Negative pressure purifier of high temperature combustible gas

A technology for purifying device and gas, applied in the direction of fuel, gas fuel, chemical instruments and methods, etc., can solve the problems of insufficient utilization of sensible heat of combustible gas, large equipment area, high equipment investment cost, and avoid equipment blockage. Problems and corrosion of low temperature sulfur dioxide, low maintenance, low operating energy consumption and low effect

Inactive Publication Date: 2008-10-29

无锡市东方环境工程设计研究所有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

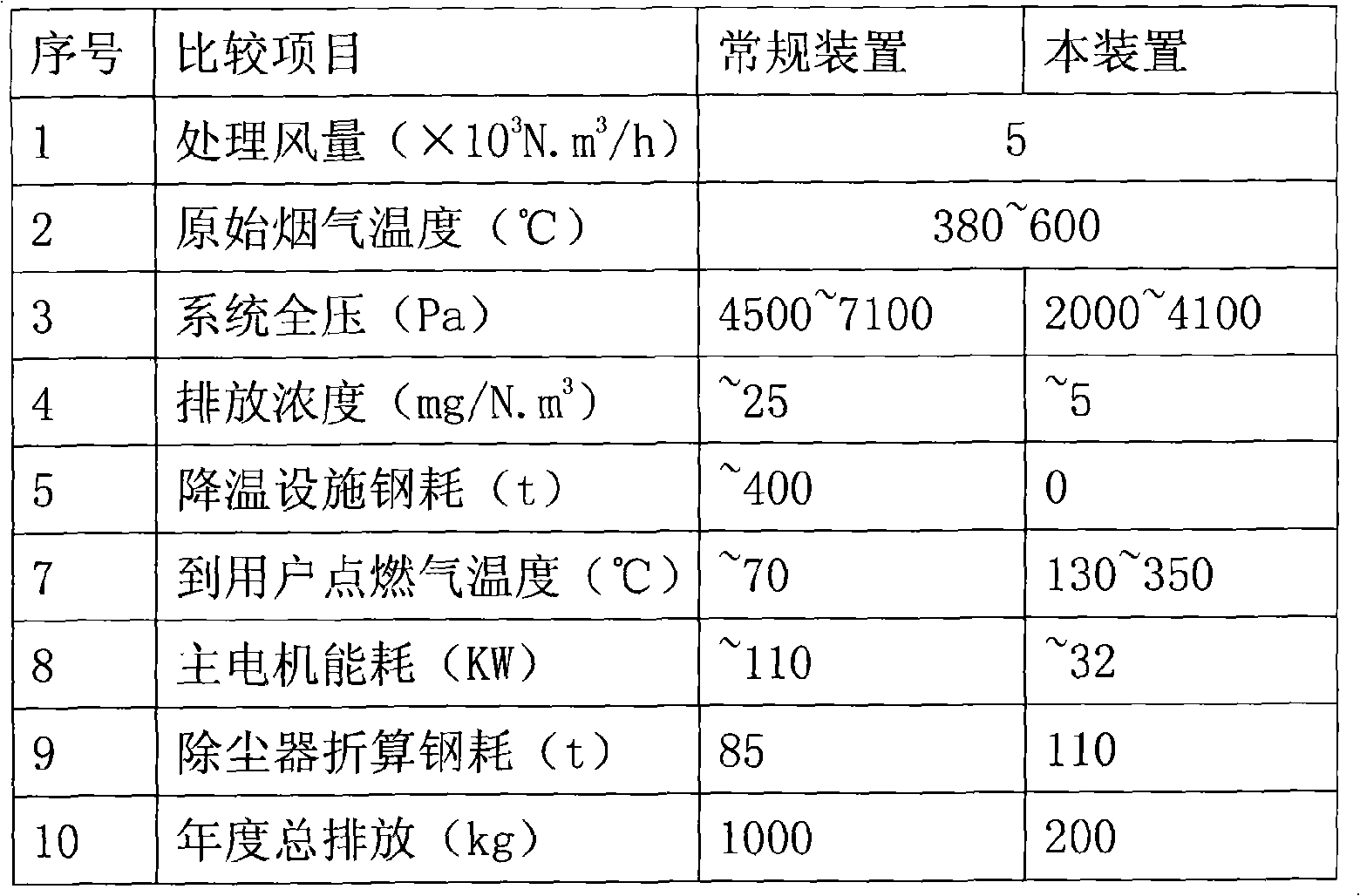

In the prior art, the high-temperature flue gas purification device is high-temperature combustible gas generating equipment, gravity cyclone facilities, cooling facilities, dust collectors, and induced draft fans connected in sequence through pipelines. Since the device is equipped with cooling facilities and gravity cyclone facilities, the device The pipeline configuration is long, the equipment occupies a large area, and the equipment investment cost is high; because the cooling facility is installed in front of the dust collector, the flue gas entering the cooling facility contains dust, causing the cooling facility to be often blocked and requires frequent maintenance; the cooling facility requires additional energy ;The resistance of the whole device is high, between 4500-7100Pa, the energy consumption of the main fan is large, and the sensible heat of the combustible gas is not fully utilized. error

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

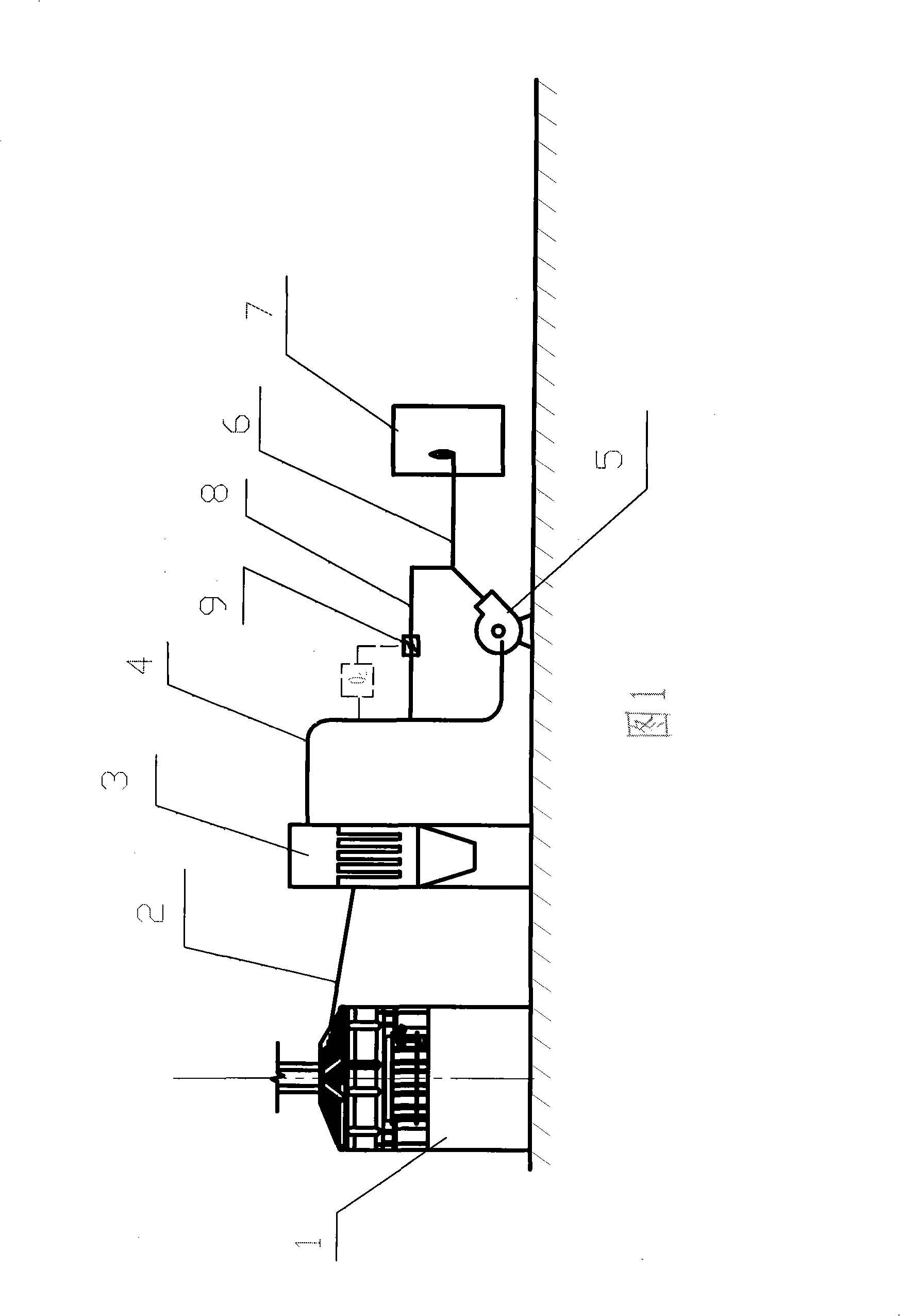

The invention discloses a negative pressure purification device for high temperature dust containing combustible gas; the technical proposal is that the negative pressure purification device for the high temperature dust containing combustible gas comprises combustible gas generating equipment, a pipeline, an induced draft fan and a hot precipitator connected between the combustible gas generating equipment and the induced draft fan by the pipeline. A high-temperature resistant filter element is arranged in the hot precipitator; the combustible gas generating equipment can be a converter or an airtight electric furnace; owing to the omission of cooling facilities, the total area of the device is saved; the workload of maintenance is small; the device is free of the works such as the clogging and the deashing of the cooling facility; the ash discharge operating point is reduced, thereby reducing the energy consumption of the systems operation and being free of the cooling energy consumption; the total pressure of a primary fan in the system is low; a motor power is reduced; sensible heat is fully utilized; as the gas temperature is maintained above a point all the time, thereby avoiding the problem of blockage of the device caused by the dew condensation and the corrosion of low-temperature sulfur dioxide.

Description

technical field The invention relates to a negative pressure purification device for high-temperature dust-containing combustible gas. Background technique In the prior art, the high-temperature flue gas purification device is high-temperature combustible gas generating equipment, gravity cyclone facilities, cooling facilities, dust collectors, and induced draft fans connected in sequence through pipelines. Since the device is equipped with cooling facilities and gravity cyclone facilities, the device The pipeline configuration is long, the equipment covers a large area, and the equipment investment cost is high; because the cooling facility is installed in front of the dust collector, the flue gas entering the cooling facility contains dust, causing the cooling facility to be often blocked and requires frequent maintenance; the cooling facility requires additional energy ;The resistance of the whole device is high, between 4500-7100Pa, the energy consumption of the main fan...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D46/00C10L3/00

Inventor 谈庆熊玉巧

Owner 无锡市东方环境工程设计研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com