Intelligent transverse and longitudinal cloth machine

A distributing machine, horizontal and vertical technology, applied in the field of distributing machines, can solve the problems of low production efficiency and slow feeding speed, and achieve the effects of improving production efficiency, reducing volume and improving feeding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

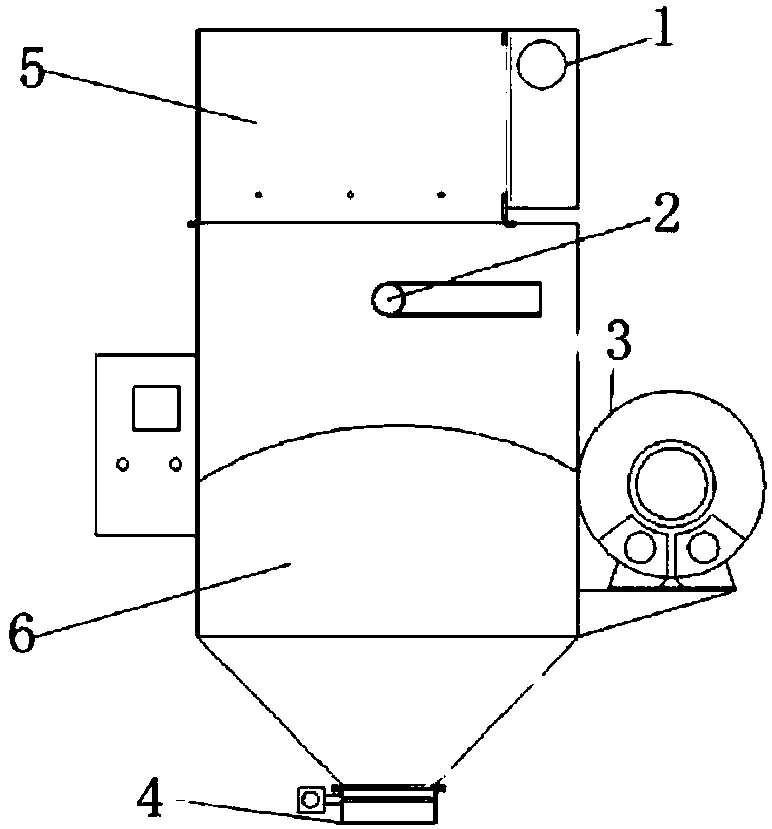

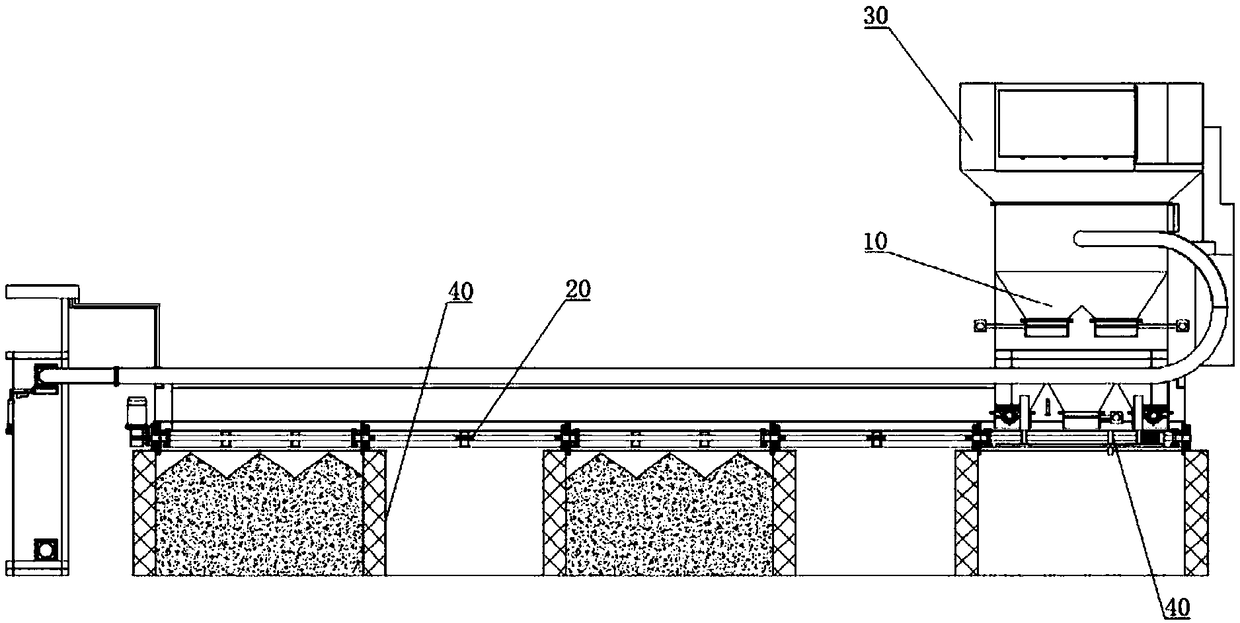

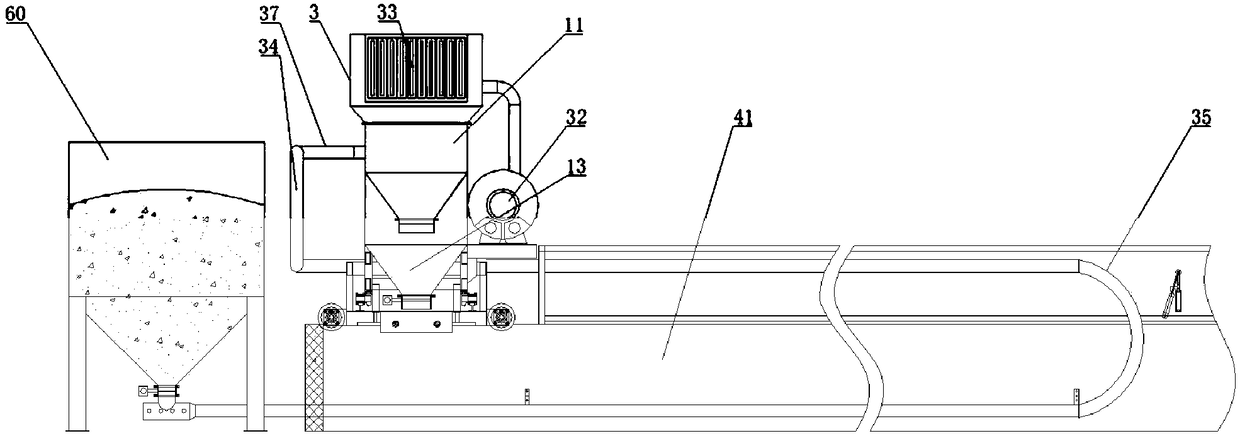

[0052] An intelligent horizontal and vertical material distribution machine, comprising a double-chamber feeder 10, the double-chamber feeder 10 includes a material suction chamber-11, and a material inlet 12 is arranged on the material-suction chamber-11; Material chamber two 13, material suction chamber one 11, and material suction chamber two 13 are connected through discharge hole 14; feeding device.

[0053] In this embodiment, the suction chamber of the prior art is changed from one to two, that is, the first suction chamber 11 and the second suction chamber 13 that are connected to each other, and the second suction chamber 13 is arranged on the first suction chamber 11 Below, that is, the first suction chamber 11 and the second suction chamber 13 are arranged vertically in turn, wherein the first suction chamber 11 is provided with a feed port 12. When working, when starting and running, the discharge device in the discharge port 15 and the discharge hole 14 is in a c...

Embodiment 2

[0055] On the basis of Embodiment 1, a funnel-shaped material guide part 16 is provided at the bottom of the material suction chamber one 11, and the discharge hole 14 is arranged at the bottom of the material guide part 16, and the material guide part 16 communicates with the material suction chamber two 13; The bottom of the second material guide part 13 is provided with a funnel-shaped material guide part two 17, and the discharge port 15 is arranged on the bottom of the second material guide part 17.

[0056]In this embodiment, the first suction chamber 11 communicates with the second suction chamber 13 through the funnel-shaped material guide portion 16 at the bottom of the first suction chamber 11, so after a period of time when the first suction chamber 11 absorbs material, the discharge hole 14 The discharge device in the middle is opened, and the material in the first suction chamber 11 enters the second suction chamber 13 along the material guide part 16 and the disch...

Embodiment 3

[0058] On the basis of Embodiment 2, two material guide parts 16 are provided; three material guide parts 17 are provided.

[0059] In this embodiment, there are two material guide parts 16 . After the pneumatic valve in the discharge hole 17 is opened, the material enters the second material suction chamber 13 along the two funnel-shaped material guides 16 under the action of its own gravity. Compared with only one funnel-shaped material guide part in the material suction room in the prior art, the two material guide parts 16 have obviously improved the transfer speed of the material from the material suction room one 11 to the material suction room two 13, thereby improving the efficiency of this implementation. The processing speed of the example improves the production efficiency. There are 3 guide parts 2 17. After the pneumatic valve in the discharge port 15 is opened, the material is thrown out along 3 funnel-shaped material guide parts 2 17 under the action of its ow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com