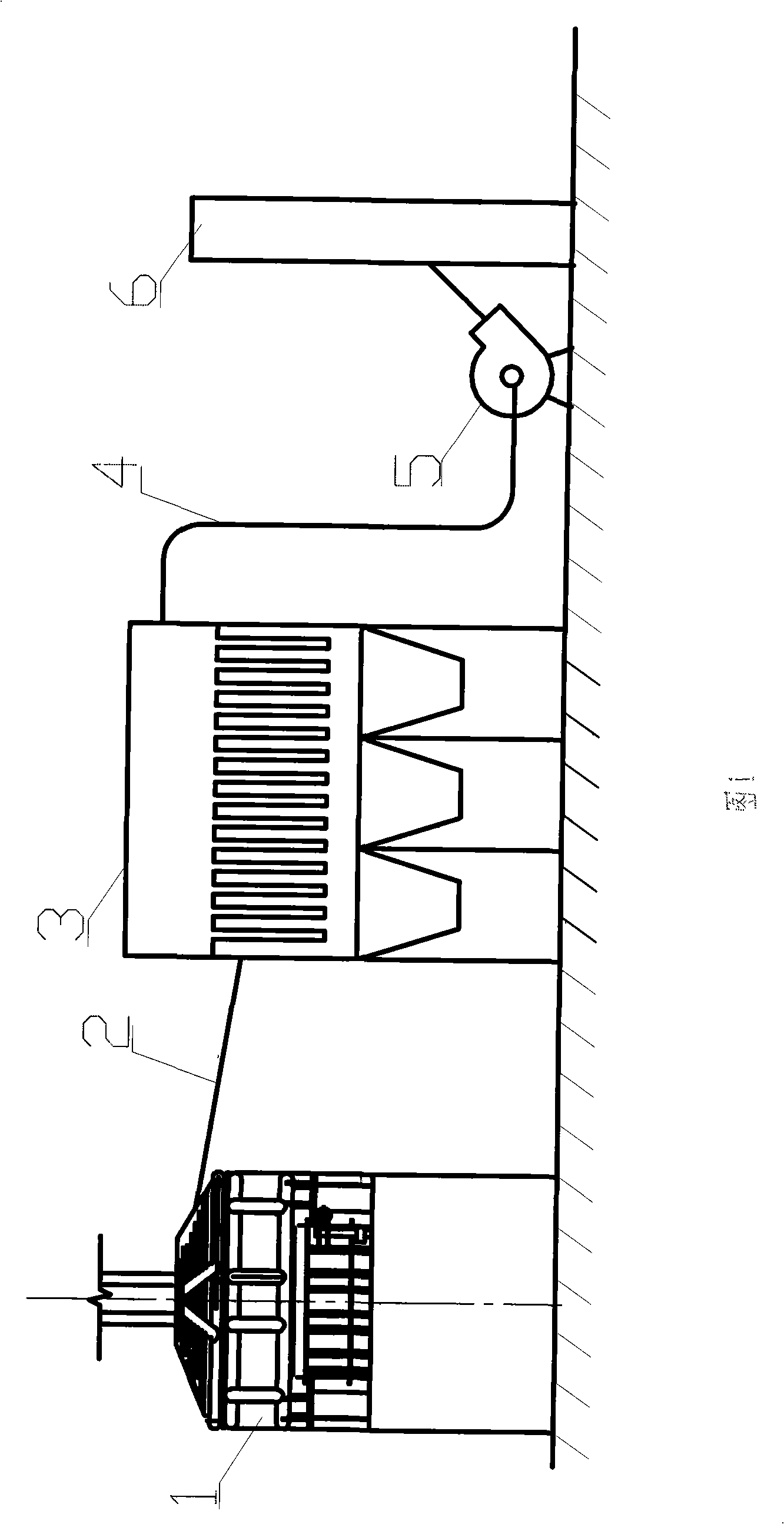

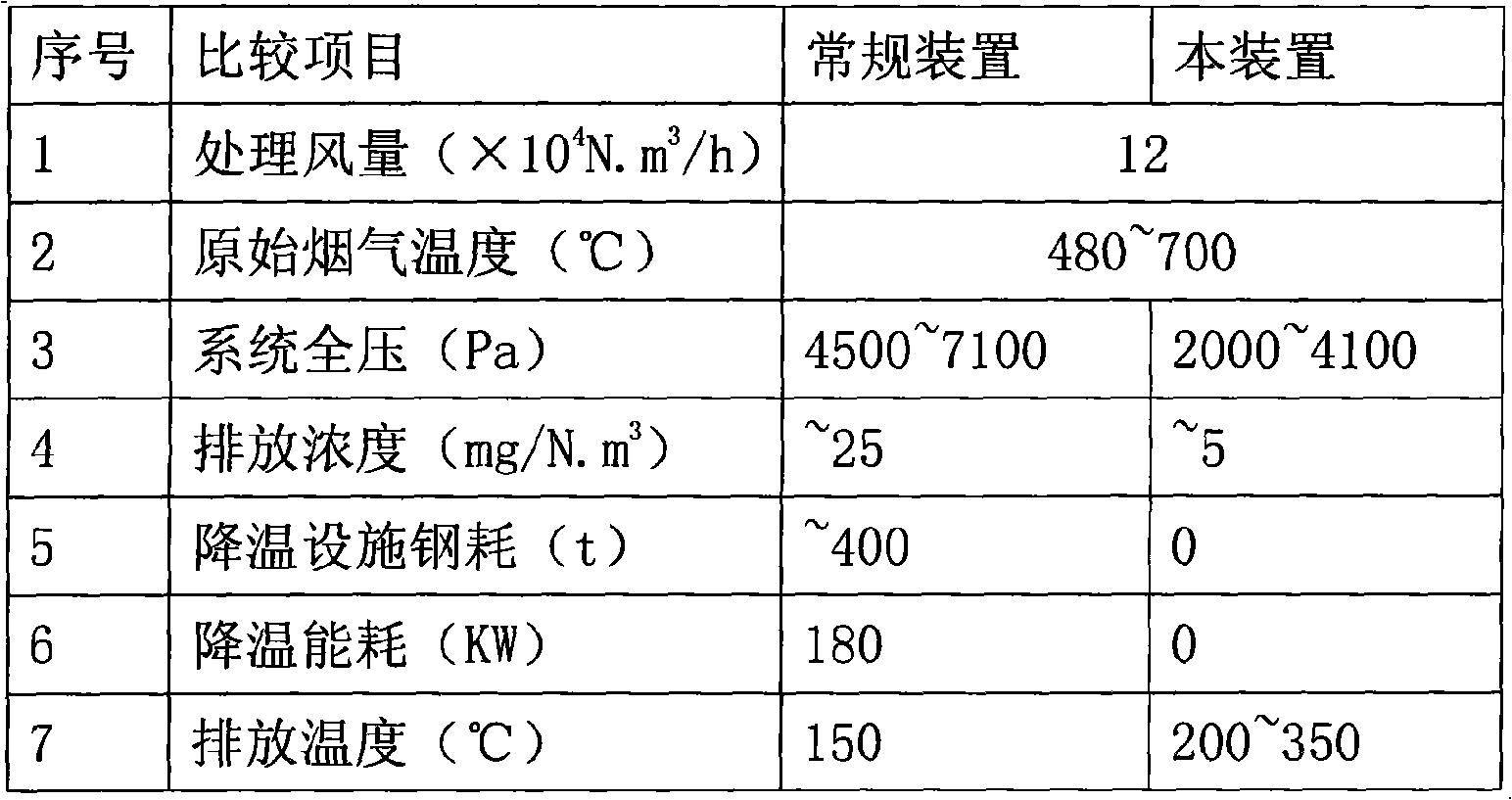

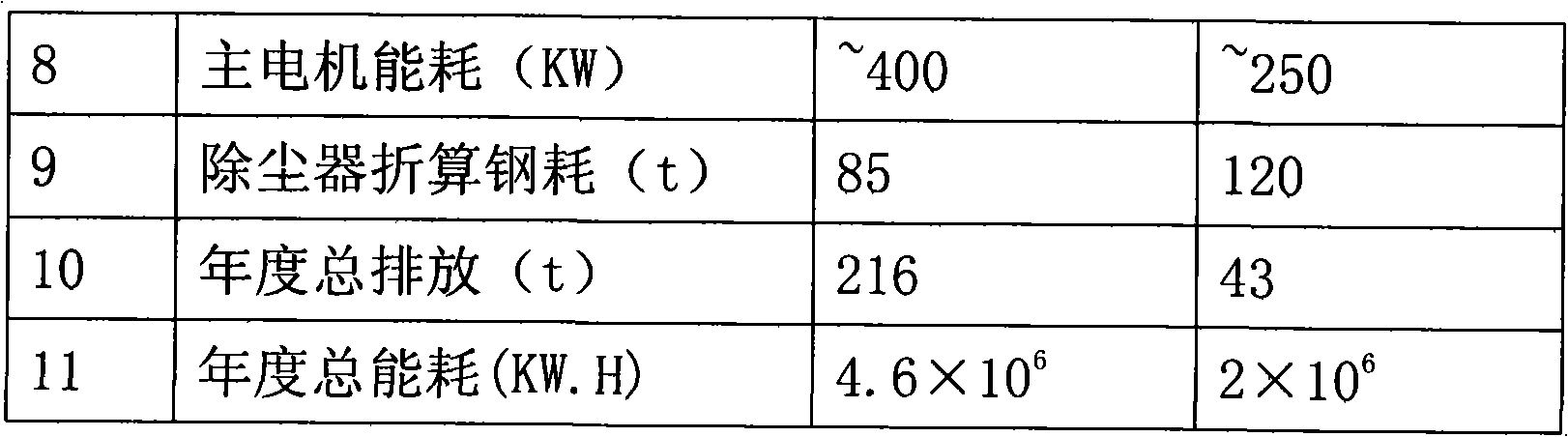

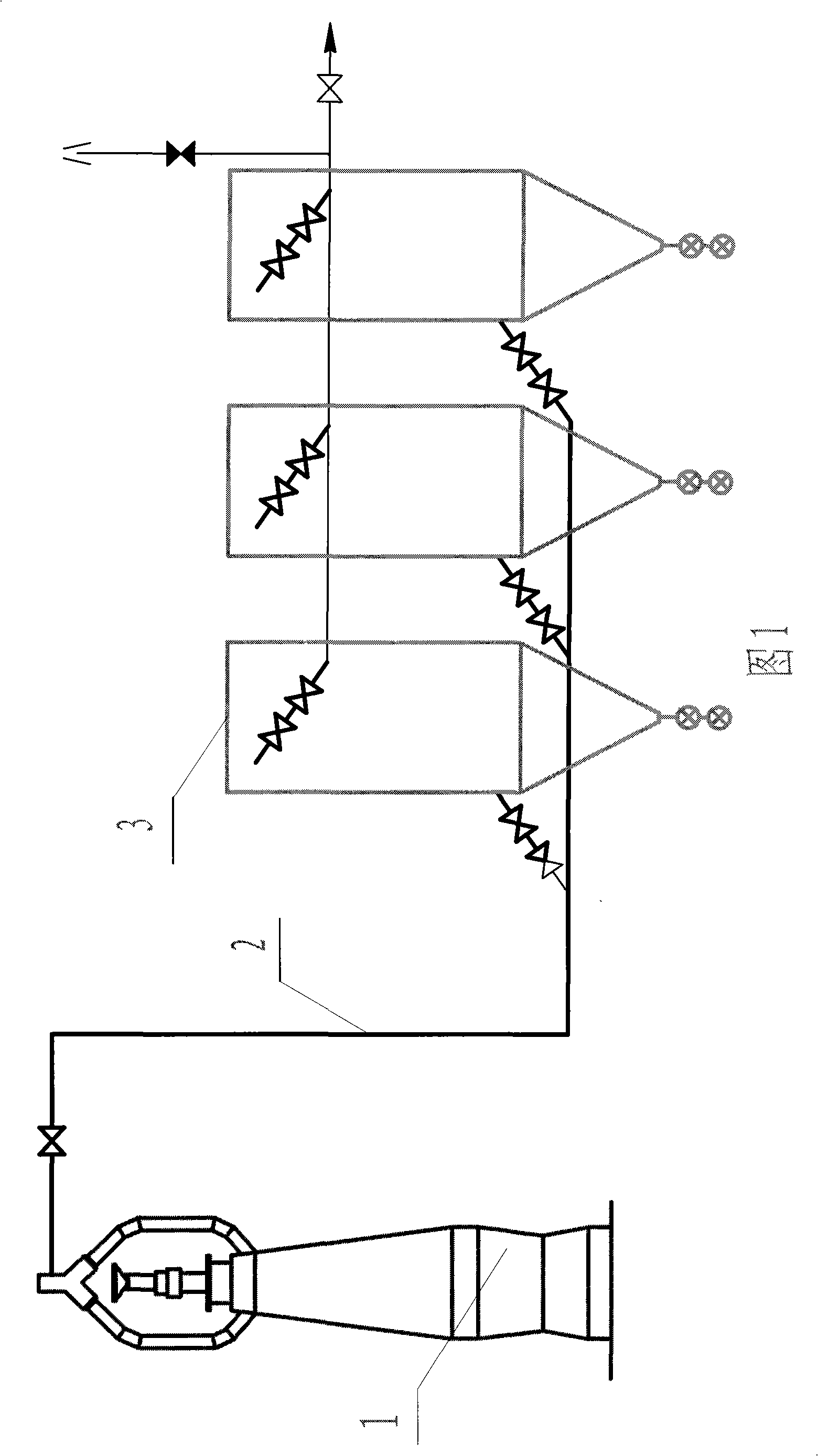

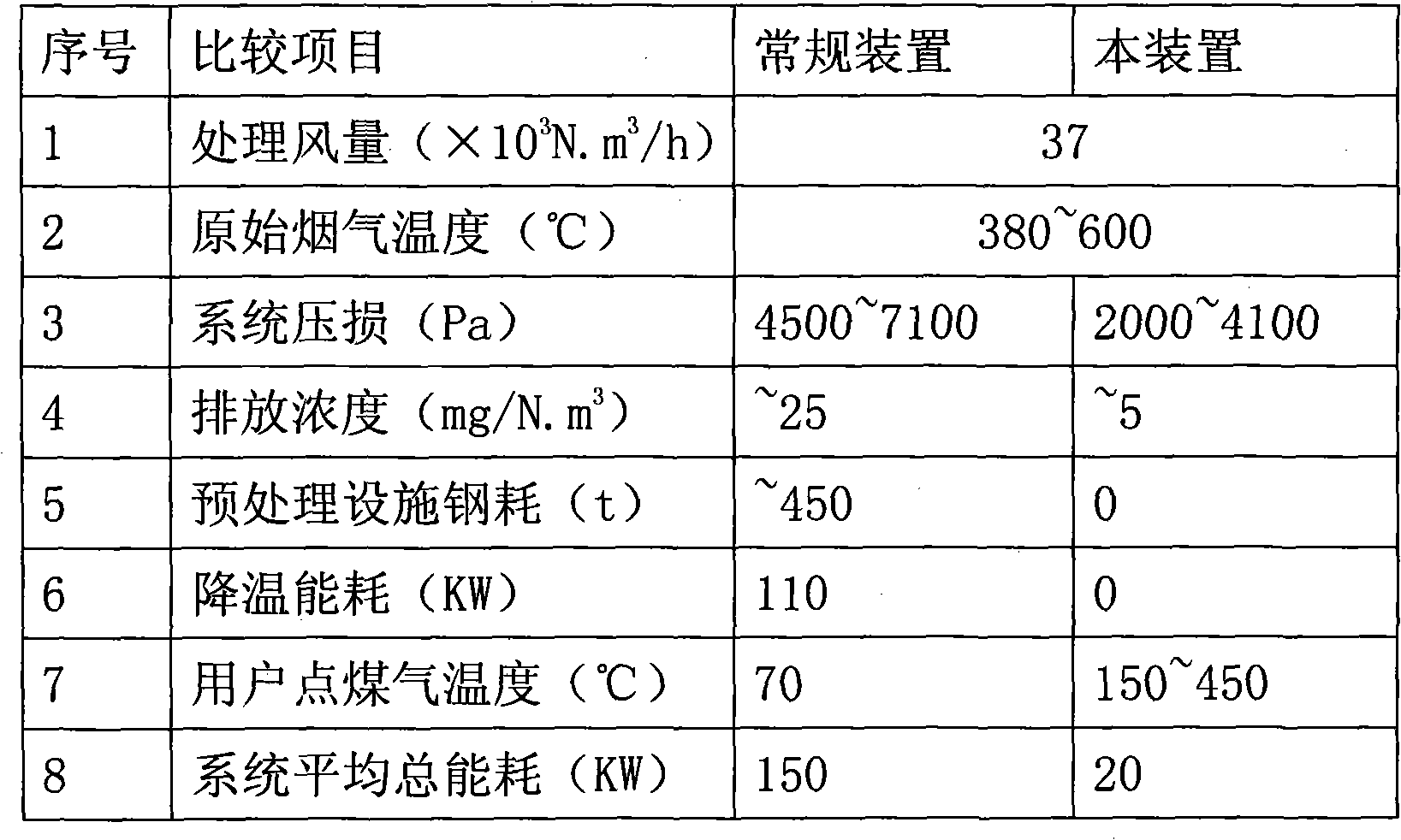

InactiveCN101298010ANo powerCut temperature rangeDispersed particle filtrationWaste heat treatmentOperating pointAtmospheric air

The invention discloses a high temperature flue gas purification device used for the metallurgy and building materials industries and provides a high temperature flue gas purification device which has the advantages of better purification effect, low concentration of the gas emission and reduction of the energy consumption; the device includes a high temperature flue gas generation device, a draft fan and an exhaust funnel which are connected by pipelines in series; the high temperature dust collector is connected with the high temperature flue gas generation device and the draft fan by the pipelines; as the cooling device is omitted, the device has the advantages of small occupy area and small maintenance, does not need dust blocking and cleaning work for the cooling device, reduces the operation points for unloading dust, reduces the energy consumption of the system, does not has cooling consumption, has low total pressure of the main system fan and reduces the motor power; As the high temperature flue gas is purified in the high temperature region directly, and then interfused into the atmosphere, the high temperature flue gas purification device can reduce the temperature rapidly and cuts down the temperature section in which the dioxin is generated.

Owner:WUXI DONGYE TECH

High-temperature resistant and acid-and-alkali resistant industrial filter cloth material

InactiveCN108993027AGuaranteed tensile strengthImprove bending resistanceMembrane filtersFiltration separationYarnPolyester

The invention discloses a high-temperature resistant and acid-and-alkali resistant industrial filter cloth material. The high-temperature resistant and acid-and-alkali resistant industrial filter cloth material is prepared from the following raw materials in parts by weight: 30 to 60 parts of tetrafluoroethylene-hexafluoropropylene copolymer, 30 to 60 parts of polyphenylene sulfide, 20 to 30 partsof ethyl alcohol, 20 to 30 parts of distilled water ethanol, 10 to 15 parts of polyester, 1 to 5 parts of polytetrafluoroethylene powder, 1 to 3 parts of chromic oxide, 10 to 15 parts of polydiphenylterephthalate propane ester, and 1 to 5 parts of graphite powder. Besides specific advantages of a common filter cloth material, the industrial filter cloth prepared by the treatment process providedby the invention has very high wear resistance, very high cost performance, high resilience and good anti-static property; the cloth which is woven by doubling and twisting multi-strand yarns is dense, high in particle retaining property, and high in stripping property and air permeability. The series of products have the characteristics of acid resistance, alkali resistance, high strength, highfiltering capacity and the like; dust is extremely cleaned; the strength, the wear resistance and the water leakage property are excellent.

Owner:ANHUI YUANYE FILTER MATERIAL

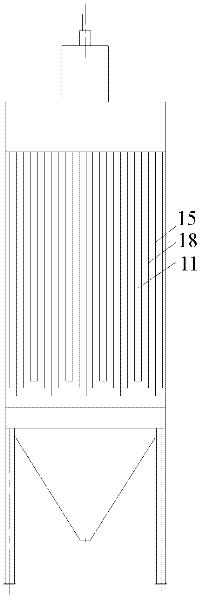

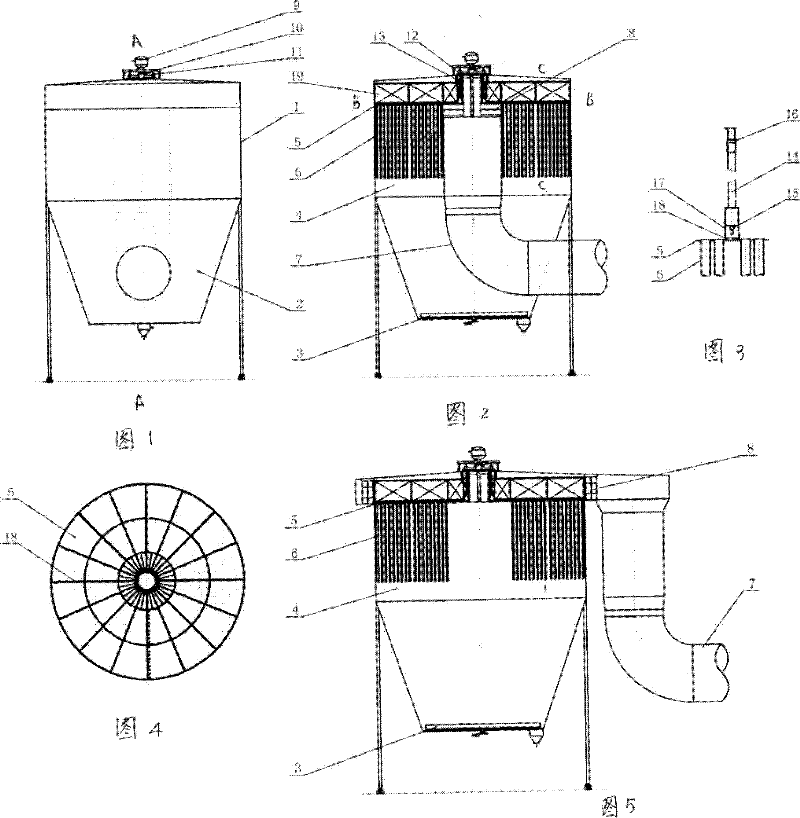

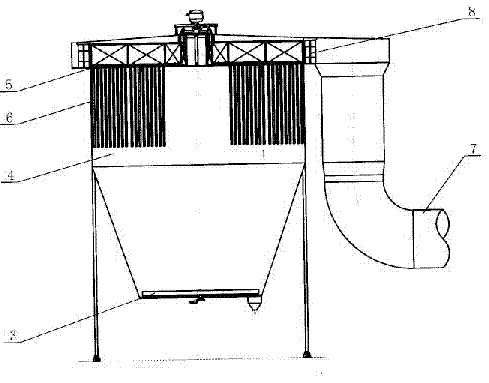

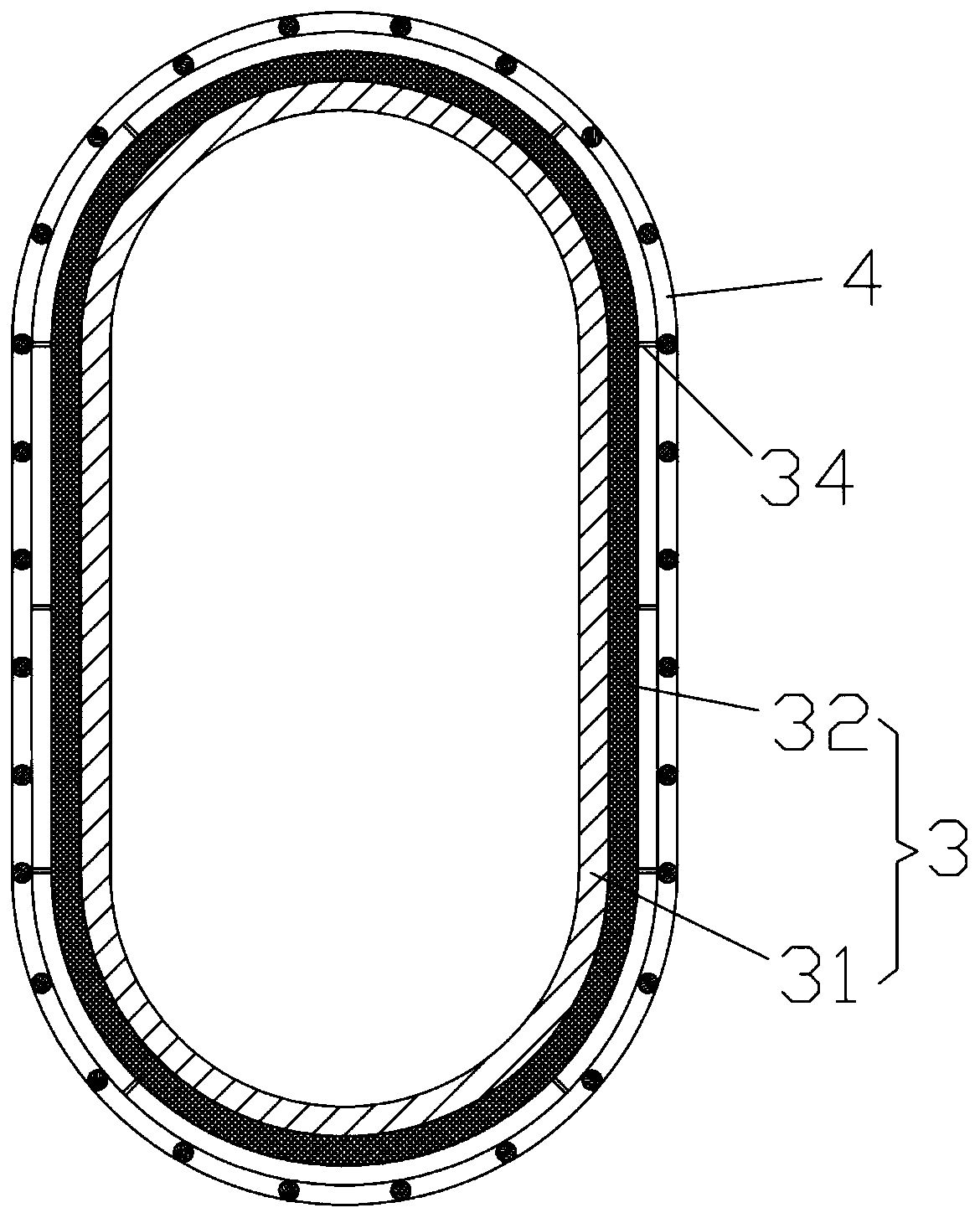

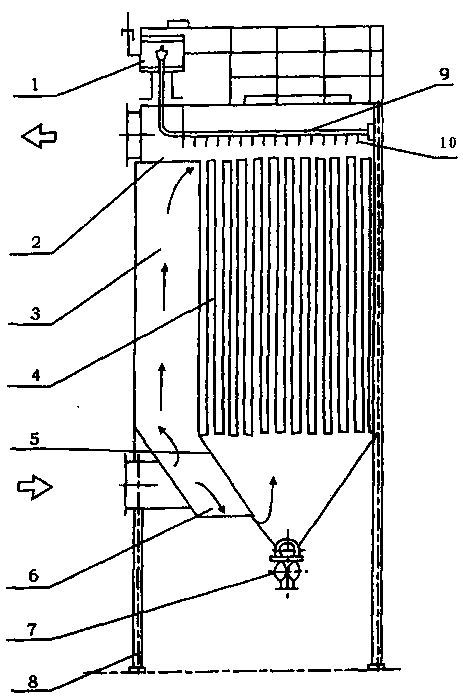

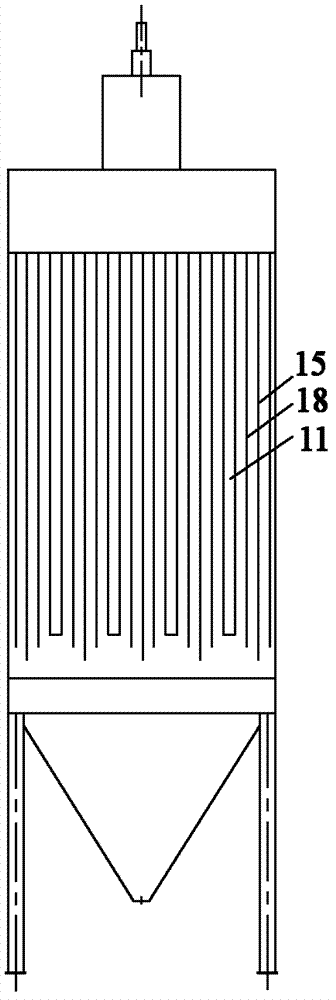

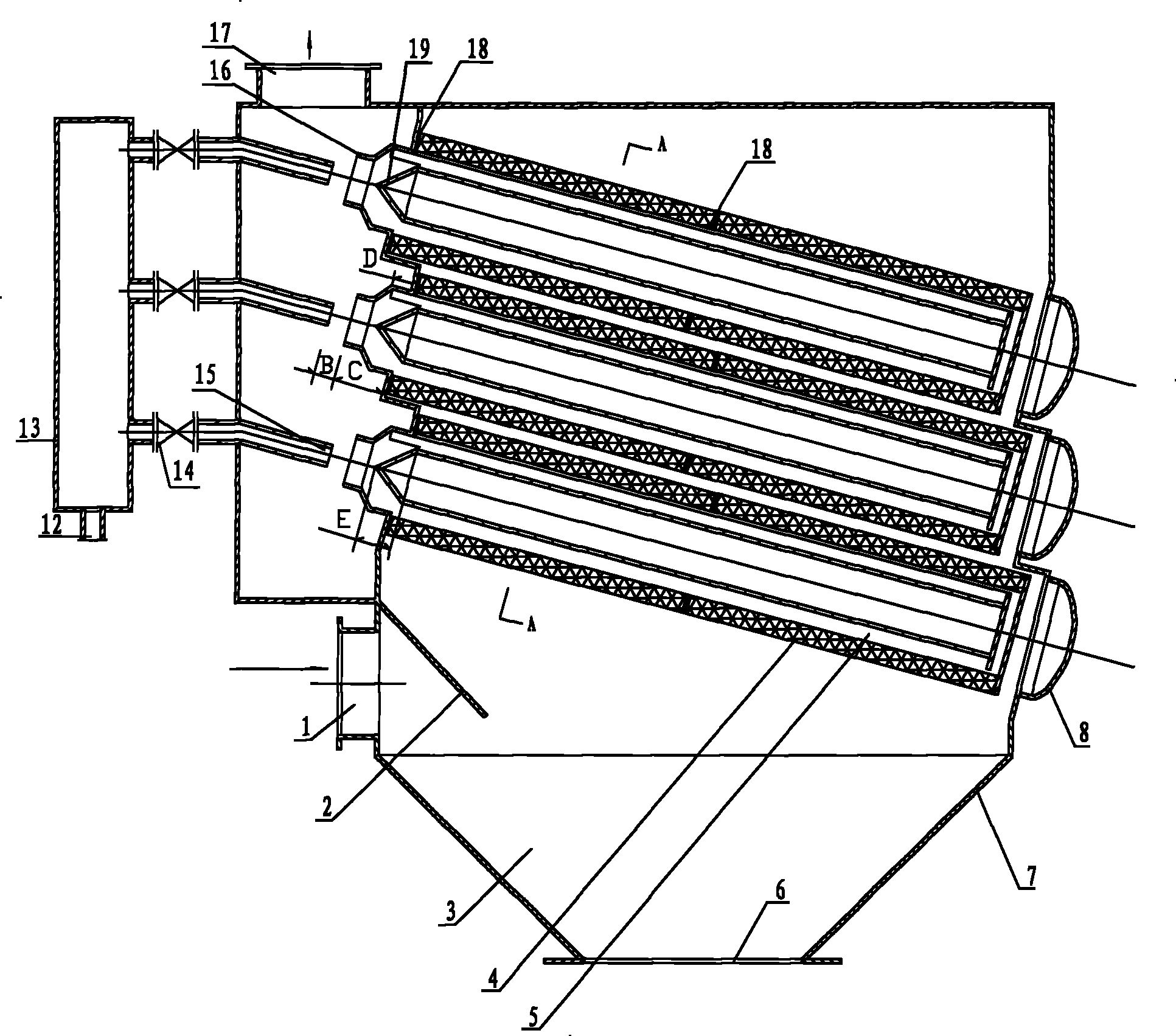

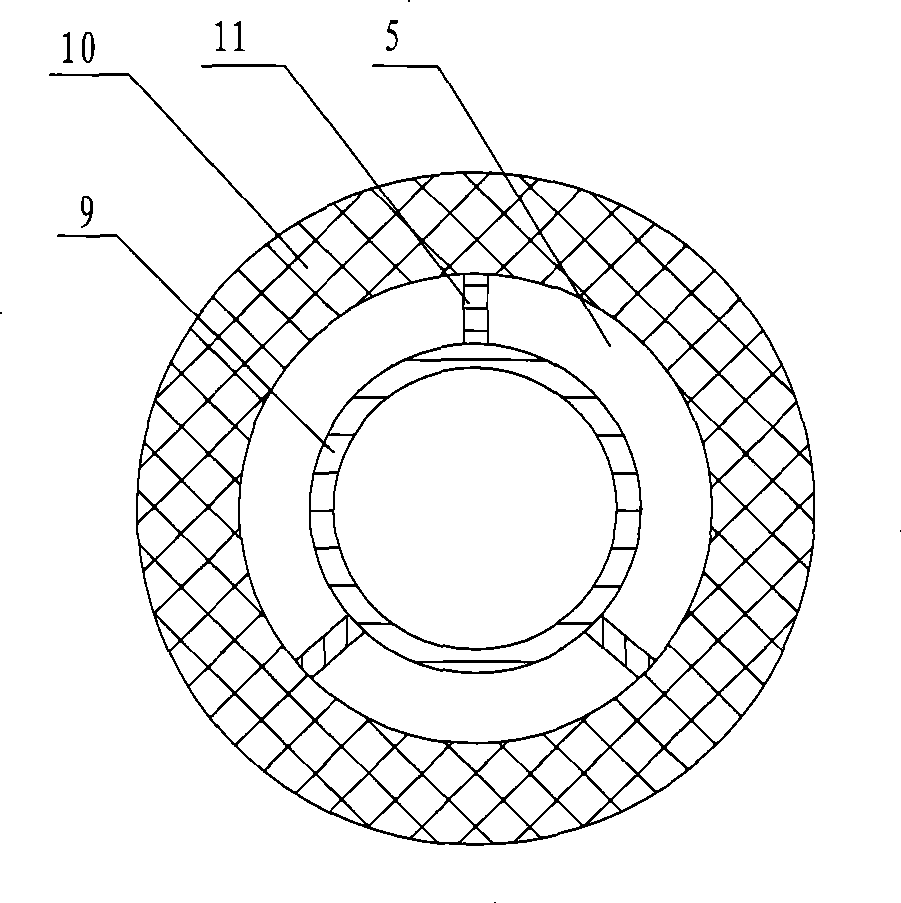

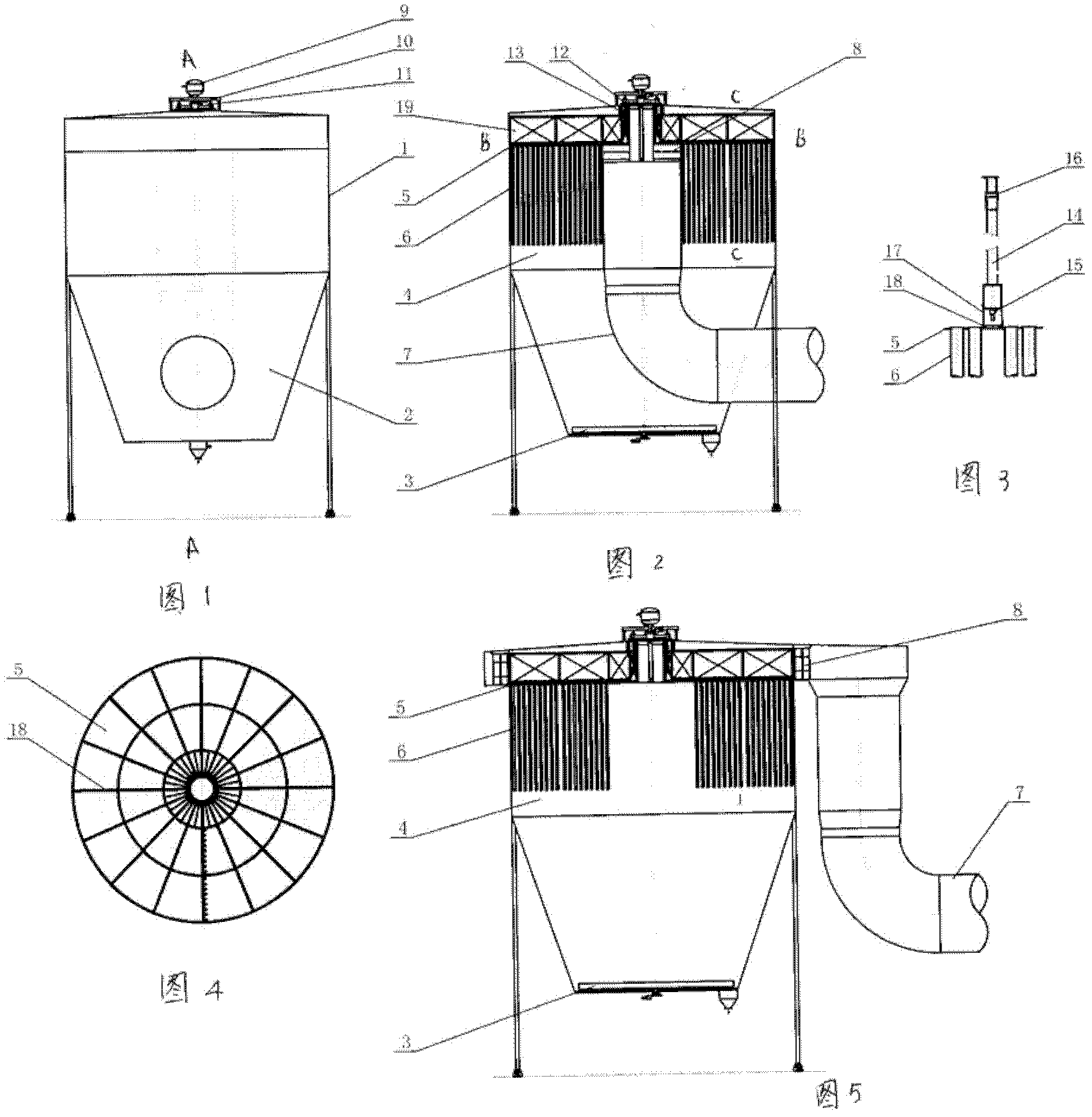

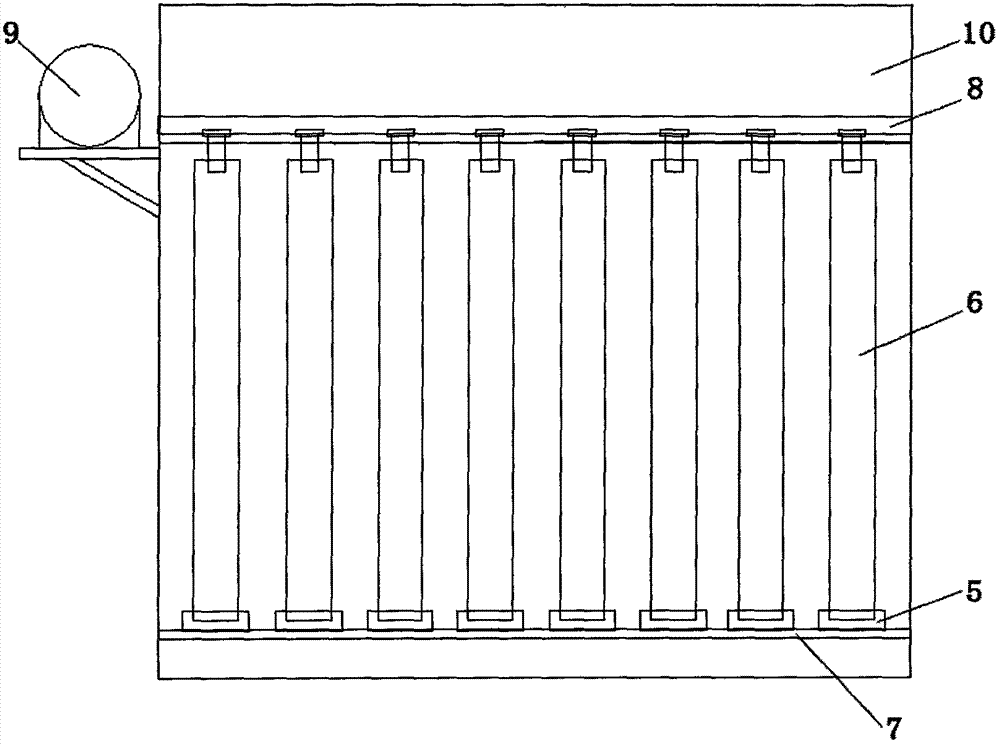

Offline ash removal online overhauling rotary pulse blowing filter-bag dust catcher

InactiveCN102430299ALower installation heightSmall resistanceDispersed particle filtrationBaghouseElectrical and Electronics engineering

The invention relates to an offline ash removal online overhauling rotary pulse blowing filter-bag dust catcher, which comprises a cylindrical main shell, an ash discharger, a filter chamber, a tube nest, filter bags and an annular clean air chamber, wherein a fixed air storage bag, pulse valves, a compressed air distributor, a rotary driving device and a plurality of rotary pulse blowing pipes are arranged in the center of the main shell; a plurality of insulating plate structures of which the peripheries are provided with sealing devices are arranged above the rotary pulse blowing pipes; offline ash removal hoods are arranged on two sides of each pulse blowing pipe; the tube nest (5) is arranged on the top of the filter chamber (4); the filter bags (6) are arranged between the tube nest (5) and the filter chamber (4) in a concentric circle; an air outlet valve is arranged at an air outlet corresponding to each fan-shaped clean air chamber; and an air outlet pipe is arranged at the periphery of the inside or outside of the main shell. By the offline ash removal online overhauling rotary pulse blowing filter-bag dust catcher, the offline ash removal and online maintenance of the dust catcher can be realized, the ash removal of all filter bags can be completed by a plurality of pulse valves; the installation height of the dust catcher can be reduced effectively; the drag loss of the dust catcher can be reduced; and the running power consumption can be reduced.

Owner:WUXI HONGCHENG ENVIRONMENTAL TECH

Electric bag composite dust removal device

The invention discloses an electric bag composite dust removal device which comprises an electric field area at the front part and an electric bag mixing area at the rear part; the electric field areais mutually communicated with the electric bag mixing area; at least one metal filter bag is arranged in the electric bag mixing area; each of the metal filter bags is taken as an anode and is grounded; the electric bag mixing area further comprises a corona electrode corresponding to each of the metal filter bags, a needle thread is arranged on the corona electrode, and the corona electrode is taken as a cathode; an electric field is formed between each of the metal filter bags and the corresponding corona electrode. The electric bag composite dust removal device disclosed by the invention has the beneficial effects that the dust removal is carried out in a manner of matching of electric field area at the front part and the eclectic bag mixing area at the rear part, most of dust is removed in the electric field area, and residual dust is removed by the eclectic bag mixing area; therefore, not only is the dust removal effect significant, but also the requirements of energy conservation can be really met.

Owner:福建远致环保科技有限公司

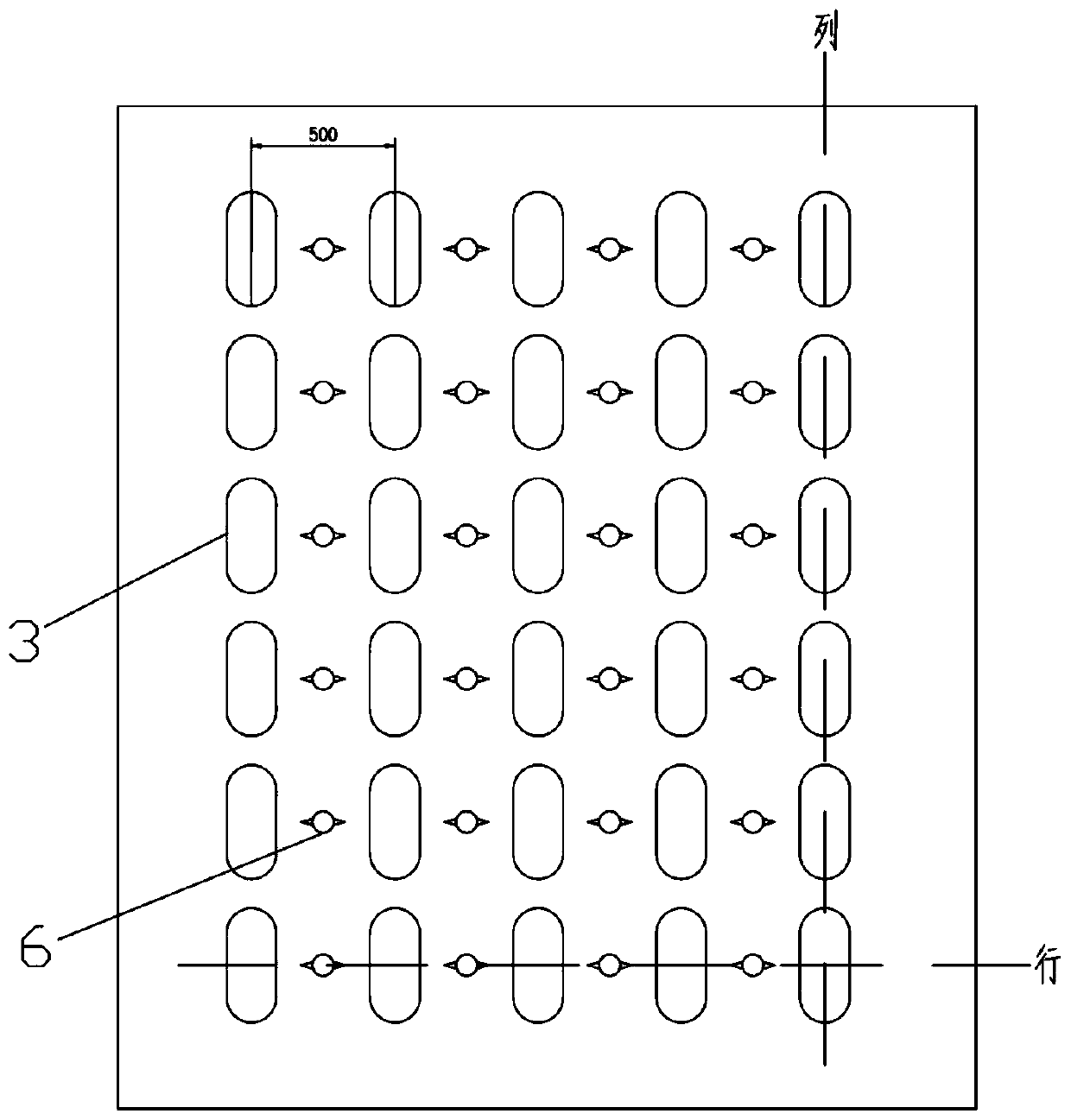

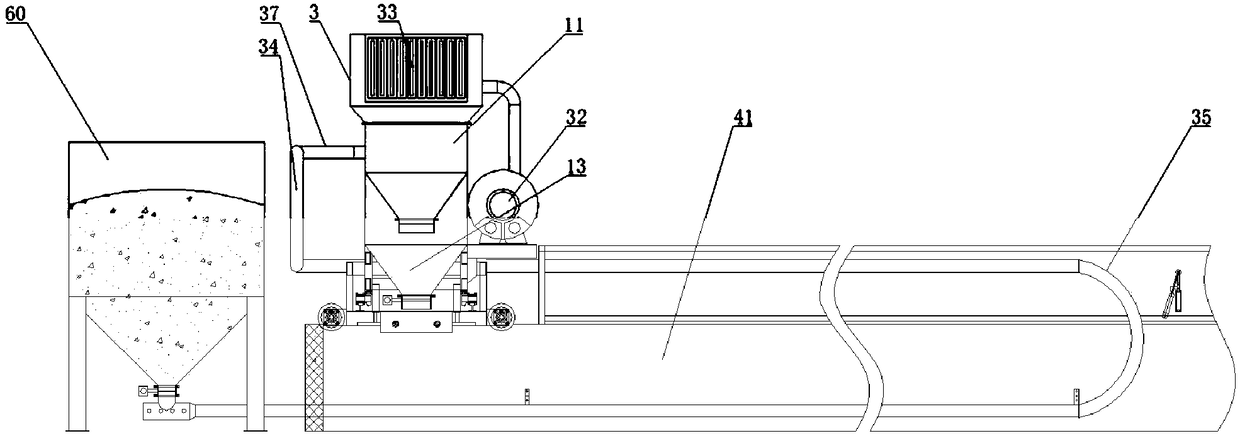

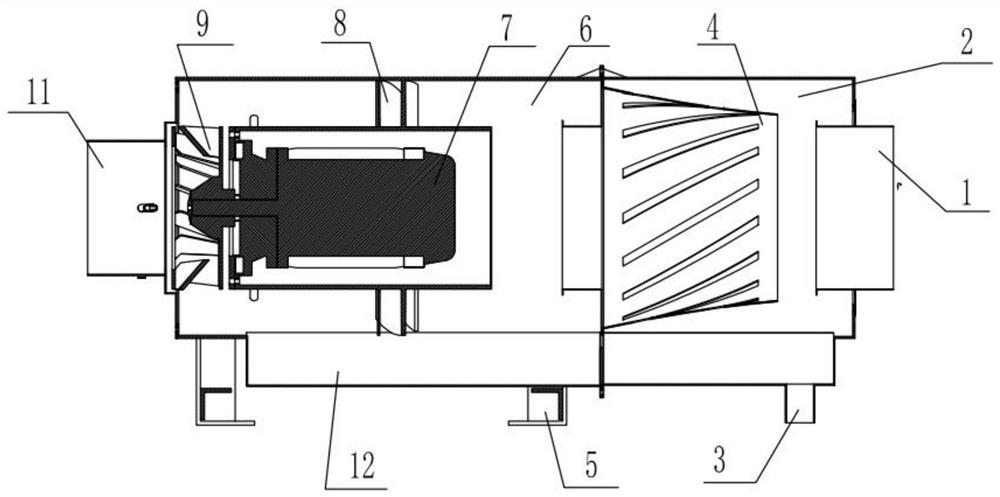

Intelligent transverse and longitudinal cloth machine

ActiveCN108220116AIncrease the feeding speedIncrease productivityVinegar preparationEngineeringBrewing

The invention discloses an intelligent transverse and longitudinal cloth machine, belongs to the field of automatic vinegar brewing equipment and aims to solve the problems of slow feeding speeds andlow production efficiency in the prior art. The machine comprises a double-chamber feeding machine, wherein the double-chamber feeding machine comprises a sucking chamber I; a feeding hole is formed in the sucking chamber I; a sucking chamber II is formed below the sucking chamber I; the sucking chamber I and the sucking chamber II are communicated through discharge holes; outlet holes are formedin the sucking chamber II; discharge devices are arranged in both the outlet holes and the discharge holes. By adopting the machine, material cloth for brewing vinegar can be put into a fermentation tank.

Owner:LUZHOU JIANGXU MACHINERY MFG

Electric bag composite dust collector

ActiveCN106552469BGuaranteed service lifeImprove charging effectCombination devicesFlue gasEngineering

The invention discloses an electrostatic-bag composite dust collector which includes an electrostatic-bag mixing area provided with a filter bag and electric field. The filter bag is a metal filter bag. A negative discharge pole is arranged on the periphery of the metal filter bag. A positive pole plate is disposed in the electrostatic-bag mixing area and is corresponding to the negative discharge pole, so that the electric field is formed by the discharge pole and the positive pole plate. A negative pole system is formed by the metal filter bag, which is corresponding to the positive pole plate, so that friction on the filter bag is avoided in the technical scheme and service life of the filter bag is ensured. The electric field is formed by the metal filter bag and the discharge pole, so that charging property of dust is improved, and when the dust is captured by the filter bag, a loose dust layer is formed on the surface of filter bag due to the principle of like charge repelling each other, thereby preventing dust caking and improving dust removal efficiency. The metal filter bag is a negative pole system, so that under the constraint of electric field force, speed of the charged dust is reduced and the dust is remained in and even deposited in the electric field, while flue gas can flow towards the metal filter bag at high speed, so that the dust collector also can increase the air flowing speed in the filter bag area, thereby increasing utilization ratio of the filter bag and utilization ratio of space.

Owner:FUJIAN LONGKING

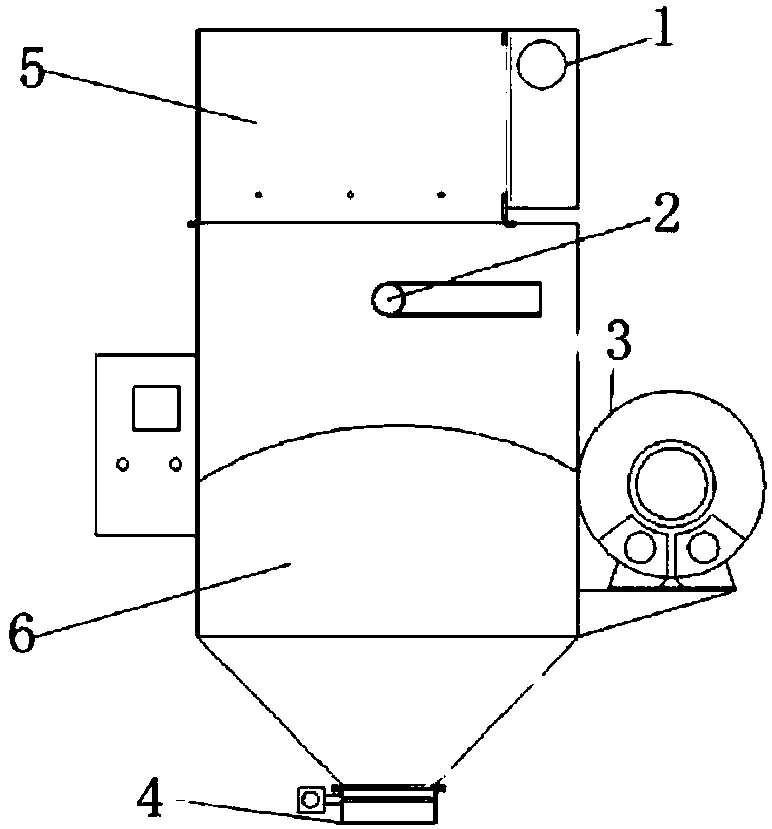

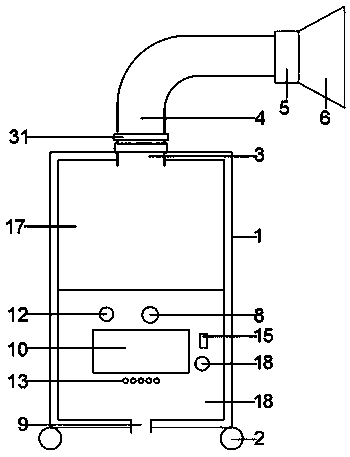

Blowing-exhausting welding-fume purifying device

ActiveCN105413329AImprove ventilationIncrease the filtration speedDispersed particle filtrationTransportation and packagingControl systemWelding fume

The invention discloses a blowing-exhausting welding-fume purifying device. The blowing-exhausting welding-fume purifying device comprises an exhausting unit, a blowing unit and a PLC control system. An air inlet and a first ventilation opening are formed in the two sides of the exhausting unit respectively, a first filter layer composed of a plurality of efficient film covering filter drums and a first draught fan are sequentially arranged in the direction of airflow, and an indoor air supplementing opening is formed in the back side of the first draught fan. A second ventilation opening and an exhausting opening are formed in the two sides of the blowing unit respectively, a primary filter, a medium-efficiency filter and a second draught fan are sequentially arranged in the direction of the airflow, the second ventilation opening is communicated with the first ventilation opening, and an outdoor air supplementing opening is formed in the front side of the primary filter. The PLC control system comprises a signal receiver and a PLC, and is electrically connected with the first draught fan and the second draught fan. According to the blowing-exhausting welding-fume purifying device, waste gas in a workshop is purified through the exhausting unit, outdoor air and indoor air can be purified through the blowing unit, a dual-air-inlet mode can be adopted, the filtering air speed is increased, and the blowing-exhausting welding-fume purifying device is suitable for filtering and purifying of a large workshop and is high in automation degree.

Owner:QINGDAO LOOBO HONGYE ENVIRONMENTAL PROTECTION TECH

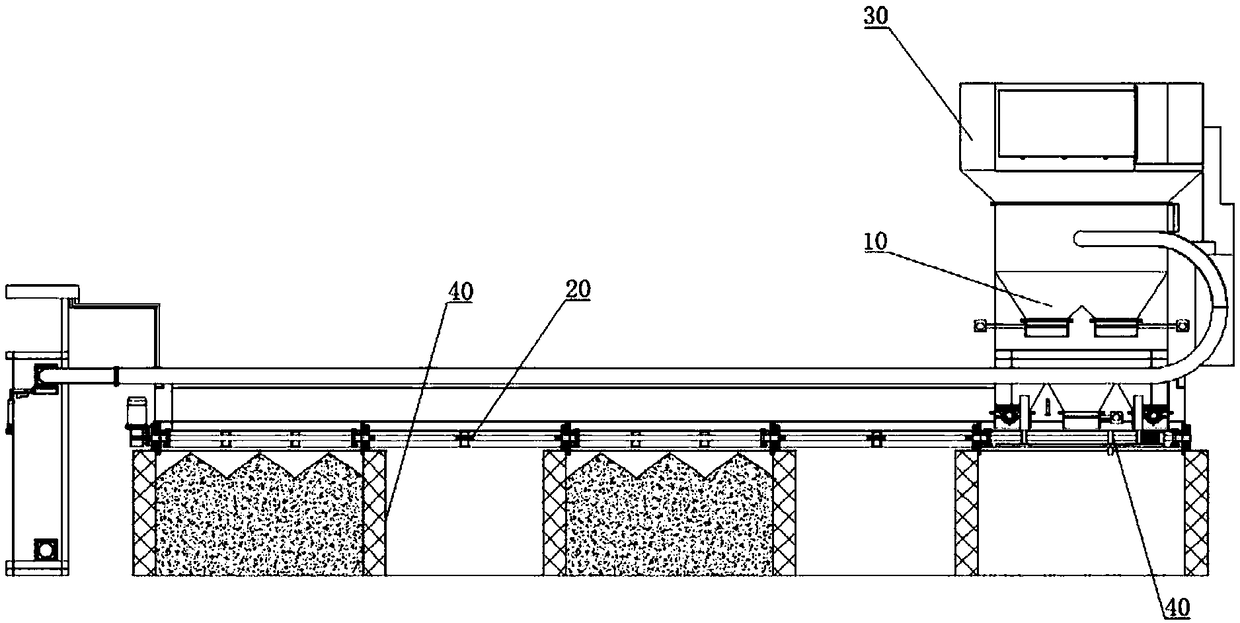

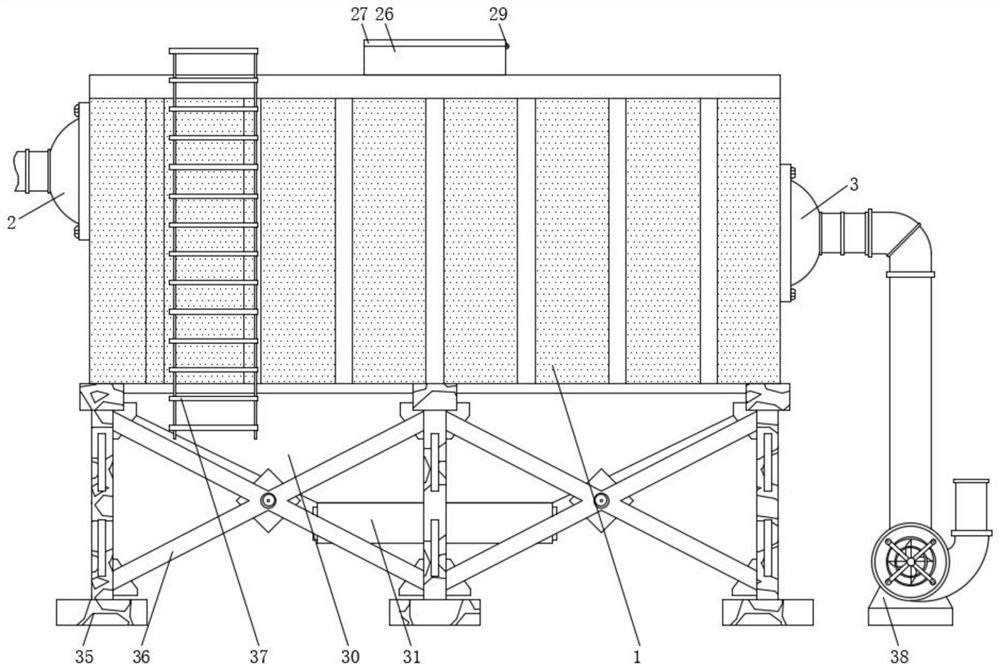

Low-pressure injection pulse-jet bag dust collector

InactiveCN103785241AImprove dust removal efficiencyGuaranteed uptimeDispersed particle filtrationMultiple injectionFlue gas

The invention discloses a low-pressure injection pulse-jet bag dust collector. The low-pressure injection pulse-jet bag dust collector comprises one or more same dust collector units. A flue gas inlet of each one of the dust collector units is connected to an air outlet of the previous dust collector unit. Each one of the dust collector units comprises an injection device, an upper box body, a middle box body, multiple filter-bags, a flow deflector, an ash bucket and an ash discharging device, the upper box body and the middle box body are arranged independently and are isolated by the filter-bags, openings of the filter-bags face upwards, the opening ends of the filter-bags are connected to the upper box body, the upper box body is communicated with the inner cavities of the filter-bags, the filter-bags are arranged in the middle box, the ash bucket is connected to the bottom of the middle box, the bottom of the ash bucket is connected to the ash discharging device, the side of the ash bucket is provided with the flue gas inlet, the side of the upper box is provided with the air outlet, an injection pipe of the injection device is arranged above the filter-bags, the injection pipe is provided with multiple injection holes, the injection holes respectively face to the opening ends of the filter-bags, the flow deflector is arranged in the ash bucket, and a flow deflector plane direction forms an acute angle with a flue gas inlet opening direction. The low-pressure injection pulse-jet bag dust collector has a unit combined structure and has a plurality of specifications according to the number of the dust collector units.

Owner:LIYANG ZHONGXING ENVIRONMENTAL PROTECTION

Mineral fiber exhaust gas treatment method

InactiveCN107694224AEasy to replaceLarge dust holding capacityGas treatmentDispersed particle filtrationFailure rateFiber

The invention relates to a mineral fiber exhaust gas treatment method. The mineral fiber exhaust gas treatment method comprises the following specific steps: after dust removal of mineral wool collecting room exhaust gas, firstly reducing the exhaust gas temperature to 40 DEG C or below by using a steam heat exchanger, and then entering a three-stage efficient filter, further treating a condensateand dust by passing through a desorbing fan and a heater for processing so as to protect a later molecular sieve adsorbent, then purifying the exhaust gas by using a molecular sieve rotating wheel adsorption and concentration device, and discharging the exhaust gas into the atmosphere, wherein the molecular sieve rotating wheel adsorption and concentration device comprises an adsorbing zone, a desorbing regeneration zone and a cooling zone, and can achieve continuous and reliable operation. By the mineral fiber exhaust gas treatment method, the dust holding capacity is high, the resistance islow, the filtering wind speed is high, and the flame retardance is achieved; the purifying efficiency is high and reaches 99%; a whole device has no moving component, so that maintenance is simple and the failure rate is low; a maintenance door is provided, so that replacement of a filter material is simple and convenient and the operation is simple and convenient; a system is automatically controlled by a PLC in the whole process, so that one-key startup and linkage control can be achieved.

Owner:SICHUAN PAWOKE MINERAL FIBER PROD CO LTD

Intelligent wet-type dust removal equipment

PendingCN113648759AUnique principleReduce volumeUsing liquid separation agentSewageElectrical and Electronics engineering

The invention provides intelligent wet-type dust removal equipment which comprises an air outlet, a rear shell, a sewage port, a front shell and an air inlet, the rear shell is connected with the front shell, a gutter channel is installed at the lower end of the rear shell and the lower end of the front shell, the sewage port is installed at the lower end of the gutter channel, a cyclone flow guide body is installed in the rear shell, and the air outlet is formed in one end of the rear shell. A driving device, a swirler and a fan impeller are respectively mounted in the front shell, the swirler is mounted on the driving device, the driving device is connected with the fan impeller, a temperature sensor is mounted on the driving device, an air inlet is formed in one end of the front shell, a dust detection module and a spraying system are respectively arranged on the air inlet, and an electric control water valve is mounted on the air inlet; the electric control water valve is connected with the spraying system through a pipeline, and the pipeline is provided with a flow sensor; the equipment is reasonable in structure, free of consumables, free of a cleaning period, high in trapping and self-cleaning capacity, capable of continuously working for a long time, free of blockage, free of disassembly, cleaning and maintenance, simple in structure and convenient to use.

Owner:申威德天津机械设备有限公司

Smog purifier

InactiveCN109011905ASimple structureImprove filtering effectGas treatmentDispersed particle filtrationHEPATransceiver

The invention discloses a smog purifier. The smog purifier comprises a body and a universal wheels, wherein the top end of the body is provided with a waste gas inlet, the waste gas inlet is providedwith a negative oxygen ion detector and a smog detector, the waste gas inlet is connected with a universal gas absorption pipe, an inlet of the universal gas absorption pipe is provided with an air volume adjuster, the air volume adjuster is connected with a gas absorption cover, the bottom of the body is provided with an air outlet, the front surface of the body is provided with a touch panel, analarming lamp and an alarming device are arranged above the touch panel, a purifying chamber and a control chamber are arranged inside the body, a treatment chip is connected with a wireless signal transceiver, the inner periphery of the purifying chamber is provided with smoke absorption cotton, a dust collection plate, an HEPA filtering plate, an active carbon filtering plate, a silver ion filtering screen and a PTFE coating filtering material are successively arranged in the purifying chamber, and pearl wool is arranged in the body. The smog purifier is simple in structure; and by adoptingmultiple layers of filtering plates, a better filtering effect can be achieved, the ash is easy to clean, the proliferation reproductionof bacteria can be inhibited, and the bacteria attached onto the filtering plates can be effectively killed.

Owner:MAANSHAN MUJI INFORMATION TECH CO LTD

Compound filter material, method and application thereof

InactiveCN101596384BNon-flammableTemperature resistantFiltration separationFolding enduranceAntistatic agent

The invention discloses a compound filter material, a method and application thereof, and relates to a filter material. The invention provides a compound filter material which has good folding endurance, corrosion resistance and wear resistance and can be used as a high-temperature environment filter material, a method and application thereof. The compound filter material comprises the following components in percentage by mass: 1 to 99 percent of basalt fiber and 1 to 99 percent of polytetrafluoroethylene fiber. The preparation method comprises the following steps of: mixing the basalt fiberand the polytetrafluoroethylene fiber to obtain a mixed fiber; and adding an antistatic agent to the mixed fiber for mixing to obtain the compound filter material. According to the mass percentage, the adding amount of the antistatic agent is 0.1 to 20 percent of the mixed fiber. The compound filter material can be used for directly preparing composite filter cloth with single-layer structure or multi-layer structure, and the prepared composite filter cloth with single-layer structure or multi-layer structure can be used for producing a filter device.

Owner:厦门美达斯环保工业有限公司

Double-row filter bag embedded type electric bag compound dust catcher with electric field area at front stage

ActiveCN102553382BReduce dust concentrationReduce processingHuman health protectionCombination devicesEngineeringAir purification

The invention discloses a double-row filter bag embedded type electric bag compound dust catcher with an electric field area at the front stage, and relates to an industrial dust catcher. The dust catcher is provided with an inlet horn, a casing, a smoke duct, a filter bag, an ash cleaning system, an ash hopper, a discharge electrode, a dust absorbing polar plate, a rear discharge electrode and dust collecting pore plates; the front end and the rear end in the casing are provided with an electric field area at the front stage and an embedded electric bag dedusting area at the rear stage, an air inlet of the electric field area is connected with the inlet horn, and a flow guiding adjusting plate is arranged between an air inlet of the dedusting area and an air outlet of the electric field area; an air purification chamber is arranged at the upper part in the casing, and the air inlet of the air purification chamber is connected with an air outlet of the dedusting area; the air inlet of the smoke duct is connected with the air outlet of the air purification chamber, and a lifting valve device is arranged at the top of the smoke duct; the ash hopper is arranged at the bottom of the casing; a bypass valve device is arranged at the top of the electric field area of the front stage, the discharge electrode and the dust absorbing polar plate are arranged at the front end of the casing to form the electric field area of the front stage; the rear discharge electrode and the dust collecting pore plates are arranged at the rear end of the casing to form an electric field of the rear stage; the filter bag is arranged between the two dust collecting pore plates to form a filter area of the filter bag; and the electric field area of the rear stage and the filter bag area form the embedded electric bag dedusting area.

Owner:FUJIAN LONGKING

Positive-pressure purification apparatus of high-temperature combustible gas

The invention discloses a high-temperature positive pressure purifying device for combustible gas with dust, which adopts the technical proposal that: the high-temperature positive pressure purifying device for combustible gas with dust comprises a combustible gas generating unit in parallel connected with at least two high-temperature dust removers through gas pipelines, wherein, high-temperature resisting filter elements are arranged in the high-temperature dust removers; either a blast furnace or a gas generator is adopted as the combustible gas generating unit. Since cooling facilities are omitted, the occupied space is saved and the maintenance load is light, without worrying about the ash fouling and removing of the cooling facilities, meanwhile, the operating points for ash unloading are reduced. Without any energy consumption from cooling, the operation energy consumption of the system is reduced, the total pressure of a main air blower of the system is lowered and the motor power is reduced. The sensible heat is fully used. Since the gas temperature is kept above the dew point, the blocking of equipment caused by condensation troubles as well as corrosion from low-temperature sulfur dioxide are avoided.

Owner:无锡市东方环境工程设计研究所有限公司

Filter drum type precipitator

ActiveCN101439252BReduce blowing areaIncrease wind speedDispersed particle filtrationAir velocityFiltration

The invention discloses a filter cartridge dust collector. The dust collector comprises a case body which is provided with an air inlet and an air outlet, a plurality of filter cartridges which are obliquely arranged inside the case body, and a dust cleaning device which blows compressed air into the filter cartridges from an open end above the filter cartridges. The inside of the filter cartridges is fixedly provided with a core tube with an upper end head sealed along the extension direction of the filter cartridges, and a cavity is arranged between the core tube and the filter cartridges. As the filter cartridges are internally provided with the core tube, the compressed air blown from the dust cleaning device can only pass from the cavity arranged between the core tube and the filter cartridges, thus reducing the blowing area in the filter cartridges; the air velocity of the blowing airflow is increased on the premise of blowing the same air flow quantity, which causes the blowingairflow to fully contact filter materials and improves the dust cleaning efficiency. As the dust cleaning efficiency is improved, even the dust which is fully stuck to the filter materials can be fully removed, thus being capable of properly increasing the filtration air velocity and indirectly improving the dedusting efficiency.

Owner:薛家华

A kind of nano copper-zinc oxide PTFE fiber air filter material and preparation method thereof

ActiveCN104436863BHas a filtering effectIncrease varietyBiocideDisinfectantsAir filtrationAdditive ingredient

The invention discloses a nano-copper-zinc oxide PTFE fiber air filter material and a preparation method thereof. The method obtains a nano-copper-zinc oxide PTFE fiber air filter material through four steps of preparing nano-copper, preparing nano-zinc oxide, mixing ingredients and manufacturing non-woven fabrics. Zinc PTFE fiber air filter material. Compared with the prior art, the present invention has the following advantages: the air filter material obtained by the present invention contains nano-metal copper and nano-zinc oxide, has a filtering effect and also has a bacteriostasis effect, and has a wide variety of antibacterial and high efficiency; The efficiency reaches 99.99%, good air permeability, high filtration wind speed, and strong chemical stability; it can be well matched with air purifiers or fresh air fans; the manufacturing process is simple, and it is easy to realize industrialization.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

Inorganic-fiber ultra-high temperature composite filter material

ActiveCN101612497BIncrease the filtration speedExtended service lifeFiltration separationFiltrationFlue gas

The invention discloses an inorganic-fiber ultra-high temperature composite filter material comprising a base cloth layer and felt layers. The base cloth layer is arranged between the two felt layers and is made of inorganic fiber; the felt layers are made of stainless steel composite filter; the inorganic fiber is basalt fiber or ceramic fiber; and the stainless steel composite filter is formed by mixing stainless steel fiber and the basalt fiber or the stainless steel fiber and the ceramic fiber, wherein the proportion of the stainless steel fiber is 10-30 percent. The stainless steel fiberis melted and sintered at a high temperature so that the stainless steel fiber is welded on crossing points of warp yarn and weft yarn of base cloth to form nodes and accordingly form a sintered filter felt. The invention effectively improves the anti-filtration airspeed capability, the fracture strength and the peeling strength of the filter material, prolongs the service life and satisfies the requirements of the ultra-high temperature flue gas abatement field.

Owner:南京际华三五二一环保科技有限公司

Offline ash removal online overhauling rotary pulse blowing filter-bag dust catcher

InactiveCN102430299BLower installation heightSmall resistanceDispersed particle filtrationBaghouseElectrical and Electronics engineering

The invention relates to an offline ash removal online overhauling rotary pulse blowing filter-bag dust catcher, which comprises a cylindrical main shell, an ash discharger, a filter chamber, a tube nest, filter bags and an annular clean air chamber, wherein a fixed air storage bag, pulse valves, a compressed air distributor, a rotary driving device and a plurality of rotary pulse blowing pipes are arranged in the center of the main shell; a plurality of insulating plate structures of which the peripheries are provided with sealing devices are arranged above the rotary pulse blowing pipes; offline ash removal hoods are arranged on two sides of each pulse blowing pipe; the tube nest (5) is arranged on the top of the filter chamber (4); the filter bags (6) are arranged between the tube nest (5) and the filter chamber (4) in a concentric circle; an air outlet valve is arranged at an air outlet corresponding to each fan-shaped clean air chamber; and an air outlet pipe is arranged at the periphery of the inside or outside of the main shell. By the offline ash removal online overhauling rotary pulse blowing filter-bag dust catcher, the offline ash removal and online maintenance of the dust catcher can be realized, the ash removal of all filter bags can be completed by a plurality of pulse valves; the installation height of the dust catcher can be reduced effectively; the drag loss of the dust catcher can be reduced; and the running power consumption can be reduced.

Owner:WUXI HONGCHENG ENVIRONMENTAL TECH

Dust remover convenient for rotating delay enclosed hood

PendingCN112742125AGreat cleaning strengthIncrease the filtration speedDispersed particle filtrationTransportation and packagingEngineeringAir velocity

The invention discloses a dust remover convenient for rotating a delay enclosed hood, and particularly relates to the technical field of dust removers, The dust remover comprises a dust removal shell, the left and right side surfaces of the dust removal shell are respectively communicated with one ends of opposite surfaces of an air inlet pipe and an exhaust pipe, and the left and right side surfaces of the inner wall of the dust removal shell are respectively provided with a one-way valve. By arranging an air compression bag, a filter bag, a filter frame and a guide pipe, compared with an existing dust remover, the dust remover has the advantages that the dust removing strength is high, dust can be removed in a filtering working state, the allowed filtering wind speed is high, and the filter does not need to be closed, so the filtering effect of the filter is further guaranteed; and when the air compression bag is used for cleaning the filter bag, dust adhered in the filter frame can be cleaned at the same time, so that the filter frame and the filter bag in the dust remover can be cleaned without stopping the operation of the dust remover in the use process of the dust remover, and the dust removal effect of the dust remover is further guaranteed.

Owner:湖北潜江江汉环保有限公司

Internal filtering dust filtering equipment

The invention relates to dust removing equipment, and discloses internal filtering dust filtering equipment, which comprises a box body, an air inlet, an air outlet, a filtering fixed seat, a filter, a blowing system and an ash storage box, wherein the filter is fixed on the filtering fixed seat; the blowing system is arranged above the filter; and the ash storage box is arranged below the box body. The internal filtering dust filtering equipment is characterized in that: the blowing system comprises an air source device and a blowing pipeline; and an air source is blown from the air source device to the opening of the filter from top to bottom through the blowing pipeline. The internal filtering dust filtering equipment has the advantages of simple structure, saving in cost, high filtering air speed, good ash cleaning effect, high purifying efficiency, large treatment air volume, long filter service life, running safety and reliability and high automatic degree.

Owner:FOSHAN S L P SPECIAL MATERIALS

Negative pressure purifier of high temperature combustible gas

InactiveCN101293157ALow powerAvoid corrosionDispersed particle filtrationGaseous fuelsOperating pointMotor power

The invention discloses a negative pressure purification device for high temperature dust containing combustible gas; the technical proposal is that the negative pressure purification device for the high temperature dust containing combustible gas comprises combustible gas generating equipment, a pipeline, an induced draft fan and a hot precipitator connected between the combustible gas generating equipment and the induced draft fan by the pipeline. A high-temperature resistant filter element is arranged in the hot precipitator; the combustible gas generating equipment can be a converter or an airtight electric furnace; owing to the omission of cooling facilities, the total area of the device is saved; the workload of maintenance is small; the device is free of the works such as the clogging and the deashing of the cooling facility; the ash discharge operating point is reduced, thereby reducing the energy consumption of the systems operation and being free of the cooling energy consumption; the total pressure of a primary fan in the system is low; a motor power is reduced; sensible heat is fully utilized; as the gas temperature is maintained above a point all the time, thereby avoiding the problem of blockage of the device caused by the dew condensation and the corrosion of low-temperature sulfur dioxide.

Owner:无锡市东方环境工程设计研究所有限公司

Full-area charged filtering dust remover

PendingCN114558388AExtended service lifeImprove dust removal efficiencyHuman health protectionDispersed particle filtrationSocial benefitsEnvironmental engineering

The invention relates to a full-area charged filtering dust remover which comprises a dust remover main box body and is technically characterized in that a pyramid-shaped air inlet is formed in the front side of the dust remover main box body, a cloth bag filtering dust removal area is arranged in the dust remover main box body, and a front air inlet charged assembly and a side air inlet charged assembly are arranged on the periphery of the cloth bag filtering dust removal area; the front air inlet charging assembly faces the pyramid-shaped air inlet, a side air inlet channel is formed between the side air inlet charging assembly and the side wall of the dust remover main box body, and the front air inlet charging assembly and the side air inlet charging assembly respectively comprise a collecting pole plate used for isolating the dust remover main box body from the cloth bag filtering dust removal area and a discharging emitting pole net corresponding to the collecting pole plate; and vent holes or vent gaps are uniformly distributed on the collector plate. The composite dust removal device solves the problem of low dust removal efficiency of the existing composite dust removal device, is stable in operation, low in energy consumption, low in system resistance, long in service life and low in operation and maintenance cost, and has remarkable economic benefits and social benefits.

Owner:沈阳远大环境工程有限公司

Portable membrane filter bag

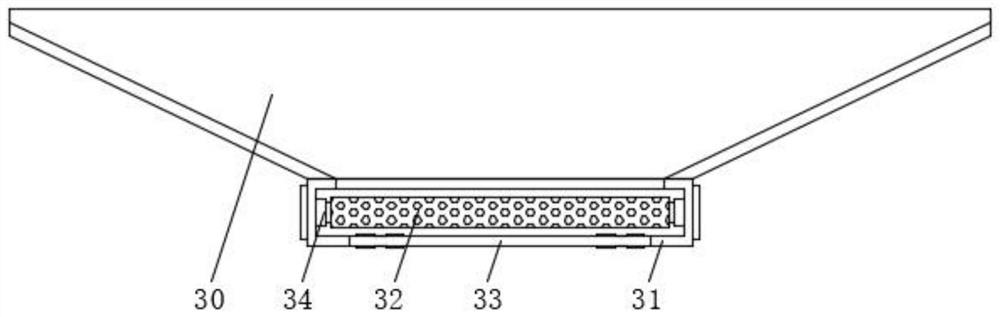

InactiveCN107051031AImprove ventilationIncrease the filtration speedDispersed particle filtrationSynthetic resin layered productsFiberYarn

A portable membrane filter bag comprises a membrane and a base cloth layer. The membrane is located on the outer side of the base cloth layer, the membrane adopts a polytetrafluoroethylene microporous membrane which is provided with micropores with the bore diameter being 0.1-3.5 micrometers, the porosity of the micropores reaches 75-90%, the base cloth layer is made from alkali-free glass fiber continuous bulk yarn fiber, the mass per unit area is 46-122.7 g / m<2>, the thickness is 0.64-1.39 mm, and the average fiber web bore diameter is 11.385-24.9691 micrometers. According to the portable membrane filter bag, surface filtration is achieved, the dust discharge amount is almost zero, the ventilation volume of dust collecting equipment is increased, pressure drop of the dust collecting equipment is reduced, the service life of the filter bag is prolonged, the dust removal cycle and the electricity consumption are reduced, the repair and maintenance cost of the dust collecting equipment is reduced, the filtering wind speed of the dust collecting equipment is increased, the use volume of the dust collecting equipment is reduced, and and the investment cost of the dust collecting equipment is lowered.

Owner:扬州市金色海岸船艇制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com